Summary of Contents for Wacker Neuson DPS 1850

- Page 1 Operator's manual Vibratory plate DPS 1850 Model Document 5100010679 Issue 04.2019 Version Language...

- Page 2 Any breach of the statutory regulations, in particular the protection of copyright, will lead to civil and criminal prosecution. Wacker Neuson Produktion GmbH & Co. KG is constantly working on the improvement of its products as part of the technical further development. Therefore, we reserve the right to make changes to the illustrations and descriptions in this documentation without incurring any obligation to make changes to machines already delivered.

-

Page 3: Table Of Contents

Storage location of the manual ....................6 Accident prevention regulations....................6 More information.......................... 6 Target group ..........................6 Explanation of symbols........................ 6 Wacker Neuson Contact partner ....................7 Disclaimer ............................ 7 Product identification of the machine................... 7 Security ..........................8 Policy ............................8 Responsibility of the operator ...................... - Page 4 Table of contents Accessories .........................29 Technical data ........................30 12.1 DPS1850 ........................... 30 12.2 Combustion engine........................31 Emission control systems information and warranty ............32 ..................33 EC Declaration of Conformity DIN EN ISO 9001 certificate ......... . 31 5100010679IVZ.fm...

-

Page 5: Preface

This operator's manual contains important information and procedures for the safe, proper and economic operation of this Wacker Neuson machine. Carefully reading, understanding and observing is an aid to avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life of the machine. -

Page 6: Introduction

The information contained in this manual is based on machines manufactured up to the time of printing. Wacker Neuson reserves the right to change this information. The manufacturer shall immediately include any modifications or additions in this manual. -

Page 7: Wacker Neuson Contact Partner

2 Introduction NOTICE Supplementary information. Wacker Neuson Contact partner Depending on the country, the Wacker Neuson contact partner is a Wacker Neuson service department, a Wacker Neuson subsidiary, or a Wacker Neuson dealer. On the Internet at www.wackerneuson.com. Disclaimer For the following violations, Wacker Neuson dismisses any liability for personal injury or material damage: Failure to follow this manual. -

Page 8: Security

The following cases are considered structural changes: Opening the machine and a permanent removal of elements. Installation of spare parts that do not originate from Wacker Neuson or are not comparable in the design system and quality of the original parts. -

Page 9: Operator Responsibilities

3 Security Operator responsibilities Know and implement the applicable industrial safety regulations. Use a risk assessment to identify the dangers that result from the working conditions at the site of application. Compile operating instructions for the operation of this machine. ... -

Page 10: Specific Safety Instructions - Vibratory Plates

3 Security Screw connections All screw connections must meet the prescribed specifications and must be firmly screwed together. Observe the tightening torques! The screws and nuts may not be damaged, bent or deformed. Pay particular attention to: Captive nuts and micro-encapsulated screws may not be reused once loosened. The locking effect ... - Page 11 The relevant rules and regulations for measuring, evaluating and reducing vibration emissions - especially the DIN 4150-3 - must be considered. Wacker Neuson assumes no liability for any damage to buildings. 100_0202_si_0009.fm...

-

Page 12: General Safety Instructions - Combustion Engines

Observe the maintenance schedule. Non-listed work must be taken over by the service department of the Wacker Neuson contact partner. Immediately replace worn or damaged machine parts. Only use spare parts from Wacker Neuson. Keep the machine clean. -

Page 13: Personal Protection Equipment

Therefore, ear protection must be worn. For exact values of noise emissions, refer to the Technical Data section. Work particularly cautiously and pay attention when wearing ear protection, as your ability to hear noises, such as screams or signal tones, is restricted. Wacker Neuson recommends always wearing ear protection. 100_0202_si_0009.fm... -

Page 14: Safety Devices

3 Security 3.12 Safety devices Safety devices protect the user of this machine from being exposed to existing hazards. These are barriers (separating protective devices) or other technical measures. This prevents the user from being exposed to a danger. The source of danger will be eliminated in certain situations or the danger will be reduced. -

Page 15: Safety And Information Labels

4 Safety and information labels Safety and information labels WARNING Illegible symbols Over time, labels and plates on the machine can become dirty or become unrecognizable in some other way. Keep all safety, warning and operating instructions on the machine in a good legible ... -

Page 16: Setup And Function

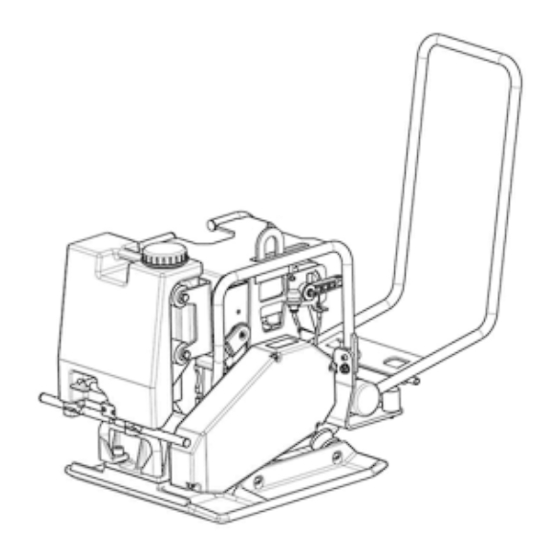

5 Setup and function Setup and function Standard package The machine is delivered fully assembled and is ready for operation out of the box. The standard package includes: Vibratory plate Operator’s manual Application areas The vibratory plate is used for the compaction of soil and is used in gardening and landscaping, civil engineering, road and highway construction as well as paving work. -

Page 17: Components And Operator's Controls

6 Components and operator's controls Components and operator's controls Components DPS1850Hb/Hv DPS1850Ha Item Designation Item Designation Engine Belt guard Base plate Water tank (optional) Exciter Handle Protective frame (optional) Nameplate Operator's controls Always keep displays and operator's controls of the machine clean, dry and free of oil and grease. Operator's controls, such as the ON/OFF switch, throttle control handles, etc. -

Page 18: Transport

Attach suitable tackle to the intended central lifting point. Perform preparations NOTE Wacker Neuson recommends emptying the fuel tank prior to transport. During loading and transport, the control handle must be locked in the vertical position or folded down. 100_0202_tr_0010.fm... - Page 19 7 Transport Lifting and lash down the machine NOTE Appoint a specialist flagman for a safe lifting operation. Item Designation Item Designation Central lifting point Belt 1. To lift the machine, mount suitable tackle to the central lifting point. 2. Carefully load the machine into or onto a stable means of transport capable of bearing the load. 3.

-

Page 20: Operation

Control procedures before commissioning Check the machine and components for damage. In the event of visible damage, do not operate the machine and immediately contact Wacker Neuson service. Ensure that loose packaging material has been removed from the machine. ... -

Page 21: Commission

Recommendation: In each case, determine the maximum dumping height through compaction tests and soil samples. Vibrating sett paving (paving stones) When compacting interlocking paving stones, Wacker Neuson recommends the application of the sliding mechanism in order to avoid damage to the machine and compaction material. See chapter Accessories. -

Page 22: Operation

8 Operation Operation The proper location of the operator is behind the machine. Guide and steer the machine using the control handle. Decommissioning 1. Push the throttle lever until the detent STOP. 2. The engine will switch off. Short-term work stoppage Move the throttle lever to idling. -

Page 23: Maintenance

9 Maintenance Maintenance WARNING Improper handling can lead to injuries or serious material damage. Read and observe all safety instructions in this manual. WARNING Danger of poisoning from exhaust fumes. Exhaust fumes contain poisonous carbon monoxide, which can lead to unconsciousness or to death. -

Page 24: Maintenance Table

Retention/replace the V-belt Note the engine operator's manual. Have this work performed by the service department of the Wacker Neuson contact partner. Maintenance jobs CAUTION Health risk from fuel, lubricants and coolants. Do not inhale fuel, lubricants, coolants or vapors. - Page 25 9 Maintenance Check the fuel level and top off NOTE Diesel fuel: Only use clean diesel fuel. Immediately lock the fuel tank. The utmost cleanliness is also essential here, as otherwise inevitable faults will occur in the injection system and premature clogging of the fuel filter will occur.

- Page 26 9 Maintenance Clean the machine WARNING Risk of fire and explosion when using flammable cleaning agents. Do not clean the machine and elements with gasoline or other solvents. NOTE Penetrating water can damage the engine, electrical operator's controls or components of the machine.

- Page 27 9 Maintenance Replace the exciter oil and check the oil level DANGER Risk of scalding Use caution when draining hot oil. NOTE Perform oil change and oil level check with warm exciter oil. Machine must not be in use and be level.

-

Page 28: 10 Troubleshooting

Have the machine repaired.* Cylinder and/or piston ring wear. Injection nozzle not functioning. No vibration with running engine. Worn V-belt. Replace V-belt. Worn clutch lining. Replace clutch lining. Have this work performed by the service department of the Wacker Neuson contact partner. 100_0202_ts_0011.fm... -

Page 29: 11 Accessories

11 Accessories 11 Accessories CAUTION Accessories and spare parts that do not originate from Wacker Neuson can increase the risk of injury and possible damage to the machine. The use of other accessories and spare parts that do not originate from ... -

Page 30: 12 Technical Data

12 Technical data 12 Technical data 12.1 DPS1850 Designation Unit DPS1850Hb DPS1850Ha DPS1850Hv Item number 5000610032 5000610033 5000610034 Centrifugal force 11/18 Oscillations 5.300 5.300 5.880 Compaction performance* (4,079.3) (4,079.3) (3,368.8) Travel speed m/min 14/20 Gradeability 46.6 46.6 46.6 Length (center pole in 1,212 1,204 1,212... -

Page 31: Combustion Engine

12 Technical data 12.2 Combustion engine Designation Unit Manufacturer Hatz Type of engine 1B20-6-325 Combustion method Four-cycle Cooling Air cooling Cylinders Displacement cm³ (in 232 (14.2) Max. slanting position ° 16.7 Fuel type Diesel EN 590 Fuel consumption l/h (gal/h) 0.4 (0.1) Tank capacity l (gal) -

Page 32: 13 Emission Control Systems Information And Warranty

13 Emission control systems information and warranty 13 Emission control systems information and warranty The Emission Control Warranty and associated information is valid only for the U.S.A., its territories, and Canada. Emission control systems warranty statement See the engine owner’s manual for the applicable exhaust and evaporative emission warranty statement. -

Page 33: Ec Declaration Of Conformity

EC Declaration of Conformity Manufacturer Wacker Neuson Produktion GmbH & Co. KG, Wackerstraße 6, D-85084 Reichertshofen This declaration of conformity is issued under the sole responsibility of the manufacturer. Product DPS1850 Product type Vibratory plate Function of product Soil compaction...

Need help?

Do you have a question about the DPS 1850 and is the answer not in the manual?

Questions and answers