Table of Contents

Advertisement

Quick Links

Technical Service Guide

May 2019

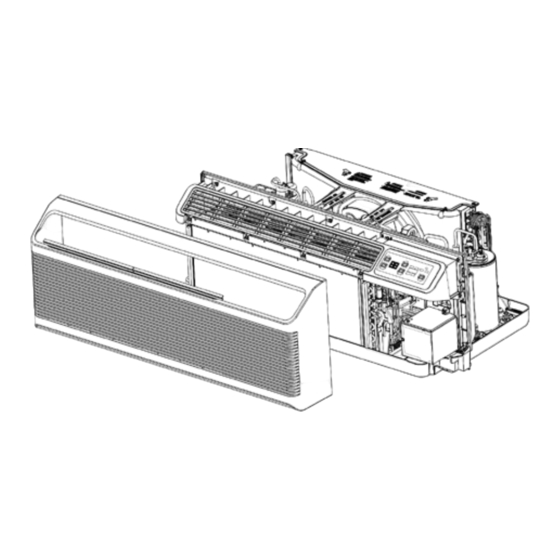

2019 Zoneline Air Conditioner

230/208 VOLT MODELS

AZ45E07DABW5

AZ45E07DACW5

AZ45E07DAPW5

AZ45E09DABW5

AZ45E09DACW5

AZ45E09DAPW5

AZ45E09DBMW5

AZ45E12DABW5

AZ45E12DACW5

AZ45E12DACW6

AZ45E12DAPW5

AZ45E12DBMW5

AZ45E12DBMW6

AZ45E12DBMW7

AZ45E15DABW5

AZ45E15DABW6

AZ45E15DABW7

AZ45E15DACW5

AZ45E15DACW6

AZ45E15DACW7

AZ65H07DABW5

AZ65H07DACW5

AZ65H07DADW5

AZ65H07DBMW5

AZ65H09DABW5

AZ65H09DACW5

AZ65H09DADW5

AZ65H09DBMW5

AZ65H12DABW5

AZ65H12DABW6

AZ65H12DABW7

AZ65H12DACW5

AZ65H12DACW6

AZ65H12DACW7

AZ65H12DADW5

AZ65H12DADW6

AZ65H12DBMW5

AZ65H12DBMW6

AZ65H15DABW5

AZ65H15DABW6

AZ65H15DACW5

AZ65H15DACW6

AZ65H15DACW7

AZ65H15DADW5

AZ65H15DADW6

Rev. 3 ~ 1/22/2021

31-9301

Advertisement

Table of Contents

Summary of Contents for Haier GE AZ45E07DABW5

- Page 1 Technical Service Guide May 2019 2019 Zoneline Air Conditioner 230/208 VOLT MODELS AZ45E07DABW5 AZ45E07DACW5 AZ45E07DAPW5 AZ45E09DABW5 AZ45E09DACW5 AZ45E09DAPW5 AZ45E09DBMW5 AZ45E12DABW5 AZ45E12DACW5 AZ65H07DACW5 AZ65H12DADW5 AZ45E12DACW6 AZ65H07DADW5 AZ65H12DADW6 AZ45E12DAPW5 AZ65H12DBMW5 AZ65H07DBMW5 AZ45E12DBMW5 AZ65H09DABW5 AZ65H12DBMW6 AZ45E12DBMW6 AZ65H09DACW5 AZ65H15DABW5 AZ45E12DBMW7 AZ65H09DADW5 AZ65H15DABW6 AZ45E15DABW5 AZ65H09DBMW5 AZ65H15DACW5 AZ45E15DABW6 AZ65H12DABW5...

-

Page 2: Safety Information

5. Locate the Warranty page. GE Appliances, a Haier Company Copyright © 2019 All rights reserved. This service guide may not be reproduced in whole or in part in any form without written permission from GE Appliances, a Haier Company. – 2 –... -

Page 3: Table Of Contents

Table of Contents Safety Information ........................2 Warranty ............................2 Table of Contents ..........................3 Safety Requirements ........................6 Tools Required ..........................7 Caution ..........................7 Nomenclature ..........................8 Operation ............................9 Cooling ..........................9 Heating ..........................9 Heat Pump Operation ......................10 All Heat Pump Lockout Mode ....................12 Boost Heat Mode ........................12 Fan Cycle Operation ......................13 Fan Cycle - Resistance Heating Mode .................14 Fan Cycle - Heat Pump Mode ....................15... - Page 4 Thermistors ...........................26 Thermistors ...........................26 Thermistors Indoor........................26 Thermistors Outdoor ......................26 Controls ............................27 Main Board: Front Cover ......................27 Power Cords .........................28 Main Board - Front ........................29 RJ-45 ............................29 Main Board ...........................30 Component Checks at Main Board ..................31 Fault Codes ..........................32 Service Mode ..........................34 Accessing Controls .......................35 Low Voltage Transformer ......................36 Service Main Board ........................37...

- Page 5 Sealed System ..........................50 Compressor ..........................51 Reversing Valve ........................51 Service Replacement Valve Assembly .................52 Sealed System: Refrigerant Flow Cooling ..................53 Sealed System: Refrigerant Flow Heating ...................54 Recovery Process ........................55 Charging Summary ........................56 Refrigerant Charge .......................56 Schematic/Wiring Diagram ......................57 New Accessories ..........................58 Index .............................59 –...

-

Page 6: Safety Requirements

Safety Requirements GE Factory Service Employees are required to use safety glasses with side shields, safety gloves and steel toe shoes for all repairs. Prescription Safety Glasses Brazing Glasses Safety Glasses must be ANSI Z87.1-2003 compliant Plano Type Safety Glasses Cut Resistant Sleeve(s) Electrically Rated Glove and Dyneema®Cut Resistant... -

Page 7: Tools Required

Tools Required • 5/16-in. socket or drive • 1/4-in. socket or drive: Ground screws and control assembly use 1/4-in. machine thread screws • 3/8-in. socket or drive: For outdoor fan blade removal • 4-mm Allen wrench: For indoor fan blade removal •... -

Page 8: Nomenclature

Nomenclature Model Number A Z 4 5 E 0 9 D A B W 5 Engineering Revision Zoneline Compressor Type Package Terminal M: MB Chassis W: Rechi Chassis Series Special Features: 45: Deluxe Electric Heat B: Base Unit Electronic Control C: Corrosion Treated 65: Deluxe Heat Pump D: Internal Condensate... -

Page 9: Operation

Operation Cooling Heating AZ4500 In the cooling mode, the AZ4500 In the heating mode, AZ4500 will compressor, indoor fan and outdoor utilize the built-in resistance heater, fan run. running with the indoor fan at one of two speeds determined by the Fan AZ6500 In the cooling mode, the Speed selection. -

Page 10: Heat Pump Operation

Upon initial start-up or resumption after a power Heat Pump Operation interruption, Stage 3 (Heater A and Heater B) are energized at full power to generate heat until the When an AZ6500 Zoneline is in the heating mode, room temperature rises to the temperature setting the resistance heater or the compressor runs with regardless of the outdoor temperature. - Page 11 NOTE: The second stage heat is not utilized in Class 2 mode. Unless the Auxiliary Set (or Aux Set) "boost heat" is selected. Stage 2 heating will operate when the thermostat calls for Stage 1 heating. • THIRD STAGE HEAT (HEATERS A AND B ONLY) When the room temperature falls below 2.7°F from the temperature control setpoint, the heat pump operation will stop.

-

Page 12: All Heat Pump Lockout Mode

All Heat Pump Lockout Mode Boost Heat Mode AZ6500 Series ONLY. AZ6500 Series ONLY. The Heat Pump Lockout is controlled through When the Boost Heat Auxiliary Set button is the Auxiliary Set mode. When this Auxiliary enabled and the outdoor temperature is above Set button is on, the control will run in electric 25°F, the first stage heat (heat pump only) is resistance heat (Stage 3) mode only, with the... -

Page 13: Fan Cycle Operation

Fan Cycle Operation There are two Fan Cycle auxiliary settings. These modes are utilized to switch between CONTINUOUS setting, the fan motor continues to operate even when the compressor or the electric heater cycles ON/ OFF. In the CYCLE setting, the indoor fan cycles ON/OFF with the heating and cooling functions. When the Class 2 mode is selected, the fan motor is controlled by the remote wall thermostat, independent of positions of Fan Cycle auxiliary set button modes. -

Page 14: Fan Cycle: Resistance Heating Mode

Fan Cycle - Resistance Heating Mode The indoor fan and heaters are turned ON at the same time. The indoor fan is turned OFF, approximately 20 seconds after the heaters are de-energized as shown. In the OFF mode, the indoor fan will continue to operate for 6 seconds after the user has stopped the Zoneline, in order to dissipate the heat inside the Zoneline. -

Page 15: Fan Cycle: Heat Pump Mode

Fan Cycle - Heat Pump Mode AZ6500 series ONLY. The indoor fan is turned on 3 seconds before the compressor and outdoor fan is turned ON. The outdoor fan and the compressor are turned ON at the same time. The indoor fan is then turned OFF 6 seconds after the compressor and outdoor fan are turned OFF. -

Page 16: Constant Fan

Constant Fan In Constant Fan mode, the Zoneline operates in High Fan mode regardless of fan setting. This feature allows the fan to operate even when the Zoneline is set in the OFF position. This will allow continuous air circulation in the room even if the Zoneline is turned off. -

Page 17: Random Restart

Random Restart The start-up condition for the different modes is shown in the following two diagrams. This function allows for the random restart of Zonelines in a building in the event of a power outage. The restart delay will reduce the initial inrush current from the building to help prevent a second power outage of indefinite length. - Page 18 Random Restart for AZ6500 Series Compressor Stop Compressor 3 mins. Power Down Power Recovered Range Cool Mode Stop Operation Operation Heat Mode Quick Heat Heat Pump Operation Recovery Range Power Down Power Recovered Stop Stop Stop Stop Mode Power Power Recovered Down The main board will power up the Zoneline randomly over a 3 to 20 seconds timing period.

-

Page 19: Freeze Prevention For Indoor Coil (Cooling)

Freeze Prevention for Indoor Coil (Cooling) Cooling Mode During the cooling operation, if the temperature of the indoor coil falls below 34°F for a period of approximately 5 minutes, the compressor will shut off. This will prevent the indoor coil from freezing. The compressor will start running again when the coil temperature reaches 50°F or above. -

Page 20: Indoor Coil Overheat Protection

Indoor Coil Overheat Protection Heat Pump Operation The Overheat Protection is only on the AZ6500 series. The Overheat Protection system protects the Zoneline from overworking when the outdoor temperature is too high for heat pump operation. The temperature of the indoor coil is monitored, and if it rises above 131°F, the control stops the outdoor fan. -

Page 21: Reverse Cycle Defrosting Heat Pump Mode

4. Run reverse cycle defrost (cooling mode Reverse Cycle Defrosting Heat Pump Mode without fans) until either: Reverse Cycle Defrost shall be controlled as a • the outdoor coil temperature rises to 68°F function of compressor run time and outdoor coil temperature. -

Page 22: Internal Condensate Removal Control

Internal Condensate Removal Control Internal Condensate Removal Control (AZ6500 Only) The Internal Condensate Removal (ICR) function will be utilized to drip the condensation, from the base pan, onto the indoor coil to evaporate it when the compressor is running during the heat pump operation. -

Page 23: Heat Sentinel Mode

Heat Sentinel Mode Auxiliary Controls To prevent the room from overheating (Zoneline The red auxiliary set (or Aux Set) button is located must be powered), cooling is energized when behind the room cabinet, below the user interface. the indoor temperature is sensed to be 85°F to There are ten different modes that can be set maintain room temperature below 85°F in any using the auxiliary set button. -

Page 24: Auxiliary Set Button

Auxiliary Set Button Auxiliary Set Button: Press the Red Aux Set Button when in the STOP Mode This menu allows the user to set-up various configurations. The display has a number 0 in the left digit, and the setting in the right digit. The heat and cool LED's are also used. On entry, the display shows AU. -

Page 25: Cdc: (Field Supplied)

CDC: (Field Supplied) Remote Thermostat CDC is not used on MUAM models. The Central The Remote Thermostat Connectors are Desk Control (CDC) is a feature that allows the included with each Zoneline. If required, order a Zoneline to be made operable/inoperable from replacement (Part #: WP26X24981). -

Page 26: Thermistors

Thermistors Indoor Thermistor Resistance (ohms) Thermistors °F COIL Thermistors provide temperature feedback to the 63260 94900 main board to maintain proper room temperature 34620 51940 and operating conditions of the sealed system. 32860 49330 On heat pump models (AZ65), thermistors also 19970 29960 provide outdoor air temperature and outdoor... -

Page 27: Controls

Controls Main Board: Front Cover MAIN BOARD The new Zoneline series uses a main board that contains the microprocessor. It processes the information input from the User Interface (UI) or wall thermostat, the thermistors, and fan motors feedback. It then activates the associated relays for the selected cycle. The main board also has a DC power supply to provide the needed DC voltage to run the indoor and outdoor fan motors. -

Page 28: Power Cords

20-amp: Single Wire DC Harness Power Cords The new Zonelines have new power cords (sold separately). Three amperage ratings are available: 15-Amp (Part #: RAK315P), 20- Amp (Part #: RAK320P), and 30-Amp (Part #: RAK330P). All cords will have the LCDI protector built in. -

Page 29: Main Board - Front

Main Board - Front Removing the front cover exposes the indoor fan connector, the indoor thermistors, User Interface and indoor fan connectors are all located on the upper left portion of the main board. Indoor Thermistors Indoor Fan User Interface (UI) 12 pin Red Aux Set Button... -

Page 30: Main Board

Main Board Outdoor Fan Motor J304 Reversing Outdoor Valve Coil Thermistor(s) J305 ICR Pump Compressor DLB Relay AC Input plug J101 voltage select jumper • Jumper between 1 and 2 230V • Jumper between 1 and 3 265V This jumper provide voltage to 24 VAC transformer and must be in place for Zoneline to function correctly. -

Page 31: Component Checks At Main Board

Component Checks at Main Board INDOOR J502 pin 1 - 2 AIR range 7k ohms to 64k ohms J502 pin 3 - 4 COIL range 10.5k ohms to 95k ohms Thermistors OUTDOOR J503 pin 1 - 2 AIR range 3k ohms to 28.5k ohms J503 pin 4 - 5 COIL range 3k ohms to 28.5k ohms J103 pin 1 - 2 Blue to Yellow ∞... -

Page 32: Fault Codes

Fault Codes Fault Code Display Mode While the Zoneline is in the "OFF" mode, press and hold the fan button with the red auxiliary set button simultaneously to enter into this mode. The Zoneline will then display all active fault codes held in memory, showing each one for 3 seconds on/off. - Page 33 Fault Effect on Operation Code Fault Meaning Fault Reset Time While Fault is ACTIVE Number Heat pump over-temperature The outdoor fan motor is Fault clears fault. The temperature of the shut down until the coil once indoor coil indoor coil is over 131°F. temperature recovers.

-

Page 34: Service Mode

Service Mode Service Mode 8. "UI": UI Test: Run the LED test sequence. While the Zoneline is in "OFF" mode, press and 9. "So": Software version is displayed. hold the "+" and "-" buttons simultaneously with AZ6500 the red auxiliary set button to enter into this mode. 1. -

Page 35: Accessing Controls

Carefully lower the control to a service friendly Accessing Controls position. Behind the control area on the bulkhead is a cover which allows access to the capacitor and some connections to the control board. Capacitor: The capacitor assists the compressor starting and lowers the running current. -

Page 36: Low Voltage Transformer

Low Voltage Transformer The low voltage transformer is mounted to the control board. If the Low Volt Transformer has failed, the main control will need to be replaced. Low Volt Transformer Diagnosing Low Volt Transformer To verify Low Volt Transformer operation, AC Volts may be checked on the Remote Thermostat Connector J401 pins 1 - 7. -

Page 37: Service Main Board

Service Main Board Personality Settings (Continued next page) – 37 –... - Page 38 Switch Switch S501-4 S502-3 and S502-4 ON: Make up air module equipped Are currently not used Switch S502-2 ON: 265V model only Outlet Air Thermistor equipped - locate on the louver assembly Switch S502-1 ON: Heat pipe equipped Switch Switch S501-2 S502-3 S502-1...

-

Page 39: User Interface

User Interface The User Interface is a display board with tactile push button switches. There aren’t any processors contained on this board. There is a ferrite ring that the harness connecting the boards wraps around to minimize Electro- Magnetic Interference (EMI). Three screws secure the User Interface/Control Assembly to the chassis. -

Page 40: Air System

Air System Fan Motors Both the indoor and outdoor fan motors are DC motors driven by the main board and provide feedback to the main board for proper speed confirmation. Indoor Fan Motor The indoor fan motor turns a blower wheel which is attached to the motor shaft with a 4-mm Allen screw. The opposite end of the blower wheel inserts into a bearing assembly. -

Page 41: Indoor Fan Bearing

Components: Indoor Fan Bearing Indoor Fan Bearing Remove six screws to remove the end cap to access the bearing assembly. Two screws are used to secure the bracket attached to the indoor coil and end cap. Proper Bearing Placement NOTE: When reinstalling the bearing, ensure the shaft goes directly into the bearing assembly. -

Page 42: Outdoor Fan Motor Shroud

Outdoor Fan Motor Shroud The outdoor fan shroud provides proper airflow through the outdoor coil and also supports the outdoor fan motor. The outdoor fan shroud and motor assembly are attached to the base pan and outdoor coil assembly with twelve screws and a “sleeve” that slides over the shroud and outdoor coil assembly. NOTE: An extension will make accessing the lower screws easier. -

Page 43: Outdoor Fan Motor

Outdoor Fan Motor The outdoor fan motor turns a slinger fan blade, which is attached to the motor shaft with a 3/8-in. regular thread nut. The motor is secured to the outdoor shroud with four 5/16-in. hex-head shoulder bolts. NOTE: If the wire clip found below the motor breaks, secure the wire to the support with a wire tie. -

Page 44: Electric Heat

Electric Heat Heater All models (with Electric Heat) of the new Zoneline have a three bank heater assembly. They have three thermal switches to protect the circuit; two are cycling (resettable) thermal switches and the one is a "one-shot" thermal switch. Features may vary depending model number throughout this Service Guide. - Page 45 Heater Assembly Remove six screws to remove the end cap to access the heater assembly. Two screws are used to secure the bracket attached to the indoor coil and end cap. After disconnecting the wire harness from the board and removing one ground screw, the heater assembly will slide out the left side of the Zoneline.

-

Page 46: Condensate Removal

Condensate Removal ICR System Slinger on Outdoor Fan Blade The Internal Condensate Removal system The water that is collected through the normal consists of a small pump that is driven by the process of air conditioning is collected in the rear main board. -

Page 47: Damper Door

Damper Door Make-Up Air Module (MUAM) This feature allows outside air into the room. The The hospitality industry has many building and door is secured with two screws from the factory occupancy codes they must follow. One of that must be removed upon installation if the those codes is for introducing fresh air into guest customer would like to use this feature. - Page 48 As viewed from the front, the MUAM is The module is secured with two screws and tabbed into a base plate mounted to the base located on the left side and located on pan. Some new zoning regulations require that the back side of the bulkhead.

- Page 49 Occupancy Sensors (optional)* A wireless door sensor (located on guest entry door) and motion sensor (ceiling or wall mount) communicate to the Zoneline through a Setback Module. The three components work collectively to determine whether the room is occupied or vacant. When the guest room door is opened and motion is sensed, the MUAM will turn on and remain running (depending outdoor temperature and humidity).

-

Page 50: Sealed System

Sealed System Features may vary depending model number throughout this Service Guide. As with any refrigeration system, Zonelines have an indoor coil, outdoor coil, compressor and refrigerant metering device (capillary tubes). A drier is part of the sealed system now included from the factory. -

Page 51: Compressor

Compressor Reversing Valve Wiring: Compressor Check On heat-pump models, the refrigerant flow direction is controlled by the reversing valve CAUTION: Risk of injury. Keep head clear of assembly. In the cooling mode, the main board terminal area when cover is removed. supplies line voltage to the solenoid coil, which causes the valve to switch flow direction. -

Page 52: Service Replacement Valve Assembly

Drier Service Replacement Valve Assembly All Zonelines will now have a drier factory installed. The drier must be replaced anytime sealed system repairs are performed. NOTE: Driers are vacuumed packed and should only be opened when it is being installed. Driers opened and left to the open air become saturated and should be discarded if not used within 45 minutes. -

Page 53: Sealed System: Refrigerant Flow Cooling

Sealed System: Refrigerant Flow Cooling Features may vary depending model number throughout this Service Guide. – 53 –... -

Page 54: Sealed System: Refrigerant Flow Heating

Sealed System: Refrigerant Flow Heating Features may vary depending model number throughout this Service Guide. – 54 –... -

Page 55: Recovery Process

Recovery Process Recovery Process High Pressure Switch On Vapor Port Closed Filter Liquid Port Open High Side Tap Valve (WX5X328) 410A Recovery Cylinder Recovery Hose Hook-Ups Complete charging and recovery information for R410A is available in Service Guide 31-9192. – 55 –... -

Page 56: Charging Summary

Charging Summary Charging Summary Safety Switch Charging Hose Hook-Ups Complete charging and recovery information for R410A is available in Service Guide 31-9192. Refrigerant Charge Model R410a (oz) Model R410a (oz) AZ45E07DABW5 29 oz AZ65H07DBMW5 29 oz AZ45E07DACW5 29 oz AZ65H09DABW5 36 oz AZ45E09DABW5 36 oz... -

Page 57: Schematic/Wiring Diagram

Schematic/Wiring Diagram Features differ by Model. All features shown may not be on all models – 57 –... -

Page 58: New Accessories

New Accessories RAK204D15C Sub-Base, 208/230-v, 15-A, w/ Power Cord RAK204D20C Sub-Base, 208/230-v, 20-A, w/ Power Cord RAK204D30C Sub-Base, 208/230-v, 30-A, w/ Power Cord RAK204E15C Sub-Base, 265-v, 15-A, w/ Power Cord RAK204E20C Sub-Base, 265-v, 20-A, w/ Power Cord RAK204E30C Sub-Base, 265-v, 30-A, w/ Power Cord RAK315P LCDI Power Cord, 208/230-v, 15-A RAK320P... -

Page 59: Index

Index auxiliary settings 13 outdoor fan blade 7, 46 outdoor fan motor 33, 42, 43 Outdoor fan shroud 42 Capacitor 35 CDC 16, 25, 58 Charging Summary 56 Personality 27 Check Valve 52 Power Cord 58 Control Lock Out 23 Recovery Process 55 drain pan plug 46 Refrigerant Flow Cooling 53...

Need help?

Do you have a question about the GE AZ45E07DABW5 and is the answer not in the manual?

Questions and answers