Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RITE-HITE FASTRAX CLEAN

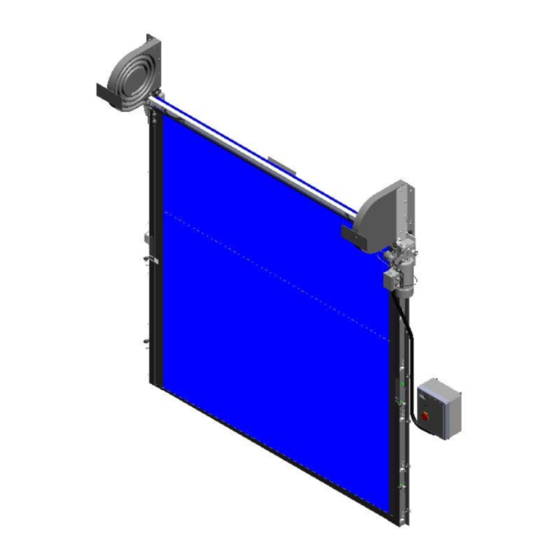

- Page 1 FASTRAX CLEAN ® This manual to remain with the door: Date Installed:____________________ This Manual Covers Doors Shipped = > 6/20/2012 - Revised i-Comm board. Refer to FasTraxCLB for doors prior. PRINTED IN U.S.A. Publication No. FasTraxCLE email: printshop@RITEHITE.com April 2014...

-

Page 2: Table Of Contents

The information contained in this manual will allow you to operate and maintain the door in a manner which will insure RITE-HITE Corporation does maximum life and trouble free operation. The serial # for your not recommend any particular... -

Page 3: Getting Started

Step 2 the serial number label. Measure Door Opening If the measurements do not Width at the floor agree, STOP! Contact your RITE-HITE DOORS, INC. representative. High Side Low Side Step 8 Using a laser level, place a mark where the laser is sighted on each side of the jamb to determine if the floor is level. -

Page 4: Mounting Methods

® FASTRAX CHAPTER 1 - SUGGESTED MOUNTING METHODS Suggested Mounting Methods For Walls Acceptable Anchor Types These anchor types provide the necessary strength for secure attachment of the unit to the building wall. Hammer Anchor Sleeve Anchor Stud Anchor Wedge Anchor Expansion Anchor Note: Length of anchor should be long enough to engage concrete structure by a minimum of 2”. - Page 5 Flat Space Required: 4 1/2” [114] 3 5/8” [92] Corrugated Metal Siding Filler Board Ordered Through Minimum Fasteners Required Rite-Hite or Supplied by Others 3/8” [10] for Header Bracket Minimum Fasteners Required 1/4” [6] for Sideframe 3/8” [10] for Header Bracket Fasteners (Supplied by Others) 1/4”...

- Page 6 ® FASTRAX CHAPTER 2 - LOWER TRACK WITH RADIAL Ordered Door Ordered Door Width Height + 28 1/2” [724] Stainless fasteners are included to mount the door to the plastic Door lumber, but thru bolt or anchors for Ordered mounting to the wall are optional. Height Optional Plastic Lumber.

- Page 7 ® FASTRAX CHAPTER 2 - LOWER TRACK WITH RADIAL I M P O R T A N T ! ! ! It is imperative that the tracks be mounted at the proper width. If mounted too wide, excess wear is placed on the drive spheres.

- Page 8 ® FASTRAX CHAPTER 2 - DRIVE TUBE Optional upper Place curtain so the vision is at the lintel. stand-off caps for Place a mark on the wall at the center of sheet metal walls visions and install lintel roller. If no vision, space evenly. DO NOT place over vision area.

- Page 9 ® FASTRAX CHAPTER 2 - UPPER TRACK WITH NON - RADIAL Upper Track Spreader Bar MUST be utilized to assure proper track spacing to prevent the curtain from binding. Upper Vertical Track ** Lightly lubricate the upper tracks with the mineral oil provided when installing track.

- Page 10 ® FASTRAX CHAPTER 2 - UPPER TRACK WITH NON - RADIAL 10.3 10.1 Lower to Upper Track Splice Upper Track Top Wall Mount Bracket 10.4 10.2 Upper Track Top Wall Mount Bracket Upper Track Center Wall Mount Bracket PUB. NO. FASTRAXCLE APRIL 2014...

- Page 11 ® FASTRAX CHAPTER 2 - MOTOR / ENCODER Ground motor wire 11.1 connected here. Terminate Slide on lock collar opposite end to junction box. after motor (115 in/lbs) Attach Encoder to gearbox bracket. If Encoder is removed, tighten to 14 in/lbs. Route Encoder cable and non-drive photoeye cable into upper fitting on motor junction box.

- Page 12 ® FASTRAX CHAPTER 2 - PHOTOEYES 12.1 Encoder Cover for Doors < 8’-0” Height 12.2 12.3 Route non-drive photoeye cable from non-drive lower track junction box to junction box on motor. Tie ends of cable on outside Route photoeye of radials to hold in place. wires from non-drive lower track junction box to junction box...

-

Page 13: Electrical Installation

® FASTRAX CHAPTER 3 - ELECTRICAL INSTALLATION I M P O R T A N T ! ! ! C A U T I O N ! ! ! To reduce risk of injury or death, an earth ground connection The first time that the door system is operated, it may move in the MUST BE made to the green/yellow control box ground terminal. - Page 14 ® FASTRAX CHAPTER 3 - ELECTRICAL INSTALLATION W A R N I N G ! ! ! DO NOT DRILL HOLES ON TOP OF CONTROL BOX TO RUN CONDUIT, AS DUST PARTICLES AND MOISTURE MAY CAUSE DAMAGE TO ELECTRICAL COMPONENTS. THE SAFEST LOCATION IS AT THE BOTTOM.

-

Page 15: Encoder Setup

® FASTRAX CHAPTER 3 - ENCODER SETUP I M P O R T A N T ! ! ! Failure to properly ground encoder drain wires may result in varying open and close stopping positions. PUB. NO. FASTRAXCLE APRIL 2014... - Page 16 ® FASTRAX CHAPTER 3 - ENCODER SETUP MUST complete before operating door. To bring the open position down (closer to the floor) adjust this value to be less than the current value. To open the door more relative to the floor, adjust this Operation of the door is not possible when using the menu system.

- Page 17 ® FASTRAX CHAPTER 3 - PROGRAMMING FOLDERS Use the Enter, Up, Down, Back buttons on the i-Comm to GENERAL FOLDER navigate through the folders. To exit system, use back See General Layout Chart to change / view settings. button until “Door Faulted” appears. Use to setup Clock, Maintenance cycles ENCODER FOLDER VIEW FOLDER...

- Page 18 ® FASTRAX CHAPTER 3 - I-COMM DISPLAY MESSAGES LCD DISPLAY MESSAGES: TOP DISPLAY BOTTOM DISPLAY REASON / FAULT MESSAGES ACTION REQUIRED Door Faulted Breakaway Door is in breakaway mode Reset / Jog Door* Breakaway FasTrax - Chainfall; 8000CL/XL - Sideframe door; 8000/CL/XL Overload Relay Reset / Jog Door* Emergency Stop E-Stop pushed, Overload Relay (8900), Inverter (8600) Push Open/Reset*...

- Page 19 ® FASTRAX CHAPTER 3 - I-COMM LAYOUT 19.1 PUB. NO. FASTRAXCLE APRIL 2014...

- Page 20 ® FASTRAX CHAPTER 3 - I-COMM II FOLDERS *NUMBER IS NOT SHOWN IN i-COMM MENU* FOLDER NUMBER NAME VALID VALUES DESCRIPTION DEFAULT Open Distance 0 -255 Used to Set Opening distance for door Motor Drive Side Right Drive / Left Drive Used to select motor drive side.

- Page 21 ® FASTRAX CHAPTER 3 - I-COMM II FOLDERS *NUMBER IS NOT SHOWN IN i-COMM MENU* VALID VALUES DESCRIPTION DEFAULT FOLDER NUMBER NAME Display Cycle Count 0 - 99999999 Displays current Cycle Count Fault History Displays fault log. Use Up and Down to scroll View Display Model # Displays door model number...

- Page 22 ® FASTRAX CHAPTER 3 - I-COMM II INPUT / OUTPUT TABLE TYPE NUMBER FUNCTION DESCRIPTION Interlock In Interlock Input - When Input is set to this function door will not open until input is ON. Valid only for inputs X3, X4, and X5. Stop N.C.

- Page 23 ® FASTRAX CHAPTER 3 - 230/460V INVERTER (VFD) PROGRAMMING FasTrax™ Inverter Program Instructions ***These instructions are only when not using the i-Comm to change parameters.*** When in Status mode, pressing and holding the “M” MODE key for 2 seconds will change the display from displaying a speed indication to displaying load indication and visa versa.

- Page 24 ® FASTRAX CHAPTER 3 - 230/460V INVERTER (VFD) CODES FasTrax - Inverter (VFD) Status Modes Left Display Status Explanation Drive ready The drive is enabled and ready for a start command. The output bridge is inactive. Drive inhibited The drive is inhibited because there is no enable command, or a coast to stop is in progress or the drive is inhibited during a trip reset.

-

Page 25: Inverter Programming

® FASTRAX CHAPTER 3 - 575V (VFD) INVERTER PROGRAMMING FasTrax™ Allen Bradley - 575V - Inverter Program Instructions Press “ESC” once to display the Display Group parameter. Press “ESC” again to enter the group menu, the group letter will flash. Press “UP” or “DOWN” arrow to scroll through the group menu. Press “Enter”... -

Page 26: Curtain Installation

® FASTRAX CHAPTER 4 - CURTAIN INSTALLATION Re-install curtain roller bracket Re-install refeed bracket Disengage brake (up) to feed curtain and engage (down) 26.1 26.3 after curtain is installed 26.2 Nuts Remove refeed brackets Remove curtain roller brackets from curtain stiffener Feed curtain thru drive tube drivers, make sure curtain is level and the bottom of the curtain is... - Page 27 ® FASTRAX CHAPTER 4 - MISC INSTALLATION 27.1 Compress seal behind track It may require the lintel seal block to be removed 27.3 Attach bracket to radial for doors <8’ O.D.H. PUB. NO. FASTRAXCLE APRIL 2014...

-

Page 28: Final Checklist

The door operations are controlled by a Universal Controller. The controller is set-up and programmed during testing at the factory. Unless you are a RITE-HITE DOORS, INC. authorized service technician, you should not attempt to change the program. A quick way of determining that the door is ready to operate, is to open the control box and look at the row of (X) green Input LED’s on the i-COMM and the label to... - Page 29 ® FASTRAX CHAPTER 5 - FINAL CHECKLIST Complete N/A Description Control box conduit mounting location (must be on the bottom) Ground wires properly terminated to ground terminal Shield wires properly terminated to ground terminal Motor ground wire terminated to lower track ground screw Encoder chain / sprockets / set screws properly aligned &...

-

Page 30: Troubleshooting

® FASTRAX CHAPTER 5 - TROUBLESHOOTING DEFINITION FUNCTION Activation It is preferred not to wire activation devices until after the door is functioning properly. (Refer to Activation Manual) Brake If the brake is not functioning properly, check the following: a) Check F7 fuse-replace. b) Brake wiring at terminals BRK &... -

Page 31: Virtual Vision

® FASTRAX CHAPTER 5 - TROUBLESHOOTING DEFINITION FUNCTION Open/Reset Push Button The open/reset push button function is when the button is pressed, a command to open the door is given. To jog door when i-Comm states “Photoeye Failure”, press and hold the “Open/Reset” button. Pressure If the curtain is blowing out because of high wind or negative pressure, check the following: a) Tracks MUST be mounted at O.D.W. - Page 32 ® FASTRAX CHAPTER 5 - MAINTENANCE PROCEDURES RITE-HITE DOORS, INC. PLANNED MAINTENANCE Model FASTRAX CL® CUSTOMER: JOB# SERIAL# DATE: Recommended P.M. Intervals (Time Shown In Months) Planned Maintenance Task Inspect and Perform the Following Activation Operate all devices to verify proper operation.

- Page 33 ® FASTRAX CHAPTER 5 - MAINTENANCE / CLEANING 33.1 Apply Mineral Oil to radials Note water drain holes Remove clips from 33.3 pins to remove lower track for cleaning or replacement 33.4 Install guards over drive ends on doors less than 8’-0” tall. Remove UHMW insert 33.2 and wall seal for cleaning...

- Page 34 To avoid cross talk when changing the settings on the Virtual Vision or activation sensors when using the remote controls, Rite-Hite offers the following three options: The BEA remote control allows you to set a unique security code for each sensor.

- Page 35 CHAPTER 5 - VIRTUAL VISION LAYOUT - BACK SIDE Virtual Vision Motion Sensor Virtual Vision Assembly 49” 36” 7826E005 FINAL ASSEMBLY I-COMM II RELEASE 6522 06/14/2012 DWG. NO. RITE-HITE DOORS INC. 7/6/2009 JBOX,ASY, VIRTUAL VISION 7/6/2009 7826E005 5352..9"=1' 2009 PUB. NO. FASTRAXCLE APRIL 2014...

- Page 36 ® FASTRAX CHAPTER 6 - WIRELESS ACTIVATION It is recommended to pair the unit(s) at the control box prior to 36.1 mounting the unit. To pair the host with a wireless device: Open the lid and remove the plastic strip under the batteries in the remote unit to energize the device.

- Page 37 ® FASTRAX CHAPTER 6 - OPTIONAL REMOTE MOUNTED CONTROLS Optional remote mounted LCD, is mounted on a stainless 37.1 steel 2-gang wall faceplate and compatible with standard 2- gang electrical box (provided by end user). On the face of the assembly there is a 4 button membrane switch: Green - Open/Reset (Up), Red - Stop (Exit), Yellow - Close (Down), and Grey - Enter (Left arrow).

- Page 38 ® FASTRAX CHAPTER 6 - MANDATORY FIELD WIRING DIAGRAM PUB. NO. FASTRAXCLE APRIL 2014...

- Page 39 ® FASTRAX CHAPTER 6 - ACTIVATION WIRING PUB. NO. FASTRAXCLE APRIL 2014...

- Page 40 ® FASTRAX CHAPTER 6 - WIRING DIAGRAM (208V-460V) PUB. NO. FASTRAXCLE APRIL 2014...

- Page 41 ® FASTRAX CHAPTER 6 - WIRING DIAGRAM (575V) PUB. NO. FASTRAXCLE APRIL 2014...

- Page 42 ® FASTRAX CHAPTER 6 - VIRTUAL VISION ELECTRICAL WIRING PUB. NO. FASTRAXCLE APRIL 2014...

- Page 43 ® FASTRAX CHAPTER 7 - FASTRAXCL CONTROL BOX SERVICE PARTS 28, 39 20, 21 25,26 13,23,27 15,16,17 CLASS II LOW VOLTAGE ONLY ! 3,5,9 8,10,11,12 37,38 Dwg# 7826E008 Rev. G 5,14 Not Shown: 39 ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION Power Supply, DIN, 24VDC, 18W (<=22W) 65700006 Ass’y (C-Box, BackPanel, Enclosure w/labels)

- Page 44 ® FASTRAX CHAPTER 7 - FASTRAXCL SERVICE PARTS LAYOUT 50,112,115 8 Back side of curtain 146,147 30,80 3, 39-47, 54,55 Parts Not Shown: 52, 53, 91, 93 PUB. NO. FASTRAXCLE APRIL 2014...

- Page 45 ® FASTRAX CHAPTER 7 - FASTRAXCL SERVICE PARTS LAYOUT 27, 96 90 - Key 110,124 113, 125 49,104 97, 127 26,94 82,87 83,88,103 25,26, 36,37, 59-66 142, 82,87,102 6 - Entire Assembly 156,157 137, 13,22 13,22, Wall Mounting Options 105, 52 - Masonry Anchor Kit 106, 53 - Thru Wall Kit...

- Page 46 ® FASTRAX CHAPTER 7 - FASTRAXCL SERVICE PARTS LAYOUT 98,117 Left Hand Non-Drive Right Hand Drive Lower Track Shown Lower Track Shown 21,97,127 19,131, 16,32 16,32 21,131, 21,131, 16,32,160,161 103, 101, 102 104, 108, 16,32 21,97,127 16,32 98,117 101, 102, 110, 21,131, 57,68,69,79...

- Page 47 ® FASTRAX CHAPTER 7 - FASTRAXCL SERVICE PARTS LIST ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION Bushing, CA Seal, 3 x 6 MM, 16 MM 15550003 Entire Door, FasTrax CL FasTraxCL Bushing, CA Seal, 2 x 8 MM, 21 MM 15550004 Assembly, Cable, Control Box 1551..

- Page 48 ® FASTRAX CHAPTER 7 - FASTRAXCL MISC SERVICE PARTS Kit, FasTraxCL Lintel Roller (a/r) - 53700730 Bracket, BEA Falcon - (a/r) 14501212 Kit, Hardware, FasTrax, Kit Masonry Anchors, SS (1) - 53700745 Univ Conn (1) - 53600186 Kit,Fastrax,Connector, 90° (a/r) - 16960073 Kit Install Lag Bolts, SS (1) - 53700762 Control Box Cable (1) - 1551..

- Page 49 ® FASTRAX CHAPTER 7 - ACTIVATION SERVICE PARTS Part # Description 5700 7100 80/XL 8600 8900 Fastrax FastraxCL FastraxFR FastraxFRLD LiteSpeed Split2nd VRTLV Kit, Virtual Vision, Stand Alone 7622 Kit, I-Zone 7623 Kit,Virtual Vision,FasTrax/FR/LiteSpeed 7624 Kit, Virtual Vision, FasTraxCL 7636 Kit, I-Zone Upgrade, Non FasTrax 7637 Kit, I-Zone Upgrade, FasTrax...

- Page 50 ® FASTRAX CHAPTER 8 - RADIAL JAMB LAYOUT FOR WELDING PUB. NO. FASTRAXCLE APRIL 2014...

- Page 51 ® FASTRAX CHAPTER 8 - VERTICAL JAMB LAYOUT FOR WELDING PUB. NO. FASTRAXCLE APRIL 2014...

- Page 52 ® FASTRAX CHAPTER 8 - ARCHITECTURAL DRAWING RADIAL PUB. NO. FASTRAXCLE APRIL 2014...

- Page 53 ® FASTRAX CHAPTER 8 - ARCHITECTURAL DRAWING VERTICAL PUB. NO. FASTRAXCLE APRIL 2014...

- Page 54 ® FASTRAX RITE-HITE DOORS NOTES PAGE This page intentional left blank. PUB. NO. FASTRAXCLE APRIL 2014...

- Page 55 ® FASTRAX RITE-HITE DOORS NOTES PAGE This page intentional left blank. PUB. NO. FASTRAXCLE APRIL 2014...

- Page 56 RITE-HITE or its agent, a reasonable opportunity to inspect any Product claimed to be defective and shall, at RITE-HITE’s option, either (x) grant RITE-HITE or its agent access to Owner’s premises for the purpose of repairing or replacing the Product or (y) return of the Product to the RITE-HITE, f.o.b.

Need help?

Do you have a question about the FASTRAX CLEAN and is the answer not in the manual?

Questions and answers