Summary of Contents for PIETRO FIORENTINI Dival 700

- Page 1 Dival 700 Medium-low pressure gas regulator Revision A - Edition 03/2023 USE, MAINTENANCE AND WARNING MANUAL...

- Page 2 MEDIUM PRESSURE REGULATOR INTRODUCTION REV. A Use, maintenance and warning manual...

-

Page 3: Introduction

It is of particular importance that the personnel responsible for the equipment be trained in its use, maintenance and ap- plication of the safety instructions and procedures indicated in this manual. Revision: A COPYRIGHT 2023 © PIETRO FIORENTINI S.P.A. MEDIUM PRESSURE REGULATOR INTRODUCTION REV. A... - Page 4 MEDIUM PRESSURE REGULATOR INTRODUCTION REV. A Use, maintenance and warning manual...

-

Page 5: Revision History

1.1 - REVISION HISTORY Revision Date Revision contents index 03/2023 First issue Tab. 1.1 MEDIUM PRESSURE REGULATOR INTRODUCTION REV. A Use, maintenance and warning manual... -

Page 6: Table Of Contents

INDEX 1 - INTRODUCTION ........................3 1.1 - REVISION HISTORY ..........................5 2 - GENERAL INFORMATION ....................11 2.1 - MANUFACTURER IDENTIFICATION ......................11 2.2 - IDENTIFICATION OF THE PRODUCT ...................... 11 2.3 - REGULATORY FRAMEWORK ......................... 11 2.4 - WARRANTY ............................11 2.5 - SYMBOLS USED IN THE MANUAL ...................... - Page 7 5.1.1 - PACKAGING AND FASTENERS USED FOR TRANSPORT ..............44 5.2 - PHYSICAL CHARACTERISTICS OF THE EQUIPMENT ................46 5.2.1 - DIVAL 700 .............................46 5.2.2 - DIVAL 700 + LA .............................47 5.3 - EQUIPMENT ANCHORING AND LIFTING METHOD................48 5.3.1 - FORKLIFT HANDLING METHOD ......................49 5.3.2 - CRANE HANDLING METHOD .......................51...

- Page 8 8.4 - CALIBRATION OF EQUIPMENT AND ACCESSORIES INSTALLED ............71 8.5 - REGULATOR COMMISSIONING PROCEDURE ..................72 8.6 - COMMISSIONING PROCEDURE OF REGULATION LINE: DIVAL 700 REGULATOR + DIVAL 700 REGULA- TOR WITH IN LINE MONITOR FUNCTION ....................74 8.6.1 - PRESSURISING WITH EXTERNAL SOURCE ..................78 8.7 - COMMISSIONING PROCEDURE OF DIVAL 700 REGULATOR WITH LA SLAM-SHUT VALVE ....

- Page 9 9.4 - ROUTINE MAINTENANCE PROCEDURES ....................99 9.4.1 - TIGHTENING TORQUES ........................100 9.4.2 - REPLACING ELEMENTS SUBJECT TO WEAR AND ABRASION............107 9.4.3 - REGULATOR MAINTENANCE PROCEDURE DIVAL 700 ..............108 9.4.4 - LA SLAM-SHUT VALVE ........................120 9.4.6 - PROCEDURE FOR RECOMMISSIONING AFTER MAINTENANCE ............132 10 - TROUBLESHOOTING......................

- Page 10 MEDIUM PRESSURE REGULATOR INTRODUCTION REV. A Use, maintenance and warning manual...

-

Page 11: General Information

PIETRO FIORENTINI S.P.A. guarantees that the equipment was manufactured using the best materials, with high quality workmanship, and complies with the quality requirements, specifications and performance set out in the order. The warranty shall be considered null and void and PIETRO FIORENTINI S.P.A. shall not be liable for any damage and/or malfunctions: •... -

Page 12: Symbols Used In The Manual

2.5 - SYMBOLS USED IN THE MANUAL Symbol Definition Symbol used to identify important warnings for the safety of the operator and/or equipment. Symbol used to identify information of particular importance in the instruction manual. The information may also concern the safety of the personnel involved in using the equipment. Obligation to consult the instruction manual/booklet. -

Page 13: Addressees, Supply And Storage Of The Manual

Keep the instruction manual near the equipment, in an accessible place known by all qualified technicians involved in using and running it. PIETRO FIORENTINI S.p.A. shall not be held liable for any damage to people, animals and property caused by failure to adhere to the warnings and operating procedures described in this manual. -

Page 14: Applied Rating Plates

Removing nameplates and/or replacing them with other plates is strictly not allowed. Should the plates be unintentionally damaged or removed, the customer must notify PIETRO FIORENTINI S.p.A. The equipment and its accessories are provided with nameplates (from Id.1 to Id.2). -

Page 15: Glossary For Rating Plates

2.8.1 - GLOSSARY FOR RATING PLATES The terms and abbreviations used on nameplates are described in “Tab. 2.6”: Term Description Accuracy class. Slam-shut valve accuracy class due to pressure increase. AG max “OPSO” (Over pressure shut off). Slam-shut valve accuracy class due to pressure decrease. AG min ”UPSO”(Under pressure shut off). -

Page 16: Glossary Of Measurement Units

Term Description Full setpoint range with regard to tripping caused by decreased pressure in the pressure switch Wdsu incorporated in the slam-shut valve. This range can be obtained by adjusting but not replacing the components. Tab. 2.6 2.9 - GLOSSARY OF MEASUREMENT UNITS Type of measurement Unit of measurement Description Sm³/h... -

Page 17: Qualified Professional Figures

2.10 - QUALIFIED PROFESSIONAL FIGURES Qualified operators in charge of using and managing the equipment throughout its technical service life: Professional figure Definition Qualified technician able to: • perform preventive/corrective maintenance operations on all mechanical parts of the Mechanical equipment subject to maintenance or repair; maintenance techni- •... - Page 18 MEDIUM PRESSURE REGULATOR GENERAL INFORMATION REV. A Use, maintenance and warning manual...

-

Page 19: Safety

3 - SAFETY 3.1 - GENERAL SAFETY WARNINGS WARNING! The equipment described in this instruction manual is: • a device subjected to pressure in pressurised systems; • normally installed in systems carrying flammable gases (for example: natural gas). WARNING! If the gas used is a combustible gas, the installation area of the equipment is defined as a “danger zone” as there are residual risks that potentially explosive atmospheres may be generated. -

Page 20: Personal Protective Equipment

3.2 - PERSONAL PROTECTIVE EQUIPMENT ”Tab. 3.9” shows the personal protective equipment (PPE) and its description. An obligation is associated with each sym- bol. Personal protective equipment means any equipment intended to be worn by the worker in order to protect them against one or several risks that are likely to threaten their safety or health during work. -

Page 21: Residual Risks

3.3 - RESIDUAL RISKS In accordance with the requirements of PED 2014/68/EU, point 1.2 of Annex I, below is an assessment of the risks as- sociated with the equipment and an indication of the principles adopted for their prevention, according to the following classification: a) Elimination and/or reduction of the risk. - Page 22 3.3.1 - TABLE SHOWING RESIDUAL RISKS DUE TO PRESSURE Effect and Risk and hazard Event and Cause Solution and prevention consequence Pressurised gas a. Handling and installation with appropri- leak. • Violent impact; • Deformation; ate devices to avoid localised stress. Projection of •...

- Page 23 Effect and Risk and hazard Event and Cause Solution and prevention consequence Pressurised gas • Deformation; leak. a. With the exclusion of what is set out in • Cracking and slot Projection of • External loads bear- the project, the user must verify that no formation;...

-

Page 24: Table Of Residual Risks For Potentially Explosive Atmospheres

3.3.2 - TABLE OF RESIDUAL RISKS FOR POTENTIALLY EXPLOSIVE ATMOSPHERES “Tab. 3.11” shows the conditions that can lead to the generation of a potentially explosive atmosphere respectively for: • DIVAL 700 pressure regulator; • the LA slam-shut valve. Considering that the silencer does not have active functional parts, in this analysis it is considered an integral part of the DIVAL 700 regulator. - Page 25 Potentially Management measures in- Operating explosive Normative references cluded in the instructions for conditions atmosphere use and warning Breakage of other This type of malfunction is not rea- non-metallic parts sonably expected as it involves static (malfunction) sealing (to the outside). •...

-

Page 26: Obligations And Prohibitions

3.4 - OBLIGATIONS AND PROHIBITIONS The following is a list of obligations and prohibitions to be observed for the safety of the operator. It is mandatory to: • carefully read and understand the instructions for use and warning; • check whether the downstream equipment is suitably sized according to the performance required of the regulator in the actual operating condition;... -

Page 27: Safety Pictograms

Depending on the operating conditions, use and configuration required, the equipment may generate noise beyond the limits allowed by current legislation in the country of installation. For the value of the noise generated by the equipment and further information, contact PIETRO FIORENTINI S.p.A. ATTENTION! - Page 28 MEDIUM PRESSURE REGULATOR SAFETY REV. A Use, maintenance and warning manual...

-

Page 29: Description And Operation

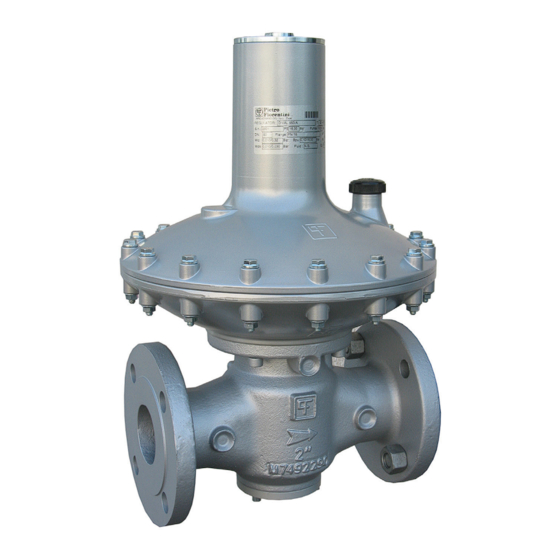

GENERAL DESCRIPTION DIVAL 700 is a direct acting pressure regulator for medium and low pressure that reduces the inlet gas pressure while maintaining a stable downstream value even when the required flow rate varies within the operating conditions of the equipment. -

Page 30: Regulator Reaction Modes

4.1.1 - REGULATOR REACTION MODES The DIVAL 700 equipment is a direct acting regulator with a “fail open” reaction (on-opening reaction), that is, it opens in the event of: • breakage of main diaphragm • downstream pressure signal missing. 4.2 -... - Page 31 In the absence of pressure, the plug (3) is held in the open position by the spring thrust acting on the plug (3) through the engagement of the rod (4) by the lever mechanism (6). The downstream pressure value (Pd) is regulated by comparing: •...

-

Page 32: Intended Use

If no written approval is provided, use shall be considered improper. In the event of “improper use”, PIETRO FIORENTINI S.p.A. shall not be held liable for any damage caused to people or property, and any type of warranty on the equipment shall be deemed void. -

Page 33: Technical Features/Performance

4.4 - TECHNICAL FEATURES/PERFORMANCE The DIVAL 700 equipment is a regulator for medium and low pressure. The regulation system is unbalanced with an outlet pressure that varies with the inlet pressure. The main specifications for this regulator are: Technical features... -

Page 34: Variation Of Outlet Pressure As Inlet Pressure Changes By 0.5 Bar

4.4.1 - VARIATION OF OUTLET PRESSURE AS INLET PRESSURE CHANGES BY 0.5 BAR HEADER Ø 280 BP/MP Springs (dimensions and col- Size [inches] ours) 1/4” 3/8” 1/2” 3/4” 1” 1” 1/4 d= 3,2 De= 65 Lo= 180 2701175 White d= 3,5 De= 65 Lo= 180 2701345 Yellow d= 4 De= 65 Lo= 180 2701620 Orange... -

Page 35: Spring Setting Range

4.4.2 - SPRING SETTING RANGE 4.4.2.1 - INLET PRESSURE 1.7 BAR HEADER Ø 280 BP/MP Size [inches] Springs (dimensions and col- 1/4” 3/8” 1/2” 3/4” 1” 1” 1/4 ours) d= 3,2 De= 65 Lo= 180 2701175 White d= 3,5 De= 65 Lo= 180 2701345 Yellow d= 4 De= 65 Lo= 180 2701620 Orange... -

Page 36: Possible Configurations

4.5 - POSSIBLE CONFIGURATIONS 4.5.1 - CONTROL HEADS “Tab. 4.24” lists the possible combinations of sizes and control heads for the equipment DIVAL 700. Size [inches] | DN [mm] 1” | 25 1” 1/2 | 40 2” | 50 BP / MP Tab. -

Page 37: Regulator With Monitor Function

4.5.3 - REGULATOR WITH MONITOR FUNCTION The regulator with monitor function (1) is used to keep the downstream pressure value (Pd) within the preset limits in case of failure of the main regulator. The regulator with monitor function is installed upstream of the main pressure regulator. pstream pressUre ownstream pressUre Fig. - Page 38 OPERATION IN STAND-BY CONDITIONS The regulator with monitor function is open during normal operation since it is calibrated higher than the calibration of the main regulator (2). pstream pressUre ownstream pressUre Fig. 4.4. In-line operation of regulator-monitor in stand-by conditions MEDIUM PRESSURE REGULATOR DESCRIPTION AND OPERATION REV.

- Page 39 OPERATION IN THE EVENT OF FAILURE OF THE MAIN REGULATOR pstream pressUre ownstream pressUre Fig. 4.5. Operation of regulator-monitor with main regulator in faulty conditions In the event of failure of the main regulator (2), the regulator with monitor function (1) will intervene maintaining the down- stream pressure value (Pd) within the established limit for its calibration.

-

Page 40: Slam-Shut Valve

4.5.4 - SLAM-SHUT VALVE The slam-shut valve is a safety device is used to shut off the gas flow if the pressure value at the control point exceeds the calibration value of the valve itself. The slam-shut valve incorporated in the regulator consists of: •... -

Page 41: La Incorporated Slam-Shut Valve

4.5.4.1 - LA INCORPORATED SLAM-SHUT VALVE The LA incorporated slam-shut valve can be operated: • by the intervention spring • manually. The main features of the LA incorporated slam-shut valve are: • tripping due to downstream pressure increase and/or decrease; •... - Page 42 Fig. 4.6. DIVAL 700 with incorporated LA slam-shut valve MEDIUM PRESSURE REGULATOR DESCRIPTION AND OPERATION REV. A Use, maintenance and warning manual...

-

Page 43: Transport And Handling

5 - TRANSPORT AND HANDLING 5.1 - SPECIFIC WARNINGS FOR TRANSPORT AND HANDLING NOTICE! Transport and handling must be carried out by personnel: • qualified (specially trained); • who are familiar with accident prevention and workplace safety regulations; • authorised to use lifting equipment; •... -

Page 44: Packaging And Fasteners Used For Transport

PIETRO FIORENTINI S.p.A.. NOTICE! PIETRO FIORENTINI S.p.A. shall not be liable for any damage to people or property caused by accidents due to failure to comply with the instructions provided in this manual. “Tab. 5.30” shows the types of packaging used: Ref. - Page 45 MEDIUM PRESSURE REGULATOR TRANSPORT AND HANDLING REV. A Use, maintenance and warning manual...

-

Page 46: Physical Characteristics Of The Equipment

5.2 - PHYSICAL CHARACTERISTICS OF THE EQUIPMENT 5.2.1 - DIVAL 700 TR Head only ONLY HEADER TR Fig. 5.7. DIVAL 700 physical characteristics DIVAL 700 overall dimensions Size [inches] 1” 1” 1/2 2” Rp 2”x 2” Nominal diameter [mm] 152.4 Rp 1/2"... -

Page 47: Dival 700 + La

5.2.2 - DIVAL 700 + LA TR Head only ONLY HEADER TR Fig. 5.8. Physical characteristics DIVAL 700 + LA Overall dimensions DIVAL 700 + LA Size [inches] 1” 1” 1/2 2” Rp 2” x 2” Nominal diameter [mm] 50”... -

Page 48: Equipment Anchoring And Lifting Method

5.3 - EQUIPMENT ANCHORING AND LIFTING METHOD HAZARD! Before moving the equipment, make sure that the capacity of the lifting equipment is suitable for the load. WARNING! Unloading, transport and handling activities must be carried out by operators qualified and specially trained: •... -

Page 49: Forklift Handling Method

5.3.1 - FORKLIFT HANDLING METHOD HAZARD! It is forbidden to: • Do not transit under suspended loads; • Do not move the load over the personnel operating in the site/plant area. WARNING! The following is not allowed on forklifts: • carrying passengers;... - Page 50 Step Action Image Sollevare lentamente il carico di qualche decina di centimetri e veri carne la stabilità facendo attenzio- Inclinare il montante all’indietro (verso il posto guida) per avvantaggiare il momento ribaltante e Adeguare la velocità d ne che il baricentro del carico sia posizionato al centro delle forche di sollevamento. garantire una maggiore stabilità...

-

Page 51: Crane Handling Method

5.3.2 - CRANE HANDLING METHOD WARNING! It is mandatory to use CE marked chains, ropes and eyebolts or marked with conformity marks/markings in accordance with the regulations in force in the place of installation. Do not use chains connected to each other by bolts. -

Page 52: Packaging Removal

• do not install the equipment; • contact PIETRO FIORENTINI S.p.A. and specify the details provided on the equipment nameplate. 5.4.1 - PACKAGING DISPOSAL NOTICE! Sort the various materials making up the packaging and dispose of them in compliance with the regula- tions in force in the country of installation. -

Page 53: Storage And Environmental Conditions

For the replacement of the rubber parts of the equipment, please refer to “9 - Maintenance and functional checks”. NOTICE! PIETRO FIORENTINI S.p.A. recommends checking the condition of rubber parts in case of downtime or storage longer than 3 years. - Page 54 MEDIUM PRESSURE REGULATOR TRANSPORT AND HANDLING REV. A Use, maintenance and warning manual...

-

Page 55: Installation

6 - INSTALLATION 6.1 - INSTALLATION PRE-REQUISITES 6.1.1 - ALLOWED ENVIRONMENTAL CONDITIONS WARNING! To safely use the equipment, in full respect of the allowed environmental conditions, follow the data shown on the regulator plate and on any accessories (refer to paragraph “2.8 - Applied rating plates”). The installation site must be suitable for the safe use of the equipment. -

Page 56: Checks Before Installation

6.1.2 - CHECKS BEFORE INSTALLATION The equipment does not require any further upstream safety device for protection against any overpressure with respect to its PS admissible pressure when, for the upstream reduction station, the maximum incidental downstream pressure MIPd ≤ 1.1 PS MIPd = Maximum incidental downstream pressure value (for further information, see UNI EN 12186:2014). -

Page 57: Specific Safety Instructions For The Installation Step

6.2 - SPECIFIC SAFETY INSTRUCTIONS FOR THE INSTALLATION STEP WARNING! Before proceeding with installation, make sure that the upstream and downstream valves installed on the line are shut off. WARNING! Installation may also take place in areas where there is a risk of explosion, which implies that all necessary prevention and protection measures have to be taken. -

Page 58: General Information On Connections

6.3 - GENERAL INFORMATION ON CONNECTIONS The equipment must be installed in-line with an arrow on the body pointing to the gas flow direction. In line installation, there must be (see Fig. 6.9 and 6.10): Pos. Description 1 shut-off valve upstream of the equipment. 2 vent valves one upstream and one downstream of the equipment. -

Page 59: Regulator Installation Positions

NOTICE! When used in gas pressure reduction stations, the device must be installed at least according to the re- quirements of standards UNI EN 12186:2014 or UNI EN 12279:2007. Equipment vents must be ducted in accordance with UNI EN 12186:2014 or UNI EN 12279:2007 or the standards in force at the place of installation of the equipment. -

Page 60: Installation Procedures

For installation after maintenance, replace the seals. 6.5.2 - CONNECTION OF THE SENSING LINES TO THE DOWNSTREAM PIPING For the Dival 700 equipment the sensing lines are internal (Fig. 6.13), for the Dival 700 with inline monitor function the sensing lines are external (Fig. 6.14). - Page 61 Fig. 6.14. Sensing line connection to downstream pipeline DIVAL 700 with monitor function For proper adjustment, it is essential that: • the downstream shut-off valve is placed at a distance of at least 6 times the nominal diameter of the pipe downstream of the regulator;...

- Page 62 To prevent the pneumatic connections of the sensing lines from collecting impurities and condensation, it is necessary that: • the connections of the pneumatic connection are always welded to the top or horizontal axis of the pipe itself (refer to Fig. 6.14); •...

-

Page 63: Post-Installation And Pre-Commissioning Checks

6.6 - POST-INSTALLATION AND PRE-COMMISSIONING CHECKS When the equipment is operating, make sure that all connections are: • properly secured/tightened to prevent any leakage during commissioning; • connected correctly. MEDIUM PRESSURE REGULATOR INSTALLATION REV. A Use, maintenance and warning manual... - Page 64 MEDIUM PRESSURE REGULATOR INSTALLATION REV. A Use, maintenance and warning manual...

-

Page 65: Commissioning/Maintenance Equipment

7 - COMMISSIONING/MAINTENANCE EQUIPMENT 7.1 - LIST OF EQUIPMENT Use of commissioning/maintenance equipment • Mechanical maintenance technician; • Electrical maintenance technician; Operator qualification • Installer; • Name of the user. WARNING! The PPE listed in this table is related to the risk associated with the equipment. PPE required For the PPE required to protect against risks associated with the workplace, installation or operating conditions, please refer to:... - Page 66 Ref. Equipment type Image T-handle hex socket wrench Phillips screwdriver Slotted screwdriver O-ring extraction tool Circlip pliers Fiorentini special key Fiorentini special key Fiorentini special tool Torx key Tab. 7.44 MEDIUM PRESSURE REGULATOR REV. A COMMISSIONING AND MAINTENANCE EQUIPMENT Use, maintenance and warning manual...

-

Page 67: Equipment Needed For The Different Configurations

Length, referred to the equipment. Ref. Reference to the equipment. Type Type (size) or code of the equipment. Tab. 7.45 DIVAL 700 | REGULATOR WITH IN LINE MONITOR FUNCTION Equipment Size [inches] | DN [mm] Ref. Type 1” | 25 1”... - Page 68 MEDIUM PRESSURE REGULATOR REV. A COMMISSIONING AND MAINTENANCE EQUIPMENT Use, maintenance and warning manual...

-

Page 69: Commissioning

8 - COMMISSIONING 8.1 - GENERAL WARNINGS 8.1.1 - SAFETY REQUIREMENTS FOR COMMISSIONING HAZARD! During commissioning the risks associated with any discharges to the atmosphere of flammable or nox- ious gases must be evaluated. HAZARD! In case of installation on distribution networks for natural gas, consider the risk associated with explosive mixtures (gas/air) being formed inside the piping, if the line is not subjected to inerting. -

Page 70: Preliminary Procedures For Commissioning

8.2 - PRELIMINARY PROCEDURES FOR COMMISSIONING HAZARD! Before commissioning the equipment, it must be ensured that any source of explosion has been eliminat- ed if there is such a danger. WARNING! Before commissioning, you need to make sure that the characteristics of the equipment are suitable for the conditions of use. -

Page 71: Proper Commissioning Check

8.3 - PROPER COMMISSIONING CHECK Completely sprinkle the equipment with a foaming solution (or equivalent control system) in order to check the tightness of the external surfaces of the regulator and the connections made during the installation. 8.4 - CALIBRATION OF EQUIPMENT AND ACCESSORIES INSTALLED NOTICE! To properly calibrate the equipment and accessories present, refer to the accuracy class indicated on the nameplates (see section “2.8 - Applied rating plates”). -

Page 72: Regulator Commissioning Procedure

In the application consisting of two pressure adjusting lines, it is advisable to commission one line at a time, starting with the line with the lowest set point. The set point value is mentioned on the test certificate enclosed with each piece of equipment. Fig. 8.17. Commissioning the DIVAL 700 regulator MEDIUM PRESSURE REGULATOR COMMISSIONING REV. A... - Page 73 Step Action Partially open the bleed cock (6). Partially open the upstream shut-off valve (V1), checking that the downstream pressure (Pd) indicated on the downstream pressure gauge (5) does not exceed the required calibration value by over 50%. NOTICE! In the first line pressurisation phase, the downstream pressure (Pd) indicated on the down- stream pressure gauge (5) could exceed that required calibration value, depending on the response time of the regulator.

-

Page 74: Commissioning Procedure Of Regulation Line: Dival 700 Regulator + Dival 700 Regulator With In Line Monitor Function

The setting spring (328.1) of the main regulator (1) must allow you to obtain the downstream pressure val- ue (Pd) 10-20% higher than the calibration pressure value of the regulator with in-line monitor function (2). Fig. 8.18. Commissioning of DIVAL 700 regulator + regulator with in-line monitor function MEDIUM PRESSURE REGULATOR COMMISSIONING REV. - Page 75 Step Action Partially open the bleed cock (6). Partially open the upstream shut-off valve (V1), checking that the downstream pressure (Pd) indicated on the downstream pressure gauge (5) does not exceed the required calibration value by over 50%. NOTICE! In the first line pressurisation phase, the downstream pressure (Pd) indicated on the down- stream pressure gauge (5) could exceed that required calibration value, depending on the response time of the main regulator (1).

- Page 76 Commissioning of DIVAL 700 regulator + regulator with in-line monitor function Step Action Slowly close the bleed cock (6). Check that the downstream pressure, after an increment phase, does not exceed the closing pressure value of the regulator with in-line monitor function (2) (refer to the SG value displayed on the plate, see par. “2.8 - Applied rating plates”).

- Page 77 Step Action Check that the downstream pressure, after an increment phase, does not exceed the closing pressure value of the main regulator (1) (refer to the SG value displayed on the plate, see par. “2.8 - Applied rating plates”). NOTICE! •...

-

Page 78: Pressurising With External Source

8.6.1 - PRESSURISING WITH EXTERNAL SOURCE If the setting spring of the main regulator (1) does not reach a sufficient pressure to put into service the regulator with in-line monitor function (2), you may pressurise the chamber (A) of the control head of the main regulator (1) by using an external source. - Page 79 MEDIUM PRESSURE REGULATOR COMMISSIONING REV. A Use, maintenance and warning manual...

-

Page 80: Commissioning Procedure Of Dival 700 Regulator With La Slam-Shut Valve

8.7 - COMMISSIONING PROCEDURE OF DIVAL 700 REGULATOR WITH LA SLAM-SHUT VALVE 8.7.1 - INTERNAL TIGHTNESS CHECK OF LA SLAM-SHUT VALVE Fig. 8.20. Commissioning of the regulatorDIVAL 700 with LA slam-shut valve Step Action Check that the slam-shut valve is in the shut-off position. -

Page 81: Commissioning Of The Dival 700 Regulator With La Slam-Shut Valve

8.7.2 - COMMISSIONING OF THE DIVAL 700 REGULATOR WITH LA SLAM-SHUT VALVE For the following procedure, please refer to Fig. 8.20 at “8.7.1 - Internal tightness check of LA slam-shut valve”: Step Action Make sure that the bleed cock (6) is partially open. - Page 82 Commissioning of the DIVAL 700 regulator with LA slam-shut valve Step Action Check that the downstream pressure (Pd), after an increment phase, does not exceed the closing pressure value (refer to the SG value displayed on the plate, see par.”2.8 - Applied rating plates”.

- Page 83 MEDIUM PRESSURE REGULATOR COMMISSIONING REV. A Use, maintenance and warning manual...

-

Page 84: Procedure For Calibrating The Pressure Switch For The La Incorporated Slam- Shut Valve

8.7.3 - PROCEDURE FOR CALIBRATING THE PRESSURE SWITCH FOR THE LA INCORPORAT- ED SLAM-SHUT VALVE Fig. 8.21. Calibration of pressure switch for LA slam-shut valve MEDIUM PRESSURE REGULATOR COMMISSIONING REV. A Use, maintenance and warning manual... - Page 85 SPRING CALIBRATION FOR MAXIMUM PRESSURE TRIP Step Action Increase the downstream pressure to the tripping value of the slam-shut valve, connecting an external pres- sure source to the bleed cock (fig. 8.16, ref. 6) placed on the downstream pipe, making sure to open an addi- tional bleed cock (fig.

- Page 86 Fig. 8.20. Calibration of pressure switch for LA slam-shut valve Fig. 8.22. Pressurising with external source for incorporated LA slam-shut valve MEDIUM PRESSURE REGULATOR COMMISSIONING REV. A Use, maintenance and warning manual...

- Page 87 SPRING CALIBRATION FOR MINIMUM PRESSURE TRIP (IF PRESENT) Step Action Partially open the bleed cock (fig. 8.16, ref. 6) to the atmosphere and keep it open for the next steps. Turn the adjustment ring nut (fig. 8.16, ref. 3) of the regulator anti-clockwise to decrease the downstream pres- sure (Pd) to the minimum pressure required for tripping of the slam-shut valve.

-

Page 88: Commissioning Procedure Of Regulation Line: Dival 700 Regulator + Dival 700 Regulator With In Line Monitor + La Slam-Shut Valve Function

8.8 - COMMISSIONING PROCEDURE OF REGULATION LINE: DIVAL 700 REGULATOR + DIVAL 700 REGULATOR WITH IN LINE MONITOR + LA SLAM-SHUT VALVE FUNCTION Fig. 8.23. Commissioning of DIVAL 700 regulator + regulator-monitor + LA Step Action Make sure that the bleed cock (6) is partially open. - Page 89 Step Action NOTICE! With regulators with calibration pressure up to 80 mbar, the response time is longer than that of regulators with calibration pressure above 80 mbar. When the main regulator (1) is put into service, the downstream pressure (Pd) indicated on the downstream pressure gauge (5) will be equal to the calibration value of the regulator (1).

- Page 90 Commissioning of DIVAL 700 regulator + regulator-monitor + LA Step Action Check that the downstream pressure, after an increment phase, does not exceed the closing pressure value of the regulator with in-line monitor function (2) (refer to the SG value displayed on the plate, see par. “2.8 - Applied rating plates”).

- Page 91 Step Action Check that the downstream pressure, after an increment phase, does not exceed the closing pressure value of the main regulator (1) (refer to the SG value displayed on the plate, see par. “2.8 - Applied rating plates”). NOTICE! •...

-

Page 92: Device Calibration

8.11 - DEVICE CALIBRATION 8.11.1 - PRESSURE SWITCH CALIBRATION FOR THE LA SLAM-SHUT VALVE Fig. 8.24. Pressure switch calibration for the LA slam-shut valve Turn the ring nut (13) for maximum tripping (11): • anti-clockwise to decrease the slam-shut device tripping pressure; •... -

Page 93: Maintenance And Functional Checks

WARNING! In case of doubt, do not perform any work. Contact PIETRO FIORENTINI S.p.A. for the necessary clarifica- tions. The management and/or use of the equipment includes interventions that are necessary as a result of normal use such as: •... - Page 94 Before beginning disassembly of the equipment, make sure that: • the spare parts and parts used in replacements have adequate requirements to ensure the original performance of the equipment. Use original, compliant spare parts; • the operator must have the necessary equipment (see chapter “7 - Commissioning/maintenance equipment”). NOTICE! The recommended spare parts are unambiguously identified with tags indicating: •...

-

Page 95: Periodically Checking And Inspecting The Equipment For Proper Operation

9.2 - PERIODICALLY CHECKING AND INSPECTING THE EQUIPMENT FOR PROPER OPERATION Periodic checks and inspections Operator qualification Mechanical maintenance technician WARNING! The PPE listed in this table is related to the risk associated with the equipment. PPE required For the PPE required to protect against risks associated with the workplace, installation or operating conditions, please refer to: •... -

Page 96: Routine Maintenance

9.3 - ROUTINE MAINTENANCE 9.3.1 - GENERAL SAFETY WARNINGS HAZARD! • Put the equipment in a safe condition (close the downstream shut-off valve and then the upstream one, and drain the line completely); • ensure that the pressure upstream and downstream of the equipment is “0”. NOTICE! Before installing new sealing elements (o-rings, diaphragm, etc.), they must be checked for integrity. -

Page 97: Replacement Frequency For Components Subject To Wear

9.3.2 - REPLACEMENT FREQUENCY FOR COMPONENTS SUBJECT TO WEAR NOTICE! The following provisions shall apply to equipment components only. The non-metallic parts of the equipment concerned are divided into the following two categories: Preventive maintenance work Parts subject to wear and/or abrasion, where: •... - Page 98 Minimum Category Part description Evaluation criterion replacement frequency Shut-off valves Yearly Lubricating parts Other equipment Yearly Filter elements Filters needed Tab. 9.61 MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

-

Page 99: Routine Maintenance Procedures

9.4 - ROUTINE MAINTENANCE PROCEDURES Routine maintenance Operator qualification Operator qualification WARNING! The PPE listed in this table is related to the risk associated with the equipment. PPE required For the PPE required to protect against risks associated with the workplace, installation or operating conditions, please refer to: •... -

Page 100: Tightening Torques

9.4.1 - TIGHTENING TORQUES 9.4.1.1 - TIGHTENING TORQUES FOR DIVAL 700 REGULATOR Fig. 9.25. Tightening torques DIVAL 700 MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual... - Page 101 DIVAL 700 1" ; 1" 1/2; 2" - BP, MP, TR HEADS Pos. Description Torque (Nm) Torque (ft - lb) Valve seat Screw M5x14 UNI 5931 Screw M5x12 UNI 8111 Screw M8X25 UNI 5931 Fixing nut Fixing nut Screw M6x50 DIN 6921 Tab.

- Page 102 9.4.1.2 - TIGHTENING TORQUES OF REGULATOR WITH MONITOR FUNCTION Fig. 9.26. Regulator with monitor function tightening torques MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 103 DIVAL 700 WITH MONITOR FUNCTION Pos. Description Torque (Nm) Torque (ft - lb) Valve seat Screw M5x14 UNI 5931 Screw M5x12 UNI 8111 Screw M8X25 UNI 5931 Fixing nut Fixing nut Screw M6x50 DIN 6921 Tab. 9.64 MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV.

- Page 104 9.4.1.3 - TIGHTENING TORQUE LA SLAM-SHUT VALVE Fig. 9.27. LA Slam-shut valve tightening torques MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 105 LA 1" ; 1" 1/2; 2 - BP, MP, TR HEADS Pos. Description Torque (Nm) Torque (ft - lb) Rod guide TSC M5X20 TORX screw M4 nut UNI 5588 TGS M4X27 TORX screw Screw M5X14 Locking nut Bushing Tab. 9.65 MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV.

- Page 106 MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

-

Page 107: Replacing Elements Subject To Wear And Abrasion

9.4.2 - REPLACING ELEMENTS SUBJECT TO WEAR AND ABRASION 9.4.2.1 - INITIAL OPERATIONS ATTENTION! Before carrying out any work, it is important to ensure that the line on which the regulator is installed has been shut off upstream and downstream, and discharged. ATTENTION! During assembly, make sure to tighten the screws as per the tables (tightening torques), according to the size for which maintenance is being carried out. -

Page 108: Regulator Maintenance Procedure Dival 700

9.4.3 - REGULATOR MAINTENANCE PROCEDURE DIVAL 700 9.4.3.1 - DIVAL 700 REGULATOR BP/MP HEADS Fig. 9.29. DIVAL 700 Regulator BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual... - Page 109 Step Action Unscrew and remove the cap (354). Remove the O-ring (353) and replace it, taking care to lubricate it with synthetic grease. NOTICE! Before inserting the replacement O-ring, clean the retaining slots with a cleaning solution. Unscrew and remove the ring nut (351) together with the washer (352). NOTICE! Turn the ring nut anti-clockwise.

- Page 110 DIVAL 700 Regulator BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 111 Step Action Insert and fix the nut (332) according to the following tightening torques: • “Tab. 9.63” Place the upper cover (340) on the lower cover (310). NOTICE! Follow the orientation of the anti-pumping valve when positioning the cover. Insert and fix the screws (360) together with the nuts (361) according to the following tightening torques: •...

- Page 112 DIVAL 700 Regulator BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 113 Step Action Remove the O-ring (65) and replace it, taking care to lubricate it with synthetic grease. NOTICE! Before inserting the replacement O-rings, clean the retaining slots with a cleaning solution. Position the flange (551) together with the O-ring (65). Insert and fix the lower screws (48) according to the following tightening torques: •...

- Page 114 9.4.3.2 - DIVAL 700 REGULATOR TR HEAD Fig. 9.30. DIVAL 700 Regulator TR head MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 115 Step Action Unscrew and remove the adjusting screw (609) together with the locking nut (607). Remove and replace the O-rings (353, 608), taking care to lubricate them with synthetic grease. NOTICE! Before inserting the replacement O-rings, clean the retaining slots with a cleaning solution. Remove the spring guide disc (610) together with the washer (352).

- Page 116 DIVAL 700 Regulator TR head MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 117 Step Action Place the upper cover (340) on the lower cover (310). NOTICE! Follow the orientation of the anti-pumping valve when positioning the cover. Insert and fix the screws (360) together with the nuts (361) according to the following tightening torques: •...

- Page 118 DIVAL 700 Regulator TR head MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 119 Step Action Remove the flange (551) together with the O-ring (65). Remove the O-ring (65) and replace it, taking care to lubricate it with synthetic grease. NOTICE! Before inserting the replacement O-rings, clean the retaining slots with a cleaning solution. Position the flange (551) together with the O-ring (65).

-

Page 120: La Slam-Shut Valve

9.4.4 - LA SLAM-SHUT VALVE 9.4.4.1 - LA SLAM-SHUT VALVE BP/MP HEADS 1” 1” 1/2 - 2” Fig. 9.31. LA slam-shut valve BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual... - Page 121 Action ATTENTION! Before servicing, remove the LA slam-shut valve by unscrewing the screws (48) on the regulator (refer to “9.4.3 - Regulator Maintenance Procedure DIVAL 700”). Unscrew and remove the locking nut (628). NOTICE! During this step, hold the spacer (626) in place.

- Page 122 1” 1” 1/2 - 2” LA slam-shut valve BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 123 Step Action Remove and replace the O-rings (535, 536, 633), taking care to lubricate them with synthetic grease. NOTICE! Before inserting the replacement O-rings, clean the retaining slots with a cleaning solution. Insert rod guide (533) together with O-rings (535, 536, 633). Fit the washer (532).

- Page 124 1” 1” 1/2 - 2” LA slam-shut valve BP/MP heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 125 Step Action Unscrew and remove the screws (510) together with the nuts (511). Remove the cover (550) from the body (501). Remove the diaphragm assembly: diaphragm (547), diaphragm protection disc (502), washer (519), diaphragm support (518), compression bushing (520), locking screw (521). Undo and remove the locking screw (521).

- Page 126 9.4.4.2 - LA SLAM-SHUT VALVE TR HEADS 1” 1” 1/2 - 2” Fig. 9.32. LA slam-shut valve TR heads MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 127 Action ATTENTION! Before servicing, remove the LA slam-shut valve by unscrewing the screws (48) on the regulator (refer to “9.4.3 - Regulator Maintenance Procedure DIVAL 700”). Unscrew and remove the locking nut (628). NOTICE! During this step, hold the spacer (626) in place.

- Page 128 1” 1” 1/2 - 2” LA slam-shut valve TR header MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 129 Step Action Remove and replace the O-rings (535, 536, 633), taking care to lubricate them with synthetic grease. NOTICE! Before inserting the replacement O-rings, clean the retaining slots with a cleaning solution. Insert rod guide (533) together with O-rings (535, 536, 633). Fit the washer (532).

- Page 130 1” 1” 1/2 - 2” LA slam-shut valve TR header MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual...

- Page 131 Step Action Unscrew and remove the screws (510) together with the nuts (511). Remove the cover (550) from the body (501). Remove the diaphragm assembly: diaphragm (547), diaphragm protection disc (502), washer (519), diaphragm support (518), compression bushing (520), locking screw (521). Undo and remove the locking screw (521).

-

Page 132: Procedure For Recommissioning After Maintenance

9.4.6 - PROCEDURE FOR RECOMMISSIONING AFTER MAINTENANCE NOTICE! For the re-commissioning procedure, please follow the instructions in section “8.5 - Regulator commis- sioning procedure” MEDIUM PRESSURE REGULATOR MAINTENANCE AND FUNCTIONAL CHECKS REV. A Use, maintenance and warning manual... -

Page 133: Troubleshooting

• qualified and authorised to carry out activities related to the equipment. WARNING! PIETRO FIORENTINI S.p.A. shall not be held liable for any damage to people and property due to services: • other than those described; • performed according to methods other than those specified;... -

Page 134: Operator Qualification Specification

10.2 - OPERATOR QUALIFICATION SPECIFICATION Commissioning • Mechanical maintenance technician; • Electrical maintenance technician; Operator qualification • Installer; • Name of the user. WARNING! The PPE listed in this table is related to the risk associated with the equipment. PPE required For the PPE required to protect against risks associated with the workplace, installation or operating conditions, please refer to: •... -

Page 135: Troubleshooting Tables

10.4 - TROUBLESHOOTING TABLES NOTICE! See chapter “9 - Maintenance and functional checks” for pictures of the regulator DIVAL 700 and its ac- cessories. 10.4.1 - TROUBLESHOOTING DIVAL 700 REGULATOR Failure Possible causes Intervention Valve seat (2) damaged Replace Plug (211) damaged... - Page 136 MEDIUM PRESSURE REGULATOR TROUBLESHOOTING REV. A Use, maintenance and warning manual...

-

Page 137: Uninstallation And Disposal

11 - UNINSTALLATION AND DISPOSAL 11.1 - GENERAL SAFETY WARNINGS HAZARD! Make sure that there are no potentially explosive ignition sources in the work area set up to uninstall and/ or dispose of the equipment. WARNING! Before proceeding with uninstallation and disposal, make the equipment safe by disconnecting it from any power supply. -

Page 138: Disposal Information

11.5 - DISPOSAL INFORMATION NOTICE! Bear in mind that the laws in force in the country of installation must be complied with. Illegal or improper disposal involves the application of the penalties provided for by the legislation in force in the country of installation. NOTICE! Proper disposal prevents damage to humans and the environment and promotes the reuse of precious raw materials. -

Page 139: Recommended Spare Parts

If non-original spare parts are used, PIETRO FIORENTINI S.p.A. their declared performance cannot be guaranteed. It is recommended to use original spare parts PIETRO FIORENTINI S.p.A. PIETRO FIORENTINI S.p.A. shall not be held liable for any damage caused by using non-original parts. 12.2 - HOW TO REQUEST SPARE PARTS NOTICE! For specific information, please refer to the sales network of PIETRO FIORENTINI S.p.A. - Page 140 MEDIUM PRESSURE REGULATOR RECOMMENDED SPARE PARTS REV. A Use, maintenance and warning manual...

-

Page 141: Flow Rate Tables

Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 50 | K1 = 98 Tab. 13.77 Dival 700 1/4 BP 1' 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,02 bar 0,05 bar 0.1 bar 0.2 bar 0,34 bar Sm³/h... - Page 142 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 92 | K1 = 91 Tab. 13.80 Dival 700 3/8 BP 1" 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,02 bar 0,05 bar 0.1 bar 0.2 bar 0,34 bar Sm³/h...

- Page 143 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 161 | K1 = 97 Tab. 13.83 Dival 700 1/2 BP 1" 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,02 bar 0,05 bar 0.1 bar 0.2 bar 0,34 bar Sm³/h...

- Page 144 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 253 | K1 = 93 Tab. 13.86 Dival 700 3/4 BP 1" 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,02 bar 0,05 bar 0.1 bar 0.2 bar 0,34 bar Sm³/h...

- Page 145 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 346 | K1 = 86 Tab. 13.90 Dival 700 1 1/4 BP 1' 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,05 bar 0.1 bar 0.2 bar 0,3 bar 0,34 bar Sm³/h...

- Page 146 Dival 700 1 1/4 BP 2" (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,05 bar 0.1 bar 0.2 bar 0,3 bar 0,34 bar Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 440 | K1 = 86 Tab. 13.92 Dival 700 1/4 TR 1"...

- Page 147 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 93 | K1 = 91 Tab. 13.96 Dival 700 3/8 TR 1" 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,03 bar 0,05 bar 0,07 bar 0.1 bar 0,13 bar Sm³/h...

- Page 148 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 180 | K1 = 97 Tab. 13.99 Dival 700 1/2 TR 1' 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,03 bar 0,05 bar 0,07 bar 0.1 bar 0,13 bar Sm³/h...

- Page 149 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 317 | K1 = 93 Tab. 13.102 Dival 700 3/4 TR 1' 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,03 bar 0,05 bar 0,07 bar 0.1 bar 0,13 bar Sm³/h...

- Page 150 Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 320 | K1 = 89 Tab. 13.104 Dival 700 1 TR 1" 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,03 bar 0,05 bar 0,07 bar 0.1 bar 0,13 bar Sm³/h...

- Page 151 Dival 700 1 1/4 TR 1' 1/2 (AC = 10 according to EN 334) Outlet pressure Inlet pressure 0,03 bar 0,05 bar 0,07 bar 0.1 bar 0,13 bar Sm³/h Sm³/h Sm³/h Sm³/h Sm³/h Cg = 530 | K1 = 85 Tab.

- Page 152 TM0023ENG...

Need help?

Do you have a question about the Dival 700 and is the answer not in the manual?

Questions and answers