Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Top Auto BRK900

- Page 1 USER MANUAL MAINTENANCE AND SPARE PARTS BRAKE BLEEDER BRK900...

- Page 2 USER MANUAL, MAINTENANCE AND SPARE PARTS Rev. 01-2022 PAGE. 2 BRK900...

-

Page 3: Table Of Contents

5.1 DELIVERY AND CONTROL ........................13 5.2 MACHINE SETUP ........................... 13 6 MACHINE USE ..........................14 6.1 PROBLEMS AND REMEDIES ........................17 7 MAINTENANCE ..........................18 7.1 NATURE AND FREQUENCY OF CHECKS AND MAINTENANCE ..............18 Rev. 01-2022 PAGE. 3 BRK900... - Page 4 9 SPARE PARTS ..........................19 9.1 GENERAL INSTRUCTIONS ........................19 9.2 SPARE PARTS REQUEST FORM ....................... 19 9.3 SPARE PARTS LIST..........................20 10 ELECTRICAL DIAGRAM ........................23 11 HYDRAULIC DIAGRAM ........................24 12 SERVICE-PROGRAM ........................25 Rev. 01-2022 PAGE. 4 BRK900...

-

Page 5: Introduction

Rev. 01-2022 PAGE. 5 BRK900... -

Page 6: Symbology

- risks to operator’s safety - declination of responsibility by the manufacturing company. 2 GENERAL INFORMATION 2.1 MANUFACTURER IDENTIFICATION DATA Top Auto S.r.l. Viale del Lavoro 40, 37030 Colognola ai colli – Italy tel. +39 0456170025 - fax. +39 6152493 info@topauto-equipment.com www.topauto-equipment.com 2.2 MACHINE IDENTIFICATION DATA... -

Page 7: General Safety Rules

Check frequently that the two filters on the device are not obstructed. • Use only the liquids recommended by the manufacturer. Failure to comply with each of the above safety rules results in the decay of any form of warranty on the machine. Rev. 01-2022 PAGE. 7 BRK900... -

Page 8: Brake Fluids - Personal Protective Equipment And Precautions

Big leak non-combustible absorbent material, such as sand, soil, vermiculite, diatomite and dispose of the product in a container in accordance with the current legislation. Dispose of waste through an au- thorized company for waste disposal. Rev. 01-2022 PAGE. 8 BRK900... -

Page 9: Warranty

Modifications or tampering carried out by the user or carried out by third parties, without specific approval by the manufac- turing company. • Use of non-original spare parts. 2.7 DURATION OF WARRANTY For warranty terms, reference is made to what is contractually agreed. Rev. 01-2022 PAGE. 9 BRK900... -

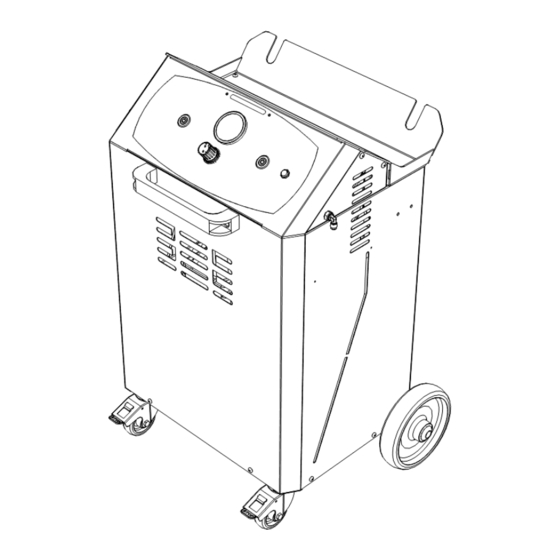

Page 10: Machine Description

6 – Connection for the charging pipe 14 – New fluid tank with level switch 7 – Handling wheels 15 – Waste fluid tank 8 – Collegamento per tubo di aspirazione 16 – Clamp for extraction pipe at rest Rev. 01-2022 PAGE. 10 BRK900... -

Page 11: Technical Specifications

30 W (1 l/min) Charging pump power 30 W (1 l/min) Charging/extraction pipe length 7,5 m Power supply 230/50-60 Volt/Hz Machine size 57x54x90H cm Pack size 60x65x115H Unladen weight 35 Kg Noise < 70 dB (A) Rev. 01-2022 PAGE. 11 BRK900... -

Page 12: Operation And Use

The dismantling of the protective casings and the consequent access inside the machine is provided only for maintenance and cleaning operations. Rev. 01-2022 PAGE. 12 BRK900... -

Page 13: Installation

Connect the spiral charging pipe with the rapid coupling to the right connector of the machine 2) Connection of the extraction pipe Connect the spiral extraction pipe with the filter to the left connector of the machine Rev. 01-2022 PAGE. 13 BRK900... -

Page 14: Machine Use

Insert the extraction pipe into the pan and press the ON button to start the pump and extract all the exhausted liquid. Stop the pump by pressing the OFF button when you start extracting air. Rev. 01-2022 PAGE. 14 BRK900... - Page 15 Identify the specific adapter and connect it to the pan making sure it is fixed correctly to avoid leakage during subse- quent operations. Connect the charging pipe to the adapter and press the ON button to start charging the new liquid. Through the pressure regulator set the working pressure (usually 1.5 – 2 bar) Rev. 01-2022 PAGE. 15 BRK900...

- Page 16 Bleeding is considered finished when new liquid comes out BLEEDING VALVE from the transparent pipe. Then close the bleeding valve and Piston switch to the next brake caliper. Carry out the bleeding operation on all 4 brake calipers. Brake pad Disk Rev. 01-2022 PAGE. 16 BRK900...

-

Page 17: Problems And Remedies

Clean the filter on the extraction pipe Check the correct operation of the non-return valve The pump starts but extracts very slowly Check that there is no narrowing on the pipes inside the ma- chine Problems with the new liquid charge Rev. 01-2022 PAGE. 17 BRK900... -

Page 18: Maintenance

The law provides for sanctions for those who release WEEE into the environment. WEEE, if released into the environment or misused, can release substances that are dangerous to the environ- ment itself and to human health. Rev. 01-2022 PAGE. 18 BRK900... -

Page 19: Spare Parts

The following is a list of the individual pieces, the number corresponding to the position occupied in the attached drawings, the code and the description. Orders (which must be sent by fax or e-mail) must be addressed to: Top Auto S.r.l. – Italy Viale dell'Artigianato 4, 37042- Caldiero (VR) tel. -

Page 20: Spare Parts List

USER MANUAL, MAINTENANCE AND SPARE PARTS 9.3 SPARE PARTS LIST Rev. 01-2022 PAGE. 20 BRK900... - Page 21 USER MANUAL, MAINTENANCE AND SPARE PARTS Rev. 01-2022 PAGE. 21 BRK900...

- Page 22 RACCORDO A L ORIENTABILE FEMMINA - 1/8 90° - Ø 8mm 7380M3X10 VITE UNI-ISO 7380 M3X10 7380M5X10 VITE UNI-ISO 7380 M5X10 7380M5X12 VITE UNI-ISO 7380 M5X12 Alimentatore BRK900 CAPP-20 TAPPO SERIE CAPP Ø20 Øe=36 H=10.5 CINGHIA FISSAGGIO TANICHE CINGHIA FISSAGGIO TANICA 25L Dado_M3 DADO M3 UNI 5588...

-

Page 23: Electrical Diagram

INSERTO FILETTATO FEMMINA ESA7 - M5 49,2 TA701053-01 BASAMENTO BRK 600/900 49.3* TA735036-01 TUBO RUOTE BRK 600 TA702061-02 CORPO MACCHINA BRK600 e BRK900 - SALDATO 50.1* TA715074-01 LAMIERA A L DI SUPPORTO 50,2 TA758019-02 MANTELLO BRK 600 e BRK 900 50.2.1... -

Page 24: Hydraulic Diagram

USER MANUAL, MAINTENANCE AND SPARE PARTS 11 HYDRAULIC DIAGRAM Rev. 01-2022 PAGE. 24 BRK900... -

Page 25: Service-Program

DATE :……………......Work carried out: …………………………………………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………………………………………….. DATE :……………......Work carried out: …………………………………………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………………………………………….. DATE :……………......Work carried out: …………………………………………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………………………………………….. DATE :……………......Work carried out: …………………………………………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………………………………………….. DATE :……………......Work carried out: …………………………………………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………………………………………….. Rev. 01-2022 PAGE. 25 BRK900... - Page 26 DECLARATION OF CONFORMITY KONFORMITÄTSERKLÄRUNG DÉCLARATION DE CONFORMITÉ DECLARACIÓN DE CONFORMIDAD Top Auto S.r.l. Viale dell'Artigianato 4 – 37042 Caldiero (VR) - Italy Telephone 045/6170025 Fax 045/6152493 (Manufacturing company in which the Technical Dossier is created and stored) DECLARES UNDER ITS OWN RESPONSIBILITY THAT THE NEW MACHINE:...

- Page 27 Top Auto S.r.l. Viale del Lavoro 40 - 37030 Colognola ai colli - Italy Telephone: +39 0456170025 - Fax: +39 0456152493...

Need help?

Do you have a question about the BRK900 and is the answer not in the manual?

Questions and answers