Rotax 914 Series Maintenance Manual

Hide thumbs

Also See for 914 Series:

- Maintenance manual (184 pages) ,

- Installation manual (142 pages) ,

- Operator's manual (92 pages)

Summary of Contents for Rotax 914 Series

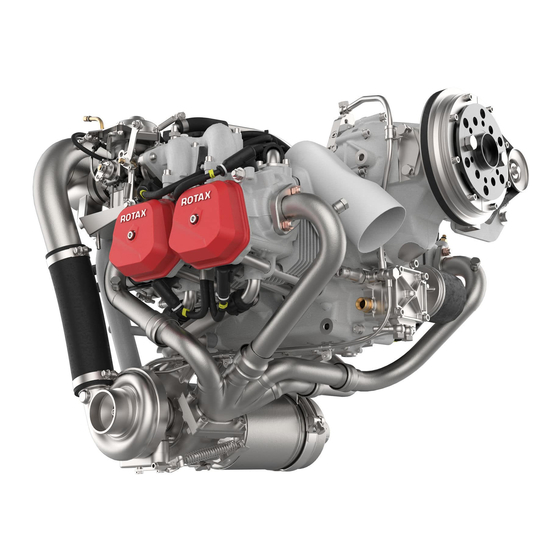

- Page 1 �������� ������� MAINTENANCE MANUAL FOR ROTAX® ENGINE TYPE 914 SERIES (LINE MAINTENANCE) ROTAX ® 914 UL 3 WITH OPTIONS part no.: 899606...

- Page 2 GmbH&Co. KG, Austria, acc, BGBI 1984 no. 448, and shall not, without prior written permis- sion of BRP-Rotax GmbH&Co. KG, be disclosed in whole or in part to third parties. This legend shall be included on any reproduction of these data, in whole or in part.

-

Page 3: Table Of Contents

5.3.1) Use for intended purpose ..........00-00-00 / 17 5.3.2) Instruction ................. 00-00-00 / 18 6) List of effective pages ................00-00-00 / 19 7) Table of amendments ................00-00-00 / 21 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 3 May. 01/07... - Page 4 BRP-Rotax MAINTENANCE MANUAL NOTES 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 4 May. 01/07...

-

Page 5: List Of Chapters

BRP-Rotax MAINTENANCE MANUAL 2) List of chapters INTRODUCTION ..........00 TIME LIMITS / MAINTENANCE CHECKS ..05 MAINTENANCE ..........12 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 5 May. 01/07... - Page 6 BRP-Rotax MAINTENANCE MANUAL NOTES 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 6 May. 01/07...

-

Page 7: Index

Lithium-base grease 05-00-00 / 10 Drip tray 05-20-00 / 9 Lock washer 05-00-00 / 13 Dry air filter 12-00-00 / 8 Loctite 05-00-00 / 10 Lubrication system 12-00-00 / 33 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 7 May. 01/07... - Page 8 Visual inspection 05-20-00 / 5, 12-00-00 / 4 12-00-00 / 48 Propeller stoppage 05-50-00 / 3 Wastegate flap 05-20-00 / 7, 12-00-00 / 14 Wiring 12-00-00 / 43 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 8 May. 01/07...

-

Page 9: Introduction

We are pleased you decided to purchase a ROTAX aircraft engine. This section describes the maintenance of engine type 914 Series. ◆ NOTE: The 914 Series includes all engines such as the 914 F and 914 UL. Before carrying out maintenance work on the engine, read the Maintenance Manual carefully. - Page 10 BRP-Rotax MAINTENANCE MANUAL NOTES 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 10 May. 01/07...

-

Page 11: Conversion Table And Abbreviations

1 bar = 100 000 Pa (1000 hPa) 04783 1 bar = 14.5037 lbf/in (psi) 1 lbf/in (psi) = 0.0689 bar 1 in HG = 33.8638 hPa 00-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 11 Sept. 01/07... - Page 12 Department of Transport Visual Flight Rules EASA European Aviation Safety Agency Maintenance Manual Installation Manual shows the serial component Exhaust Gas Temperature number Illustrated Parts Catalog Federal Aviation Administration 00-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 12 Sept. 01/07...

-

Page 13: Safety Notice

BRP-Rotax MAINTENANCE MANUAL 5) Safety notice This Manual has been prepared as a guide to correctly service and maintain all ROTAX 914 aircraft engines. This edition was primarily published to be used by aircraft mechanics who are already familiar with all service procedures relating to ROTAX made aircraft engines. -

Page 14: Symbols Used

BRP-Rotax MAINTENANCE MANUAL This information relates to the preparation and use of ROTAX aircraft engines and has been utilized safely and effectively by BRP-Rotax. However, BRP-Rotax disclaims liability for all damage and/or injuries resulting from the improper use of the contents. -

Page 15: Maintenance Concept

"Line Maintenance". ◆ NOTE: This Manual must be used in conjunction with the Line Mainte- nance Manual on which it is based. 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 15 May. 01/07... -

Page 16: Technical Documentation

Service Bulletins Service Instructions Service Letters Any reference to a document refers to the latest edition issued by BRP-Rotax, if not stated otherwise. The information contained is based on data and experience that are considered applicable for skilled mechanics under normal conditions. -

Page 17: 1) Use For Intended Purpose

(log book, maintenance records etc.) are enclosed. 5.3.1) Use for intended purpose The engine ROTAX 914 F is intended for use in certified aircraft. In case of doubt the regulations of the national authorities or the respective sportive federations have to be observed. -

Page 18: 2) Instruction

(see Warranty Conditions). Spare parts are available at the authorized ROTAX Distribution- and Service centers. Any warranty by BRP-Rotax becomes null and void if spare parts and or accessories other than ORIGINAL- ROTAX spare parts and/or accessories are used (see latest Warranty Conditions). -

Page 19: List Of Effective Pages

4 05 01 2007 6 05 01 2007 5 05 01 2007 6 05 01 2007 7 05 01 2007 8 05 01 2007 9 09 01 2007 00-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 19 Sept. 01/07... - Page 20 42 09 01 2007 43 05 01 2007 44 05 01 2007 45 05 01 2007 46 05 01 2007 47 05 01 2007 48 05 01 2007 rear page 00-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 20 Sept. 01/07...

-

Page 21: Table Of Amendments

20 to 22 05-00-00 9 to 12 09 01 2007 DOA* 05-20-00 09 01 2007 DOA* 12-00-00 9,10,25 to 30 09 01 2007 DOA* 39 to 42 00-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 21 Sept. 01/07... - Page 22 BRP-Rotax MAINTENANCE MANUAL NOTES 00-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 22 May. 01/07...

- Page 23 2) Time limits for engine operation ............. 05-10-00 / 3 3) Time limit for rubber parts ............... 05-10-00 / 5 4) Time limit for the coolant................. 05-10-00 / 7 5) Annual inspection ................... 05-10-00 / 5 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 1 May 01/2007...

- Page 24 2.2) Checking of the overload clutch ............ 05-50-00 / 5 2.3) Examination after engine failure ............ 05-50-00 / 7 2.4) Returning engine to service after submerging in water ....05-50-00 / 8 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 2 May 01/2007...

- Page 25 2.18) Orange caution lamp of the boost pressure control is flashing ..05-50-00 / 20 2.19) Failure of the voltage supply for the turbo control unit (TCU) ..05-50-00 / 20 2.20) Reporting ..................05-50-00 / 21 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 3 May 01/2007...

- Page 26 BRP-Rotax MAINTENANCE MANUAL NOTES 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 4 May 01/2007...

-

Page 27: Maintenance

2) Maintenance 2.1) General note In this section the maintenance of engine 914 Series is described. The description is subdivided into sections and description of function of the various systems. Some overlapping maintenance instructions are treated as generally valid information at the beginning of this section. -

Page 28: Authorized Personnel

Suitable work environment to prevent contamination or damage to engine parts or modules. Suitable tools and fixtures as outlined in the ROTAX Maintenance Manual. Reasonable and prudent maintenance practices are utilized. And the Requirements of the applicable regulatory authority regarding maintenance procedures are met. -

Page 29: Procedure Notes

If not respected, damage may be the conse- quence. ▲ WARNING: Exactly observe the tightening torques for screws and nuts. Overtightening or too loose connection could cause serious engine damage. 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 7 May 01/2007... -

Page 30: Trouble Shooting

In the Operators Manual, possible problems are listed. At the same time, a brief description of the necessary remedial action is given. See section 12 in the Operators Manual for engine type 914 (Series). 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 8 May 01/2007... -

Page 31: Consumable Materials

11 897166 MOLYKOTE 44 medium, long-term lubricant for shaft seals ....100 g (0.22 lb) 12 897330 Lithium-base grease, to prevent leakage current ......250 g (0.55 lb) 05-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 9 Sept. 01/07... - Page 32 (CASTROL ZA 30 or OMV- SOFT SOL). When using solvents, observe the safety regulations for persons and environment. 20 898570 Screw securing paint ...... 20 ml (0.005 gal (US)) 05-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 10 Sept. 01/07...

- Page 33 The granulates used are of sizes 40 to 60 µ . It is possible to achieve a surface roughness of 0.5 to 1 µ , which represents fine processing of surfaces. 05-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 11 Sept. 01/07...

-

Page 34: Acceptable Methods, Techniques And Practice

DIN 980 is positioned towards outside. Lock washer See Fig. 2. ◆ NOTE: When fitting lock washers, the curved-up ends (1) must point towards the screw head or nut. 00144 Fig. 2 05-00-00 Effectivity 914 Series Edition 1 / Rev. 0 page 12 May 01/2007... -

Page 35: Time Limits

BRP-Rotax MAINTENANCE MANUAL SECTION 05-10 TIME LIMITS 1) General note These checks, related to limited periods of operation, are planned to help avoid engine troubles by the use of preventive maintenance. 05-10-00 Effectivity: 914 Serie Edition 1 / Rev. 0... - Page 36 BRP-Rotax MAINTENANCE MANUAL NOTES 05-10-00 Effectivity: 914 Serie Edition 1 / Rev. 0 page 2 May 01/2007...

-

Page 37: Time Limits For Engine Operation

The time limit for engine operation will be specified by the TBO. ▲ WARNING: After reaching this time limit, the engine has to be shipped to an authorized ROTAX overhaul facility. For an overhaul, the engine must be removed from the aircraft, be cleaned, preserved and all openings to be closed to prevent entering of contaminants. - Page 38 BRP-Rotax MAINTENANCE MANUAL The shipment to an authorized ROTAX overhaul facility must include the following: - Engine log book - Maintenance records of the engine (i.e. all maintenance check lists, and reports of operation, of maintenance, of findings and of oil analyses).

-

Page 39: Time Limit For Rubber Parts

BRP-Rotax MAINTENANCE MANUAL 3) Time limit for rubber parts The following components and systems must be replaced every 5 years: - venting hose of the carburetors - all rubber hoses of the cooling system - all rubber hoses of the fuel system - all rubber hoses of the lubrication system which are part of the engine supply volume and if they are not in the maintenance schedule of aircraft manufacturer. - Page 40 BRP-Rotax MAINTENANCE MANUAL NOTES 05-10-00 Effectivity: 914 Serie Edition 1 / Rev. 0 page 6 May 01/2007...

- Page 41 BRP-Rotax MAINTENANCE MANUAL SECTION 05-20 SCHEDULED MAINTENANCE CHECKS 1) General note This section lists the periodic inspections which must be carried out after a specified periods of operation. Periodic inspections are those which must be performed at 50, 100, 200, 600 and 800 hr.

-

Page 42: Maintenance Schedule Procedures (Maintenance Check List)

Replacement of equipment (e.g. carburetor, fuel pump, governor...) and execution of SB (LTA) must be entered in the log book, stating S/N, TSN and date. 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 2 May. 01/07... -

Page 43: Check List / Maintenance Schedule

This check is applicable (circle one) 25h* 100h 200h 600h Next check due at: ______________________ hr. (TS__) (engine h) * shaded column for the first 25 h (new or overhauled) 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 3 May. 01/07... - Page 44 BRP-Rotax MAINTENANCE MANUAL Page 2 of 9 NOTES 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 4 May. 01/07...

-

Page 45: Maintenance Schedule

Inspect the expansion tank for damage and abnormalities. Check coolant level, replenish as necessary. Inspect radiator cap. Inspect protection rubber on expansion tank base for secure fit. See 12-00-00, sec. 3.1 - 3.4 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 5 May. 01/07... -

Page 46: 3) Checking The Engine Suspension

See 12-00-00, sec. 6.1 2.2.3) Checking the engine suspension a) Inspect engine suspension and fasteners for secure fit, including damage from heat, deformation, cracks. See 12-00-00, sec. 2.4 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 6 May. 01/07... -

Page 47: 4) Engine External Parts

This process is completed when air flows back to the oil tank. This air flow can be perceived as a murmur (gurgling) when the cap of the oil tank is open. See 12-00-00, sec. 5.1 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 7 May. 01/07... -

Page 48: 8) Oil Change

2.2.9) Flushing the cooling system a) Flushing the cooling system where conventional coolants are used. See 12-00-00, sec. 3.3 and See 05-10-00, sec. 4 with replacing the coolant 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 8 May. 01/07... -

Page 49: 10) Checking The Air Filter

See 12-00-00, sec. 4.3 d) Removal/assembly of the two carburetors for carburetor inspection. See 73-00-00, sec. 3.2 e) Check carburetor synchronization. Mechanical or pneumatic synchronization. See 12-00-00, sec. 4.1.1 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 9 May. 01/07... -

Page 50: 13) Checking The V-Belt Tension

Test pressure ___ hPa (psi) Pressure drop cyl. 1 _____ cyl. 2 _____ (% or fraction) cyl. 3 _____ cyl. 4 _____ See 12-00-00, sec. 2.6 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 10 May. 01/07... -

Page 51: 18) Engine Test Run

Check at _____hr. (TSN__,TSO__) was carried out according to recommendations of the engine manufacturer and was recorded in the Engine Log book. (location) , (date) (Aircraft mechanic) Inspector (certificate no). 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 11 May. 01/07... - Page 52 BRP-Rotax MAINTENANCE MANUAL NOTES 05-20-00 Effectivity 914 Series Edition 1 / Rev. 0 page 12 May. 01/07...

-

Page 53: Unscheduled Maintenance Checks

(e.g. hydraulic governor) is applicable. After each special check/repair work, an engine test run and a leakage check must be conducted. ▲ WARNING: Observe without fail all the specified instructions. 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 1 May. 01/07... - Page 54 BRP-Rotax MAINTENANCE MANUAL NOTES 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 2 May. 01/07...

-

Page 55: Special Checks

Observe the directives of the aircraft manufacturer. Remove the gearbox and roller bearing of the propeller shaft. The whole gearbox must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. Carry out detailed inspection of all gearbox components. -

Page 56: 2) Propeller Gearbox Without Integrated Overload Clutch

2.1.2) Propeller gearbox without integrated overload clutch The whole engine must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. Detailed inspection of affected engine components. NDT for cracks in the crankshaft, gearbox housing, fly wheel hub, propeller shaft or gear set. -

Page 57: Checking Of The Overload Clutch

Do not exceed 800 Nm (590 ft.lb.) otherwise gearbox damage can occur. If the value is greater or smaller than the limit value, the whole gearbox must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. 05-50-00 Effectivity 914 Series Edition 1 / Rev. - Page 58 BRP-Rotax MAINTENANCE MANUAL If the torque is below or above this value, inspect, repair or overhaul the propeller gearbox in accordance with the ROTAX instructions for continued airworthiness. Detailed inspection of all gearbox components. Länge L (m)/ length L in m...

-

Page 59: Examination After Engine Failure

The entire assembly must be dismantled, inspected and repaired. The whole engine must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. - Inspect all systems for correct functioning. Detailed inspection of affected engine components. -

Page 60: Returning Engine To Service After Submerging In Water

Flying in areas with extreme climatic conditions or in extreme altitudes requires adjustment of the carburetor jetting and of the cooling system. To do this, it is necessary to contact the aircraft manufacturer and an authorized ROTAX distributor. 05-50-00 Effectivity 914 Series Edition 1 / Rev. -

Page 61: Exceeding Of Max. Admissible Engine Rpm

If the limit was exceeded for more than 1 minute: The whole engine must be inspected, repaired or overhauled in accordance with the ROTAX instructions for continued airworthiness. - Check that the push-rods are straight. - Inspect all systems for correct functioning. -

Page 62: Exceeding Of Max. Cylinder Head Temperature

All cylinder heads and cylinders must be removed and subjected to a detailed check including hardness testing. See 72-00-00 in the Heavy Maintenance Manual. Time 30 min. 07140 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 10 May. 01/07... -

Page 63: Exceeding The Max. Permissible Oil Temperature

With oil temperature in excess of 160 °C (320 °F) consequential damage is likely. Temperature The whole cooling system must be inspected, repaired or overhauled in accordance with the ROTAX instructions para Proceed as instructed in 2.8.2 160 °C for continued airworthiness. -

Page 64: Oil Pressure Below Minimum Value

If after the previous checks and oil change the oil pressure is still too low, repair or overhaul the engine in accordance with the BRP-Rotax instructions for continued airworthiness. Inspect all systems for correct function. - Page 65 Consequent damage can be expected if the oil pressure falls below the minimum value more than 0.5 bar (7.25 psi). The whole cooling system must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. Inspect all further systems for correct functioning.

-

Page 66: Oil Specification Not Respected

Remove propeller gearbox. The gearbox must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. Detailed inspection of all gearbox components. ◆ NOTE: An entry by the pilot in the engine logbook of all pertinent details is required. -

Page 67: Spark Plug Not In Accordance With Specification

2.11) Spark plug not in accordance with specification If by error any of the 8 spark plugs were installed which are not according to specification of the engine manufacturer and/or not genuine ROTAX parts, the following verification will be necessary. -

Page 68: Engine Runs Sluggishly

Carry out detailed inspection of crank drive. Länge L (m) / length L in m Fig. 6 Kraft F in N / force F in N 05694 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 16 May. 01/07... -

Page 69: Sudden Drop In Boost Pressure And Speed

See sec. 13.6. ■ CAUTION: If the permissible operating limits are exceeded or values fall below the minimum, the corresponding checks must also be carried out. 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 17 May. 01/07... -

Page 70: Red Boost Lamp Of The Boost Pressure Control Lights

The pistons, cylinders, valves and cylinder heads must be inspected. ■ CAUTION: If values have fallen below or exceeded further operating limits, the corresponding checks must also be carried out. 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 18 May. 01/07... -

Page 71: Red Boost Lamp Of The Boost Pressure Control Is Flashing

The pistons, cylinders, valves and cylinder heads must be inspected. ■ CAUTION: If values have fallen below or exceeded further operating limits, the corresponding checks must also be carried out. 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 19 May. 01/07... -

Page 72: Orange Caution Lamp Of The Boost Pressure Control Is Flashing

See sec. 13.6. ■ CAUTION: If the permissible operating limits have been exceeded or values have fallen below the minimum, the corresponding checks must also be carried out. 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 20 May. 01/07... -

Page 73: Reporting

In case of any relevant occurrences that may involve malfunction of the engine, the form on the next page should be filled out and sent to the responsible authorized ROTAX distributor. ◆ NOTE:... - Page 74 BRP-Rotax MAINTENANCE MANUAL 05-50-00 Effectivity 914 Series Edition 1 / Rev. 0 page 22 May. 01/07...

- Page 75 4.1.2) Mechanical synchronization ..........12-00-00 / 25 4.1.3) Pneumatic synchronization ..........12-00-00 / 27 4.2) Idle speed adjustment ..............12-00-00 / 30 4.3) Checking the carburetor actuation ..........12-00-00 / 31 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 1 May. 01/07...

- Page 76 7) Propeller gearbox ................... 12-00-00 / 47 7.1) Checking the friction torque in free rotation ........12-00-00 / 47 7.2) Checking the propeller gearbox ............ 12-00-00 / 48 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 2 May. 01/07...

-

Page 77: General Note

For reasons of clarity, only headlines and keywords are listed in the Maintenance Schedule. Please refer to the following pages for further explanation if needed. As far as possible, the content has been arranged according to system. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 3 May. 01/07... -

Page 78: Engine Cleaning

Carry out visual inspection of compressor and turbo housing for cracks. Engine suspension frame - see also MM Heavy 71-00-00 sec. 6.1.3 Airbox - see also 73-00-00 Fuel and oil lines - see also 73-00-00 and 79-00-00 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 4 May. 01/07... - Page 79 There is a condensation trap between the airbox and the pressure sensor. It must be replaced when it fills with condensation. ◆ NOTE: Only fitted on engines with airbox of older model. Fig. 7 00048 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 5 May. 01/07...

-

Page 80: Leakage Check

If damage is detected, replace hose immediately. ■ CAUTION: Avoid overstretching the fixing elements. Tighten as far as possible by hand. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 6 May. 01/07... -

Page 81: Checking The Engine Suspension

(black ring), there may be loose attachments. Inspect engine isolating mounts including for heat damage, wear and cracks. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 7 May. 01/07... -

Page 82: Checking The Air Filter

After soaking period, flush with cold water from inside to outside, shake off and let it dry naturally. ■ CAUTION: Do not dry over naked flame, with compressed air or with hot air gun. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 8 May. 01/07... - Page 83 Only use dry type air filters which are specified by the aircraft manufacturer. ■ CAUTION: Attach new air filter, free of grease, at connection faces, and wire-secure against loss. 00183 Fig. 10 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 9 May. 01/07...

-

Page 84: Checking The Compression

(5). The maximum permissible pressure drop is 25 %, e.g. from 6 to 4.5 bar (87 psi to 65 psi). If the value is below 4.5 bar (65 psi), inspection, repair or overhaul must be carried out in accordance with the BRP-Rotax instructions for continued airworthiness. Detailed inspection of affected engine components. - Page 85 If the value is below 6 bar (87 psi), inspection, repair or overhaul must be carried out in accordance with the instructions for continued airworthiness. Detailed inspection of affected engine components. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 11 May. 01/07...

-

Page 86: Checking The V-Belt Tension

Tightening torque for screws M8 is 22 Nm (195 in.lb) and for screw M10 35 Nm (25.8 ft.lb). Fig. 12 00353 Inspect V-belt tension as per drawing below. Fig. 13 00354 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 12 May. 01/07... -

Page 87: Locking The Crankshaft

M8 x 20 (1) along with a new sealing ring with a torque of 15 Nm (133 in.lb). To check, use wrench SW 24 to rotate the crankshaft at hex. screw (7) on the magneto side. 04625 00344 Fig. 14 Fig. 15 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 13 May. 01/07... -

Page 88: Checking The Wastegate Flap

1/2 revolution and then remains in closed position. In this position, the wastegate flap must be completely closed. If necessary, readjust using the adjusting screw (2). See sec. 13.5. 00147 Fig. 16 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 14 May. 01/07... -

Page 89: Inspection Of The Fuel Filter In The Airframe

If the filter in the airframe is heavily soiled, the two fine filters (4) integrated in the fuel pumps must also be inspected. MAIN Fig.17 00103 00157 Fig. 18 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 15 May. 01/07... -

Page 90: Test Run Of Engine

This is necessary to prevent steam locks in the cooling and fuel system after shut-down. ▲ WARNING: When shutting down the engine, always switch off ignition and remove the ignition key. shut engine down. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 16 May. 01/07... - Page 91 ■ CAUTION: If the oil filter has been replaced, re-tighten by hand after the trial run. Inspect engine for oil, fuel or coolant leaks and repair as necessary. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 17 May. 01/07...

- Page 92 BRP-Rotax MAINTENANCE MANUAL NOTES 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 18 May. 01/07...

-

Page 93: Cooling System

Use only coolant as recommended in the current Operators Manual. Inspect coolant with densimeter or glycol tester. If necessary, replenish with coolant of same composition. Strongly discolored or thickened coolant must be replaced. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 19 May. 01/07... -

Page 94: Replacing The Coolant

Refill newly mixed coolant into the expansion tank (highest point of the cooling system). Fit radiator cap. ◆ NOTE: Run the engine briefly and replenish with clean coolant as required. Fig. 19 00155 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 20 May. 01/07... -

Page 95: Flushing The Cooling System

Refill newly mixed coolant into the expansion tank (highest point of the cooling system). ◆ NOTE: Run the engine for a minute and replenish coolant as required. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 21 May. 01/07... -

Page 96: Expansion Tank, Radiator Cap

2 return valve 3 rubber seal 4 pressure spring 5 connection to overflow bottle 6 opening pressure of the radiator cap 7 sealing surface 8 tube connections 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 22 May. 01/07... -

Page 97: Overflow Bottle

Accessories (including radiator, radiator hoses, hose clamps, cooling air ducts). ■ CAUTION: Equipment is to be inspected in accordance with the Mainte- nance Manual of the aircraft manufacturer. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 23 May. 01/07... - Page 98 BRP-Rotax MAINTENANCE MANUAL NOTES 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 24 May. 01/07...

-

Page 99: Fuel System

1.5 turns counter clockwise. Hook the return spring (5) back up to the throttle lever (1) in its original position. Check that the throttle valve opens fully automatically. 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 25 Sept. 01/07... - Page 100 (2). Check the true running of the engine. If necessary, adjust with the idle mixture screw (6). See 12-00-00, sec. 4.2. 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 26 Sept. 01/07...

-

Page 101: 3) Pneumatic Synchronization

If no satisfactory result can be achieved, inspect the idle jets for contamination and clean if necessary ■ CAUTION: Also check for translucent, jelly-like contamination. Inspect for free passage. 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 27 Sept. 01/07... - Page 102 Follow the instructions of the instrument manufacturer. Refit the screw plug M3,5 x 5 (pos. 8 Fig. 25) and hex.screws M6 x 6 (pos. 6 Fig. 27). 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 28 Sept. 01/07...

- Page 103 BRP-Rotax MAINTENANCE MANUAL 01393-1 Fig. 26 Fig. 27 05491 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 29 Sept. 01/07...

-

Page 104: Idle Speed Adjustment

Turning the idle mixture control screw in clockwise direction results in a leaner mixture and turning counter clockwise in a richer mixture. 02726 02725 Fig. 29 Fig. 28 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 30 May. 01/07... -

Page 105: Checking The Carburetor Actuation

Inspect and lubricate linkage on carburetor and carburetor joints with engine oil. Inspect return springs (3) and inspect engagement holes for wear. ~1 mm 00352 Fig. 30 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 31 May. 01/07... - Page 106 BRP-Rotax MAINTENANCE MANUAL NOTES 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 32 May. 01/07...

-

Page 107: Lubrication System

(over servicing), oil will escape via the venting passage see also SI-27-1997,"oil level check", latest issue. Difference between "max." and "min." - mark = 0.45 l (0.95 liq.pt). 05489 Fig. 31 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 33 May. 01/07... -

Page 108: Oil Change

(approx. 20 turns) to completely refill the entire oil circuit. Compressed air must not be used to blow through the oil system (or oil lines, oil pump housing, oil bores in the housing). 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 34 May. 01/07... -

Page 109: 1) Cleaning The Oil Tank

Fit drain screw (1) M12 x 12 with a new sealing ring (7) tighten to 25 Nm (18.5 ft.lb) and safety wire. Reassemble the oil tank by following the same steps in reverse order. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 35 May. 01/07... -

Page 110: 2) Venting The Oil System

It must be carried out in accordance with SI-914-020 "Purging the lubrication system", latest issue. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 36 May. 01/07... - Page 111 BRP-Rotax MAINTENANCE MANUAL to oil pump back from engine 05448 05017 Fig. 33 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 37 May. 01/07...

-

Page 112: Oil Filter Replacement And Inspection Of The Filter Insert

This inspection is important as it allows conclusions to be drawn regarding the internal condition of the engine and provides information about the possible cause of any damage. * or equivalent 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 38 May. 01/07... - Page 113 ■ CAUTION: To ensure correct functioning of the oil circuit and the forced flow lubrication, use genuine ROTAX oil filter only. Only these filters will ensure correct pressure in the by-pass valve. Fig. 36...

- Page 114 3/4 turn (270°). ■ CAUTION: After test run inspect tight fit of oil filter. contact surface oil pump housing gasket oil filter 08197 Fig. 37 12-00-00 Effectivity 914 Series Edition 1 / Rev. 1 page 40 Sept. 01/07...

-

Page 115: Inspecting The Magnetic Plug

Afterwards conduct engine test run and inspect the oil filter once more. If there are larger accumulations of metal chips on the magnetic plug, the engine must be repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. -

Page 116: Flushing The Oil Circuit

Venting of the oil system, see 12-00-00, sec. 5.2.2. 5.6) Accessories (including radiator, oil hoses, clamps etc.) ■ CAUTION: Inspect all the equipment in accordance with the Maintenance Manual of the aircraft manufacturer. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 42 May. 01/07... -

Page 117: Electric System

(TCU), 2x pressure sensors, tacho-generator, throttle potentiometer, airbox temperature sensor, servo motor, disconnector, control valve and the two lamps for corrosion or damage and tight fit and replace as necessary. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 43 May. 01/07... -

Page 118: Inspection And Replacement Of Spark Plugs

Heat conduction compound, see 05-00-00 sec. 2.5. ▲ WARNING: Rinse off with water in the case of contact with eyes or skin. May be harmful if swallowed. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 44 May. 01/07... - Page 119 ◆ NOTE: Operation with leaded fuels (e.g. AVGAS 100LL) can result in increased wear of the spark plugs. Reduce renewal intervals accordingly. 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 45 May. 01/07...

- Page 120 BRP-Rotax MAINTENANCE MANUAL NOTES 12-00-00 Effectivity: 914 Series Edition 1 / Rev. 0 page 46 May. 01/07...

-

Page 121: Propeller Gearbox

12-00-00, sec. 2.8. Reconnect negative terminal of aircraft battery. ▲ WARNING: If the above mentioned friction torque is not achieved, inspect, repair or overhaul the gearbox in accordance with the ROTAX instructions for continued airworthiness. Detailed inspection of all gearbox components. -

Page 122: Checking The Propeller Gearbox

7.2) Checking the propeller gearbox The gearbox must be inspected, repaired or overhauled in accordance with the BRP-Rotax instructions for continued airworthiness. Detailed inspection pf the affected gearbox components in accordance 72-00-00 sec. 3.9.10 in the Heavy Maintenance Manual. Crack testing of the propeller shaft is not normally planned, but can be carried out if cracks are suspected. - Page 124 Motornummer / Engine serial no. Flugzeugtype / Type of aircraft Flugzeugkennzeichen / Aircraft registration no. ROTAX® Vertriebspartner ROTAX® authorized distributor www.rotax-aircraft-engines.com ® and TM are trademarks of BRP-Rotax GmbH & Co. KG. © 2006 BRP-Rotax GmbH & Co. KG. All rights reserved.

Need help?

Do you have a question about the 914 Series and is the answer not in the manual?

Questions and answers