Advertisement

Quick Links

Advertisement

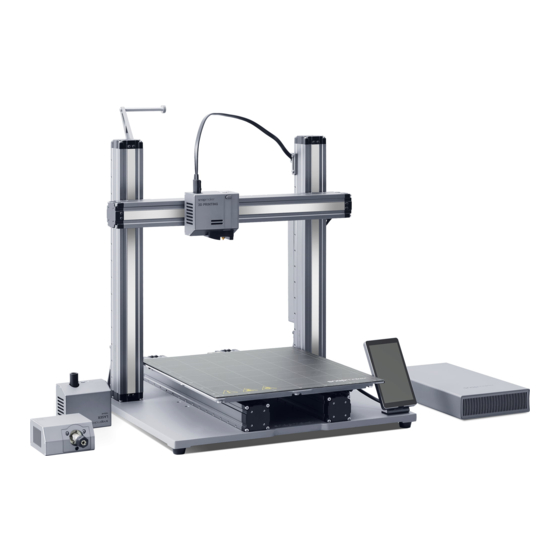

Summary of Contents for Snapmaker A350T

- Page 1 | A350T QUICK START GUIDE MAKE SOMETHING WONDERFUL...

- Page 2 We believe that wonderful things lofty goal: to be the holy trinity for at-home boundaries of possibility, and we eventually us feel alive. The Snapmaker 2.0 will help you will happen when creative minds meet the makers by using detachable modules to made the impossible possible.

- Page 3 Modular System This machine is built for innovators. Our goal is to assist Snapmaker is not only a 3D printer, but also a powerful you to make the world a better place with a machine machine that you can customize with addons. You can we built with love.

-

Page 4: Table Of Contents

CONTENTS BEFORE START Before You Start Machine Assembly 3D Printing Laser Engraving and Cutting CNC Carving Quick Start Guide |... -

Page 5: Before You Start

Please read and understand the contents of the manual of this product carefully. Failure to read the manual may lead to personal injury, inferior results or damage to the Snapmaker products. Always make sure that anyone who uses this product knows and understands the contents of this manual to make the most out of it. - Page 6 Before You Start Turn off the machine immediately and stop using this product, if any of the following occurs: FCC Compliance - You smell burning in this machine at any point. This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant - The machine stops working unexpectedly.

- Page 7 (e.g. On the CNC Module CNC Bits). Build Volume A250T: 230 x 250 x 235 mm A350T: 320 x 350 x 330 mm Heated Bed Temperature A250T: Up to 100°C A350T: Up to 80°C Class 4 laser product.

- Page 8 Before You Start 1.6 Parts List | A350 QUICK START GUIDE MAKE SOMETHING WONDERFUL Linear Module Quick Start Guide 3D Printing Module Laser Module CNC Module Laser Safety Goggles Fixture Accessory Filament Arched Fixture Touchscreen Touchscreen Holder Controller CNC Safety Goggles Filament Holder Sheet Toolhead Cable Y Conversion...

- Page 9 Apart from this Quick Start Guide, we also make video tutorials. Read this guide to finish assembly, and if you are feeling adventurous, tricks that are not included in this guide can be found in the video tutorials. Visit our Tool Box website at https://support.snapmaker.com/hc/en-us-> select Snapmaker 2.0 -> Go to Video Tutorial. M4 x 30 Screw x 12...

-

Page 10: Machine Assembly

Machine Assembly MACHINE ASSEMBLY Quick Start Guide |... - Page 11 Machine Assembly 01 02 Attach the feet to the Base Plate. All Linear Modules must be assembled in their intended position. Now, identify two Linear Modules with the laser pattern "Lead 20 mm"; they will be the Y Axes. M4 x 10 Hex Socket Head Screw Foot Linear Module ×...

- Page 12 Machine Assembly 03 04 Make sure the sliders are aligning with each other. If not, you can move Attach the Y Axes to the Platform. Do not tighten the screws until Step 6. them to the same position as illustrated. Hold the Linear Modules carefully to prevent them from falling.

- Page 13 Machine Assembly 05 06 Attach the Y Axes to the Base Plate. Tighten the screws on the Y-axis sliders. M4 x 8 Screw x 16 Make sure the Y-axis Linear Modules are accurately mounted onto the grooves of the Base Plate. If the screws on the sliders are not aligning with the screw holes on the Base Plate, move the Platform to the proper position.

- Page 14 Machine Assembly 07 08 Attach the Z-axis Holders to the Base Plate. Attach the Touchscreen Holder to the Base Plate. Z-axis Holder Touchscreen Holder M4 x 8 Screw M4 x 8 Screw Quick Start Guide |...

- Page 15 Machine Assembly 09 10 Identify the two Linear Modules with the laser pattern "Lead 08 mm". They will Thread the connecting cables through the holes of the holders, and then attach be the Z Axes. the Z Axes to the Z-axis Holders. Do not tighten the screws until Step 14. Linear Module ×...

- Page 16 Machine Assembly 11 12 Install the screws to the bottom of the Z Axes. Do not tighten the screws From the middle, move the Platform to the position as illustrated. Then move the until Step 15. Z-axis sliders to the farthest end. M4 x 8 Screw Quick Start Guide |...

- Page 17 Machine Assembly 13 14 The last Linear Module with the laser pattern "Lead 20 mm" will be the X Tighten the screws that are used to attach the Z Axes to the Z-axis Holders. Axis. Attach the X Axis to the Sliders on the Z Axes. Linear Module M4 x 8 Screw Quick Start Guide |...

- Page 18 Machine Assembly 15 16 Tighten the screws to the bottom of the Z Axes. Put your hands at each end of the Linear Module, and then move the X Axis to the top. Make sure both ends of the Linear Module are in horizontal alignment with each other throughout the process.

- Page 19 Machine Assembly 17 18 Locate the Y Conversion Cable, and the attached cable on both of the two Attach the Y-axis Converter to the Base Plate. Y Axes as illustrated. Connect them to the Converter. Y Conversion Cable Converter Y Conversion Cable M4 x 30 Screw Quick Start Guide |...

- Page 20 Machine Assembly 19 20 Locate the Z Conversion Cable, and the attached cable on both of the two Attach the Z-axis Converter to the Base Plate. Z Axes as illustrated. Connect them to the Converter. Z Conversion Cable Converter Z Conversion Cable M4 x 30 Screw Use the provided cable tie to organize the cables.

- Page 21 Machine Assembly 21 22 Attach the Controller to the Z Axis. Open the dust plugs, and then connect the X, Y and Z Axes with the Controller. X Axis Y Axis Z Axis Make sure the connectors are in the right direction. M4 x 30 Screw Controller Keep the protective dust plugs...

- Page 22 Machine Assembly 24 23 Connect the cables for the Power Module. Place the Touchscreen, and then connect the Touchscreen with the Controller. Do not connect or disconnect any cables when the machine is powered on. Touchscreen Power Module AC Power Cable DC Power Cable Make sure the power switch is in the Off position.

- Page 23 Machine Assembly Absolutely amazing! You have successfully assembled the machine body. Now just select one function to complete the assembly and bring your first job into the world! 3D Printing CNC Carving Laser Engraving and Cutting PAGE 40 PAGE 60 PAGE 76 Quick Start Guide |...

-

Page 24: 3D Printing

3D Printing 3D Printing 3.1 Assembly 3.1.1 Assemble the 3D Printer 3.1.2 Initial Setup 3.2 Get Started 3.2.1 Calibrate the Bed 3.2.2 Load Filament 3.3 Start Printing 3.3.1 Prepare the G-code File 3.3.2 Start Your First Print 3.3.3 Remove the Print Quick Start Guide |... - Page 25 3D Printing 3.1.1 Assemble the 3D Printer Connect the 3D Printing Module with the Controller. Guides & Pictures / Snapmaker Make sure the connector is in the right direction. Toolhead Cable Attach the 3D Printing Module to the slider on the X Axis.

- Page 26 3D Printing Attach the Filament Holder to the Z Axis. Attach the Heated Bed to the Platform. M4 x 10 Hex Socket Head Screw Filament Holder Tube Filament Holder Sheet M4 x 10 Hex Flat Head Screw x 22 M4 x 10 Hex Socket Head Screw Heated Bed Quick Start Guide |...

- Page 27 3D Printing Place the Print Sheet. Connect the Heated Bed with the Controller. Make sure the Heated Bed is contamination-free before you place the Print Sheet. Make sure the Print Sheet aligns perfectly with the Heated Bed. Heated Bed Print Sheet Quick Start Guide |...

- Page 28 3.1.2 Initial Setup Attach the Cable Holder to the Z Axis, and then lock the Toolhead Cable into place. Guides & Pictures / Snapmaker Cable Holder Plug the AC Power Cable into an electrical outlet. Switch the power on and follow the prompts on the M4 x 8 Screw touchscreen: Read the Terms ->...

- Page 29 How to Level 1. Run the Auto Leveling procedure on the touchscreen. Guides & Pictures / Snapmaker 2. Place the Calibration Card or a piece of A4 paper between the nozzle and the Heated Bed, and manually calibrate the Z Offset for the last point.

- Page 30 2. Tap Start on the Load Filament screen. After the temperature reaches the target temperature, tap Load and then gently push the filament into the 3D printing module until you can feel the motor pulling the filament in. Guides & Pictures / Snapmaker How It Works: Filament Loading The motor drives the filament into the extruder, where the filament extrudes through the nozzle after being heated by the heated block.

- Page 31 Then generate the G-code file. connect Snapmaker Luban to your machine through the same Wi-Fi network: Enter Workspace -> Connection -> Select Wi-Fi -> Click Refresh -> Select your machine -> Click Connect -> Tap Yes on the Touchscreen.

- Page 32 3D Printing 3.3.2 Start Your First Print 3.3.3 Remove the Print Guides & Pictures / Snapmaker Guides & Pictures / Snapmaker Wait for the temperatures of the nozzle and the Heated Bed to drop to room temperature (displayed on the After receiving the G-code file, tap Touchscreen) .

- Page 33 Facebook group and our forum. : Download our firmware from https://snapmaker.com/product/snapmaker-2/downloads > Insert the USB flash drive into the Controller > Turn on the machine > Swipe left on the Touchscreen > Tap Files > Tap USB > Tap the firmware file to update.

-

Page 34: Laser Engraving And Cutting

Laser Engraving and Cutting Laser Engraving and Cutting 4.1 Assembly 4.1.1 Assemble the Laser Engraver and Cutter 4.1.2 Initial Setup 4.2 Get Started 4.2.1 Measure the Focal Length 4.2.2 Calibrate the Camera 4.2.3 Fasten the Material 4.3 Prepare the G-code File and Start Cutting Quick Start Guide |... - Page 35 Laser Engraving and Cutting 4.1.1 Assemble the Laser Engraver and Cutter Connect the Laser Module with the Controller. Guides & Pictures / Snapmaker Make sure the connector is in the right direction. Toolhead Cable Attach the Laser Module to the slider on the X Axis.

- Page 36 Laser Engraving and Cutting Attach the Laser Engraving/Cutting Platform to the Platform. Attach the Cable Holder to the Z Axis, and then lock the Toolhead Cable into place. Cable Holder M4 x 8 Screw M4 x 10 Hex Socket Head Screw x 14 Laser Engraving/ Cutting Platform...

- Page 37 Laser Engraving and Cutting 4.1.2 Initial Setup 4.2.1 Measure the Focal Length Guides & Pictures / Snapmaker Guides & Pictures / Snapmaker Plug the AC Power Cable into an electrical outlet. Switch the power on and follow the How It Works: Focal Point prompts on the Touchscreen: Read the Terms ->...

- Page 38 Laser Engraving and Cutting How It Works: Work Origin 2. Set the thickness of the material (1.5 mm) and tap Save. Find out where the engraving/cutting will take place by setting the Work Origin. The Work Origin corresponds to the (0, 0) coordinate origin in the software. 3.

- Page 39 Run Boundary to check if the work origin is proper. If not, reset the Work Origin and run boundary again. Guides & Pictures / Snapmaker If the Laser Module runs into any portions of the machine, turn off the machine immediately.

- Page 40 Remove the engraved paper, and then fasten another provided material on the center of the Laser Engraving/ Then connect Snapmaker Luban to your machine through the same Wi-Fi network: Enter Workspace -> Cutting Platform. Connection -> Select Wi-Fi -> Click Refresh ->...

- Page 41 You can also start engraving/cutting by using the USB disk, connecting with the USB cable, or sending G-code files via Wi-Fi, in which case you will need to set the work origin yourself. For detailed instructions, refer to our Snapmaker Luban User Manual. 4. Remove the finished work and complete the assembly.

-

Page 42: Cnc Carving

CNC Carving CNC Carving 5.1 Assembly 5.1.1 Assemble the CNC Carver 5.1.2 Initial Setup 5.2 Get Started 5.2.1 Fasten the Material 5.2.2 Attach the Bit 5.3 Start Carving 5.3.1 Prepare the G-code File 5.3.2 Set the Work Origin and Start Carving 5.3.3 Clean the Finished Work Quick Start Guide |... - Page 43 CNC Carving 5.1.1 Assemble the CNC Carver Connect the CNC Module with the Controller. Guides & Pictures / Snapmaker Make sure the connector is in the right direction. Toolhead Cable Attach the CNC Module to the slider on the X Axis.

- Page 44 CNC Carving Attach the CNC Carving Platform to the Platform. Attach the Cable Holder to the Z Axis, and then lock the Toolhead Cable into place. Cable Holder M4 x 10 Hex Socket Head Screw x 14 M4 x 8 Screw CNC Carving Platform Make sure there is enough cable length for the toolhead to move.

- Page 45 CNC Carving 5.1.2 Initial Setup 5.2.1 Fasten the Material Guides & Pictures / Snapmaker Guides & Pictures / Snapmaker Plug the AC Power Cable into an electrical outlet. Switch the power on and follow the prompts on the 1. Place the provided material on the center of the CNC Carving Platform.

- Page 46 5.2.2 Attach the CNC Bit Do not screw the screws all the way down through the CNC Carving Platform. Guides & Pictures / Snapmaker Make sure the clamp set will not collide with any portions of the machine. How It Works: CNC Bit Usage Flat End Mill is typically used for slotting or cutting materials into flat surface.

- Page 47 Download our software the Snapmaker Luban at https://www.snapmaker.com/download and install. Then connect Snapmaker Luban to your machine through the same Wi-Fi network: Enter Workspace -> Connection -> Select Wi-Fi -> Click Refresh -> Select your machine -> Click Connect -> Tap Yes on the Touchscreen.

- Page 48 1. After receiving the G-code file, tap Disconnect on the Touchscreen. Then find and select the received G-code file, and tap Next to enter the Set Work Origin screen. Guides & Pictures / Snapmaker How It Works: Work Origin Find out where the carving will take place by setting the Work Origin. The Work Origin corresponds to the (0, 0) coordinate origin in the software.

- Page 49 CNC Bit using Z- or Z+ buttons until you feel slight resistance when you pull out the Calibration Card, and it should be wrinkled when you push it forward. Tap Set Work Origin. Guides & Pictures / Snapmaker Slight Resistance 1.

- Page 50 This guide is subject to change. The latest version is on our Support website: Select Snapmaker 2.0 -> Go to Quick Start Guide. https://support.snapmaker.com/hc/en-us Besides this guide, a User Manual is available on our Support website: Select Snapmaker 2.0 -> Go to User Manual. https://support.snapmaker.com/hc/en-us We are here for you whenever you need general information or technical support: support@snapmaker.com.

- Page 51 CNC Carving...

Need help?

Do you have a question about the A350T and is the answer not in the manual?

Questions and answers