Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tanco Autowrap A100 EH

- Page 1 A100 EH OPERATOR MANUAL V.02_EN Address Phone & Online Tanco Autowrap Ltd. Phone: + 353 59 972 1336 Royal Oak Road, Email: info@.itanco.com Bagenaltown Website: www.itanco.com Co. Carlow Support: tanco.zendesk.com Ireland...

- Page 2 A100-EH Tanco Autowrap Ltd congratulates you on your choice the safety instructions, before starting the machine. of the TANCO AUTOWRAP A100 EH bale wrapping Follow the instructions thoroughly, if problems machine. We are certain you will be satisfied with the...

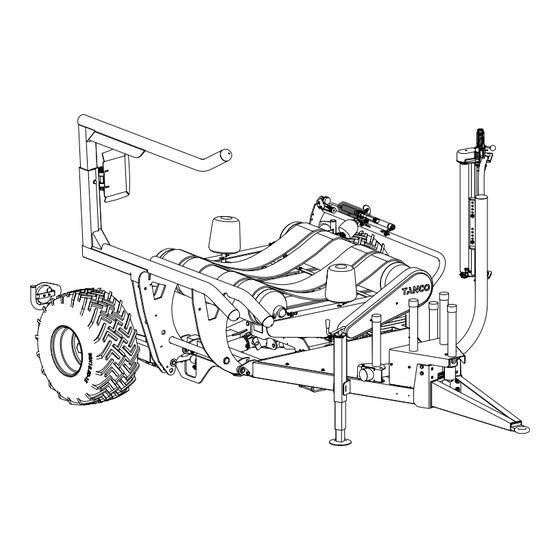

- Page 3 A100 EH Operator’s Manual 3 // Item No. Description Chassis Load Arm Bale Stop Turntable Dispenser Mounting Frame Dispenser Cut & Start Lights Jack Hitch...

-

Page 4: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS ............. . 4 SAFETY DECALS . -

Page 5: Safety Decals

SAFETY DECALS Areas which cannot be protected by devices are and follow these declas. If for any reason a decal is clearly marked by safety decals. It is important missing or is damaged please contact you TANCO that all users of the this machine fully understand dealer for replacements. - Page 6 A100 EH Operator’s Manual 6 // DECAL LOCATIONS & EXPLANATIONS No. Part Number Description CDE00016 Film Mounting CDE00017 Tighten Bolts CDE00019 70% Prestretch CDE00022 Read Operator Manual - Languages CDE00068 CDE00042 Chain Drive Hazard (13) CDE00068 CDE00051 Turn off Tractor...

-

Page 7: Technical Specifications

TECHNICAL SPECIFICATIONS Tanco Autowrap Ltd. reserves the right to modify the construction and/or technical specifications without warning and without rights to changes on already delivered products. TECHNICAL SPECIFICATIONS ........9... - Page 8 A100 EH Operator’s Manual 8 // TECHNICAL SPECIFICATIONS 4170 mm Height 2343 mm Width 2792 mm Length 4170mm Weight 1460 Kgs Wrapping Table Speed (Recommended) 28 R.P.M Wrapping Table Speed (max) 30 R.P.M. Maximum Bale Diameter 1500mm Maximum Bale Weight...

-

Page 9: Safety Precautions

SAFETY PRECAUTIONS Tanco Autowrap Ltd does not take responsibility for damages that may occur to machine, persons or other equipment, because of the machine NOT being used as described in this manual, or because of the safety precautions NOT being followed. -

Page 10: Safety Precautions

A100 EH Operator’s Manual 10 // SAFETY PRECAUTIONS BASIC PRINCIPLES 10. Special care should be taken when attaching or removing the machine from Before operating the machine, always ensure that the tractor and machine the tractor. meet with work safety and road traffic regulations. -

Page 11: Attaching Implements To Tractor

A100 EH Operator’s Manual 11 // SAFETY PRECAUTIONS 21. Do not stand between the tractor and the machine unless the hand break machine circuits are not under pressure. is tight and/or stops have been placed under the wheels. 4. It is strongly recommended that the operator marks the hydraulic 22. -

Page 12: Special Safety Instructions

A100 EH Operator’s Manual 12 // SAFETY PRECAUTIONS 5. It is forbidden to discard any oil, grease or filters. These must be given to waste disposal organizations to protect the environment. 6. Ensure platform rollers are parallel to Lift Arm before arm is raised. -

Page 13: Operating Safety Instructions

A100 EH Operator’s Manual 13 // SAFETY PRECAUTIONS OPERATING SAFETY INSTRUCTIONS 1. Operators should have their hands on the controls at all times when the machine is in use. 2. Autowrap control unit and level controls must remain in the tractor cap at all times. -

Page 14: Bale Wrapping

BALE WRAPPING BALE WRAPPING ..........16 BALE WRAPPING PRINCIPLES . - Page 15 A100 EH Operator’s Manual 15 // BALE WRAPPING BALE WRAPPING PRINCIPLES TYPES OF PLASTIC The advantages of round bale silage are many, and include fewer feed units, A good type of plastic with good adhesive properties, and which is a flexible harvesting system, large capacity and the possibility of selling feed recommended for bale wrapping, must be used.

- Page 16 A100 EH Operator’s Manual 16 // BALE WRAPPING STACKING / PROTECTION If bales are hard and well formed, they can be stacked vertically, but loose and misshapen bales with low solid content should not be stacked higher than one layer, as this could easily cause deformity and the danger of runoff will be increased.

-

Page 17: Machine Setup

MACHINE SETUP MACHINE SETUP ..........19 HITCHING THE MACHINE (SEE FIG. -

Page 18: Machine Setup

A100 EH Operator’s Manual 18 // MACHINE SETUP HITCHING THE MACHINE Before attempting to hitch the wrapper to the tractor remove the lower links of the tractor to avoid them touching the drawbar (1). The machine can be hitched to the tractor using the towing hook of the tractor. Prior to hitching to the tractor the correct height of the hitch eye (2) must be determined. -

Page 19: A100Eh Controller

A100 EH Operator’s Manual 19 // MACHINE SETUP A100EH CONTROLLER The A100EH electronic controller activates the automatic functions of the machine and also enables the operator to manually operate the machine. This unit should be mounted in the tractor cab within in reach and where it can be conveniently viewed by the operator. -

Page 20: Mounting Of Plastic Film

Pull the film from the roll and tie it to the bale. TANCO DUAL STRETCH DISPENSER All Tanco Autowrap machines are supplied with a patented dual stretch gear system. This system enables a quick change of stretch levels on the Film Dispenser. - Page 21 A100 EH Operator’s Manual 21 // MACHINE SETUP...

-

Page 22: Support Rollers

A100 EH Operator’s Manual 22 // MACHINE SETUP SUPPORT ROLLERS To allow for stability of the bale during the wrapping process the support rollers can be adjusted different sized bales. It is important that the support rollers are adjusted so that the bale is in the middle of the table. -

Page 23: Chain Tensioning (See Fig 6.11)

A100 EH Operator’s Manual 23 // MACHINE SETUP CHAIN TENSIONING The roller drive chain is located inside the plastic guard. To adjust the chain tension loosed the bearing mounting bolts (1). Use the adjusting screw (2) to move the bearing and so adjust the chain tension. Retighten the bearing mounting bolts. -

Page 24: Attaching The End Tip (Optional)

A100 EH Operator’s Manual 24 // MACHINE SETUP ATTACHING THE END TIP (OPTIONAL) 1. Allign the Pivot Profile holes (1) with the brackets on the wrapper chassis (2) 2. Put the Pivot Pin (3) through the holes and retain with an ‘R’ clip. -

Page 25: Controller Information

INFORMATION A100 EH Controller Please read and understand the instructions for using this The Tanco Autowrap Bale Wrap Controller enables the operator controller before operating the machine. to monitor and control the operation of the bale wrapper at any This controller is fitted with a push-button type On/Off stage of the wrapping cycle. -

Page 26: Controller Information

A100 EH Operator’s Manual 26 // CONTROLLER INFORMATION CONTROLLER MAIN OPERATING, FUNCTIONS & DISPLAY Display shows in the normal operating mode: Current No. of wraps Target No. of wraps Wrapping speed (rpm) Bale total (10 separate Emergency Stop/Emergency Stop(Press STOP switch to stop during the wrap cycle –... -

Page 27: The Display Menu

A100 EH Operator’s Manual 27 // CONTROLLER INFORMATION THE DISPLAY MENU The Display menu is divided into 3 sections. At the top level are the settings used during the daily work with the machine – i.e. Store totals, No. of Wraps, Debug information and Bale count down for service interval. - Page 28 A100 EH Operator’s Manual 28 // CONTROLLER INFORMATION Summary of the Display menu: PRESS TO CYCLE MENU Default Screen NOTE: ESC button will retutn to previous screen...

- Page 29 A100 EH Operator’s Manual 29 // CONTROLLER INFORMATION Selecting a Store Total There are 10 individual memory registers labeled ‘Store A’ to ‘Store J’ for bale totals. Each time a bale cycle is completed, the currently selected store total and the grand total increments by...

-

Page 30: Operation In Automatic Mode

A100 EH Operator’s Manual 30 // CONTROLLER INFORMATION AUTO OFFLOAD OPERATION IN AUTOMATIC MODE If Auto Off-Load (in Operator Setup) is set to ON the bale will be The controller is generally used in automatic mode. tipped off automatically without pressing the off-loading button. -

Page 31: Operation In Manual Mode

A100 EH Operator’s Manual 31 // CONTROLLER INFORMATION OPERATION IN MANUAL MODE ‘M’ on the display indicates that the controller is set in manual mode. If not, press L6 to select. In manual mode you have total control of every stage of the wrapping cycle. -

Page 32: Programmable Factors - Operator Level

A100 EH Operator’s Manual 32 // CONTROLLER INFORMATION PROGRAMMABLE FACTORS - OPERATOR LEVEL Parameter ¼ Turn Static Range Units Description Operator Menu Contrast 0-12 Set Screen Contrast Film Break On/Off Toggles Film Break sensing on/off AutoLoad On/Off Activate loading via autoloading sensor... -

Page 33: Electro-Hydraulics

A100 EH VALVE BLOCK AND VALVE LEAD LABELS ....... . . -

Page 34: Electro-Hydraulics

A100 EH Operator’s Manual 34 // ELECTRO- HYDRAULICS Electro-Hydraulics There are 3 basics, which must ALWAYS be followed if the machine is to function correctly. Working Pressure; 185 bar Free Return; Max 10 bar (Direct to Tank) Voltage; 12 V (Straight from Battery) -

Page 35: A100 Eh Electrical Schematic

A100 EH Operator’s Manual 35 // ELECTRO- HYDRAULICS Description A100 EH ELECTRICAL SCHEMATIC Expert Plus Controller Junction Box Autoload Sensor Cable Load Arm Sensor Table Tip Sensor Rotate Sensor Autoload Sensor 3 Way Amp Receptacle [LOAD ARM SENSOR] [TIP SENSOR]... -

Page 36: Junction Box Lid Label

A100 EH Operator’s Manual 36 // Tanco Expert A100/A200 Junction Box Wiring Label Part No. = Z785-784 issue 02 ELECTRO- HYDRAULICS This labels chart is linked to the latest microsoft excel table which Q:\Product information\Current Products\OEM\Tanco A100-A200 Expert (498)\Development Documents... -

Page 37: Hydraulic Circuit

A100 EH Operator’s Manual 37 // ELECTRO- HYDRAULICS HYDRAULIC CIRCUIT... - Page 38 A100 EH Operator’s Manual 38 // ELECTRO- HYDRAULICS Hydraulic Components Pos. Part No. Designation 2008250 A100EH Control Valve 1308075 In-line FIlter with Bypass and Indicator 1208250 3 Way Pressure Compensated Flow Regulator 2008151 Table Drive Motor Z01-03-1046 3/8" Speed control valve...

-

Page 39: A100 Eh Valve Block And Valve Lead Labels

A100 EH Operator’s Manual 39 // ELECTRO- HYDRAULICS A100 EH VALVE BLOCK AND VALVE LEAD LABELS LeadNo. Description Cut & Start Open Cut & Start Open Load Up Load Down Forward rotate Fast Speed Tip Up Reverse Rotation Master Valve (Powered For All Functions) -

Page 40: Sensor Locations And Setup

ELECTRO- HYDRAULICS SENSOR LOCATIONS AND SETUP Sensor Sensor Function Sensor Type Sensor Tip Color Sensor Setting Distance (x) Rotation Inductive Black Inductive Black Load Arm Inductive Green AutoLoad Inductive Green... -

Page 41: Troubleshooting & Maintenance

TROUBLESHOOTING & MAINTENANCE Check Points Prior to Troubleshooting There are some general check points that must be examined first if something is wrong with the machine. There are three basic assumptions that must be fulfilled for the machine to function properly; 1. - Page 42 A100 EH Operator’s Manual 42 // TROUBLESHOOTING & MAINTENANCE CHECK POINTS PRIOR TO TROUBLESHOOTING battery or bad wiring will result in the voltage dropping when the machine is working. The controller displays a battery warning when voltage is low. Oil Pressure...

- Page 43 A100 EH Operator’s Manual 43 // TROUBLESHOOTING & MAINTENANCE Area Problem Remedy Hydraulic Oil supply under high - Hydraulic feed or return couplings not properly engaged. pressure immediately - Hydraulic couplings connected to a double acting supply on the tractor and supply is in the wrong direction. This can cause the the tractor hydraulic poppet in the return coupling to lock closed.

- Page 44 A100 EH Operator’s Manual 44 // TROUBLESHOOTING & MAINTENANCE PERIODIC MAINTENANCE Nut & Bolts All nuts and bolts should be tightened after the first hour’s use, thereafter Bearings regularly. All ball-bearings are packed with grease, and do not need any more Road Wheels maintenance.

- Page 45 A100 EH Operator’s Manual 45 // TROUBLESHOOTING & MAINTENANCE LUBRICATION 1. Lift Arm Pivot Pins - Grease every 24 hours 2. Hydraulic Cylinders - Grease every 24 hours 3. Roller Drive Bearing - Grease every 24 hours 4. Drive Chain & Sprocket - Grease every 24 hours 5.

-

Page 46: Guarantee / Declaration Of Conformity

GUARANTEE / DECLARATION OF CONFORMITY GUARANTEE / DECLARATION OF CONFORMITY ......48 GUARANTEE ..............48 EC DECLARATION OF CONFORMITY . - Page 47 A100 EH Operator’s Manual 47 // GUARANTEE / DECLARATION OF CONFORMITY GUARANTEE upon discovery of the alleged defect written notification is sent to the Sellers Subject to hereunder provided, the sellers undertake to correct either by repair giving, at the same time, the name of the Buyer from whom the goods were...

- Page 48 A100 EH Operator’s Manual 48 // GUARANTEE / DECLARATION OF CONFORMITY EC DECLARATION OF CONFORMITY Manufacturer: Tanco Autowrap Ltd. Bagenalstown Co. Carlow IRELAND CERTIFIES THAT THE FOLLOWING PRODUCT: TANCO AUTOWRAP MODEL: A100 EH SERIAL NO: To which this declaration relates, corresponds to the essential requirements of the Directive 2006/42/EC.

- Page 49 CONTACT Address Phone & Online Tanco Autowrap Ltd. Phone: + 353 59 972 1336 Royal Oak Road, Email: info@.itanco.com Bagenaltown Website: www.itanco.com Co. Carlow Support: tanco.zendesk.com Ireland...

Need help?

Do you have a question about the A100 EH and is the answer not in the manual?

Questions and answers