ABB Power2 340-H44 Operation Manual

Hide thumbs

Also See for Power2 340-H44:

- Operation manual (116 pages) ,

- Operation manual (116 pages) ,

- Operation manual (116 pages)

Table of Contents

Advertisement

Quick Links

Turbo Systems Switzerland Ltd

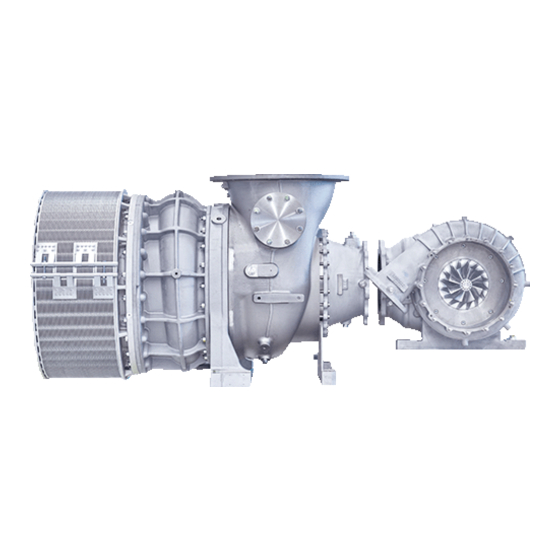

Operation Manual / Power2 340-H44

High-pressure stage PT004024

Document identification

Document number

Revision

Language

Product identification

Serial number

Customer part number

Delivery date (yyyy-mm-dd)

Weight

Operating limits according to rating plate

Speed limit in test rig operation only

Speed limit during operation

Gas inlet temperature limit in test rig operation only

Gas inlet temperature limit during operation

Compressor inlet temperature after intercooler

HZTL4054

F

English

Original Operation Manual

PT004024

1241495

2022-07-14

280

n

Mmax

n

Bmax

t

Mmax

t

Bmax

t

Cmax

kg

786

1/s

785

1/s

650

°C

650

°C

50

°C

Advertisement

Chapters

Table of Contents

Summary of Contents for ABB Power2 340-H44

- Page 1 Turbo Systems Switzerland Ltd Operation Manual / Power2 340-H44 High-pressure stage PT004024 Document identification Document number HZTL4054 Revision Language English Original Operation Manual Product identification Serial number PT004024 Customer part number 1241495 Delivery date (yyyy-mm-dd) 2022-07-14 Weight Operating limits according to rating plate...

-

Page 3: Table Of Contents

Commissioning after taking out of operation............44 Monitoring during operation................45 Lubricating oil pressure..................... 45 Lubricating oil temperature ..................46 Speeds........................... 47 Operation and service ..................50 Noise emission ......................50 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 4 Taking the engine out of operation for more than 12 months ......94 Material and Disposal..................95 12.1 REACH and RoHS Compliance Declaration For Products ........95 12.2 Disposing of low-pressure and high-pressure stage components ....96 Spare parts ......................97 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

- Page 5 Table of contents 13.1 Ordering spare parts....................97 13.2 Spare part – Illustrations ................... 99 Tools ........................110 Gas piping (option)..................... 111 Figures........................112 Tables ........................113 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 6: Introduction

Contact information for the Turbo Systems service stations is available online. Scan the QR code to access our website. Turbo Systems Switzerland Ltd Bruggerstrasse 71a CH-5401 Baden Switzerland www.abb.com/turbocharging © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 7: Essential Information

(see Contact information at www.abb.com/turbocharging). Accuracy of illustrations The illustrations in this document are general in nature and intended for ease of understand- ing. Differences in detail are therefore possible. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 8 Operation Manual / Power2 340-H / High-pressure stage 1 Introduction / 1.3 Essential information © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 9: Power2 Layout And Function

(26) into the compressor (21) of the high-pressure stage. Here the air or air/gas mixture is compressed further and leaves the two-stage turbocharging (Power2) in the direction of the charge air cooler. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 10: Layout And Function Of The High-Pressure Stage

03 Compressor casing Nozzle ring 04 Diffuser Support 05 Axial thrust bearing Turbine-end bearing flange 06 Bearing casing Turbine casing 07 Radial plain bearings Compressor-end bearing flange 08 Turbine Compressor wheel © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 11: Fig. 3: Function Of The High-Pressure Stage

The air is compressed further in the HP compressor (21) and the downstream diffuser (04) and sub- sequently supplied to the charge air cooler via the compressor casing (03). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 12: Symbols, Definitions

Official service stations are identified in this document as Turbo Systems service stations. These Turbo Systems service stations are regularly audited and certified by Turbo Systems Switzerland Ltd. See also chapter Contact information →4. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 13: Registered Trademarks

Dispose of in an environmentally compatible, professional way and in compliance with locally applicable regulations. Table 1: Definition of pictograms Registered trademarks The trademarks of outside companies are used in this document. These are marked with the ® symbol. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 14: Storage Of New Low-Pressure And High-Pressure Stages

Old VCI corrosion protection emitters must be disposed of in an environmentally compat- ible, professional way and in compliance with locally applicable regulations. Close the package. The more tightly the package is sealed, the longer the protection will last. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 15: Fig. 5: Package With Hygrometer

The corrosion protection effect ends after the material is unpacked from the VCI package. To avoid the formation of condensation, the surroundings and the content of the package must have the same temperature during unpacking. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 16: Safety

(see section Definition of safety instructions) must also be observed. CE conformity Information Low-pressure and high-pressure stages from Turbo Systems comply with the machinery dir- ective 2006/42/EC and are partly completed machinery as defined by Article 2 g. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 17: Definition Of Mandatory Signs

Non-compliance or inaccurate compliance with working or operating in- structions indicated by this symbol and the word CAUTION can lead to seri- ous damage to engine or property with grave consequences. Caution signs must always be observed. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 18: Intended Use

The Operation Manual ¡ The instructions of the enginebuilder State of the art The Power2 is designed and built according to the state of the art and is safe to operate. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 19: Deflagration On Gas Engines

This inspection and evaluation must be carried out by a Turbo Systems service station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 20: Warning Plates On The High-Pressure Stage

High and low-pressure stages supplied to the enginebuilder without insulation must be equipped later with warning plates to be attached to the insulation. This is the responsibility of the enginebuilder. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 21: Rating Plate Of The High-Pressure Stage

Year of construction of the low or high-pressure stage Weight of the low or high-pressure stage Part number of the customer of the low or high-pressure stage Table 7: Further data © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 22: Periodic Check Of The Pressure Vessels

Necessary repair or maintenance work must be performed promptly, and the required safety measures must be taken. Pressure equipment must not be operated if defects are present. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 23: Lifting Of Loads

The assembly devices must be completely screwed in and must not unscrew during use. Use assembly devices only for the described applications. Put down dismantled components of the low-pressure and high-pressure stage in such a way that they cannot tip over. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 24: Prerequisites For Operation And Maintenance

Power2 and can cause serious damage to property and injury to personnel. Only use original parts from Turbo Systems. Turbo Systems accepts no liability for any damage resulting from the use of non-original parts and corresponding accessories. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 25: Hazards During Operation And Maintenance

Wear heat-resistant safety gloves and protective clothing. Wait for the low-pressure and high-pressure stage to cool down before carrying out any work. Wear safety gloves to protect against thermal hazards. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 26 With the engine stopped, the rotor can rotate due to the stack draught alone. Operate the low-pressure and high-pressure stage in compliance with the specifications. Secure the rotor against unintentional rotation during maintenance. Wear safety gloves to protect against mechanical hazards. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 27: Safe Operation

In case of damage, take the Power2 out of operation immediately and safeguard against accidental/unauthorised use. When switching on operating energy supplies (hydraulics, pneumatics, electricity), pay at- tention to the risks that may occur as a consequence of this energy input. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 28: Safe Maintenance

Use of assembly devices Assembly devices are specially constructed and designed for the defined use; they are not commercially available products. Use assembly devices only for the described applications. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 29 Safety when taking out of operation or preparing for mothballing Observe the material safety data sheet for the cleaning and mothballing agents. Wear personal protective equipment (PPE) according to the material safety data sheet. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F...

- Page 30 Comply with local legislation. Do not allow any exposed flame or ignition source during cleaning work. Carry out cleaning in the open or provide sufficient ventilation. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

- Page 31 Dispose of insulation materials properly and in an environmentally com- patible manner in compliance with the legal regulations. Wear safety goggles. Wear a respiratory mask to protect against dusts. Wear safety gloves to protect against chemical hazards. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 32: Removal And Installation

Depending on the specification, the weight specified on the rating plate may be lower than the standard values specified here. Fig. 12: Transport Weight 280 kg Table 9: Weight of complete high-pressure stage © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 33: Removing The High-Pressure Stage

4. Attach lifting gear to high-pressure stage with two swivel lifting eyes (03). 5. Loosen and remove the fixing screws (02) of the support (61300). Loosen the clamping nuts (42201) in accordance with the following section. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 34: Fig. 14: Loosening The Clamping Nut

3. Working in a circle, loosen each pressure screw by 90° in 1…5 rounds until all of the pres- sure screws have been relieved. Loosen clamping nut by hand. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 35: Fig. 15: Removing The High-Pressure Stage

5. Screw down clamping nuts (42201) to the end of the expansion bush (42190). The threaded rod remains in position. 6. Remove the high-pressure stage. 7. Cover the oil connections (01) in the bracket to protect them from dirt. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 36: Installing The High-Pressure Stage

Bearing casing 42198 O-ring 42199 O-ring Oil supply Oil drains The oil is supplied (01) and drained (02) through the bracket. Insert the O-rings (42198 and 42199) into the slots of the bearing casing. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 37: Fig. 17: Preparing The Fastening Elements Of The High-Pressure Stage

4. Lead threaded rod (42191) with screwed-on clamping nut through thrust washer, expan- sion bush and bearing casing. 5. Screw the centering bush (42193) flush onto the threaded rod from below. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 38: Fig. 18: Placing The High-Pressure Stage On The Bracket

Step 1. Observe the steps for fastening the high-pressure stage (see following section). Value X Value L 106 ±2 mm 60 mm Table 10: Values X and L © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 39: Fig. 19: Steps For Fastening The High-Pressure Stage

Steps for fastening the high-pressure stage Fig. 19: Steps for fastening the high-pressure stage 1. Tighten the clamping nuts (42201) (see section Tightening the clamping nut). 2. Connect the cable connector (86515) to the speed sensor. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 40: Fig. 20: Steps For Fastening The High-Pressure Stage

3. Fit the support (61300) using the fixing screws (01). Observe tightening torque. 4. Tighten the screw (61003) of the connection between gas outlet casing (61001) and sup- port (61300). Connect all gas pipes and air lines. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 41: Fig. 21: Preparing The Clamping Nut For The Tightening Procedure

4. Tighten clamping nut (03) by hand. 5. Unscrew clamping nut (03) by ¼ of a turn (90°). The distance between the thrust washer and the clamping nut is now about 1 mm. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 42: Fig. 22: Tightening Pressure Screws

4. Work in a circle to tighten all pressure screws to 100 % of the tightening torque specified in the table. 5. Tighten pressure screws to 100 % in 5 … 7 rounds until the required residual tightening angle of < 20° is achieved. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 43: Commissioning

With an oil inlet pressure of more than 3 bar (when engine under load) before the high-pres- sure stage, the bearing casings are equipped as standard with an orifice at the oil inlet. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 44: Inspection Procedures

Check the oil pressure in the oil supply pipes. Warning plates Check whether warning plates are present and legible. Check whether the protective sheets have been removed from new warning plates. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 45 Con- tinual escape of an oily fluid indicates a possible oil leak. In the event of a leak, contact a Turbo Systems service station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F...

-

Page 46: Commissioning After Taking Out Of Operation

Put engine-side oil circulation to the low-pressure and high-pressure stage into opera- tion. Prepare the low-pressure and high-pressure stage for operation according to section Checks before commissioning. The low-pressure and high-pressure stage is now operational. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 47: Monitoring During Operation

Warning signal: (n ≥ 0.5 x n 0.5 < p ≤ 1.25 Bmax Alarm signal: Not admissible. Stop the engine immedi- 0.0 < p ≤ 0.5 ately. Table 13: Lubricating oil pressure at oil inlet upstream of the turbocharger © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 48: Lubricating Oil Temperature

If the low-pressure or high-pressure stage has been operated outside of the admissible range for a long period of time, Turbo Systems recommends having the low-pressure or high-pressure stage inspected by an Turbo Systems Service Station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 49: Speeds

42188 Screw plug 86515 Cable connector 42189 Gasket 86526 F/I converter Plug with integrated voltage limiter 86528 Tachometer Alternative mounting position for speed sensor 32109 Sealing disc with cams © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 50 If the engine can be stopped temporarily: Inspect air lines, exhaust gas pipes and the low-pressure and high-pressure stages and remedy any malfunctions. In any case, contacting the nearest Turbo Systems service station is recommended. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

- Page 51 Switch on lubricating oil supply to the low-pressure or high-pressure stage. 5.3.5 Malfunction of the speed measurement system The possible reasons for malfunction of the speed measuring system are described in chapter Troubleshooting / Speed measurement system →68. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 52: Operation And Service

Directive 2006/42/EC, 1.7.4.2 / u / Paragraphs 5 + 7: A-weighted emission sound pressure level The enginebuilder must provide acoustically equivalent measures in case of deviating in- sulation versions © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 53: Fig. 25: Noise Insulation, Bellows

Suggestion for noise insulation, bellows Fig. 25: Noise insulation, bellows Compressor casing Bellows Charge air duct / scavenging air duct Insulation cushion Insulation mat (at least 15 mm) Sheet metal cover © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 54: Service Work

Service work according to instructions of enginebuilder Clean or replace the oil filter located in the supply pipe to the low-pressure and high-pres- sure stage while the engine is stopped. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 55 Air temperature before and after the compressor and after the charge air cooler ¡ Exhaust gas temperature before and after the turbine ¡ Atmospheric humidity of the suction air (before the low-pressure stage) © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 56: Expected Replacement Intervals

12000 … 24000 Other casings 50000 Table 16: Expected replacement intervals [h] = Gas = Marine Diesel Oil The specified values are guideline values and are not guaranteed, see influencing paramet- ers. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... - Page 57 ¡ Lubricating oil quality (oil filtering, oil condition, oil monitoring) ¡ Load profile (speed, pressure conditions, temperature) ¡ Number of starts/stops ¡ Unbalance of the rotor (degree of contamination). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022...

-

Page 58: Stopping The Engine

[°C] [bar] ≥ 550 imperative 15 … 20 0.5 < p ≤1.0 < 550 necessary until the ro- 0.5 < p ≤1.0 tor comes to a stand- recommended still Table 17 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 59: Periodic Maintenance

LP compressors as well as the parallel clean- ing of the HP compressors. This cleaning process is faster and reduces the risk of surging of the low-pressure and high- pressure stages. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 60: Cleaning The Compressor During Operation

The water does not act as a solvent. The coating is removed by the mechanical action of the impacting droplets. The process is particularly suitable as long as the fouling is not too ad- vanced. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 61: Table 19: Parameters For Wet Cleaning Of Compressor

The cleaning process can be repeated up to three times. The success of the cleaning can be recognised based on the charging pressure or the ex- haust gas temperature. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 62: Cleaning The High-Pressure Stage Bellows (If Present)

Always replace bellows with a damaged sealing point with a new bellows. Cleaning turbine and nozzle ring during operation Power2 340-H is carried out without turbine cleaning function. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 63: Troubleshooting

If there is any doubt about the extent of the rubbing, contact a Turbo Systems service station. ¡ Have a dimension check carried out by a Turbo Systems service station. Table 22: Malfunctions when starting – Rubbing of rotating parts © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 64: Malfunctions During Operation

Increase in low-pressure stage speed Possible causes Remedy Low-pressure Heavy contamination of the nozzle Contact a Turbo Systems service sta- stage ring tion Table 26: Malfunctions during operation – Power2 LP speed increases © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 65: Table 27: Malfunctions During Operation - Power2 Hp Speed Increases

Cooling water volume too low Fill cooler Inlet temperature of cooling water Check/clean cooling system too high Insufficient ventilation Improve ventilation Table 28: Malfunctions during operation – Exhaust gas temperature too high © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 66: Table 29: Malfunctions During Operation - Charge Air Pressure Too Low

Set correctly Engine performance higher than ex- Check engine performance pected Low-pressure Manometer display not correct Replace manometer high-pressure stage Table 30: Malfunctions during operation – Charge air pressure too high © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 67: Table 31: Malfunctions During Operation - Compressor 1 Contamination

Contact a Turbo Systems service sta- tion Table 33: Malfunctions during operation – Blow-by too high © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 68: Surging Of The Low-Pressure Or High-Pressure Stage

A surge blow is accompanied by a loud bang and escape of hot air or air/gas mixture from the filter silencer of the low-pressure stage. There is no escape of air or air/gas mixture from the high-pressure stage. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 69: Malfunctions When Stopping

Clean Bearing damaged Contact a Turbo Systems service sta- high-pressure tion Rotor rubbing stage Foreign object in the pressure stage Table 36: Malfunctions when stopping – Runout time too short © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 70: Speed Measurement System

Table 39: Speed measurement – speed too low Other causes of malfunction If none of the measures described above remedy the malfunction, have the speed measure- ment system checked by a Turbo Systems service station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 71: Disassembly And Assembly

Tightening torques for assembly devices Unless otherwise described, the screws and nuts of the assembly devices supplied by Turbo Systems must be tightened in such a way that they are tight-fitting. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 72: Material Required

Identification of the assembly devices Not all assembly devices are marked with a part number. Identification is guaranteed by the tool list. This list is enclosed with the toolbox. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 73: Fig. 27: Swivel Lifting Eye (Example)

Swivel lifting eyes are required for the safe lifting of loads, which are not supplied by Turbo Systems. Fig. 27: Swivel lifting eye (example) Thread M Length L Minimum load limit Quantity 21 mm 200 kg 13 mm 200 kg Table 40: Swivel lifting eyes © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 74: Weights Of Assemblies

Bellows Compressor casing Wall insert Diffuser Cartridge group Nozzle ring Turbine casing Gas outlet flange Radial gas outlet casing Support Axial gas outlet casing Table 41: Weights of the assemblies © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 75: Removing The Gas Outlet Casing

4. Loosen nuts (51009) and remove with Verbus Ripp® washers (51004) and lugs (51015). 5. Remove the gas outlet casing (61001). 6. Remove the metal C-rings (57004) and (51026). Measure clearance R (see Measuring radial clearances N and R →85). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 76: Removing Air Inlets

3. Remove the bellows (82300) together with the radial air suction branch (82000) or the axial air suction branch (82000) with the O-ring (82010), respectively. Measure clearance N (see Measuring radial clearances N and R →85). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 77: Removing The Compressor Casing

2. Screw two swivel lifting eyes (01) into compressor casing (72000) and secure lifting gear. 3. Remove compressor casing (72000) and place on soft surface. 4. Loosen nuts (77022) and remove with washer (77021). Wall insert (77000) is loose. 5. Remove the O-ring (77005). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 78: Removing The Cartridge Group

If an oil orifice is fitted in the oil inlet of the bearing casing, it must not be removed. Oil orifice in the bearing casing 01 Bearing casing 02 Oil orifice 03 Circlip © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 79: Fig. 32: Removing The Cartridge Group

7. Hand-tighten the cartridge group with the threaded rod (42191) and the clamping nut (42201) on the service support (90012). 8. Remove the metal C-ring (51105). Measure axial clearance A and radial clearance B (see Measuring clearance A and B →86). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 80: Fig. 33: Removing The Gas Outlet Flange / Nozzle Ring

6. Remove the gas outlet flange (57002). 7. Remove the lamellar sealing ring (56005) from the nozzle ring and replace it with a new one after cleaning the nozzle ring. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 81: Installing The Cartridge Group

1. Measure dimensions A, B, and S on cleaned surfaces. 2. Calculate compression (PD). If the calculated value (PD) lies outside the specified range, contact a Turbo Systems ser- vice station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 82: Fig. 35: Installing The Gas Outlet Flange / Nozzle Ring

(see above illustration). 6. Insert the nozzle ring into the turbine casing as far as it will go and check for correct pos- itioning, chamfering (02). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 83: Fig. 36: Installing The Cartridge Group

5. Move cartridge group into turbine casing. When doing this, ensure that the metal C- ring (51105) is not crushed at one side. 6. Secure fastening strips (51002) together with nuts (51007) and secure and tighten the Verbus Ripp® washers (51003). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 84: Installing The Compressor Casing

4. Thoroughly clean the fastening strips (72012) before assembly. 5. Fit the diffuser (79000) with screw (42007). 6. Insert new O-ring (42012). 7. Position compressor casing (72000) on cartridge group (10900). 8. Fit the fastening strips (72012) with screws (72011) and tighten. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 85: Installing The Air Inlets

Table 46: Tightening torque (72013) 1. Install the radial air suction branch (82000) with the bellows (82300) or the axial air suc- tion branch together with the O-ring (82010), respectively. 2. Tighten screw (72013). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 86: Installing The Gas Outlet Casing

6. Fit gas outlet casing (61001) with lugs (51015), Verbus Ripp® washers (51004) and nuts (51009) and tighten. 7. Fit support (61300) with Verbus Ripp® washer (61004) and screw (61003) and tighten. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 87: Measuring Radial Clearances N And R

Serious damage to engines or property can be caused by clearances outside the tolerance and excessively worn parts. Have the components assessed and, if necessary, replaced by a Turbo Systems service station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 88: Measuring Clearance A And B

Serious damage to engines or property can be caused by clearances outside the tolerance and excessively worn parts. Have the components assessed and, if necessary, replaced by a Turbo Systems service station. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 89: Table Of Tightening Torques

40 Nm 42007 25 Nm 72011 75 Nm 42009 20 Nm 51007 45 Nm 51005 25 Nm 51009 45 Nm 51028, 61005 M18x1.5 60 Nm 61003 180 Nm 86505 M12x1.5 15 Nm 42188 M12x1.5 35 Nm Table 50: Tightening torques [Nm] © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 90: Taking Out Of Operation At Short Notice

If a replacement cartridge group is not available: Fit the cover plate and contact a Turbo Systems service station. Observe the following sections in connection with the emergency repairs mentioned. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 91: Installing A Replacement Cartridge Group

For information on how to remove and install the cartridge group, see chapter Disas- sembly and assembly. Send the defective cartridge group to a Turbo Systems service station for inspection and repair. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 92: Fitting The Cover Plate

4. Fasten cover plate (01) to turbine casing (51000) with fastening strips (51002), Verbus Ripp® washers (51003) and nuts (51007) and screw to bracket. Part number Tightening torque [Nm] 51007 Table 51: Tightening torque (51007) © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 93: Cover Plate Drawing

Material: General structural steel, in accordance with DIN EN 10025-2. Fig. 44: Cover plate drawing ØD1 ØD2 ± 0.5 ± 0.2 ± 0.2 82.5 47.9 251.2 ≤ 115 Table 52: Cover plate dimensions [mm] © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 94: Fig. 45: Figure For Cover Plate, Slots For O-Rings

10 Taking out of operation at short notice / 10.4 Cover plate drawing Slots for O-rings in cover plate Fig. 45: Figure for cover plate, slots for O-rings 19.5 16.8 Table 53: Dimensions of cover plate, slots for O-rings [mm] © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 95: Mothballing The High-Pressure Stage

The rotor and bearing parts must be dismantled and subsequently refitted by a Turbo Systems service station. Clean all parts. Coat plain surfaces of steel and cast parts with anticorrosive oil. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 96: Taking The Engine Out Of Operation For More Than 12 Months

State of the mothballed low-pressure and high-pressure stage Check the low-pressure and high-pressure stage parts annually for corrosion If there are signs of rust: Thoroughly clean parts and renew corrosion protection. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 97: Material And Disposal

6c) Copper alloy containing up to 4 % lead by weight. The maximum concentration of lead and lead compounds for our products is known to reach max. 0.8 % (mass % in homogeneous material). © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F... -

Page 98: Disposing Of Low-Pressure And High-Pressure Stage Components

Wear safety gloves. Wear safety goggles. Wear a respiratory mask to protect against dusts. Wear safety gloves to protect against mechanical hazards. Dispose of thermal insulation as hazardous waste. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 99: Spare Parts

Dispose of placed and unusable parts in an environmentally-friendly and professional manner in accordance with the local regulations. Dispose of the packaging of new parts in an environmentally-friendly and professional manner in accordance with the local regulations. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 100: Table 54: Customer Spare Part Set (97070)

56005 Lamellar sealing ring 57004 Metal C-ring 77005 O-ring 82010 O-ring (only for P135) 61007 Metal C-ring (only for axial gas outlet casing) Table 54: Customer spare part set (97070) © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 101: Spare Part - Illustrations

42188 Hexagon-head screw 42189 Gasket 42190 Expansion bush 42191 Threaded rod 42193 Centering bush 42196 Orifice oil inlet 42197 Safety ring 42198* O-ring 42199* O-ring 42201 Clamping nut Table 55 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 102: Table 56

42010* O-ring 42188 Hexagon-head screw 42189 Gasket 42196 Orifice oil inlet 42197 Safety ring 42301 Bearing cover 42304* O-ring 42400 Heat shield 42402 Heat sheet metal 79000 Diffuser Table 56 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 103: Table 57

Sealing disc 32110 Bearing flange 32112 Bearing flange 32113* Socket screw 32114* Socket screw 32115 Hexagon-head screw 32116 32167* Snap ring 32175* O-ring 42002 Socket screw 42302* Piston ring Table 57 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 104: Table 58

Hexagon nut 51015 Fastening strip 51026* Metal C-ring 51028 Screw plug 51105* Metal C-ring 56001 Nozzle ring 56005* Lamellar sealing ring 57002 Gas-outlet flange 57004* Metal C-ring 61072 V-clamp Table 58 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 105: Table 59

52120 Metall C-Ring 52125 Connection part 52130 Stud 52135 Hexagon nut 52140 Hexagon-head screw 52145 Extension sleeve 52150 Stud 52155 Hexagon nut 52160 Hex socket head cap screw Table 59 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 106: Table 60

* = Available within the spare part set HZTL443347 Mod. B Part no. Designation 61001 Gas outlet casing 61005 Screw plug 61007* Metal C-ring 61072 V-clamp 61205 Protective grid Table 60 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 107: Table 61

61205 61004 61300 61001 61005 HZTL443289 Mod. B Part no. Designation 61001 Gas-outlet casing 61003 Hexagon-head screw 61004 Verbusripp washer 61005 Screw plug 61205 Protective grid 61300 Support Table 61 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 108: Table 62

Compressor casing 72005 Screw plug 72006 Gasket 72011 Hexagon-head screw 72012 Fastening strip 72013 Hexagon-head screw 72014 Washer 77000 Wall insert 77005* O-ring 77022 Hexagon nut 81080 Warning plate Table 62 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 109: Table 63

82008 82010* 82000 * = Available within the spare part set HZTL443285 Mod. A Part no. Designation 82000 Air suction branch 82007 Screw plug 82008 Gasket 82010* O-ring Table 63 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 110: Table 64

Part no. Designation 82000 Air suction branch 82007 Screw plug 82008 Gasket 82021 Washer 82022 Hexagon-head screw 82130 Insulation cushion 82140 Cleaning nozzle 82145 Verbusripp washer 82300 Compensator Table 64 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 111: Table 65

13 Spare parts / 13.2 Spare part – Illustrations Speed measurement system 86528** 86526** 86505 86515 ** = if provided HZTL443348 Mod. A Part no. Designation 86505 Speed sensor 86515 Cable connector 86526** F/I-converter 86528** Tachometer Table 65 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 112: Tools

This tool set can be ordered from any Turbo Systems Service Station. The following specific- ations must be included in the order: ¡ Equipment type ¡ Designation and part number of the tool set. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 113: Gas Piping (Option)

Operation Manual / Power2 340-H / High-pressure stage 15 Gas piping (option) / Gas piping (option) The gas piping documentation can be found in the Operation Manual of the Power2 low- pressure stage. © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Rev.F March 2022... -

Page 114: Figures

Fig. 26: Bellows ............. 60 Fig. 27: Swivel lifting eye (example)......71 Fig. 28: Weights of the assemblies ......72 Fig. 29: Removing the gas outlet casing....73 Fig. 30: Removing the air inlets ......... 74 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Revision F March 2022... -

Page 115: Tables

Table 50: Tightening torques [Nm]......87 HP speed reductions ........... 62 Table 51: Tightening torque (51007)......90 Table 26: Malfunctions during operation – Power2 LP speed increases ............62 Table 52: Cover plate dimensions [mm]....91 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Revision F March 2022... - Page 116 Table 58 ................ 102 Table 59 ................ 103 Table 60................ 104 Table 61 ................ 105 Table 62 ................ 106 Table 63 ................. 107 Table 64................ 108 Table 65 ................ 109 Table 66: Customer tool set 90000......110 © Copyright 2022 ABB. All rights reserved. HZTL4054_EN Revision F March 2022...