Summary of Contents for Emerson Rosemount 3812

- Page 1 Maintenance and Troubleshooting Manual 00809-0100-3812, Rev AA April 2022 ™ Rosemount 3812 Liquid Ultrasonic Flow Meters for Direct or Remote Mount Meter Electronics...

- Page 2 Emerson employees. Emerson will not accept your returned equipment if you fail to follow Emerson procedures. Return procedures and forms are available on our web support site at Emerson.com, or by phoning the Emerson Customer Service department.

-

Page 3: Table Of Contents

3.11 Meter sealing.........................117 Appendix A Conversion factors....................127 A.1 Conversion factors per units of measurement................. 127 A.2 K-Factor and inverse K-Factor....................128 Appendix B Engineering drawings.................... 129 B.1 Rosemount 3812 Liquid Ultrasonic Flow Meter drawings............129 Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 4 Contents Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Emerson.com/Rosemount...

-

Page 5: Chapter 1 Routine Maintenance

00809-0100-3812 April 2022 Routine Maintenance Meter maintenance This section includes discussion of the maintenance of Rosemount 3812 Series Ultrasonic Meters. For reference, you may download the MeterLink Quick Start Manual from: http://www2.emersonprocess.com/en-US/brands/Flow/ultrasonics/Pages/Ultrasonic.aspx MeterLink may be downloaded at no charge from: https://www.emerson.com/en-us/catalog/rosemount-sku-meterlink-diagnostics-... -

Page 6: Field Hydrostatic Pressure Testing Procedures

Field hydrostatic pressure testing procedures The Rosemount 3812 Liquid Ultrasonic Flow Meter can be field hydrostatic tested without any special preparations or disassembly. The transducers are not exposed to the process pressure and can remain installed in the meter. -

Page 7: Routine Maintenance

Preferably, collect the log files at several velocities within the operating range of the meter. This helps establish that the flow profile is relatively constant throughout the meters operating range (except velocities below 3 ft/sec where the profile may vary). Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 8 Trending the logs indicates changes from the original installation of the meter, or over time. Looking at a single inspection report, that is either collected monthly or quarterly, can give you an indication of the meter's health. Emerson.com/Rosemount...

- Page 9 Daily log - generated every 24 hours on the Contract Hour • Hourly log - generated every hour at the top of the hour • Event log - collects the alarm and event log records Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 10 April 2022 00809-0100-3812 Figure 1-3: Archive log collection parameters The logs may be collected in a single file or you can choose to collect one type of log. Each of the Meter Archive logs include the Meter Configuration file. Emerson.com/Rosemount...

- Page 11 Plugging hazard Pipeline cleaning and maintenance (“pigging operations”) through the ultrasonic meter is not recommended. The transducer ports may become plugged with debris and adversely affect the transducer’s signal strength. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 12 Routine Maintenance Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Emerson.com/Rosemount...

-

Page 13: Chapter 2 Troubleshooting

The alarms are shown with the primary causes listed first. Click the question mark, , next to the alarm to display a help topic related to the alarm and recommended actions to resolve the issue. Figure 2-2: Status Summary Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 14 The System alarm indicates a failure in the hardware that should be addressed by a service technician. This includes memory checksum errors and communication errors within the hardware. A Red LED indicates a System alarm condition. Collect a Maintenance log and an audit/alarm log and then, contact your Emerson Flow service representative. Emerson.com/Rosemount...

- Page 15 TCP/IP commands between MeterLink and the connected meter. For ® troubleshooting communications with the 475 Field Communicator for the HART Protocol, refer to Section 5 of the Emerson 475 Field Communicator User’s Manual, Rev D. Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 16: Troubleshooting The Meter

Emerson Flow service representative. Acquisition Module is not • Upgrade the firmware in the meter to the latest version compatible with firmware using MeterLink. Contact your Emerson Flow service representative to obtain the latest firmware. • Replace the Acquisition Module. Emerson.com/Rosemount... - Page 17 Check the CPU Module LED1 is on (either solid red or flashing green). If the LED is not on, check power to the meter — If the LED is on, check the Ethernet cable connections Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 18 Ensure that the meter is properly powered. MeterLink program • Ensure that the computer cable is properly connected and check your interface pins (RS-485 or RS-232). • Verify that the communication parameters of the MeterLink program are correctly set. • Check RS-485 or RS-232 communication. Emerson.com/Rosemount...

- Page 19 00809-0100-3812 April 2022 Table 2-1: Troubleshooting (continued) Error Recommended action(s) Cannot communicate with Field Refer to the Emerson 475 Field Communication User’s Manual, Communicator Rev D. This manual may be downloaded from the following location: http://www2.emersonprocess.com/en-US/brands/ Field-Communicator/Pages/Documentation.aspx Note The 375 Field Communicator is no longer available for purchase since the release of the 475 Field Communicator.

- Page 20 65 °C, you must remote mount the electronics off of the meter body. • Collect a Maintenance log using MeterLink while the meter is experiencing the issue and contact your Emerson Flow service representative. Flow pressure is outside the •...

- Page 21 If a flow computer is writing values to the fixed flow temperature, verify that the flow computer is still writing valid values without Modbus write errors. — Re-verify the temperature input settings are correct. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 22 If the database does need to be reinitialized, it could take up to five minutes. • After an upgrade, it is recommended to reconnect to the meter and repeat the Program Download process. Emerson.com/Rosemount...

- Page 23 11-36 VDC at the meter. • If this was a known power fail or restart of the meter, just acknowledge this alarm. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 24 StackSize until noise level decreases (settings can be 1 (none) 2, 4, 8, or 16). If increasing the StackSize is not successful, try turning on the filter or consult with Emerson Customer Support if you are unsure of how stacking a signal can affect the meter's operation.

- Page 25 Resolve and acknowledge active alarms as displayed on the Status Summary page. Click the Help button, , beside the alarm description to display information about the alarm and recommended actions to resolve the issue. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 26 (LA), and delay time). • If present, resolve transducer issues (failed transducer, cabling or debris buildup on the transducer face, or path length configured incorrectly). • Adjust SSMin or SSMax (consult a Emerson Flow service representative before making these adjustments). Emerson.com/Rosemount...

- Page 27 MeterLink Tools Menu Frequency output • Run the Frequency Outputs test. • If the output reads zero, you may require a pull up resistor 1.2kOHM, 0.5W. • Check frequency output from minimum to maximum values. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 28 • Check firmware revision and upgrade if necessary using MeterLink Tools → Program Download. • If the CPU Board LED 5 is not flashing green, replace Acquisition Module (see Replace the Acquisition Module for direct or remote mount electronics). Emerson.com/Rosemount...

- Page 29 11-36 VDC at the meter. • Collect an Archive event log (Audit log) using MeterLink. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 30 Dial-up Networking. If more than one modem driver is installed for a particular COM port, Dial-up Networking will always use the last driver installed regardless of what is selected. The only work around is to only install one modem driver per COM port Emerson.com/Rosemount...

-

Page 31: Troubleshoot Maintenance Log Files And Trend Files

Troubleshooting 00809-0100-3812 April 2022 on the PC at a time. Refer to the MeterLink Quick Start Manual (00809-0100-7630) for phone and modem details. The manual may also be downloaded from the Emerson website. Emersonprocess.com/en-US/brands/Flow/ultrasonics/Pages/Ultrasonic.aspx 2.2.3 Unable to connect to meter If you receive the error message “Unable to connect to meter”... - Page 32 Excel can be configured to allow MeterLink ® to run the Visual Basic script by following the instructions below. ® To enable Excel 2000 to work with MeterLink, Procedure 1. Select Tools → Macros → Security menu path. Emerson.com/Rosemount...

- Page 33 Figure 2-5: Excel 2000 Tools Menu 2. The Security dialog appears. Select the Trusted Sources tab. 3. Click the Trust access to Visual Basic Project radio button and click OK to apply your selections. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 34 Maintenance Logs or Trend files are not created ® To enable Excel 2007 to work with MeterLink, customize the Ribbon to include the Developer tab. ® Figure 2-7: Excel 2007 Tools Menu Procedure 1. Select Macro Security to access the Trust Center. Emerson.com/Rosemount...

- Page 35 It is not necessary to take action on this issue to use the Trend Maintenance Logs dialog, but you should be aware of possible slow downs if the issue is unresolved. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 36 Troubleshooting Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Emerson.com/Rosemount...

-

Page 37: Chapter 3 Meter Maintenance

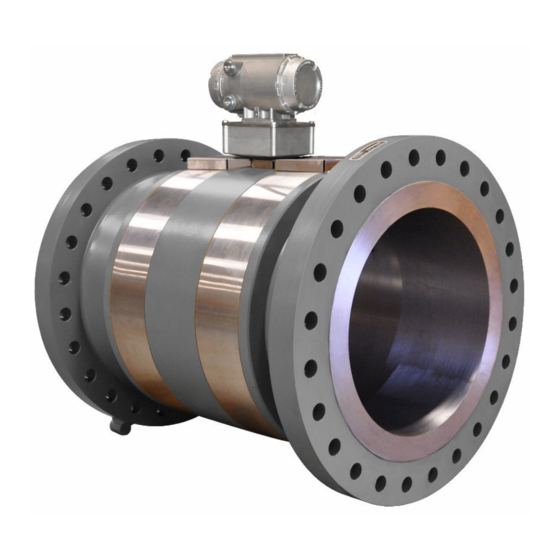

April 2022 Meter maintenance General maintenance tasks Rosemount 3812 Liquid Ultrasonic Flow Meters require minimal maintenance. The Meter Maintenance section discusses procedures to re-wet the transducers, replacing the transducer housings or transducers, and the Transmitter Electronics. Choose the section that details the specific meter (e.g. 2” - 3”, 4” - 10”, and 12” and larger sizes) for direct or remote mount transmitter electronics with a bolted band shroud, split shroud, band shroud or latched shroud. -

Page 38: Important Safety Information

Inserting the forks may cause the meter to become unstable, resulting in injury to personnel or damage to the bore and sealing face. CAUTION TRIPPING HAZARD Clear all obstacles or obstructions from the work area when transporting, installing or removing the meter. Failure to comply may cause injury to personnel. Emerson.com/Rosemount... - Page 39 Maintenance and Troubleshooting Manual Meter maintenance 00809-0100-3812 April 2022 NOTICE Prior to lifting the unit, refer to the Rosemount 3812 Liquid Ultrasonic Flow Meter nameplate or outline dimensional (general arrangement) drawing for the assembled weight. WARNING FLUID CONTENTS MAY BE UNDER PRESSURE When the meter is under pressure, DO NOT attempt to remove or adjust the transducer housing.

-

Page 40: 3812 Meter Options

Meter maintenance Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Consult your Emerson Sales and Service representative to ensure you purchase the correct components and seals for your application, below safety message. 3812 meter options Figure 3-1: Direct mount transmitter electronics options A. - Page 41 Table 3-9. • LT-10 transducers are designed for 2 through 10 inch meter sizes. • LT-11 transducers are designed for 12 inch and larger meters sizes. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 42 F. Transducer capsule and cable assembly (LT-10 P/N 1-360-01-624) or (LT-11 P/N 1-360-01-823) G. O-ring (part numbers vary with service conditions) H. Transducer housing: • LT-10 (P/N 1-360-01-632 for 900 ANSI 316L SS or P/N 1-360-01-633 Inconel) • LT-11 (P/N 1-360-01-819 for 900 ANSI 316L SS or P/N 1-360-01-818 Inconel) Emerson.com/Rosemount...

-

Page 43: Remove The Shrouds

Table 3-2: Band shroud removal tool list Tools required Standard ½ inch socket or a standard ½ inch wrench Appropriate personal protective equipment Figure 3-4: Bolted band shroud meter assembly - top view A. Bolted band shroud Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 44 Failure to comply may cause serious injury. Table 3-3: Clamped band shroud removal tool list Tools required Standard ½ inch socket or a standard ½ inch wrench Flat blade screw driver or 5/16 inch nut driver Appropriate personal protective equipment Emerson.com/Rosemount...

- Page 45 A. Top end shroud B. Front band shroud Figure 3-7: Clamped top end shroud assembly A. Top end shroud B. Top end shroud bolts Procedure 1. Remove top end band shroud security seals, if installed. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 46 To remove the worm screw clamp threaded part, move it to approximately perpendicular to the shroud and rotate slightly to release the "T" end from the rectangular hole in the shroud. Repeat this procedure for the second worm screw clamp threaded part. Emerson.com/Rosemount...

- Page 47 OD and raise the shroud end engaged with the guide pins enough to disengage the band shroud from the guide pins. Remove the nut part of the worm screw clamps following the same procedure described above. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 48 Place the band shroud assembly on its side edge on a flat surface. Move the back band shroud with respect to the front band shroud, freeing the sheet metal hem bend joint assembly. Emerson.com/Rosemount...

- Page 49 3.4.3 Remove split shrouds WARNING SHARP EDGES - CUTTING HAZARD Equipment may have sharp edges. Wear safety approved gloves, eye protection and shoes when disassembling the shrouds. Failure to comply may cause serious injury. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 50 4. Move the shroud assembly and bolts out of your immediate work area. This completes the split shroud removal procedure. 3.4.4 Remove latched band shrouds The latched band shroud is utilized on 2 inch to 10 inch ultrasonic flow meters. Emerson.com/Rosemount...

- Page 51 Band shrouds may have sharp edges. Wear safety approved gloves, eye protection and shoes when disassembling the shrouds. Procedure 1. If installed, remove the security wires and shroud latch retainers. 2. Lift the one of the shroud latches and slowly disengage the latch from the strike. Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 52: Re-Wet The Transducers

Dow Corning 200 is a trademark of Dow Corning Corporation, U.S.A. Procedure 1. Disassemble the shrouds. Refer to the appropriate sections below for your meter: • Remove bolted band shrouds • Remove clamped band shrouds • Remove split shrouds • Remove latched band shrouds Emerson.com/Rosemount... - Page 53 Figure 3-16: Feed-thru cable seal removal A. Feed-thru cable seal 4. Use the Retaining Ring pliers and remove the retaining ring, shoulder washer, and spring from the transducer housing. 5. Pull the transducer capsule from the housing. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 54 (12,500 Centistokes) (P/N 1-360-01-650) on the face of the transducer. Make sure the oil is evenly distributed across the transducer face. 7. Wipe excess oil from the transducer sides. Dow Corning 200 is a trademark of Dow Corning Corporation, U.S.A. Emerson.com/Rosemount...

- Page 55 Device Manager or a HART Field Communicator and select Overview → Zero Calibration → Start menu or Service Tools → Maintenance → Zero Calibration → Start. 15. Reinstall the shroud. To do so, go to: Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 56: Transducer Housings Or Housing Seals Replacement

FLUID CONTENTS MAY BE UNDER PRESSURE When the meter is under pressure, DO NOT attempt to remove or adjust the transducer housing. Attempting to do so may release pressurized fluid, resulting in serious injury for personnel or equipment damage. Emerson.com/Rosemount... - Page 57 The meter has not been drained and/or depressurized. 3. Disassemble the shrouds. Refer to the appropriate sections below for your meter: • Remove bolted band shrouds Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 58 Figure 3-21: Feed thru cable seal removal A. Feed thru cable seal 6. Use the Retaining Ring pliers and remove the retaining ring, shoulder washer, and spring from the transducer housing. 7. Pull the transducer capsule from the housing. Emerson.com/Rosemount...

- Page 59 If replacing the o-ring seal remove the used seal and discard. Apply Molykote grease to the new seal and install on the transducer housing. ® Dow Corning Molykote 111 is a trademark of Dow Corning Corporation, U.S.A. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 60 Install the retaining ring into the groove within the transducer housing while compressing the spring by applying force to shoulder washer. ® Dow Corning Molykote 111 is a trademark of Dow Corning Corporation, U.S.A. Dow Corning 200 is a trademark of Dow Corning Corporation, U.S.A. Emerson.com/Rosemount...

- Page 61 Calibration → Start. ™ ® 19. Close your application connection (MeterLink, AMS Device Manager or HART Field Communicator). 20. Reinstall the shroud: • Install bolted band shrouds • Install clamped band shrouds • Install split shrouds Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 62: Transducers Replacement

FLUID CONTENTS MAY BE UNDER PRESSURE When the meter is under pressure, DO NOT attempt to remove or adjust the transducer housing. Attempting to do so may release pressurized fluid, resulting in serious injury for personnel or equipment damage. Emerson.com/Rosemount... - Page 63 3/8 inch drive - at least 3.5 inch extension (89mm) with 7/16 (11mm) socket wrench 1/4 inch (7mm) flat-blade screw driver 1/8 inch (3mm) flat-blade screw driver (3mm) Allen wrench - size 3mm (Rosemount P/N 2-4-9200-501) Retaining ring pliers (Rosemount P/N 1-504-90-043) Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 64 Figure 3-24: Conduit removal A. Transmitter electronics enclosure B. Conduit gland fitting 4. Use a 7/16 inch (11mm) wrench and remove the four hex head bolts and split lock washers securing the Transmitter Electronics Enclosure to the Base Enclosure. Emerson.com/Rosemount...

- Page 65 Disconnect the transducer cable wires from the terminal blocks so that the cables can be removed from the meter. NOTICE Ensure the transducer cables are labeled for the chord configuration (A1, A2, B1 and B2). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 66 Acquisition Module from the Base Enclosure. 9. Remove the three Base Enclosure hex head bolts, shoulder washers, flat washers and split lock washers with a 7/16 inch (11 mm) socket wrench. Then remove the Base Enclosure from the meter body. Emerson.com/Rosemount...

- Page 67 12. If it is a band shroud meter, remove all foil tape from the body top and circular grooves and remove the cable from the grooves. Repeat this procedure for each transducer pair you are removing. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 68 Figure 3-29: Bolted band shroud transducer removal A. Base Enclosure B. Transducer cable with foil tape C. Transducer cable circular grooves D. Feed-thru cable seal 13. Use Retaining Ring pliers to pull the transducer feed-thru cable seal from the transducer housing. Emerson.com/Rosemount...

- Page 69 Figure 3-31: Feed thru cable seal removal A. Feed-thru cable seal 15. Use the Retaining Ring pliers and remove the retaining ring, shoulder washer, and spring from the transducer housing. 16. Pull the transducer capsule from the housing. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 70 1-360-01-650) on the face of the transducer to be installed. 19. Insert the transducer capsule into the transducer housing in the meter body. 20. Slide the spring and shoulder washer along the cable to the transducer capsule. Dow Corning 200 is a trademark of Dow Corning Corporation, U.S.A. Emerson.com/Rosemount...

- Page 71 At the meter top, position the cable in the body top cable groove and tape to hold. d) Ensure that a flat surface will be available for the band shroud to be installed without squeezing the transducer cable. e) Repeat for each transducer being replaced. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 72 A. Meter body top circular cable groove and foil taped cable B. Meter body circular cable groove C. Transducer cable D. Meter body transducer pocket 23. For split shroud meters only, feed the transducer cables through the hole in the upper split shroud on top of the meter body. Emerson.com/Rosemount...

- Page 73 26. Using tape, mark each transducer cable with the transducer location to identify which cable goes to which transducer (e.g., A1, A2, B1 and B2 are the transducer location identity names). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 74 29. Place the Acquisition Module into the Base Enclosure, align the thee holes of the Acquisition Module with the three holes in the base enclosure and secure with the three split lock washers and flat head screws (see Figure 3-39). Position the cables Emerson.com/Rosemount...

- Page 75 1/8 inch (3mm) flat blade screw driver and screw the terminal block onto the Acquisition Module for the corresponding transducer (A1, B1, A2, or B2). Make sure the transducer wires have good contact with the terminal block and the terminal block screws are tight. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 76 A. Transducer wiring terminal blocks B. Acquisition cable C. Acquisition Module D. Base enclosure O-ring E. Base Enclosure 34. When you have completed wiring the transducer cables to the Acquisition Module, check the Base Enclosure O-ring and reinstall it if necessary. Emerson.com/Rosemount...

- Page 77 (A1 and A2 or B1 and B2). Also, if a transducer pair is moved from one chord position to another, the transducer pair’s delay time and delta delay time configuration parameters must be properly re-configured. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 78 3. Remove the shrouds. Refer to the appropriate sections below for your meter: • Remove bolted band shrouds • Remove clamped band shrouds • Remove split shrouds • Remove latched band shrouds 4. Use Retaining ring pliers to pull the transducer feed-thru cable seal from the transducer housing. Emerson.com/Rosemount...

- Page 79 Figure 3-43: Feed thru cable seal removal A. Feed-thru cable seal 6. Use the Retaining Ring pliers and remove the retaining ring, shoulder washer, and spring from the transducer housing. 7. Pull the transducer capsule from the housing. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 80 Figure 3-44: Transducer removal A. Feed-thru cable seal B. Shoulder washer C. Spring D. Transducer capsule Figure 3-45: LT-10 Transducer and cable assembly removed from meter 8. Prepare to disassemble transducer cables from the terminal blocks inside the Junction Box. Emerson.com/Rosemount...

- Page 81 9. Pull the transducer cable for the transducer to be replaced, down through the foam feed-thru cable seal on and the base cover gasket. If a split shroud meter, pull cable through the top hole in top shroud (Figure 3-47). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 82 B. Transducer cable with foil tape C. Transducer cable circular grooves D. Feed-thru cable seal 10. Use a 7/16 inch (11 mm) wrench and remove the four hex head bolts and split lock washers securing the junction box cover. Emerson.com/Rosemount...

- Page 83 16. Make sure the cables are labeled for the correct transducer (A1, A2, B1, and B2). 17. Place one drop of Dow Corning 200 Silicon Oil (12,500 Centistokes) (P/N 1-360-01-650) on the face of the transducer to be installed. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 84 At the meter top, position the cable in the body top cable groove and tape to hold. d) Ensure that a flat surface will be available for the band shroud to be installed without squeezing the transducer cable. Repeat for each transducer being replaced. Emerson.com/Rosemount...

- Page 85 B. Meter body circular cable groove C. Transducer cable D. Meter body transducer pocket 22. For split shroud meters only, feed the transducer cables through the hole in the upper split shroud on top of the meter body. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 86 A. Upper Shroud B. Transducer cable 23. Carefully feed the transducer cables through the center of the Junction Box rubber gasket and the feed-thru foam cable seal and gasket, then into the hole in the bottom of the Junction Box. Emerson.com/Rosemount...

- Page 87 27. Reattach the Junction Box to the meter body with the three shoulder washers, flat washers, split lock washers and hex head bolts. Tighten the bolts with a 7/16 inch ® (11 mm) socket driver. Apply a light coat of Loctite 290 to the three bolts. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 88 Figure 3-54: Junction box assembly A. Junction box hex head bolts B. Junction box cover and gasket C. Terminal blocks D. Terminal block mounting plate E. Meter mount junction box F. Junction Box rubber gasket and feed-thru foam cable seal Emerson.com/Rosemount...

- Page 89 S-pin (Shield). Reattach the transducer cables to the terminal blocks with a 3 mm flat blade screw driver and screw the terminal block onto the Terminal block mounting plate for the corresponding chord (A1, B1, A2, or B2). Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 90: Meter Electronics Replacement

This completes the procedure for replacing the transducers on meters with remote mount transmitter electronics option. Meter electronics replacement The following procedure should be performed by a qualified service technician or trained personnel. Observe all warning before starting this procedure. Emerson.com/Rosemount... -

Page 91: Transmitter Electronics Maintenance

Ground Strap while handling the circuit boards. If one is not available, make sure you are electrically discharged before touching the boards by first touching a metal surface such as a ground lug on the meter body, piping or metal structure. Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 92 4. If replacing the CPU Module (located closest to the terminal end of the enclosure) or the Optional I/O Module, use a 3mm flat blade screw driver and disconnect the CPU Module terminal blocks (or the Optional I/O Module) terminal blocks). Note The Optional I/O Module is scheduled for future release. Emerson.com/Rosemount...

- Page 93 9. Close your application connection (MeterLink, AMS Device Manager or HART Field Communicator). 10. If you are not replacing other electronics, replace the end caps and security latches (requires a 3 mm Allen wrench). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 94 Replace the Acquisition Module for direct or remote mount electronics before replacing the end caps and sealing the enclosure. 12. If you encounter problems replacing the electronics, see the Emerson Customer Support contact information on the back cover of this manual. 3.9.2...

- Page 95 6. Pull the Backplane board out of the enclosure. This disconnects the I.S. Barrier Board. Lay the Backplane board down with the Acquisition Cable still attached (the Power Supply board may remain attached to the Backplane when you remove it from the enclosure). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 96 12. Install the four Phillips head screws to secure the Backplane to the enclosure standoffs. 13. Reinstall the terminal blocks on the CPU Module, Optional I/O Module, and the Power Supply board using a 3 mm flat head screw driver. Emerson.com/Rosemount...

- Page 97 Device Manager or HART Field Communicator). 20. This completes the Backplane board replacement procedure. If you encounter problems with this procedure, see the Emerson Customer Support contact information on the back cover of this manual. 3.9.4 Replace the I.S. Barrier board Procedure 1.

- Page 98 Zero Flow Calibration Wizard; select the Calibrate → Zero Calibrate menu and generate the report. Then, collect and save a Maintenance log to show the “as left” condition of the meter. Or use Emerson.com/Rosemount...

- Page 99 18. Apply power to the meter. This completes the I.S. Barrier Board replacement procedure. If you encounter problems with this procedure, see the Emerson Customer Support contact information on the back cover of this manual. 3.9.5 Replace the Power Supply Board Procedure 1.

- Page 100 Zero Flow Calibration Wizard; select the Calibrate → Zero Calibrate menu and generate the report. Then, collect and save a Maintenance log to show the “as left” condition of the meter. Or use Emerson.com/Rosemount...

- Page 101 16. Apply power to the meter. This completes the Power Supply Board replacement procedure. If you encounter problems with this procedure, see the Emerson Customer Support contact information on the back cover of this manual. 3.9.6 Replace the Acquisition Module for direct or remote...

- Page 102 A. Transmitter electronics enclosure B. Base enclosure bolts and security seals 5. For direct mount electronics, Use a 7/16 inch (11mm) wrench and remove the four hex head bolts and split lock washers securing the Transmitter Electronics Enclosure to the Base Enclosure. Emerson.com/Rosemount...

- Page 103 A. Transmitter electronics enclosure B. Base enclosure bolts C. Base enclosure For remote mount electronics, if necessary, loosen the mounting bracket bolts and lower the Transmitter Electronics Enclosure and the Base Enclosure to a suitable working level. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 104 6. Use a 7/16 inch (11mm) wrench and remove the four hex head bolts and split lock washers securing the Base Enclosure. 7. Use a 1/8 inch (3 mm) flat head screw driver and disconnect the Acquisition cable terminal block and the transducer wire terminal blocks from the Acquisition Module inside of the Base enclosure. Emerson.com/Rosemount...

- Page 105 Base unit to the its original height and retighten the mounting bracket bolts. 13. Retighten or reattach the conduit to the Transmitter Electronics Enclosure using a crescent wrench or channel lock pliers. Apply conduit sealing compound according to manufacturer’s recommendations. Rosemount 3812 Liquid Ultrasonic Flow Meter...

-

Page 106: Shrouds Installation

Acquisition cable from the Acquisition Module in the Base Enclosure. Emerson recommends that you contact Emerson Customer Support (see contact information on the back cover of this manual) if you need to replace the Acquisition cable. - Page 107 3. Align the hole near the end of the shroud with the tapped hole in the body OD and insert the bolt with lock washer into the meter body hole. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 108 This completes the assembly of the bolted band shrouds. 3.10.2 Install clamped band shrouds WARNING CUTTING HAZARD Sharp edges may be present on the band shrouds. Wear appropriate personal protective equipment when working on the meter. Failure to comply may cause serious injury. Emerson.com/Rosemount...

- Page 109 2. One end of the clamped band shroud assembly has two holes which will engage guide pins and rectangular shaped holes. Assemble one nut end of a worm screw clamp into one of these rectangular holes. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 110 Align the guide pin holes in the shroud with the guide pins in the body and hold this band shroud end against the body outside diameter. Emerson.com/Rosemount...

- Page 111 Reposition the misaligned band. 7. Install the top end shroud cap over the the worm screw clamps and insert the end shroud pins into the Base electronics shroud. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 112 Wear appropriate personal protective equipment when working on the meter. Failure to comply may cause serious injury. Procedure 1. For direct mount electronics, install the upper split shroud during the assembly of the Base Enclosure or, for remote mount electronics, during the junction box assembly. Emerson.com/Rosemount...

- Page 113 Refer to Meter sealing for detailed sealing instructions. This completes the split shroud installation procedure. 3.10.4 Install latched band shroud Latched band shrouds are utilized on 2 inch to 10 inch ultrasonic meters. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 114 If required, install the latch security wires. Before starting shroud assembly, check around the body outside diameter to be sure all of the transducer cables are positioned so the shroud does not pinch or crimp the cables. Emerson.com/Rosemount...

- Page 115 Step 5 for the other band shroud. 7. Visually inspect the shrouds covering for proper fit on the meter body. Ensure the bands are flush against the body shoulders and the latches are evenly aligned. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 116 (maximum wire diameter .078 inch; 2.0 mm). 9. Remove all slack and seal. 10. Cut wire ends to remove excess wire. 11. Repeat these steps for the other shroud latch. This completes the split shroud security seal installation procedure. Emerson.com/Rosemount...

-

Page 117: Meter Sealing

2. Install the security seal wire into and through one of the two holes in the end cap. Choose holes that minimize counterclockwise rotation of the end cap when the security wire is taut (maximum wire diameter .078 inch; 2.0 mm). Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 118 Use the following instructions to install the security seal wire on the Base Enclosure. Procedure 1. Install security wire seal into and through two of the four the holes in the socket head screws on the Base Enclosure cover (maximum wire diameter .078 inch; 2.0 mm). Emerson.com/Rosemount...

- Page 119 Use the following instructions to install the security seal wire on the junction box, if required. Procedure 1. Install security wire seal into and through two of the four the holes in the socket head screws on the Junction Box cover (maximum wire diameter .078 inch; 2.0 mm). Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 120 Security seals protect the integrity of the meter metrology and prevent tampering with transducer assemblies. The following sections detail how to properly seal the Rosemount 3812 Liquid Allocation Ultrasonic Flow Meter after commissioning or maintenance procedures. The security seal wires are commercially available. Emerson.com/Rosemount...

- Page 121 Clamped band shroud security seals Use the following instructions to install the security seal wires, if required, on the two top end shrouds covering the worm screw clamps. This procedure applies to clamped band shroud meters. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 122 4. Cut wire ends to remove excess wire. This completes the clamped band shroud security seal installation procedure. Split shroud security seals Use the following instructions to install the security seal wires on the split shroud covering the meter body and transducer assemblies. Emerson.com/Rosemount...

- Page 123 This completes split band shroud security seal installation procedure. Latched band shroud security seals Use the following instructions to install the security seal wires on the latched band shrouds covering the meter body and transducer assemblies. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 124 D. Meter body recess for pop rivet allowance E. Meter body shoulder F. Shroud latch Procedure 1. Install the security seal wire into and through the holes in one of the shroud latches (maximum wire diameter .078 inch; 2.0 mm). Emerson.com/Rosemount...

- Page 125 B. Right shroud holes for security wires 2. Remove all slack and seal. 3. Cut wire ends to remove excess wire. 4. Repeat these steps for the other shroud latch. This completes the latched shroud security seal installation procedure. Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 126 Meter maintenance Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Emerson.com/Rosemount...

-

Page 127: Appendix A Conversion Factors

Conversion factors Conversion factors per units of measurement The following table includes conversion factors for many of the Metric and U.S. Customary units of measure used with Rosemount 3812 Liquid Allocation Ultrasonic Flow Meters and ™ MeterLink Table A-1: Conversion factors per units of measurement... -

Page 128: K-Factor And Inverse K-Factor

= 60 s/m • volume/hour = 3600 s/h • volume/day = 86400 s/d (**) Volume = where the volume is selected via data points: • Units System • VolUnitUS — gallons — barrels • VolUnitMetric — cubic meters — liters Emerson.com/Rosemount... -

Page 129: Appendix B Engineering Drawings

Maintenance and Troubleshooting Manual Engineering drawings 00809-0100-3812 April 2022 Engineering drawings Rosemount 3812 Liquid Ultrasonic Flow Meter drawings This appendix contains the following engineering drawing(s) for the ultrasonic meter: DMC-004936 Rosemount 3810 Liquid Ultrasonic Flow Meter System Wiring Diagram Rosemount 3812 Liquid Ultrasonic Flow Meter... - Page 130 Engineering drawings Maintenance and Troubleshooting Manual April 2022 00809-0100-3812 Emerson.com/Rosemount...

- Page 131 Maintenance and Troubleshooting Manual Engineering drawings 00809-0100-3812 April 2022 Rosemount 3812 Liquid Ultrasonic Flow Meter...

- Page 132 2022 Emerson. All rights reserved. Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a mark of one of the Emerson family of companies. All other marks are the property...

Need help?

Do you have a question about the Rosemount 3812 and is the answer not in the manual?

Questions and answers