Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Delem DA-56

- Page 1 Delem DA-56 Reference Manual Operation of Version V1 Manual version V0505...

- Page 2 PREFACE This manual describes the operation of the Delem controller type DA-56 and is meant for operators who are instructed for operation of the total machine. Only authorised people should be able to create new or edit existing programs, as well as pro- gramming or editing of the tooldata.

-

Page 3: Table Of Contents

1.8. Delem Limited warranty ........ - Page 4 4. Product selection ........4.1 4.1.

- Page 5 Delem • Corrections ..........9.4 •...

- Page 6 V0505, 0.6...

-

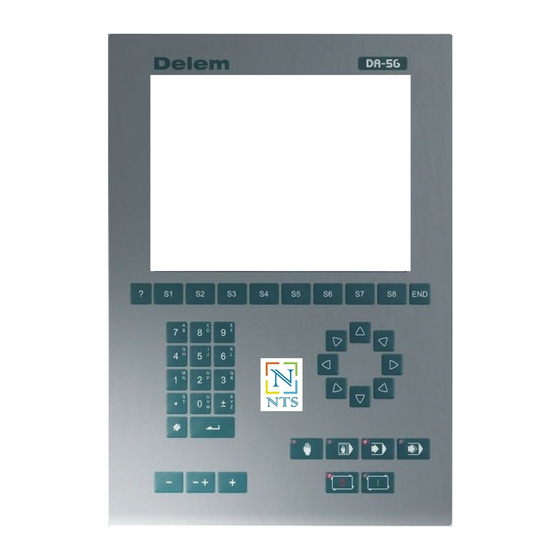

Page 7: Operation Overview And General Introduction

Delem Operation overview and general introduction 1.1. The control unit The control looks as follows: screen function keys arrows mode keys manual start/stop movement key num. keys The precise outfit of your control may vary. Operation of the control is done with the various keys on the front panel. A description of all keys and their functions is given in the next section. -

Page 8: Operation Modes

1.2. Operation modes The control has the 4 following modes: Manual mode In this mode it is possible to program all parameters of just one bending. After pushing the start button all param- eters are active and the backgauge will go into position. It is also possible to move the axes manually. -

Page 9: Frontpanel

Delem 1.3. Frontpanel The frontpanel, besides the 4 operation mode buttons, consists of the following items : Keyboard: 10 numerical keys (0- 9) incl. alphanumeric input decimal point plus/minus toggle clear key: Clearance of the input data field enter key, to confirm a... - Page 10 Manual movement of any axis (Y + backgauge axes) Softkeys; The function of these keys is stated at the bottom side of the monitor screen. End of menu program. It is also possible to leave a menu by pressing <ESC> on an external keyboard or clicking with the mouse on the menu symbol in the upper left corner.

-

Page 11: Programming Mode

Delem 1.4. Programming mode 1.4.1. The main menu Programming Select the programming mode. mode The main menu in programming mode looks as follows: Each of these menu items can be selected in several ways: enter the menu number and press ENTER... - Page 12 Creation of a new CNC-program by data entry (numeri- cal). To edit an existing CNC-program by data entry (numeri- cal). To select a program out of the product library. Write programs to or read programs from a back-up medium. To program the dimensions of the upper tools. To program the dimensions of the under tools.

-

Page 13: 1.4.2. Help Text

Delem 1.4.2. Help text The control has been equipped with an online help text possibility. This help text is available when the question mark ‘<?>’ appears on the screen (lower right corner). To activate a help window for a parameter: press the question mark key (‘?’) on the frontpanel or... - Page 14 The help window can be used as follows: If the text is located in a single window, remove the window by pressing any key. If there is a lot of text across multiple windows, an arrow sign appears below the help symbol. Use the left and right arrow keys or click on the arrow symbols to browse back and forth through the help text.

-

Page 15: 1.4.3. Listbox Functionality

Delem 1.4.3. Listbox functionality Several parameters on the control have a limited number of possible values. Beside such parameters, the sign appears. This means that the key can be pressed to get a listbox with possible values of this parameter. -

Page 16: Graphical Programming

1.5. Graphical programming From the main menu you can select one of the programming possibilities. In order to design or edit a new product, the graphical programming facility is present. This facility is a complete product design tool that allows you to draw the profile of your prod- uct. - Page 17 Delem Zoom function: At bendsimulation overview in case of 2D-products (bendsequence menu and automatic mode): Enlargement Reducement Drawing cursor control for 2D-products In case you are drawing the profile of your product or tools the cursor keys can be used to give directly multiples 45 degree angles.

-

Page 18: Network Option

Vertical projection with L is normal entered line length V is vertical projected line length H is horizontal projected line length It will be noted on the screen if projection is not possible. 1.6. Network option The CNC control is equipped with a network interface. If activated, the network function offers the operators the possibility to import product files directly from the network directories or to export the finished product files to the required network directory. - Page 19 Delem VA 2.1 VA stands for version 2 is version number 1 is version level The version number is increased when new features are added to the software, the level num- ber is increased when minor corrections are needed in the existing version number.

-

Page 20: Delem Limited Warranty

DA-control in normal operation or even when it fails to function according to its specifications. Delem provides the manual "as is" without warranty of any kind, either expressed or implied; including but not limited to the particular purpose. Delem may make improve- ments and/or changes in the product(s) and or program(s) described in the manual at any time. -

Page 21: Product Drawing/Product Edit For 2-Dimensional Products

Delem Product drawing/Product edit for 2-dimensional products 2.1. Introduction With Menu selection 1 you can draw a new product. With Menu selection 2 you can make changes in an existing product. On this page you have to enter first the product number and then the drawing number. The drawing number may also contain alphanumeric characters, which can be entered with the help of the function key ‘alphanum’... - Page 22 Function keys copy prod- Copy the current product. When pressed, you must enter a new product number for the new copy. draw. nr. Go to the screen with product number and drawing num- ber, in order to edit the drawing number. Thickness .

- Page 23 Delem Figure 2.c gives the definition of both the dimensions. Press the key to select the required setting. After entering the general product data the drawing screen appears. In the upper information row you will find the information about product number, drawing number and inside/outside dimensions selection.

- Page 24 In ‘product drawing’ or ‘product edit’ of a 2D product you can program up to a maximal of 25 bendings per product (graphical programming). Function keys: insert / Delete an angle/line or insert an angle, depending on the delete drawing cursor position (section 2.2). precision To define selected line segment, with round cursor, for high precision or if it is to be a "closing"...

-

Page 25: Delete An Angle/Line Or Insert An Angle

Delem 2.2. Delete an angle/line or insert an angle The function of softkey (S1) depends on the position of the drawing cursor. If the cursor is within a line segment, it is possible to insert a new angle to bend, in com- bination with the enter key. - Page 26 Example: Line interval marked with the open circle should be, if possible, directly placed between back stop and the centre of the die. Notes: Specifying line intervals with high precision and closing dimensions may result in longer pro- duction time. Also it will have priority over the "front extend ratio", if that is set to "comply if possible".

-

Page 27: Large Radius: Bumping

Delem 2.4. Large Radius: Bumping To make a bend with a large radius, the control uses the bumping method. With this method, a large radius in a product is obtained by a series of slight bends in succession. To program such a bend, you must program the following parameters:... -

Page 28: Assignments

Specification items: Radius input: min. value = 0.1 mm max. value = 2500.0 mm In the ‘assignments’ menu, it is possible to modify the way the radius bend is divided into seg- ments. See section 2.5 for more information. 2.5. Assignments Pressing ‘Assignments’... - Page 29 Delem Function keys: previous page next page load To load default assignment settings. It is possible to defaults determine a set of assignments which have the most opti- mal values to work within your surrounding. This set can be stored into the internal memory by pressing softkey S4 (save as default).

-

Page 30: Parameter Explanation

• Parameter explanation Lay-on backstop limit ........BL= This parameter (mm) is usefull in case the pressbrake has been equiped with back- gaugefingers on a moving R-axis, having a so-called “lay-on”... -

Page 31: Bend Sequence

X-allowance DIN......... . .XA = For the calculation of the developed length and bend-allowance during the postprocess- ing of a graphical 2D product, a Delem formula is used. It is also possible to select the standard DIN-formula (DIN6935). - Page 32 This selection will give an overview of the tools including the main properties of each tool. In your machine and tool library you can program 1 machine uppersides, 1 machine undersides (tables), 30 different dies and 30 different punches. One of each must be selected, and can also be changed during the bending sequence determination.

- Page 33 Delem The product, as it was drawn, is placed directly under the punch, at one of the last bending positions possible. The shape of your product before this last bend is placed on top of the die. A bigger circle on an angle indicates that this bending is also possible without collision.

- Page 34 With this function key you can switch the collision protection check on or off. This is indicated at the top of the screen. When you have selected collision "off" you can also select other bends which will give colli- sion with the tools or machine parts. The inner radius resulting after this bend is displayed at the top of the screen.

- Page 35 Delem When a bendsequence has been determined, a CNC program can be calculated and stored. This process is called postprocessing. When postprocessing is finished, the ‘blank length’ of the product is dis- played. Open a graphical overview of the bend sequence, in order to have a visual check.

-

Page 36: Restoring A Bend Sequence

Function keys: Enlarge Enlarge all bend pictures, thereby decreasing the number of bends shown on the screen. Reduce Shrink the bend pictures, thereby increasing the number of bends shown on the screen. Move bend In the graphical overview of the bendsequence, it is possible to change the order of bends sim- ply by moving a bend to another place. -

Page 37: Minimum Bending Length

Delem ‘continue’ continue with current bend sequence, the existing (par- tial) bend sequence is restored and shown on the screen If you have loaded a drawing from which a postprocessed bending program already exists, there is a third option when you enter the bend sequence menu: ‘restore’... -

Page 38: Turn Indication

In order to get a graphical overview of the available tools while you are in the bend sequence menu, press the function key 'show library' (S2). If pressed, an overview appears of available tools. Which type of tools is shown depends on which type was prompted in the bend sequence screen: punch, die, machine upper- or lowerside. -

Page 39: Function- And Control Keys Summary

Delem Col.prot.on Collision and backgauge checks on or off Punch: 1 Punch number selected die: 1 Die number selected R-in = 1.3 Inner radius of the bend to be obtained with selected die Variants On Variants programming enabled: the product has a valid CNC pro- gram that can be modified from the graphical menu. -

Page 40: Store

Function keys secondary row: show. To show a mosaic screen with a step-by-step graphical bendseq. overview of the bendsequence. show Softkey to get a graphical overview of the tool library. library Control keys: Zoom enlargement Zoom reducement • Store After you have completed the bend sequence a CNC-program can be generated. This generated program will be stored in the controller program memory. - Page 41 Delem When update (S4) is chosen, the existing CNC program is changed with regard to modified values (angle, length), but other values of bend parameters stay the same. The expression ‘re- use corrections’ refers to the corrections that may have been entered in one of the production modes.

- Page 42 If you choose 'yes' (S4), the indication 'Variants On' will disappear from the title bar. This means that the next time when a new 'postprocess' command is started, a new CNC program is built and old corrections will be lost. When 'No' (S5) is chosen, the action is cancelled and 'Variants on' remains.

-

Page 43: Data Preparation/Data Edit

Delem Data preparation/Data edit 3.1. Introduction To create a new CNC program, choose ‘Data preparation’ in the main menu. To edit an existing CNC program, choose ‘Data edit’ in the main menu. In both cases, a screen as shown below should appear. Programming and changing data is done in the same way for both modes. -

Page 44: Parameters Explanation

After pressing the enter key the programmed value will be placed at the corresponding parameter. Function keys: first Bend The cursor jumps to the page with the first bend informa- tion. Finishing the data preparation and returning to the pro- gram menu. -

Page 45: Connecting Cnc Programs

Delem has been processed from a 2D drawing, this value has been calculated. This parameter is also required for 2D visualisation in a production mode (Automatic or Step). Connect ..........CN The parameter "connect"... -

Page 46: Bend Programming

3.2. Bend programming The parameters of one bend are divided over 2 screen pages. The bend number, product number and drawing number are displayed in the top row on the screen, the function of the "softkeys" in the bottom row. Function keys: prev. -

Page 47: Axis Functions

Delem Function keys: axis func- axis functions, to change speed and retract distance of tions available axes in the current bend. This function is machine-dependant. all bends to the listing of all bends of this program (only possible in data-editing). -

Page 48: Parameter Explanation

maximum possible speed. Retract Retract distance of the selected axis in the current bend. The distance is always programmed in millimeters. If the retract distance of the X-axis is altered in this window, the Retract parameter of the X-axis is automatically adjusted. •... - Page 49 Delem flattening The sheet is folded in two. This is possible after the sheet has been bent into a sharp angle in a previous bend. The control calcu- lates the precise Y-axis position for this action: the surface of the die plus twice the sheet thickness.

- Page 50 If you press ‘gauge func’ a window appears with three programmable parameters. Gauge pos..........GP With this function you can program another ‘gauge position’...

- Page 51 Delem (GN) = 3) gauge position = 3. lay on third level (only possible when number of gauge positions (GN) =4) When you program another ‘Gauge position’ the backgauge position changes, but the gauge position for the plate does not change. This means that the next two parameters ‘R-finger position’...

-

Page 52: Parameter Explication (Second Page)

ters active). 1 = Step change at muting position when the beam moves in opening direction. 2 = Step change at upper dead point. 3 = Step change at upper dead point without movement of any axis and the control goes to "stop". - Page 53 Delem Repetition ..........CY 0 = bending is skipped.

- Page 54 Auxiliary axis ..........R/Z/Aux. If you have one or more auxiliary axes (for instance a R-axis, Z-axis or part support) the parameters of these axes appear here.

- Page 55 Delem Note: The last 2 parameters are used for graphic simulation of the product in a production mode (Automatic mode or Step mode). This visualisation does not require a product drawing, only these parameters must be programmed correctly. Furthermore, the parameter ‘Blank Length’...

- Page 56 Example: Product to make: 0 to 5 are possible backgauge positions. 1 to 4 are angle numbers. Bend Angle (AN) Backgauge (XN) V0505, 3.14...

-

Page 57: List Of Bendings Of The Prepared Program

Delem When in, for example, the 1st bend the plate must rest on the backgauge finger, see table below for programming values. Bend Angle (AN) Backgauge (XN) • List of bendings of the prepared program Pressing this softkey in the data editing mode will result in a complete overview of the bend- ings programmed. - Page 58 Function keys: prev. bend To go to a previous bend when available. next bend To go to a next bend when available. insert bend To insert a new bend between one of the bends, select with the cursor keys first the bend after which a bend must be inserted.

-

Page 59: Ending Data Preparation/Data Editing

Delem that must be replaced. Then press the button ‘mark bend’ and the bend is highlighted. Now use the arrow key to move to the right place in the sequence. When the correct bend number is highlighted, press ‘move bend’. The bend will be inserted on the current place. -

Page 60: Special Edit Function

3.3. Special edit function When a new program has been made and several tests are required, the operator can switch from "editing"-mode directly to the "auto"-mode and vice versa by pressing the particular mode buttons. When in "data editing" a specific bending is selected, the operator can now select the "auto- matic mode"... -

Page 61: Product Selection

Delem Product selection 4.1. Introduction This chapter describes the menu ‘product selection’. In the "product selection" overview, a listing of all the programs which are present in the main memory is given. In the enter field a new product number or drawing number can be entered to select (load) a new program from the mainmemory. - Page 62 Functions keys: previous Previous page with products overview page next page Next page with products overview view Button to select one out of three possible viewing modes: - normal dir. - dir. expand filter Function key to open a new button bar with extra function keys for product selection functions: - prod.

-

Page 63: Expanded Directory

Delem The other function keys cannot be selected here, until one of these three function keys has been chosen. The temporary bar will disappear again. When the function key ‘filter’ has been pressed a new, temporary button bar appears with addi-... -

Page 64: Search Function

Expanded directory, a product overview which contains the following information for each product is displayed: • Product number • Drawing number • Number of bends • Type indication • Connected program (0 = no connection) • Selected tools (in first bend) •... -

Page 65: Directories

Delem 4.2. Directories Bend programs on the control can be stored in different directories. This directory can be used for storage of the products. The active local directory name is displayed in the header. When the function key ‘local directory’ has been pressed in the product menu, a new window appears with an overview of directories on the control. - Page 66 Function keys: Cursor key Select another subdirectory. Up/Dn Use the function key 'select' to make a subdirectory active. Press ENTER to look inside a sub- directory. To move up, go to the <PARENT> map and press ENTER. To select the directory you are currently in, go to and press ‘select’.

-

Page 67: Programming Of Tools

Delem Programming of tools 5.1. Introduction This chapter describes the programming of the tools and machine shapes. 5.2. Programming of Punches 5.2.1. The punch menu The programming of punches is started by choosing ‘Punches’ in the main menu. The punch profile can be created with help of the programming facilities of the control. -

Page 68: Edit Punch Drawing

Function keys: previous To select a previous page within the several pages of the page punch library. next page To select the next page within the several pages of the punch library backup Save tools from library to disk. restore Load tools from disk into the control. - Page 69 Delem Function keys: auto finish Finishing the tool outline to the top of the tool automati- cally change To change the height dimension of the tool height delete line To delete a line segment delete To delete the complete tool from the library...

-

Page 70: Drawing Orientation Of The Punch On The Screen

• Drawing orientation of the punch on the screen The right hand side of the tool is the backgauge side. The bottom point of the punch will be placed on the center line of the press brake shape. 5.2.2. Specific Punch Data Code. - Page 71 Delem Radius ...........RA The radius of the punch.

- Page 72 cause inaccuracies in the tool height and the resulting Y-axis position. The control makes a distinction between two settings, 'head mounted' and 'shoulder mounted'. 0 = shoulder mounted (default setting) 1 = head mounted Press the key to select the required setting. If 'shoulder mounted' is chosen, the Y-axis position is calculated from the standard tool height.

-

Page 73: Programming Of Bottom Dies

Delem 5.3. Programming of bottom dies 5.3.1. The die menu The programming of dies is started by choosing ‘Bottom dies’ in the main menu. A listing of the programmed dies is given. A die can be selected with the highlighted cursor. - Page 74 Function keys: next page To select the next page within the several pages of the die library. backup Save tools from library to disk. restore Load tools from disk into the control. delete tool Remove tool from library. edit tool To edit the tool drawing or check the die data.

- Page 75 Delem The width V is the distance between the touching lines crossing. After entering these parameters you are ready to draw the important outer dimensions of your die. The right side of the die is the backgauge position. The mid-position of the V-opening will be placed on the centre line of the press brake shape.

-

Page 76: 5.3.2. Specific Die Data

5.3.2. Specific die data Code........... . .C Alphanumeric tool name with a maximum 20 characters. - Page 77 Delem Flattening height ......... . .FH The flattening height need to be programmed when you make use of a special flattening die to flatten your product.

- Page 78 left side is used. These values are calculated each time the die drawing changes. These 2nd-values cannot be changed manually. H2 is the height of the 2nd-values. H2 is not visible on the screen. See for explanation upon the safety zones the example drawing. V0505, 5.12...

-

Page 79: Machine Upper Side And Lower Side

Delem 5.4. Machine upper side and lower side Function keys: backup Save tools from library to disk. restore Load tools from disk into the control. delete tool Remove tool from library. edit tool To edit the machine shape drawing or check the dimen- sions. - Page 80 centre. The length prompted after entering the height of the machine shape is the distance from the center line to the front side or the back side of the machine. For the lower side of the machine the height is defined from the table surface to the floor level. V0505, 5.14...

- Page 81 Delem V0505, 5.15...

-

Page 82: Saving/Loading Of Tools

5.5. Saving/loading of tools With the function key 'save to disk' (in any of the tool menus) the dialogue 'Save Punches' is opened. From this menu, it is possible to save tools to a back-up location. This procedure works the same for all tools and machine shapes and regardless of the back-up location (floppy disk, network). - Page 83 Delem Function keys: code Select on code instead of number. view Button to select one out of two possible viewing modes: - normal dir. - dir. expand For backup operations, it is possible to make use of subdirectories. Subdirectories can be cre- ated in this menu.

- Page 84 Function keys: remove Delete a subdirectory. If the subdirectory is not empty the subdir controller returns the message 'UNABLE TO REMOVE DIRECTORY'. The 'load tools' procedure is different from the 'save tools' procedure. When you select 'load tools' the control checks if the toolnumber already exists in the control. If not, then the tool is automatically copied from disk to the control.

-

Page 85: Products And Tools Back-Up

Delem Products and tools back-up 6.1. Introduction This chapter describes the procedures to make a back-up of your products and tools. The procedures for saving or reading data are similar for all types of back-up media: floppy disk, network or USB disk. -

Page 86: Directory Navigation

6.2. Directory navigation When softkey ‘backup directory’ is pressed, a new window appears with a list of available back-up directories. In this window you can browse through the directory structure of your back-up device. Press ENTER to look inside a subdirectory. To move one level up, go to the <PARENT> map and press ENTER. -

Page 87: Product Backup

Delem Function keys: remove Delete a subdirectory. If the subdirectory is not subdir empty the controller returns the message ‘UNABLE TO REMOVE DIRECTORY’. 6.3. Product backup To make a back-up of programs to disk, choose ‘Product backup’ in the main menu. - Page 88 When ‘backup products’ has been selected, a screen like shown below should appear. At the top of the screen, the back-up location is shown. If this location is not correct you can change the subdirectory with the softkey ‘backup directory’ or you should go to the program constants menu to change the device where products are saved to.

-

Page 89: Tool Back-Up

Delem Function keys: Button to select one out of two possible viewing view modes: - normal dir. - dir. expand - graph. dir. A back-up operation is carried out unconditionally. When a restore operation is started, the control checks whether the product is already present on the control. If it is, you are asked whether to replace the existing product or to cancel the restore operation. - Page 90 Function keys: restore tools restore all tools from disk. backup direc- change, make or remove backup directory tory To load or save only a few tools, go to the specific menus of those tools and save or load each tool individually. This has been explained in detail in the chapter about tools. A restore operation runs similar to a back-up operation, when it is started a warning is given that the existing tools on the control will be replaced by the tools that are imported.

-

Page 91: Program Constants

Delem Program Constants 7.1. Introduction Choose ‘Program constants’ in the main menu to program the programming constants. The program constants are divided across several pages. They are discussed in the following sec- tions. 7.2. General Inch-select 1/0 ..........IS... - Page 92 Language selection .........LA 0 = GB (English) 10=P...

-

Page 93: Materials

Delem 7.3. Materials In this window, material properties can be programmed. You can edit existing materials, pro- gram new materials or delete existing materials. A maximum of 99 materials can be pro- grammed on the control. For each material, three properties are present and can be viewed and edited. -

Page 94: Program Settings

Function keys delete mate- To delete the material that is currently shown on the rial screen. The materials are initially listed according to their material number, which is shown in the first column (ID). The list can be sorted according to the different properties. If you have a mouse available, click on the title of a column. - Page 95 Delem question the action will be aborted. The machine number is also stored in the filenames of tools. When the machine number is changed in this screen, you are prompted to make a new backup of your tools because the filenames of all tools have been changed according to the new machine number.

- Page 96 then the following parameters are automatically recomputed and changed by the control: - Pressure - Decompression distance - Crowning device setting 2. In case you change the value of the parameter ‘length’ then the following parameters are automatically recomputed and changed by the control: - Pressure - Decompression distance - Crowning device setting...

-

Page 97: Computation Settings

Delem dling. 7.5. Computation settings Active bend allowance table ....... . .BE = 0 = Internal / 1 = bendallw.tab... - Page 98 uses the postprocess command to calculate a CNC program from a drawing with bendse- quence, the control will allways take bend-allowance into account. When a bend-allowance table is present and the cursor is on the parameter ‘active bend allow- ance table’ then an extra function key is available: ‘edit table’. With this softkey the table can be modified to meet user requirements.

- Page 99 ENTER. It is not possible to create a table through this menu. Only when a table has been loaded into the control is it possible to edit its contents. For more information about bend-allowance tables, we refer to the Delem manual of the bend- allowance table.

-

Page 100: Production Settings

7.6. Production settings Stock count mode ......... .SC= Setting for the stock counter in production mode, to have the stock counter (product counter) count up or down. - Page 101 Delem during production. The parallelism which can be programmed for each bending (Y2) is only active below the clamping point. The parallelism below the clamping point is the sum of the two parameters (Y2 + Par. offset). Flattening opening .........OP =...

- Page 102 be confused with the parameter ‘X-safety’ of each die. This parameter is especially useful when several dies of different sizes are placed on the machine. In that situation, this intermediate X-value should be larger than the safety zone of the largest die that is installed. When the backgauge has to move to a different Z-position, it is checked whether the cur- rent X-position is safe.

-

Page 103: Serial Ports

Delem 7.7. Serial ports Serial port 1/2 ..........C1/C2 The control is equipped with two serial ports (RS-232). -

Page 104: Backgauge Dimensions

7.8. Backgauge dimensions With these finger dimensions the R-axis movement and work/backgauge collision can be com- puted. Gauge positions ......... . .GN = The number of possible gauge positions (max. - Page 105 Delem Finger width ..........FW The width of the backgauge finger.

-

Page 106: Maintenance

Gauge height..........H1/H2/H3/H4 The height of the different finger levels. -

Page 107: Manual Mode

Delem Manual mode 8.1. Introduction Manual mode By pushing this key the CNC is in manual mode. In manual mode you program the parameters for one bending. This mode is useful for testing and for calibration. All the parameters can be programmed independently of the programs in memory. - Page 108 Function keys axis func- To change speed and retract distance of available axes in tions the current bend. This function is machine-dependant and is described in detail in the chapter ‘Data preparation’. manual pos Start the function to move axes manually with the hand- wheel.

-

Page 109: Parameter Explanation

Delem • Parameter Explanation Punch ........... .UP Number of selected punch in the library. - Page 110 Mute ........... .M Sequence point where the Y-axis is switched from fast closing speed to pressing speed.

- Page 111 Delem D-time ...........T Dwell time of punch at the bending point.

-

Page 112: Zoom Function

• Zoom function When the function key ‘zoomed values’ has been pressed, the control switches to a new view with only axes values on the screen. V0505, 8.6... -

Page 113: Manual Operation Of The Axes

Delem 8.2. Manual operation of the axes It is possible to move an axis by turning the handwheel on the front panel of the control. After pressing the function key ‘manual pos’ in the main screen of manual mode, the following screen appears: Put the cursor bar on the axis you wish to move with the handwheel. -

Page 114: To Teach

The Y-axis must be below mute-point. A pressing command must be given to the CNC. • To teach You can teach an axis a correct position within the manual positioning mode. When you have moved an axis to a certain position with the handwheel, you may want to store this position. To do so, press the ENTER key within this screen. -

Page 115: Automatic / Step By Step Mode

Delem Automatic / step by step mode 9.1. Introduction The automatic mode executes the program (programming mode) automatically bend by bend after pushing the ‘start’-key.When a new bending program is selected you must check your tools and tool positions in your machine. This is also indicated with a ‘check tools’ warning message when you enter the automatic mode. - Page 116 Function keys: previous Switch to previous bend of the program. bend next bend Switch to next bend of the program. view Button to activate pop-up bar with additional functions. select rept Switch between display of bend number or the number of repetitions of this bend.

-

Page 117: Parameters

Delem Function keys: aux. axes Switch to second view with parameters of auxiliary axes. view bends Switch to a table view in which all bends are shown. graphical Switch to graphical visualisation of the program. zoomed Switch to view with axes values. -

Page 118: Corrections

ing corrections If a correction is entered, it will be stored in the database. At each next bend with the same properties, this same correction will be offered. See the chapter ‘Program constants’ for more information on the angle correction database. Corr X . - Page 119 Delem In this window the corrections of all bends are shown. You can browse through all corrections and change them as you see fit. If a correction for α1 is entered then this value is copied to the correction for α2. Different corrections for α2 can be entered in the field itself.

-

Page 120: Functions Screen

• Functions screen • Graphical visualisation V0505, 9.6... -

Page 121: Zoomed Values

Delem • Zoomed values V0505, 9.7... -

Page 122: Bumping Correction

• Bumping correction With this function a general correction for a radius bend can be entered. This function can be activated when the cursor is on the parameter for angle correction (‘corr. α1/α2’). It is only available if a product is loaded that contains a radius bend. When the function is activated, a new window appears in which the correction can be entered. -

Page 123: Manual Positioning

Delem • Manual positioning In the automatic production mode it is possible to move the selected axis manually with the handwheel and change the axis-positions with the teach function like in manual mode. V0505, 9.9... -

Page 124: Step Mode

9.2. Step mode In the step-by-step mode you have the same possibilities as in the automatic mode. There is only one difference. After each bend cycle, the control will stop. To continue working, you must start the control again by pressing ‘start’ on the front panel of the control. After each bending step, the control can stay in the current bend or jump to the next bend. -

Page 125: Parameter Index

Delem Parameter index Flattening offset ..... . . 7.9 Flattening opening ....7.11 Force . - Page 126 Thickness ......3.2 Thickness ......8.3 Ton/kN select 1/0 .

Need help?

Do you have a question about the DA-56 and is the answer not in the manual?

Questions and answers

مرحبا اريد برمجة هذا الجهاز

The Delem DA-56 can be programmed by authorized users who have access to create or edit programs and tool data. The controller has a keyswitch to prevent unauthorized programming. When the keyswitch is in the off position, the operator can only execute a selected program without changing parameters. Programming is simplified through 2D graphical tools, and the system automatically determines bend sequences.

This answer is automatically generated