Table of Contents

Advertisement

Quick Links

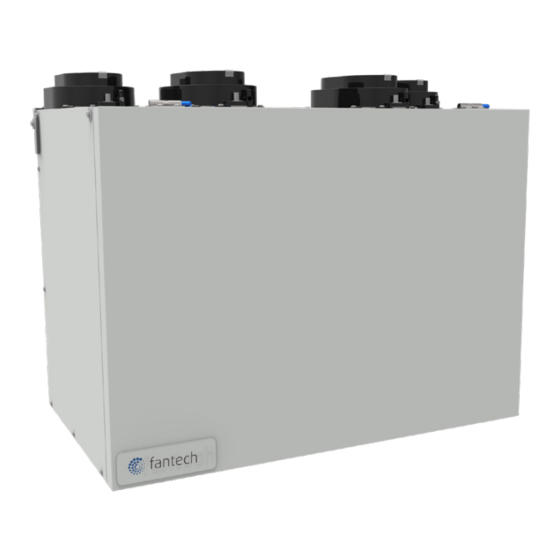

VER200

Energy Recovery Ventilator

PARTS IN THE BOX

Energy Recovery Ventilator, 1 pc

Hanging Chain Kit, 1 pc

Hardware Kit, 1 pc

Drain Hose Kit, 1 pc

Operation and Installation Manual, 1 pc

Your ventilation system should be installed in conformance with the appropriate provincial/state requirements or, in the

absence of such requirements, with the current edition of the National Building Code, and / or ASHRAE's "Good Engineering

Practices".

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Fantech reserves the right to modify, at any time and without notice, any or all of its products' features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

Installation Manual

Item #: 445508

Rev Date: 2020-11-02

Advertisement

Table of Contents

Summary of Contents for SystemAir Fantech VER200

- Page 1 Item #: 445508 Rev Date: 2020-11-02 Installation Manual VER200 Energy Recovery Ventilator PARTS IN THE BOX Energy Recovery Ventilator, 1 pc Hanging Chain Kit, 1 pc Hardware Kit, 1 pc Drain Hose Kit, 1 pc Operation and Installation Manual, 1 pc Your ventilation system should be installed in conformance with the appropriate provincial/state requirements or, in the absence of such requirements, with the current edition of the National Building Code, and / or ASHRAE’s “Good Engineering Practices”.

- Page 2 Note Warning/ Information Technical Practical tip Important information note PLEASE READ AND SAVE THESE INSTRUCTIONS Before installation careful consideration must be given to how this system will operate if connected to any other piece of mechanical equipment, i.e. a forced air furnace or air handler operating at a higher static pressure.

-

Page 3: Table Of Contents

TABLE OF CONTENTS DETERMINING YOUR AIRFLOW REQUIREMENT ........... . . 4 INSTALLATION EXAMPLES Fully dedicated system . -

Page 4: Determining Your Airflow Requirement

DETERMINING YOUR AIRFLOW REQUIREMENT Room Count Method Room classification Number of rooms CFM (L/s) CFM Required Master bedroom x 10 L/s (20 CFM) if yes add 10 L/s (20 CFM) Basement yes or no if no = 0 Bedrooms x 5 L/s (10 CFM) Living room x 5 L/s (10 CFM) Others... -

Page 5: Installation Examples

INSTALLATION EXAMPLES Suggested installation for: Example only – duct configuration may differ depending on the model. • Hydronic baseboard • Infloor heating FULLY DEDICATED SYSTEM • Electric baseboard BEST FOR NEW CONSTRUCTION • Mini split heat pump Benefits: Provides the best fresh air distribution in the Stale air is drawn from key areas of the home requiring local exhaust house;... -

Page 6: Partially Dedicated System

INSTALLATION EXAMPLES (CONT'D) Suggested installation for: • Central furnace (air DIRECT CONNECTION of the FRESH air to living area to the RETURN PLENUM handling unit or central of the AIR HANDLER (Stale air drawn from key areas of home) air conditioners) •... -

Page 7: Simplified Installation

INSTALLATION EXAMPLES (CONT'D) Suggested installation for: DIRECT CONNECTION of both the ERV SUPPLY AIR STREAM and EXHAUST AIR STREAM • When bathroom and kitchen to the FURNACE COLD AIR RETURN already have local exhaust SIMPLIFIED INSTALLATION (GOOD) system (RETURN/RETURN METHOD) - OPTION 1 •... -

Page 8: Option 1

Installation examples (Cont'd) Suggested installation for: DIRECT CONNECTION of the ERV SUPPLY AIR STREAM to the SUPPLY AIR SIDE on the • When bathroom and FURNACE & EXHAUST AIR STREAM to the FURNACE COLD AIR RETURN kitchen already have local exhaust system SIMPLIFIED INSTALLATION (GOOD) •... -

Page 9: Exterior Ducting Installation

EXTERIOR DUCTING INSTALLATION WEATHERHOOD LOCATION OUTSIDE CORNER INSIDE CORNER • Decide where your intake and exhaust hoods will be located. 36" (1m) 36” (1m) min. min. Locating the Intake Weatherhood • Should be located upstream (if there are prevailing winds) from the 6' (2m) exhaust outlet. -

Page 10: Interior Ducting Installation

INTERIOR DUCTING INSTALLATION • To maximize airflow through the ductwork system, all ducts should be kept short and have as few bends or elbows as possible. • 45º elbows are preferable to 90º. • Use “Y“ ducts instead of “T” ducts whenever possible. •... -

Page 11: Erv Installation

ERV INSTALLATION LOCATION The ERV must be located in a conditioned space where it will be possible to conveniently service the unit. Typically the ERV would be located in the mechanical room or an area close to the outside wall where the weatherhoods will be mounted. - Page 12 INSTALLING DRAIN LINE Through normal operation and during its defrost mode, the ERV may produce some condensation. This water should flow into a nearby drain, or be taken away by a condensate pump. The ERV and all condensate lines must be installed in a space where the temperature is maintained above the freezing point. A “P”...

-

Page 13: Airflow Adjustment & Balancing

AIRFLOW ADJUSTMENT & BALANCING BALANCING THE AIRFLOWS IS CRUCIAL TO ENSURE OPTIMAL OPERATION OF THE UNIT. IF THE AIRFLOW IS NOT PROPERLY BALANCED, THE FOLLOWING ISSUES MAY OCCUR: • SIGNIFICANT POSITIVE OR NEGATIVE PRESSURE INSIDE THE HOUSE • UNIT’S EFFICIENCY MAY BE NEGATIVELY AFFECTED •... -

Page 14: Balancing Steps

BALANCING STEPS Use balancing chart located on the BALANCING CHART (example only) door of the ERV Airflow Normal Speed Reduced Speed ∆In W.G. ∆In W.G. STEP #1: Identify the desired airflow using the provided chart. From ∆Pa ∆Pa Pressure reading Pressure reading the desired airflow (left column) identify the pressure reading 0.36... -

Page 15: Low Voltage Control Systems

WALL CONTROLS * Please see instruction manuals for individual controls for proper wiring and set up of control systems. 1. Ensure that unit is not plugged when connecting the control 2. Recirculation mode is only available with the Flex100H ES, HERO series and the models with the “R” suffix at the end of the model number. - Page 16 WALL CONTROLS (CONT'D) EDF SERIES FEATURES CONNECTS TO • MODE button provides 3 modes of operations: Ventilation , Recirculation and Standby EDF7 • User selected fan speed: Reduced, Medium, Normal and 20 minutes per hour • AUTO setting allows the homeowner to deactivate the dehumidistat •...

-

Page 17: Wiring Diagram

WIRING DIAGRAM fantech... - Page 18 WIRING DIAGRAM (CONT'D) WIRING DIAGRAM TO Standard Accessory Control Contact Standard Furnace Interlock Wiring FURNACE THERMOSTAT TERMINALS FOUR WIRE TWO WIRE heating only FOR A FURNACE CONNECTION TO A COOLING SYSTEM: On some newer furnaces and older FURNACE thermostats, energizing the R and 24-VOLT TERMINAL BLOCK G terminal at the furnace has the...

-

Page 19: Troubleshooting

TROUBLESHOOTING Problem Causes Solutions Air is too dry Dehumidistat control is set too low Increase the desired level of humidity. Change ventilation mode from continuous mode to standby. ERV out of balance Have contractor balance ERV airflows Air is too humid Dehumidistat control is set too high Reduce the desired level of humidity. -

Page 20: Erv Maintenance Chart

ERV MAINTENANCE CHART Limited Warranty • The Energy recovery core has limited 5 year warranty. Maintenance Required Recommended Frequency Date Maintenance Performed Check and Clean Filters Every 3 months or if • The warranty is limited to 5 years on parts and 7 years on fans from the dirty date of purchase, including parts... -

Page 21: Erv Core Washing Instructions

ERV core washing instructions For proper maintenance of your energy recovery core please follow these instructions Remove both filters by sliding them out. Remove the core from the unit. With one of your core's air inlets facing down, place it in a large sink, bathtub, or shower. -

Page 22: Parts List

Parts list VER200 BOM # Description (463278) Kit, Repl, Motor, R2E190 Rad,mini 428515 Kit, Enth Cell,DP,12X15,Wpr 427789 Filter, 2xR-200 (11.5x15), Rep. Kit 40327 Door Switch 410867 Collar 6”, Oval, w/Hole 413893 Collar 6”, Oval, w/o Hole 413894 Kit,RV-CTRL,Replacement,H:F 428252 Kit, Drain Plug 40315 Auto-Transformer 411963... - Page 23 Notes fantech...

- Page 24 Fantech reserves the right to make technical changes. Fantech se réserve le droit de faire des changements tech- For updated documentation please refer to www.fantech.net niques. Pour de la documentation à jour, s'il vous plaît se référer au www.fantech.net Fantech®...

Need help?

Do you have a question about the Fantech VER200 and is the answer not in the manual?

Questions and answers