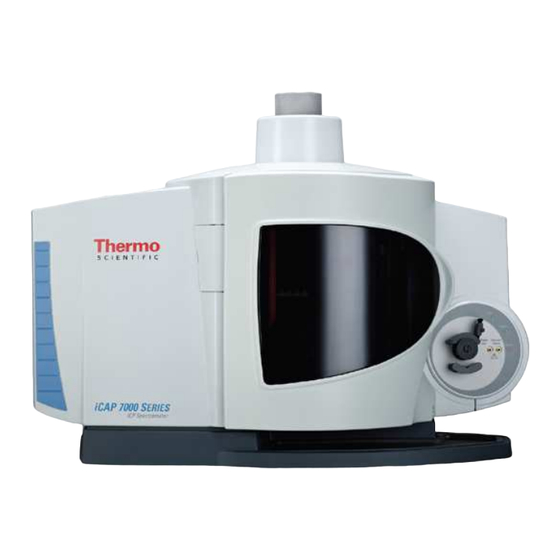

Thermo Scientific iCAP 7000 Series Manual

Icp-oes spectrometer

Hide thumbs

Also See for iCAP 7000 Series:

- Manual (36 pages) ,

- Hardware installation (14 pages) ,

- Reference manual (45 pages)

Summary of Contents for Thermo Scientific iCAP 7000 Series

-

Page 1: Icap 7000 Series Icp-Oes Spectrometer

7000 Series ICP-OES Spectrometer Customer Familiarisation and Maintenance Manual © March 2013 Thermo Fisher Scientific Inc. www.thermoscientific.com http://www.thermofisher.com... -

Page 2: Table Of Contents

Customer Familiarisation Manual 1 Contents iCAP 7000 Series ICP-OES Spectrometer ..................1 Customer Familiarisation and Maintenance Manual ............... 1 Contents ..........................2 Instrument Overview ........................ 4 General ..........................4 Optical system and light path ..................4 Further information ........................6 Qtegra ISDS Help ...................... - Page 3 iCAP Customer Familiarisation Manual Suggested maintenance in the case of poor precision and detection limits ...... 65 10.1 Introduction ........................65 10.2 Typical Maintenance Schedule ..................65 10.3 Replacing pump windings ....................65 10.4 Preventing blocking of the nebuliser ................66 10.5 Removing solids from the nebuliser ................

-

Page 4: Instrument Overview

2 Instrument Overview 2.1 General The iCAP 7000 Series is a range of Inductively Coupled Argon Plasma Optical Emission Spectrometers (ICP-OES) which use an Echelle optical design and a Charge Injection Device (CID) solid-state detector to measure trace elemental concentrations in a wide range of samples. - Page 5 iCAP Customer Familiarisation Manual The dispersive elements in the optic system are the Echelle grating and the prism. The orientation of the prism is such that the light is dispersed at right angles to the direction of light dispersal by the grating. This combined dispersal generates a two dimensional spectrum (“echellogram”) consisting of a wavelength and order separation.

-

Page 6: Further Information

OES Spectrometer, including application notes and other material visit the Thermo Scientific website including application notes and other material visit the Thermo Scientific website including application notes and other material visit the Thermo Scientific website and search for iCAP 7000: www.thermoscientific.com www.thermoscientific.com... -

Page 7: Instrument Hardware

iCAP Customer Familiarisation Manual 4 Instrument Hardware The iCAP 7000 is designed to be constantly powered up and the optical system continuously purged. The instrument is powered via an on/off switch at the rear of the left side. 4.1 LED indicators On the rear right hand side of instrument there are row of LED’s which indicate the status of the instrument. -

Page 8: Instrument Shut-Down

iCAP Customer Familiarisation Manual 4.3 Instrument Shut-down After an analysis is finished a blank sample should be aspirated for five minutes to insure the sample introduction part have been rinsed of sample. To remove the blank sample deionised or distilled water should be aspirated for a further minute. When organic solvent based samples are being analysed the final rinse should be the pure solvent. -

Page 9: Standard Sample Introduction Glassware Assembly

iCAP Customer Familiarisation Manual 5 Standard Sample Introduction Glassware Assembly Warning: Appropriate care and safety procedures should be followed to avoid breaking any glassware and causing injury to the operator. Broken glassware should be handled with appropriate care. ▲ Gloves must be worn when handling glass or ceramic torches as handprints will reduce the life of the torch and may cause the torch not to light. -

Page 10: Center Tube Options

iCAP Customer Familiarisation Manual 5.2 Center Tube Options 5.2.1 1mm with 2 RED bands centre tube Used for organic solvents. Used for both radial and duo instruments. This is to reduce the amount of sample reaching the plasma as larger center tubes result in too much sample reaches the plasma and the plasma may go out. -

Page 11: Centre Tube Insertion Into Torch Holder

iCAP Customer Familiarisation Manual 5.4 Centre tube insertion into torch holder Insert the centre tube assembly into the metal torch holder. Screw the centre tube holder assembly in a clockwise direction into the metal torch holder until the o-ring is compressed. Do not over tighten as this will reduce the lifetime of the O-ring seal. When fitted the center tube should be 1-3mm lower than the intermediate tube as shown above. -

Page 12: Position Of The Nebulizer In The Spray Chamber

iCAP Customer Familiarisation Manual occurs during the liquid removal. 5.7 Position of the nebulizer in the spray chamber Liquid should be delivered to the nebulizer using an identical plastic tubing connector but with narrow bore tubing (0.50mm inner diameter). Push the white plastic tubing connector with the attached narrow bore sample tubing into the rear of the nebulizer as far as possible without exerting undue pressure. -

Page 13: Connection Of Spray Chamber Adaptor To Torch Assembly

WARNING: It is extremely important that the correct Thermo Scientific parts are used for the sample introduction system. In addition interlocks on the torch holder and other parts of the instrumentation are there for safety and must not be bypassed. -

Page 14: Connection Of Pump Tubing

iCAP Customer Familiarisation Manual 5.9 Connection of pump tubing The following figure shows the peristaltic pump and 2-stop windings are typical of the iCAP 7200. iCAP 7200 sample pump tubing has white and orange stops and the drain tubing has white and white stops. - Page 15 iCAP Customer Familiarisation Manual Note: the drain tubing should be connected correctly to the peristaltic pump to account for the anticlockwise flow. • Release the pump tubing clamps and locate the sample and drain pump tubing over the pump rollers, locking the lugs on the pump tubing into the left and right clamps. •...

-

Page 16: Radial View Window On A Duo Instrument

iCAP Customer Familiarisation Manual 5.10 Radial view window on a Duo instrument. For a Duo instrument check that the radial view bucket shaped window is in place and clean. It is possible to rotate the window holder to gain access (take the torch out before inspection). When assembling the torch and radial view window insure the window is located against the torch as shown below: This document is part numbered 849940090071... -

Page 17: Icap Sprint Valve Installation Guide (Icap 7600 Only)

iCAP Customer Familiarisation Manual 5.11 iCAP Sprint Valve installation guide (iCAP 7600 only) 5.11.1 Connecting the tubing Fit the drain fitting to the spray chamber (black ringed), insert the fittings capillary tube into the yellow/blue peristaltic pump tubing and attach it to the pump so that the waste runs counter clockwise across the pump: Cut a length of the supplied drain tubing so it can reach between the pump... - Page 18 iCAP Customer Familiarisation Manual Inset the tubing with the green valve fitting and the carrier uptake tube (bubbler) into the white/white peristaltic pump tubing: Attach the pump tubing onto the peristaltic pump so that the bubbler runs counter clockwise across the pump: Screw the green valve fitting into port 5 on the valve head: Next take the white valve fitting tube and...

- Page 19 iCAP Customer Familiarisation Manual Screw the other end of the fitting tube into the vacuum valve connector on the iCAP: Attach the vacuum pump waste tubing to the waste out connector on the iCAP, and insert the other end into the waste container: Screw the autosampler probe valve fitting into port 2 on the valve head:...

- Page 20 iCAP Customer Familiarisation Manual Screw the fitted nebulizer tube into port 6: Attach the other end on the nebulizer line and the nebulizer gas fitting onto the nebulizer: 5.11.2 Manual sampling using the Sprint Valve Manual sampling uses the Inject position (5) with a standard or non-aerating sample probe. This document is part numbered 849940090071 Version 1.02 Page 20 of 72...

-

Page 21: Autosampler Use

iCAP Customer Familiarisation Manual 6 Autosampler Use 6.1 Introduction The autosampler can be configured to suit an application, or several applications. The volume, number and type of sample will all influence the set-up of the autosampler and instrument. 6.2 Autosampler Installation To comply with safety and warranty requirements the iCAP 7000, accessories and associated equipment must be installed by a Thermo Fisher trained and certified engineer. -

Page 22: Instrument Optimization

It is also important that a suitable quality control regime is established that verifies the continuing validity of data. Training courses are available through a local Thermo Scientific Sales Office; contact details are available at www.Thermoscientific.com. 7.1 Instrumental method optimization The following parameters can all affect the data obtained and should be optimized. -

Page 23: Example Standard Operating Procedures

iCAP Customer Familiarisation Manual 7.2 Example Standard Operating Procedures This method setup procedure, which by no means covers all the possible parameters used in Qtegra, should be enough for setting up a basic analysis. It is recommended that the user reads the iCAP software manual for more advanced use of the system. - Page 24 iCAP Customer Familiarisation Manual Torch Compartment Interlock:- If red this indicates the torch door is open or the torch holder is not inserted correctly. The plasma will not light. Plasma gas pressure:- should be green if the plasma gas input pressure is 5.5 Bar, if it turns red during the ignition sequence it indicates problems with the external gas supply to the iCAP If red the plasma will not light.

-

Page 25: Setting Up Analyses

iCAP Customer Familiarisation Manual This will bring a page up with several options. 1. The ‘Warm Up’ time is normally set to 15 minutes to enable the system to stabilize prior to spectrometer optimization. 2. ‘Spectrometer Optimization’ is normally turned on to make an automatic minor adjustment to the spectrometer optics. - Page 26 iCAP Customer Familiarisation Manual LabBooks can be created from blank Templates, existing Templates, imported Templates of appropriate configuration, or from existing LabBooks. From Analytes use the Periodic Table to begin selecting your elements of choice by pausing cursor over the element symbol to see a preferred wavelength list as shown below. This document is part numbered 849940090071 Version 1.02 Page 26 of 72...

- Page 27 iCAP Customer Familiarisation Manual From Analytes use the Periodic Table and a left click on the element of choice to auto pick from the top of the preferred wavelength list. Where the first element wavelength is not desired, a right click will bring up a window and allow optional selections.

- Page 28 iCAP Customer Familiarisation Manual From Measure Modes, source parameters such as RF Power, Nebulizer and Additional Gas flows (if used) and Exposure Time(s) may be adjusted. The Acquisition Parameters window shows (among other things) default slit positions, measure mode view used and left and right background settings. Here Analysis Modes Speed, Normal, Sprint, and sample pump RPM’s can be set.

- Page 29 iCAP Customer Familiarisation Manual Note:- Blanks (all zero concentration) are selected in the sample list view and not in the standards list. From the Standards window select “New” to add a standard where “Elemental Standard” should be selected. The default concentration can be set prior to creating the standard by clicking the button to minimize typing.

- Page 30 iCAP Customer Familiarisation Manual As above, double click each Concentration field and type in appropriate values. As above, double click each Concentration field and type in appropriate values. This document is part numbered 849940090071 Version 1.02 Page 30 of 72...

- Page 31 iCAP Customer Familiarisation Manual Select the Quality Control checkbox to bring up the Quality control menu. When an autosampler is being used, define Wash Time and Uptake Times by selecting the appropriate autosampler. Rack type selection changes may also be made here. NOTE: For the iCAP 7600 Sprint Valve the Wash Time may be set to ZERO as this function is multi-tasked with the Uptake Time, which can also be reduced to about 20 seconds as using the Valve provides quicker sampling.

- Page 32 iCAP Customer Familiarisation Manual Use Manual Sample Control to disable the autosampler and define the Uptake and wash times. Use the Sample list to build a sequence and define the samples to be analyzed. Add lines individually for BLANK and each of the calibration standards and QC checks. Use the label identifier and sample type drop down list as required.

- Page 33 iCAP Customer Familiarisation Manual Enter the number of Unknown samples you wish to run and click OK. Under the Label column you can type individual identifiers’ or type one followed by a number such as sample 1, then highlight the column, right click in the highlighted column and select Increment fill to fill down with numbering.

- Page 34 iCAP Customer Familiarisation Manual >>> For incremental QC Checks, highlight the QC Check standard row, click the “Copy” tool bar button, click the location where you would a check performed then click the “Insert” tool bar button, repeat for each location desired. Every 10 samples is common, for this example 5 was used.

-

Page 35: Running The Analysis

iCAP Customer Familiarisation Manual In the toolbar of your LabBook click Save. 7.6 Running the Analysis In the toolbar of your LabBook click Run to schedule the LabBook for execution (will not be active unless properly saved). The LabBook is added to the scheduler. If the check box Automatic has been selected for Start Queue in the options settings of the scheduler the measurement is started immediately. - Page 36 iCAP Customer Familiarisation Manual This document is part numbered 849940090071 Version 1.02 Page 36 of 72...

-

Page 37: Auto Peak Adjust

For optimum performance it is important that the analyte wavelengths are correctly aligned in the centre of the sub array measurement window. The iCAP 7000 Series Spectrometer will automatically check a reference line each time the plasma is ignited to maintain wavelength accuracy. -

Page 38: Setting The Pump Tension

iCAP Customer Familiarisation Manual Introduce the sample “Method development standard” (high standard concentration solution of the selected element(s)). Ensure you leave enough time for the sample to enter the plasma and then click OK. This procedure will set the default position for this line until the next auto peak adjustment takes place. -

Page 39: Torch Alignment

iCAP Customer Familiarisation Manual nebulizer to free aspirate. Tighten the tension adjustment until the flow just stops then tighten by one turn. Turn on the pump and, if necessary, increase the tension until a smooth flow is produced. Do not over-tighten the pump clamps as it will result in excessive wear and tear of the pump tubing and require replacement tubing at more frequent intervals. - Page 40 iCAP Customer Familiarisation Manual The report structure works by group with two types of groups: Result Group and Method Parameter Group. 7.10.1 Result Group. The general structure of reports is shown here with Result groups divided into Headers, Rows and Columns: This document is part numbered 849940090071 Version 1.02 Page 40 of 72...

- Page 41 iCAP Customer Familiarisation Manual The general structure of reports is shown here with one group and several results (samples): Having selected the Result group option different groups can be created and selected for the report. The order of the groups can be changed as well using the arrows next to Create report. This document is part numbered 849940090071 Version 1.02 Page 41 of 72...

- Page 42 iCAP Customer Familiarisation Manual A name for the Result Group can be added and ticking boxes selects groups to add to data reporting. Press Create Report. Selecting Show Calibration Graphs will display the graph before any results. This document is part numbered 849940090071 Version 1.02 Page 42 of 72...

- Page 43 iCAP Customer Familiarisation Manual The Header section allows selection of the information for each sample. This is displayed before the results table. The Rows section allows the selection of data appearing for each sample (Concentration average, RSD...). This document is part numbered 849940090071 Version 1.02 Page 43 of 72...

- Page 44 iCAP Customer Familiarisation Manual The Columns selection allows the individual Analytes to be reported. This can be done individually or transfer “Analytes” to the right to select all. Save Groups saves changes to the group settings. Any groups saved can then be used or modified for other LabBooks.

- Page 45 iCAP Customer Familiarisation Manual 7.10.2 Method parameter group As for the Result group, name the group. Select the source of the data to be included in the report (create different groups to include different sources) and within one source select the required fields to be included: Table Options are used to set the formatting and the arrows next to Create Report are used to set the positioning.

-

Page 46: Exporting Labbooks

iCAP Customer Familiarisation Manual 7.11 Exporting Labbooks. This can be used to obtain help by e-mail (Problem reporting). From the home page go to File Manager, Right hand click a LabBook and select Export from the menu: Select the location to save the data and press OK: Other data (such as instrument logs) can also be exported as a .csv file. -

Page 47: Shutting Down The System

iCAP Customer Familiarisation Manual 7.12 Shutting Down the System Follow the procedure detail earlier. On the Dashboard Page, click on the “green ringed” Qtegra Driven icon. Figure 5-9. System shut down For the 7600 Sprint Valve open the Sprint Valve Configurator software from the desktop icon. When the software starts most of the options will be grayed out, click “Connect to Sprint Valve”. - Page 48 iCAP Customer Familiarisation Manual This document is part numbered 849940090071 Version 1.02 Page 48 of 72...

-

Page 49: Maintenance

iCAP Customer Familiarisation Manual 8 Maintenance The iCAP 7000 has been designed for minimum maintenance. However, it is critical that the sample introduction components be checked regularly for contamination and wear. Failure to do so could result in loss of instrument performance. Therefore, routine user maintenance of the iCAP 7000 is mainly concerned with keeping the instrument clean. -

Page 50: Preventive Maintenance

iCAP Customer Familiarisation Manual 8.1.3 Spray Chamber Cleaning If the spray chamber becomes greasy and droplets form on the inside soak the spray chamber in a dilute analytical-grade surfactant for five minutes. If the spray chamber becomes dirty or deposits form inside it, soak the spray chamber in a 10 % acid solution for two hours (a mixture of nitric and hydrochloric acid is normally suitable). - Page 51 iCAP Customer Familiarisation Manual Warning: Failure to maintain your chiller with the appropriate cooling fluid may cause internal damage to your instrument. An effective maintenance plan would include replacing the cooling fluid with new fluid at least once every six months depending on the usage of your instrument, and also to ensure that any air filters and water filters a kept clean.

- Page 52 iCAP Customer Familiarisation Manual 8.2.4.3 Daily External Cleaning The Sprint Valve is often operated in environments where spills and exposure to vapors is common. Good maintenance requires that you clean the system daily. 8.2.4.4 Cleaning the 6-Port Valve It will be necessary to periodically disassemble the 6-port valve and clean the inside to prolong the life of the valve.

- Page 53 iCAP Customer Familiarisation Manual Remove the Stator and the separator, noting their orientation: Carefully remove the rotor, from the valve: Using a clean cloth, gently clean the channels, ports and surfaces of the stator and rotor. If necessary use low-pressure, canned air to blow the channels and ports free of any remaining debris.

- Page 54 iCAP Customer Familiarisation Manual Carefully replace the rotor into the valve, the rotor will only fit in the correct orientation, forcing it will cause damage. This document is part numbered 849940090071 Version 1.02 Page 54 of 72...

- Page 55 iCAP Customer Familiarisation Manual Place one of the screws through the stator and separator and reattach it to the valve, in the orientation noted during removal: Using the hexagonal key, tighten all three screws, to firmly set the parts in place: NOTE The screws should be finger tight with the separator unable to move independently, over tightening can cause damage to the rotor.

- Page 56 iCAP Customer Familiarisation Manual Reattach the tubing connectors and use the ‘manual cycle’ function in the sprint valve Configurator software to check for leaks: 8.2.4.5 Checking for Leaks{ XE "inspection" }{ XE "leaks:finding" } The tubing has a finite lifespan{ XE "tubing:lifespan" }, and will wear out under normal use. Standard maintenance procedures require that you periodically check for leaks.

- Page 57 iCAP Customer Familiarisation Manual Note that any time the 6-port valve body is removed from its actuator; the valve will require retraining (re-initialization). { XE "valve:retraining" } To replace or re-orientate the 6-port valve: Remove all of the tube connectors to the 6 port valve: Using the provided hex key (9/64), loosen the hex screw on the locking collar which secures the base of the valve to the instrument: Firmly but carefully remove the valve head:...

- Page 58 iCAP Customer Familiarisation Manual This document is part numbered 849940090071 Version 1.02 Page 58 of 72...

- Page 59 iCAP Customer Familiarisation Manual Push in the valve to make sure that it is completely seated, there should be no gap between the valve and the collar: Use the hex key to tighten the locking collar: Open the sprint valve Configurator software: Expand the software using the arrow button on the right side of the window and click ‘home valve’: This document is part numbered 849940090071...

- Page 60 iCAP Customer Familiarisation Manual Reconnect the tubing: Check for any leaks using the manual cycle function: This document is part numbered 849940090071 Version 1.02 Page 60 of 72...

-

Page 61: Analytical Problems Hints And Tips

iCAP Customer Familiarisation Manual iCAP Customer Familiarisation Manual 9 Analytical Problems Hints and Tips Analytical Problems Hints and Tips Poor Precision Poor Precision A quick test should be run to determine if the poor analytical results are matrix quick test should be run to determine if the poor analytical results are matrix quick test should be run to determine if the poor analytical results are matrix related. - Page 62 iCAP Customer Familiarisation Manual iCAP Customer Familiarisation Manual usually indicative of dripping. In a usually indicative of dripping. In a glass or Teflon chamber the chamber glass or Teflon chamber the chamber should be wetted properly; that is operly; that is there should be no water droplets there should be no water droplets building up on the walls of the spray...

- Page 63 iCAP Customer Familiarisation Manual iCAP Customer Familiarisation Manual 9.1.1 Teflon capillary tubing: Teflon capillary tubing: Should be free of kinks and scissor or Should be free of kinks and scissor or pinch cut ends. For best results, razor cut pinch cut ends. For best results, razor cut at 45°...

-

Page 64: Poor Accuracy/Feedback

iCAP Customer Familiarisation Manual iCAP Customer Familiarisation Manual 9.2 Poor accuracy/feedback Poor accuracy/feedback First we should define accuracy as reproducing the standard value once standardised First we should define accuracy as reproducing the standard value once standardised First we should define accuracy as reproducing the standard value once standardised Proceed by making a standard as in the previous section (10 ppm Cu, Mn, Cd, Zn, Fe) Proceed by making a standard as in the previous section (10 ppm Cu, Mn, Cd, Zn, Fe) Proceed by making a standard as in the previous section (10 ppm Cu, Mn, Cd, Zn, Fe) -

Page 65: Suggested Maintenance In The Case Of Poor Precision And Detection Limits

iCAP Customer Familiarisation Manual 10 Suggested maintenance in the case of poor precision and detection limits 10.1 Introduction Maintenance refers to a series of periodic activities that should be performed on a periodic basis to optimise the short term and long term performance of the system. In this chapter we describe activities that should be performed by the typical user of the instrument. -

Page 66: Preventing Blocking Of The Nebuliser

iCAP Customer Familiarisation Manual 10.4 Preventing blocking of the nebuliser The most common problem with the nebuliser is the blockage of the tip by the deposition of particulate matter. In this section we provide a series of suggestions to minimise blockage. In most instances blockage in the nebuliser is caused by either particulate matter (from the sample) -

Page 67: Removing Solids From The Nebuliser

iCAP Customer Familiarisation Manual 10.5 Removing solids from the nebuliser If solids inside the nebuliser are interfering with performance of the system, the steps described below will generally remove them and provide normal operation. 10.5.1 To rinse the nebuliser Introduce a rinsing agent into the shell, either from the gas input or the nozzle (a squeeze bottle works well in both cases). - Page 68 iCAP Customer Familiarisation Manual 10.5.3 Solid deposit in sample capillary Note: This step assumes that a passage still exists through the contaminating material (i.e. the tip is not entirely clogged). Try to deduce the chemical nature of the deposit from the type of samples that are being analysed and select the solvent most likely to dissolve it.

-

Page 69: Cleaning The Glass Mixing Chamber

iCAP Customer Familiarisation Manual 10.5.5 Plugged capillary (fusible solids e.g. waxes) Note: This procedure should be used when no passage remains through the deposit. Carefully heat the nebuliser in the region of the capillary obstruction. Simultaneously (or intermittently) apply gentle gas pressure at the sample input tube. Caution: Avoid overheating residues that may produce insoluble pyrolysis products Stop treatment when you have opened a passage through the blockage. -

Page 70: Sample Introduction Spares & Consumables

iCAP Customer Familiarisation Manual 11 Sample Introduction Spares & Consumables Spare Parts for Sample Introduction Kits 8423 120 51141 Radial Torch (Tulip) 8423 120 51741 Radial Torch (Parallel) 8423 120 51151 Radial Spray Chamber Adaptor 8423 120 51241 Duo Torch (Tulip) 8423 120 51841 Duo Torch (Parallel) 8423 120 51251... - Page 71 iCAP Customer Familiarisation Manual Ball Joint Clip (for jacketed spray chamber - previously 8423 120 51421 842312051581) 8423 120 51611 Replacement Tubing Kit for enhanced Hydride system Nebuliser non-return valve (with tubing for 6mm connector 4301 228 41731 from gas box) 4301 166 21851 Torch connector for enhanced hydride kit Sample Introduction Kits Radial...

- Page 72 iCAP Customer Familiarisation Manual Sample loop assembly for oil samples 1mm internal diameter – 1.02ml volume 842347004054 Sample loop assembly for oil samples 1mm internal diameter – 1.48ml volume 842347004055 Sample loop assembly for oil samples 1mm internal diameter – 2ml volume 842347004056 Sample loop assembly for oil samples 1mm internal diameter –...

Need help?

Do you have a question about the iCAP 7000 Series and is the answer not in the manual?

Questions and answers