Perkins 1103 Operation And Maintenance Manual

Hide thumbs

Also See for 1103:

- Disassembly and assembly (136 pages) ,

- Operation and maintenance manual (85 pages) ,

- Workshop manual (54 pages)

Chapters

Table of Contents

Summary of Contents for Perkins 1103

- Page 1 SEBU7833-04 January 2015 Operation and Maintenance Manual 1103 and 1104 Industrial Engines DC(Engine) DD(Engine) DJ (Engine) DK (Engine) RE (Engine) RG (Engine) RJ(Engine) RR(Engine) RS(Engine) RT(Engine) DF(Engine) DG (Engine)

- Page 2 These changes can affect the service that is given to the product. Obtain the complete and most current information before you start any job. Perkins dealers or Perkins distributors have the most current information available. When replacement parts are required for this product Perkins recommends using Perkins replacement parts.

-

Page 3: Table Of Contents

SEBU7833 Table of Contents Table of Contents Warranty Section Warranty Information ........86 Foreword............4 Index Section Safety Section Index............... 87 Safety Messages..........5 General Hazard Information ......6 Burn Prevention..........8 Fire Prevention and Explosion Prevention ..9 Crushing Prevention and Cutting Prevention . -

Page 4: Foreword

Operation and Maintenance Manual except for the Operation interval and the maintenance items in that interval. Major repairs should only be carried out by Perkins Operating techniques outlined in this manual are authorized personnel. Your Perkins dealer or your basic. They assist with developing the skills and... -

Page 5: Safety Section

If a warning sign is attached to a part of the engine that is replaced, install a new warning sign on the replacement part. Perkins dealers or Perkins distributors can provide new warning signs. Do not work on the engine and do not operate the engine unless the instructions and warnings in the Operation and Maintenance Manual are understood. -

Page 6: General Hazard Information

SEBU7833 Safety Section General Hazard Information Illustration 3 g01682820 The ether warning label (2) is located on the cover of the inlet manifold. Refer to illustration 2 . Illustration 5 g03715821 3 Cylinder Engine. (1) Universal Warning Label (2) Ether Warning Label The universal warning label (1) is located at the rear of the valve mechanism cover on the three cylinder engine. - Page 7 SEBU7833 Safety Section General Hazard Information Start the engine from the operators station (cab). Never short across the starting motor terminals or the batteries. This action could bypass the engine neutral start system and/or the electrical system could be damaged. Engine exhaust contains products of combustion which may be harmful to your health.

-

Page 8: Burn Prevention

SEBU7833 Safety Section Burn Prevention Any contact with hot coolant or with steam can cause severe burns. Allow cooling system components to cool before the cooling system is drained. Check that the coolant level after the engine has stopped and the engine has been allowed to cool. Ensure that the filler cap is cool before removing the filler cap. -

Page 9: Fire Prevention And Explosion Prevention

Personal injury, property damage, or engine damage could result. If the application involves the presence of combustible gases, consult your Perkins dealer and/ or your Perkins distributor for additional information about suitable protection devices. Remove all flammable combustible materials or conductive materials such as fuel, oil, and debris from the engine. -

Page 10: Crushing Prevention And Cutting Prevention

Do not clip any other items to the high- pressure lines. Repair any lines that are loose or damaged. Leaks can cause fires. Consult your Perkins dealer or your Perkins distributor for repair or for replacement parts. Check lines, tubes, and hoses carefully. Do not use your bare hand to check for leaks. -

Page 11: Mounting And Dismounting

SEBU7833 Safety Section Mounting and Dismounting i05875651 i02207232 Engine Starting Mounting and Dismounting Do not climb on the engine. The engine has not been designed with mounting or dismounting locations. Refer to the OEM for the location of foot and hand Do not use aerosol types of starting aids such as holds for your specific application. -

Page 12: Engine Stopping

SEBU7833 Safety Section Engine Stopping To ensure that the engine and the engine electrical i01928905 systems function correctly, an engine-to-frame Engine Stopping ground strap with a direct path to the battery must be used. This path may be provided by way of a direct engine ground to the frame. -

Page 13: Product Information Section

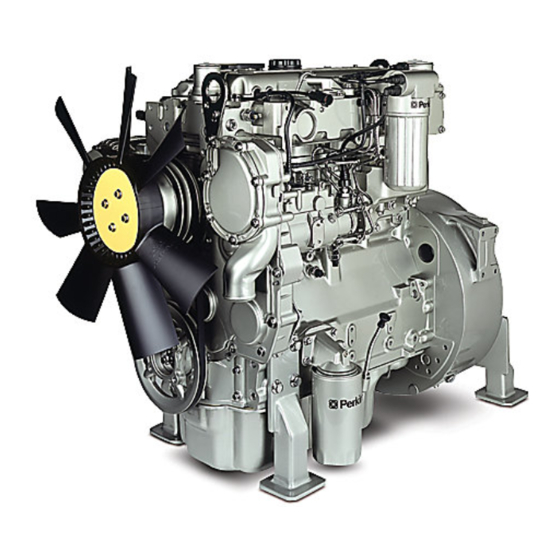

SEBU7833 Product Information Section Model View Illustrations Product Information Section Model Views i05874119 Model View Illustrations The following model views show typical features of the engine. Due to individual applications, your engine may appear different from the illustrations. 1104 Engine Model Views Illustration 12 g03706445 Typical example... - Page 14 SEBU7833 Model Views Model View Illustrations Illustration 13 g03706446 Typical example (12) Rear lifting eye (15) Turbocharger (18) Coolant drain (13) Front lifting eye (16) Oil drain plug (14) Alternator (17) Flywheel...

- Page 15 SEBU7833 Model Views Model View Illustrations 1103 Engine Model Views Illustration 14 g03705844 Typical example (1) Coolant out let (6) Oil gauge (Dipstick) (11) Coolant intake (2) Secondary fuel filter (7) Primary fuel filter (12) Water pump (3) Fuel injector...

- Page 16 SEBU7833 Model Views Engine Description Illustration 15 g03705848 Typical example (14) Alternator (16) Starting motor (18) Flywheel housing (15) Turbocharger (17) Flywheel (19) Coolant drain plug i05899588 Engine Description • Turbocharged aftercooled • Turbocharged • Naturally aspirated Engine Specifications Note: The front end of the engine is opposite the flywheel end of the engine.

- Page 17 0.45 mm (0.018 inch) Stroke 127 mm (5.0 inch) Aspiration Turbocharged aftercooled Table 4 Turbocharged Naturally aspirated 1103 Constance Speed Specifications Compression Ratio NA 19.25:1 NA Number of Cylinders 3 In-Line T 18.23:1 T, TA Bore 105 mm (4.134 inch) Displacement 4.4 L (268 in...

- Page 18 SEBU7833 Model Views Engine Description Engine Service Life Engine efficiency and maximum utilization of engine performance depend on the adherence to proper operation and maintenance recommendations. In addition, use recommended fuels, coolants, and lubricants. Use the Operation and Maintenance Manual as a guide for required engine maintenance. Expected engine life is generally predicted by the average power that is demanded.

-

Page 19: Product Identification Information

Serial Number Plate i02280116 Engine Identification Perkins engines are identified by a serial number. This number is shown on a serial number plate that is mounted on the left hand side of the engine block. An example of an engine number is RE12345U090001H. - Page 20 SEBU7833 Product Identification Information Emissions Certification Film Primary Fuel Filter Water Separator Element Secondary Fuel Filter Element Lubrication Oil Filter Element Auxiliary Oil Filter Element Total Lubrication System Capacity Total Cooling System Capacity Air Cleaner Element Fan Drive Belt Alternator Belt i02758852 Emissions Certification Film Label for compliant engines...

- Page 21 SEBU7833 Product Identification Information Emissions Certification Film Illustration 19 g01156733 This typical example of a label is installed on engines that have mechanical fuel injection pumps. Label for engines that comply with MSHA emissions Illustration 20 g01381316 Typical example The label that is shown in illustration 20 is for engines that operate in underground coal mines in North America.

- Page 22 SEBU7833 Product Identification Information Emissions Certification Film Label for engines that do not comply with emissions Illustration 21 g01156734 This typical example of a label is installed on engines that do not comply with emissions. Illustration 22 g01157127 This typical example of a label is installed on engines that are stationary engines.

-

Page 23: Operation Section

If alterations are made, ensure that correct lifting devices are provided. Consult your Perkins dealer or your Perkins distributor for information regarding fixtures for correct engine lifting. Illustration 24... - Page 24 Lifting and Storage Engine Storage Sealed Coolant System i05876583 Engine Storage Ensure that the cooling system is filled with Perkins ELC, or an antifreeze that meets “ASTM D6210” specification. Perkins are not responsible for damage which may Open Cooling System occur when an engine is in storage after a period in service.

-

Page 25: Gauges And Indicators

Determine and correct the cause of any significant change in the readings. Consult your Perkins dealer Ammeter – This gauge indicates the or your Perkins distributor for assistance. -

Page 26: Engine Starting

SEBU7833 Engine Starting Before Starting Engine Engine Starting • Do not start the engine or move any of the controls if there is a “DO NOT OPERATE” warning tag or similar warning tag attached to the start switch or i02194223 to the controls. - Page 27 SEBU7833 Engine Starting Cold Weather Starting 1. If equipped, move the throttle lever to the full 2. If equipped, turn the engine start switch to the throttle position before you start the engine. HEAT position. Hold the engine start switch in the HEAT position for 6 seconds until the glow plug indicator light illuminates.

- Page 28 SEBU7833 Engine Starting Starting with Jump Start Cables 4. Start the engine. i02177935 Starting with Jump Start 5. Immediately after the stalled engine is started, disconnect the jump start cables in reverse order. Cables After jump starting, the alternator may not be able to fully recharge batteries that are severely discharged.

-

Page 29: Engine Operation

The engine The efficiency of the engine can affect the fuel will reach normal operating temperature sooner economy. Perkins design and technology in during a low engine speed (rpm) and during a low- manufacturing provides maximum fuel efficiency in all power demand. -

Page 30: Engine Stopping

SEBU7833 Engine Stopping Stopping the Engine Engine Stopping i01903608 After Stopping Engine i01929389 Stopping the Engine Note: Before you check the engine oil, do not operate the engine for at least 10 minutes in order to allow the engine oil to return to the oil pan. NOTICE •... -

Page 31: Cold Weather Operation

• The cooling system and the lubrication system for Perkins Diesel Engines can operate effectively in cold the engine do not lose heat immediately upon weather. During cold weather, the starting and the shutdown. - Page 32 An effective block heater is less acid and less sludge in the oil. This lubrication typically a 1250/1500 W unit. Consult your Perkins will provide longer service life for the engine bearings, dealer or your Perkins distributor for more the piston rings, and other parts.

- Page 33 SEBU7833 Cold Weather Operation Fuel and the Effect from Cold Weather Note: Perkins discourages the use of all air flow Be aware of these properties when diesel fuel is purchased. Consider the average ambient air restriction devices such as radiator shutters.

- Page 34 SEBU7833 Cold Weather Operation Fuel Related Components in Cold Weather The micron rating and the location of a primary fuel filter is important in cold weather operation. The primary fuel filter and the fuel supply line are the most common components that are affected by cold fuel. Fuel Heaters Note: The OEM may equip the application with fuel heaters.

-

Page 35: Maintenance Section

1103Engine Engines with auxiliary oil filters will require additional oil. Refer to the OEM specifications for the capacity of the auxiliary oil filter. Table 9 1103 Naturally Aspirated Engine without an oil cooler Compartment or System Quarts Liters Engine Only 4.21... - Page 36 SEBU7833 Refill Capacities Fluid Recommendations • Contamination of the cooling system (Table 9, contd) 1103 Naturally Aspirated Engine without an oil cooler • Overheating of the engine Compartment or System Quarts Liters • Foaming of the coolant External cooling system capacity (OEM...

- Page 37 • Leakage of the water pump seal • ASTM American Society for Testing and Materials • Plugging of radiators, coolers, and small passages The following two coolants are used in Perkins diesel engines: Glycol Preferred – Perkins ELC Glycol in the coolant helps to provide protection against the following conditions: Acceptable –...

- Page 38 Perkins provides ELC for use in the following Do not use standard supplemental coolant additive applications: (SCA). • Heavy-duty spark ignited gas engines When using Perkins ELC, do not use standard SCA's or SCA filters. • Heavy-duty diesel engines • Automotive applications ELC Cooling System Cleaning...

- Page 39 Check the antifreeze (glycol concentration) in order to ensure adequate protection against boiling or 9. Fill the cooling system with the Perkins Premixed freezing. Perkins recommends the use of a ELC. refractometer for checking the glycol concentration. A hydrometer should not be used.

- Page 40 Heavy-duty antifreeze of all types REQUIRE periodic the American Petroleum Institute (API) is recognized additions of an SCA. by Perkins. For detailed information about this system, see the latest edition of the “API publication Test the antifreeze periodically for the concentration No.

- Page 41 Certain abbreviations follow the nomenclature of intervals. API CH-4 oils are recommended for “SAE J754”. Some classifications follow “SAE J183” conditions that demand a premium oil. Your Perkins abbreviations. In addition to Perkins definitions, there distributor has specific guidelines for optimizing oil are other definitions that will be of assistance in purchasing lubricants.

- Page 42 Some synthetic base oils have performance Greater than 1.0 0.50 of normal characteristics that enhance the service life of the oil. Perkins does not recommend the automatic extending of the oil change intervals for any type of Lubricant Viscosity Recommendations oil.

- Page 43 Re refined base stock oil Aftermarket Oil Additives Re refined base stock oils are acceptable for use in Perkins does not recommend the use of aftermarket additives in oil. The use aftermarket additives in order Perkins engines if these oils meet the performance to achieve the engines maximum service life, or rated requirements that are specified by Perkins .Re...

- Page 44 21 . Fluid Recommendations NOTICE (Fuel Recommendations) The footnotes are a key part of the Perkins Specifica- tion for Distillate Diesel Fuel Table. Read ALL of the footnotes. • Glossary • ISO International Standards Organization • ASTM American Society for Testing and Materials •...

- Page 45 Regional regulations, national regulations, or international regulations can require a fuel with a specific sulfur limit. Consult all applicable regu- lations before selecting a fuel for a given engine application. Perkins fuel systems and engine components can operate on high sulphur fuels where allowed by legislation.

- Page 46 "Contamination Control Recommendations for Fuels" in this chapter. Viscosity NOTICE Operating with fuels that do not meet the Perkins rec- Viscosity is the property of a liquid of offering ommendations can cause the following effects: Start- resistance to shear or flow. Viscosity decreases with ing difficulty, poor combustion, deposits in the fuel increasing temperature.

- Page 47 UMK8276 ULSD and sulphur fuel diesel fuels are acceptable to Perkins Diesel Fuel Conditioner is the approved use in all engine models. The lubricity of these fuels additive refer to “Perkins Diesel Fuel Conditioner”.

- Page 48 Note: Minimum cetane number of 40 is Protection Agency (EPA) and European Certification recommended otherwise cold starting problems or fuels. Perkins does not certify engines on any other light load misfire might occur. Since jet fuel fuel. The user of the engine has the responsibility of...

- Page 49 If biodiesel or biodiesel blends of fuel are to be used, There are five classes that are given to arctic climates Perkins require the use of Perkins fuel cleaner. For and severe winter climates. 0, 1, 2, 3 and 4.

- Page 50 80 hours. designs such as common rail injection systems and Perkins fuel cleaner can be used on an on-going unit injection systems. Injection system designs utilize basis with no adverse impact on engine or fuel higher fuel pressures and tight clearances between system durability.

- Page 51 500 ppm water or less. • Perkins recommends the use of bulk fuel filter / coalescer units which clean the fuel of both particulate contamination and water in a single pass.

-

Page 52: Maintenance Interval Schedule

SEBU7833 Refill Capacities Maintenance Interval Schedule “Fuel System Primary Filter (Water Separator) i05927155 Element - Replace”..........73 Maintenance Interval Schedule “Fuel System Secondary Filter - Replace” ....77 When Required “Hoses and Clamps - Inspect/Replace”....80 “Radiator - Clean” ............81 “Battery - Replace”...........55 Every 1000 Service Hours “Battery or Battery Cable - Disconnect”....56 “Engine Valve Lash - Inspect/Adjust”... -

Page 53: Aftercooler Core - Inspect

SEBU7833 Refill Capacities Aftercooler Core - Inspect 2. Turn the aftercooler core upside-down in order to 9. Inspect the core in order to ensure cleanliness. remove debris. Pressure test the core. If necessary, repair the core. 10. Install the core. Refer to the OEM information for the correct procedure. -

Page 54: Alternator - Inspect

Refill Capacities Alternator - Inspect i02322311 Alternator - Inspect Perkins recommends a scheduled inspection of the alternator. Inspect the alternator for loose connections and correct battery charging. Check the ammeter (if equipped) during engine operation in order to ensure correct battery performance and/or correct performance of the electrical system. -

Page 55: Battery - Replace

SEBU7833 Refill Capacities Battery - Replace The battery cables or the batteries should not be removed with the battery cover in place. The bat- tery cover should be removed before any servic- ing is attempted. Removing the battery cables or the batteries with the cover in place may cause a battery explosion resulting in personal injury. -

Page 56: Battery Or Battery Cable - Disconnect

SEBU7833 Refill Capacities Battery or Battery Cable - Disconnect 4. Clean all disconnected connection and battery terminals. All lead-acid batteries contain sulfuric acid which can burn the skin and clothing. Always wear a 5. Use a fine grade of sandpaper to clean the face shield and protective clothing when working terminals and the cable clamps. - Page 57 For information regarding the disposal and the Drain recycling of used coolant, consult your Perkins dealer or your Perkins distributor. Flush Pressurized System: Hot coolant can cause seri- 1.

-

Page 58: Cooling System Coolant (Elc) - Change

SEBU7833 Refill Capacities Cooling System Coolant (ELC) - Change 2. Fill the cooling system with Commercial Heavy- NOTICE Duty Coolant. Add Supplemental Coolant Additive Keep all parts clean from contaminants. to the coolant. For the correct amount, refer to the Operation and Maintenance Manual, “Fluid Contaminants may cause rapid wear and shortened component life. - Page 59 Run the engine at high idle For information regarding the disposal and the for 1 minute in order to purge the air from the recycling of used coolant, consult your Perkins cavities of the engine block. Stop the engine. dealer or your Perkins distributor.

-

Page 60: Cooling System Coolant Level - Check

8. Run the engine and check for coolant leaks. i05907697 Cooling System Coolant Extender (ELC) - Add In order for Perkins ELC to achieve 12000 hours an extender must be added at 6000 hours. For a suitable extender, contact your Perkins dealer or Perkins distributor. - Page 61 SEBU7833 Refill Capacities Cooling System Coolant Level - Check Check the coolant level when the engine is stopped and cool. NOTICE When any servicing or repair of the engine cooling system is performed, the procedure must be per- formed with the engine on level ground. This will allow you to accurately check the coolant level.

-

Page 62: Engine - Clean

SEBU7833 Refill Capacities Driven Equipment - Check i01930350 Engine - Clean Pressurized System: Hot coolant can cause seri- ous burns. To open the cooling system filler cap, stop the engine and wait until the cooling system components are cool. Loosen the cooling system pressure cap slowly in order to relieve the pressure. -

Page 63: Engine Air Cleaner Element (Dual Element) - Clean/Replace

Servicing the Air Cleaner Elements Note: The air filter system may not have been provided by Perkins . The procedure that follows is for a typical air filter system. Refer to the OEM information for the correct procedure. - Page 64 SEBU7833 Refill Capacities Engine Air Cleaner Element (Dual Element) - Clean/Replace Cleaning the Primary Air Cleaner Elements NOTICE Observe the following guidelines if you attempt to clean the filter element: Do not tap or strike the filter element in order to re- move dust.

-

Page 65: Inspect/Replace

SEBU7833 Refill Capacities Engine Air Cleaner Element (Single Element) - Inspect/Replace Inspecting the Primary Air Cleaner NOTICE Elements Never service the air cleaner element with the engine running since this will allow dirt to enter the engine. A wide variety of air cleaners may be installed for use with this engine. -

Page 66: Engine Oil Level - Check

Engine Ground - Inspect/Clean Inspect the wiring harness for good connections. Perkins use the starter motor in order to ground the engine. Check the connection on the starter motor at every oil change. Ground wires and straps should be combined at engine grounds. -

Page 67: Engine Oil Sample - Obtain

Engine Oil and Filter - Change Perkins recommends using a sampling valve in order to obtain oil samples. The quality and the consistency of the samples are better when a sampling valve is used. - Page 68 Refer to the Operation and cations. Use of an oil filter that is not recommended Maintenance Manual for more information on refill by Perkins could result in severe damage to the en- capacities. gine bearings, crankshaft, etc., as a result of the larg- er waste particles from unfiltered oil entering the engine lubricating system.

-

Page 69: Fuel Injector - Test/Change

Adjust starting the engine. Do not crank the engine for more than 30 seconds. This maintenance is recommended by Perkins as 2. Start the engine and run the engine at “LOW IDLE” part of a lubrication and preventive maintenance for 2 minutes. Perform this procedure in order to schedule in order to help provide maximum engine life. - Page 70 The fuel injectors should not be cleaned as cleaning Disassembly and Assembly Manual for more with incorrect tools can damage the nozzle. The fuel information. Consult your authorized Perkins dealer injectors should be renewed only if a fault with the or your Perkins distributor for assistance.

-

Page 71: Fuel System - Prime

SEBU7833 Refill Capacities Fuel System - Prime i05909104 Fuel System - Prime If air enters the fuel system, the air must be purged from the fuel system before the engine can be started. Air can enter the fuel system when the following events occur: •... - Page 72 SEBU7833 Refill Capacities Fuel System - Prime Injection Pump Types 1. Turn the keyswitch to the ON position and allow 180 seconds for the electric priming pump to prime There are two different types of fuel injection pump the system. that can be installed.

-

Page 73: Fuel System Primary Filter (Water Separator)

SEBU7833 Refill Capacities Fuel System Primary Filter (Water Separator) Element - Replace Engines with Mechanically i05910440 Operated Priming Pumps Fuel System Primary Filter (Water Separator) Element - Replace Fuel leaked or spilled onto hot surfaces or electri- cal components can cause a fire. To help prevent possible injury, turn the start switch off when changing fuel filters or water separator elements. - Page 74 SEBU7833 Refill Capacities Fuel System Primary Filter (Water Separator) Element - Replace 2. Install O ring (9) into lower casing and install O ring (7) into bowl. 3. Assemble lower casing (10) to bowl (8), install canister (6) onto bowl assembly. 4.

-

Page 75: Fuel System Primary Filter/Water Separator

SEBU7833 Refill Capacities Fuel System Primary Filter/Water Separator - Drain i05914093 Fuel System Primary Filter/ Water Separator - Drain Fuel leaked or spilled onto hot surfaces or electri- cal components can cause a fire. To help prevent possible injury, turn the start switch off when changing fuel filters or water separator elements. -

Page 76: Fuel System Secondary Filter/Water Separator - Drain

SEBU7833 Refill Capacities Fuel System Secondary Filter/Water Separator - Drain Illustration 54 g03721682 Typical examples 1. Place a suitable container below the water i06020909 separator. Fuel System Secondary Filter/ 2. Open the drain (1). Allow the fluid to drain into the Water Separator - Drain container. -

Page 77: Fuel System Secondary Filter - Replace

SEBU7833 Refill Capacities Fuel System Secondary Filter - Replace 2. Open the drain (1) and allow fluid to drain from the filter. When clean fuel can be see close the drain. Tighten the drain by hand pressure only. Dispose of the drained fluid in accordance with local regulations. - Page 78 SEBU7833 Refill Capacities Fuel System Secondary Filter - Replace 2. Lubricate the O ring seal (6) with clean engine oil. Do NOT fill the filter bowl (2) with fuel before the filter assembly is installed. 3. Do not use a tool in order to install the filter assembly.

- Page 79 SEBU7833 Refill Capacities Fuel System Secondary Filter - Replace Illustration 61 g03721949 Typical example Illustration 60 g03721948 Typical example 1. Clean the outside body of the filter assembly. Install 3. Remove the O ring (5) from the filter bowl and a suitable tube onto drain (2).

-

Page 80: Fuel Tank Water And Sediment - Drain

SEBU7833 Refill Capacities Fuel Tank Water and Sediment - Drain Open the drain valve on the bottom of the fuel tank in order to drain the water and the sediment. Close the 4. Install the spin-on filter (5) into filter base (1). drain valve. -

Page 81: Radiator - Clean

Perkins. The following text describes a typical method of replacing The radiator is not usually supplied by Perkins. The coolant hoses. Refer to the OEM information for following text describes a typical cleaning procedure further information on the coolant system and the for the radiator. -

Page 82: Severe Service Application - Check

Refer to the standards for the engine or consult your Perkins dealer or your Perkins distributor in order to Pressurized water may also be used for cleaning. The determine if the engine is operating within the defined maximum water pressure for cleaning purposes must parameters. -

Page 83: Starting Motor - Inspect

Turbocharger - Install” for further information. and Adjusting Manual, “Electric Starting System - Test” for more information on the checking procedure Inspecting and for specifications or consult your Perkins dealer or your Perkins distributor for assistance. NOTICE The compressor housing for the turbocharger must i02184788 not be removed from the turbocharger for cleaning. -

Page 84: Walk-Around Inspection

4. Fasten the air intake pipe and the exhaust outlet “Water Pump - Remove and Install” for more pipe to the turbocharger housing. information or consult your Perkins dealer or your Perkins distributor. i02177973 • Inspect the lubrication system for leaks at the front... - Page 85 SEBU7833 Refill Capacities Water Pump - Inspect • Cracks in the cylinder head • A piston seizure • Other potential damage to the engine Note: The water pump seal is lubricated by the coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract.

-

Page 86: Warranty Section

Emissions Warranty. Consult your authorized Perkins dealer or your authorized Perkins distributor in order to determine if your engine is emissions certified and if your engine is subject to an Emissions Warranty. -

Page 87: Index

SEBU7833 Index Section Index Engines Without a Coolant Recovery Tank . 61 Crushing Prevention and Cutting Prevention .. 10 After Starting Engine........28 After Stopping Engine........30 Aftercooler Core - Clean/Test ......52 Aftercooler Core - Inspect........ 53 Driven Equipment - Check....... 62 Alternator - Inspect .......... - Page 88 SEBU7833 Index Section Engine Storage..........24 Fuel System Secondary Filter - Replace ..77 Condition for Storage ........24 Install the Element ........78 Engine Valve Lash - Inspect/Adjust....69 Type 1 Secondary Fuel Filter ....... 77 Engine Warm-up..........29 Type 2 Secondary Fuel Filter .......

- Page 89 SEBU7833 Index Section Model View Illustrations........13 Inspect the Engine for Leaks and for Loose 1103 Engine Model Views......15 Connections ..........84 1104 Engine Model Views......13 Warranty Information ........86 Model Views ............ 13 Warranty Section ..........86 Mounting and Dismounting.......11...

- Page 90 SEBU7833 Index Section...

- Page 91 Product and Dealer Information Note: For product identification plate locations, see the section “Product Identification Information” in the Operation and Maintenance Manual. Delivery Date: Product Information Model: Product Identification Number: Engine Serial Number: Transmission Serial Number: Generator Serial Number: Attachment Serial Numbers: Attachment Information: Customer Equipment Number: Dealer Equipment...

- Page 92 ©2015 Perkins Engines Compony Limited All Rights Reserved...

Need help?

Do you have a question about the 1103 and is the answer not in the manual?

Questions and answers