Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for SPEX SamplePrep ShatterBox 8550

- Page 1 8550 ShatterBox ® Automatic Ring Mill...

- Page 3 Thank you for having chosen the 8550 ShatterBox Ring Mill from SPEX SamplePrep. To enjoy years of reliable, efficient and safe use of this instrument, please read this manual thoroughly and keep it in a safe and handy place for future reference.

-

Page 4: Table Of Contents

Index Index ....................2 Introduction ..................4 Historical background ................4 The 8550 ShatterBox ................5 Accessories ....................7 Main features ................... 7 Precautions ..................9 Installation ..................10 Location ....................10 Unpacking ....................11 Connection - electrical ................12 Connection –... - Page 5 Grinding troubleshooting ............. 37 Unit does not turn on ................37 Unit does not run ................... 37 Door remains locked ................37 Grinding container locked up, won’t grind ..........37 Excessive vibration, unit “walks” ............. 38 Periodic inspection ............... 39 Warning ....................

-

Page 6: Introduction

Historical background Since its introduction in the 1980’s, the SPEX SamplePrep ShatterBox has become the most popular “swing mill” in America. Now as then, it remains the most efficient way to pulverize up to 100ml in volume (or 100g in weight) of brittle material to analytical fineness. -

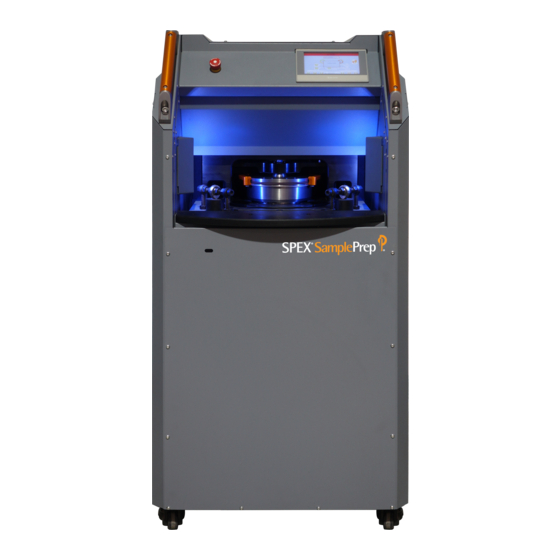

Page 7: The 8550 Shatterbox

The 8550 ShatterBox General view Emergency stop button LCD screen interface Door handle Grinding dish Safety door Door lock override Rear wheel Front caster wheel Working principle The 8550 ShatterBox swings a dish-shaped grinding container, with a puck and (often) a ring inside, in a tight high-speed circle; the sample is quickly crushed between the wall and floor of the container and the moving puck/ring grinding elements. - Page 8 minimize contamination, grinding containers are available in hardened steel, tungsten carbide, alumina ceramic, and zirconia ceramic. The full range of 8550 ShatterBox grinding containers is described in detail in the SPEX Handbook of Sample Preparation and Handling, the SPEX ShatterBox Accessories Manual and on our website: www.spexsampleprep.com Automated dish holder Unlike some other units, this mill provides a simple and efficient system to...

-

Page 9: Accessories

Accessories The 8550 ShatterBox requires the use of a dish with a handle assembly. For existing dishes without handle assembly, the corresponding handle assembly may be purchased separately and secured to the dish. Available Grinding Dishes: Dish and Handle part Dish part handle number... - Page 10 Productivity • Automated door opening after a grinding operation • Automated dish clamping Durability • Sturdy industrial-grade modular electronics • Robust IP65 rated industrial interface • Dedicated PLC-based programming • Low-maintenance Simplicity • Easy installation, easy use • Single-phase power, no separate power supply •...

-

Page 11: Precautions

Precautions Pinch point This unit features a door that opens automatically. Do not touch the unit after grinding, until the door has fully opened. High voltage Disconnect power cord before attempting any cleaning, maintenance or repair operation. Be careful that no liquid infiltrates into the unit’s casing. Heavy instrument It is advisable that at least two persons roll this instrument to avoid injuries. -

Page 12: Installation

Installation Please read the following section for proper commissioning of your instrument. Do not hesitate to contact SPEX SamplePrep with any question you might have with this crucial step. IMPORTANT: It is advisable that several persons carry this instrument to avoid injuries. -

Page 13: Unpacking

Safety and working clearances When this unit operates, it shakes in place, and so appropriate clearances must be kept all around the unit. Our minimum recommendations are: • 5 cm (2 in) at the left side • 5 cm (2 in) at the right side •... -

Page 14: Connection - Electrical

Crate contents The instrument comes with its essential accessories. In addition to optional items you might have ordered, the box should contain: • 1 8550 ShatterBox (main grinder unit) • 1 instruction manual (this booklet) • 1 power cable • 1 USB memory stick •... -

Page 15: Connection - Exhaust

Connection – exhaust A standard 3-in (76 mm) outlet allows the unit to be connected to your dust extraction/exhaust system. To connect it, a safety screw must be removed to allow for the blade of the blast gate to be pulled down in open position. We suggest using a standard flexible 3-in duct hose with worm-drive clamps to link the unit with your air extraction system. -

Page 16: Setting Up

To lift the front of the unit, use the provided 10-mm wrench and turn the caster nut in the direction shown below. (A finger adjustment with the orange knob is not sufficient.) IMPORTANT: Always lift the unit with the casters leveling nut before operating the 8550 ShatterBox. -

Page 17: Questions

Questions ? Should you have any question regarding the proper installation and start-up of your instrument, please contact SPEX SamplePrep directly (see information on page 51) for assistance. -

Page 18: Choice Of The Grinding Container

Choice of the grinding container There are at present ten different ShatterBox grinding containers in five different materials and four sizes; while each of the ten has a puck-shaped grinding element or a puck and ring, each has different requirements for sample size and/or grinding time. -

Page 19: Size

Alumina Ceramic is harder than tungsten carbide, but is comparatively lightweight. It grinds fairly slowly with low contamination levels and is subject to fracture. Major elements: Al. Minor elements: Si, Mg, and Ca. Size There are four sizes of ShatterBox grinding container: small, medium, large, and extra-large. - Page 20 grinding time or decreasing the sample size, or both. If caking occurs, consult the ShatterBox Accessory Manual for information about grinding aids.

-

Page 21: How The Unit Works

How the unit works Grinding methods The 8550 ShatterBox comes pre-loaded with a basic grinding method that can be used as is, or can be customized. All grinding methods can be saved, renamed, deleted or copied, just like computer files. Only the preset method is protected to avoid accidental overwriting. -

Page 22: Using The 8550 Shatterbox

Using the 8550 ShatterBox Operation of the safety door As mentioned above, the 8550 ShatterBox is equipped with a semi-automatic safety door, which has a safety interlock to prevent the user from starting a grinding cycle if the door is still open. Automatic lock operation When the user closes the door, an electronic system will engage mechanical locks, so that the door cannot be accidentally re-opened. - Page 23 Safety door Lock override access Thin tool...

-

Page 24: The Main Running Screen

The main running screen After the booting screen, you will obtain a display similar to the following (not all buttons/icons will appear, depending on the unit’s settings): Here is a short explanation of the various zones and buttons: This zone offers a selection of Spex dish types, for enhanced safety and detection upon automatic clamping. - Page 25 This button allows the user to access the Special parameters screen (see page 33 for details). This zone is where the parameters for each grinding stage are set. The first line indicates the speed (in RPM) and the second the duration of that stage. In this example, the unit is set to run at 800 RPM, for 4 minutes (and zero seconds).

-

Page 26: Loading A Program

This zone is used to select the current active grinding method. See page 24, Loading a program for details. The padlock icon/button shows the state grinding recipe parameters. A closed padlock means that the parameters locked, password required unlock parameter access. Conversely, an open padlock means... -

Page 27: During A Grinding

Touch the green button to confirm, or red to cancel. During a grinding While the instrument is running, the main screen will display additional information and buttons, as well as the number of the step currently being executed and a countdown showing the total time remaining to the grinding program. -

Page 28: A General Grinding

The Stop button, as the name implies, is used to halt an ongoing grinding process, stopping all motors and resetting the system. This can be used when one realizes that the dish was not properly prepared or filled, or in case of emergency, for example. - Page 29 13. Once the timers are elapsed, the motor slows to a stop, the dish clamping system is released and the safety door automatically opens. Warning: Pinch point – keep clear of the door when it slides down. 14. Remove the dish containing your ground sample. Transfer the sample to an appropriate container, and clean the dish for the next run.

-

Page 30: Programming The 8550 Shatterbox (Advanced)

Programming the 8550 ShatterBox (advanced) When specific sample types do not seem to be easily processed by a preset grinding method, it is necessary to manually modify its parameters. Unlocking the advanced mode Before being allowed to manage grinding programs and edit parameters, one must enter the correct password. -

Page 31: Managing Grinding Methods

NOTE: If you prefer to always keep the unit in “advanced mode”, it is possible to do so, in the Global Parameters (refer to page 31). Managing grinding methods Grinding methods can be managed just like files on a computer. In the main screen, you can press the icon corresponding to Copy, Delete and Save. -

Page 32: Grinding Steps

Grinding steps Grinding methods all have the same simple structure, having up to two steps (or stages), each featuring two parameters: Speed and Duration. Many sample types actually require only one grinding step. If you need only one grinding step, you can touch the icon of the second step, to toggle it from active (with green arrows all around) to inactive (Off, with red arrows all around.) Speed... -

Page 33: Global Parameters

Global parameters In addition to recipe-specific parameters, your mill provides extra versatility through flexible parameters that will apply to all grinding programs. To modify the global parameters, first unlock the advanced mode (see page 28, Unlocking the advanced mode), then touch the Global Parameters icon that is now available on the main display screen. - Page 34 This box shows the serial number of the ShatterBox unit. The number to the right of the orange “odometer” icon shows the total number of grinding cycles that the ShatterBox unit has performed.

-

Page 35: Special Parameters

Special parameters This section presents an advanced interface window that can be used to adjust the sensitivities and offsets of various sensors on the mill. WARNING: Changing these parameters should only be done by trained personnel. Incorrectly setting these parameters could cause damage to the unit. Accessing the Special parameters... -

Page 36: Parameters Description

Parameters description This parameter controls the calibration of the motor speed drive. This has been factory-set and should not be changed unless advised by a Spex service technician. This parameter controls the delay for the opening of the shield. This has been factory-set and should not be changed unless advised by a Spex service technician. -

Page 37: Dish Calibration Procedure

This section is used to set the maximum allowed motor speed for a given dish. Tungsten carbide large hardened steel dishes should always be limited to 1050. If you create a new calibration for those, make sure the RPM limit is limited to 1050. - Page 38 In the Special parameters screen, use the left/right arrows to navigate to the dish that you wish to re-calibrate. With the arrows beside the dish name, select the dish number for which you want to update the calibration or select an unused calibration number to create one.

-

Page 39: Grinding Troubleshooting

Grinding troubleshooting This section presents the most common grinding-related problems. For specific assistance, please do not hesitate to contact us (see page 51, Contacting SPEX). Unit does not turn on No power at all Make sure power cord is plugged into outlet. Check outlet for power and correct voltage as required. -

Page 40: Excessive Vibration, Unit "Walks

Excessive vibration, unit “walks” Casters not locked. Lock casters. -

Page 41: Periodic Inspection

If unsure, do not hesitate to get in touch with a SPEX SamplePrep technician (see page 51, Contacting SPEX). Assistance by phone or email is always free of charge. -

Page 42: Service Operations

Service operations This section describes tasks that are performed on a regular basis, and are performed to adjust or repair a malfunctioning system of the instrument. Some sections also describe initial operations, which need to be performed before first using the unit. Should you have any question, or need further assistance, please do not hesitate to contact us (see page 51, Contacting SPEX). -

Page 43: Top Panel Removal

Top panel removal In order to gain access to most electronic components, it is necessary to remove the top panel. IMPORTANT: Always disconnect the instrument from the power outlet when working with panels removed. 240 Volts inside! Risk of electrocution! 1. -

Page 44: Front Panel Removal

Front panel removal In order to gain access to the door mechanism and sensors, it is necessary to remove the front panel. IMPORTANT: Always disconnect the instrument from the power outlet when working with panels removed. 240 Volts inside! Risk of electrocution! 1. -

Page 45: Door Removal

Door removal The following procedure describes how to remove the sliding door. This may be necessary to resolve door operating issues (e.g. adjust the height of the locking solenoid, access the safety switch...) IMPORTANT: Always disconnect the instrument from the power outlet when working with panels removed. - Page 46 4. Remove the screws from the two bumper brackets and the counterweight bracket. 5. Hold the door up, while pulling the counterweight bracket down, to disengage it. (WARNING: Door is heavy!)

- Page 47 6. Gently let the door slide down and pull it off its guide rails.

-

Page 48: Back Panel Removal

Back panel removal In order to gain access to the flexible motor link, it is necessary to remove the back panel. IMPORTANT: Always disconnect the instrument from the power outlet when working with panels removed. 240 Volts inside! Risk of electrocution! Never operate the instrument with the back panel removed 1. -

Page 49: Firmware And Program Transfers

ShatterBox. It is not possible for the user to alter or delete them. Note that SPEX SamplePrep cannot be held responsible for any damage to dish or mill incurred by the use of those methods. If unsure, please contact SPEX SamplePrep. - Page 50 7. Now, choose where you want the data to be written. Double-click on “USBDISK”, then click on its sub-directory, named “disk_a_1”. 8. Click “OK” to start the transfer to the USB drive. The screen will black out, and the mill will re-boot. 9.

-

Page 51: Technical Specifications

Technical specifications Type of mill: Grinding Mill Grinding mechanism: Grinding containers with puck and ring Weight (without grinding container): 200 kg (440 lbs) Dimensions (w x d x h): 67.5 x 66 x 138 cm (26.6 x 26 x 54.3 in) Electrical: 115 V / 60 Hz (10-amp fuse) 230 V / 50~60 Hz (5-amp fuse) -

Page 52: Warranty

Return shipments We want you to be happy with whatever you purchase from SPEX SamplePrep LLC. Please bring any problem to our attention, but please DO NOT RETURN any item before contacting us for a Return Authorization Number and instructions. -

Page 53: Contacting Spex

Fax: 732-906-2492 Website: www.spexsampleprep.com E-mail: sampleprep@spex.com Outside the United States, contact the SPEX SamplePrep representative from whom you bought your equipment. A list of our current representatives is on our website, above. When contacting us, kindly have the serial number of the instrument at hand.

Need help?

Do you have a question about the ShatterBox 8550 and is the answer not in the manual?

Questions and answers