Summary of Contents for VWR avantor Premium Balance Analytic PBA

- Page 1 Operating Instructions Original Operating Instructions Premium Balance Analytic PBA ® Premium Balance Precision PBP ® Analytical and Precision Balances 1000085028 | Last updated: 07 | 2021...

- Page 2 Legal Address of Manufacturer Europe VWR International bv, Researchpark Haasrode 2020 Geldenaaksebaan 464 B-3001 Leuven +3216385011 be.vwr.com UK Importer VWR International Ltd Hunter Boulevard, Magna Park Lutterworth, Leicestershire, LE17 4XN uk.vwr.com Country of Origin Germany...

-

Page 3: Table Of Contents

Contents Contents 1 About these Instructions ......5 6 Getting Started........17 Scope . - Page 4 Contents 9 Cleaning and Maintenance......31 15 Technical Data........36 Detaching the Draft Shield .

-

Page 5: About These Instructions

About these Instructions About these Other Applicable Documents Instructions In addition to these instructions, observe the following documentation: − Installation instructions for the accessories, e.g. printer Scope Target Groups These instructions are part of the device. These These instructions are addressed to the following target instructions apply to the device in the following versions: groups. -

Page 6: Other Symbols

If these instructions are lost, request a replacement or download the latest version from the VWR website Appropriate containers must be used for loading each (www.vwr.com). type of material. -

Page 7: Symbols On The Device

Personal Protective Equipment If the electrical equipment of the device is defective, Personal protective equipment protects against risks cut off the power supply and contact VWR Service. arising from the material being processed. Keep live parts away from moisture. Moisture can cause short circuits. -

Page 8: Device Description

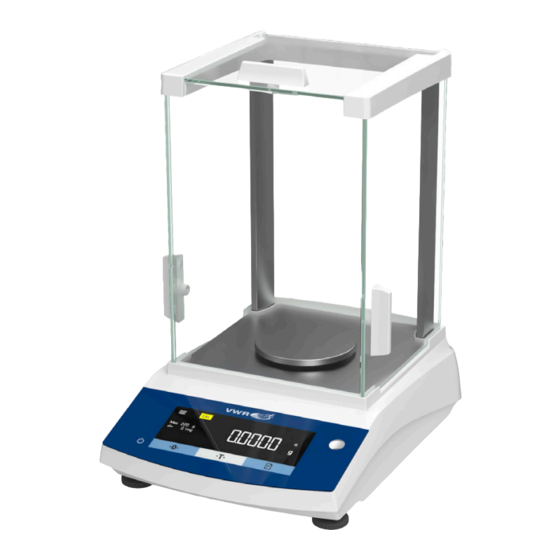

Device Description Device Description Device Connections Device Overview Fig. 2: Precision balance with round draft shield (rear view) Pos. Designation Description Access switch Protects the device from changes to the device settings. Is sealed for conformity-assessed devices Power supply Connection for power supply to the device Fig. -

Page 9: Weighing Pan And Associated Components

Device Description Weighing Pan and Associated Components Fig. 3: Analytical balance with analytical draft shield, precision balance with analytical draft shield, and precision balance with round draft shield (example) Pos. Designation Description Weighing pan Pan support Pan retainer Symbols on the Device Symbol Meaning NOTICE! Read the operating instructions. -

Page 10: Operating Concept

Operating Concept Operating Concept Menu and System Settings Display Operating Display in Weighing Mode Fig. 5: Menu and System Settings Display (example) Pos. Designation Description Menu or parameter entry [Selection] display Fig. 4: Operating display in weighing mode (example) Menu level Shows the position of the Pos. -

Page 11: Buttons

Operating Concept 4.2.1 Buttons Symbol Designation Description [On/Off] button − When the button is pressed: Switches the operating display on. − If the button is held down: Switches the operating display off. [Menu] button − When the button is pressed: The settings menu opens. −... -

Page 12: Displays In The Operating Display

Operating Concept Displays in the Operating Display Symbol Designation Description [Counting] display Indicates that the “Counting” application is selected. [Weighing in percent] Indicates that the “Weighing in percent” application is selected. display [Animal weighing] Indicates that the “Animal weighing” application is selected. display [Density Indicates that the “Density determination”... -

Page 13: Menu Structure

Operating Concept Menu Structure 4.4.1 “Main Menu” Menu Structure Navigating in menus (see Chapter 4.5, page 14). Level 1 Level 2 Description SETUP BALANCE Set the functions of the device. GEN.SERV. Reset the menu to factory settings. “General services” DEVICE RS-232 Define the parameters for the COM interface. -

Page 14: Toggle Between Weight Units

Operating Concept Level 1 Level 2 Description INFO VERSION Display the software version number. “Device “Version number” information” SER. NO. Display the device’s serial number. “Serial number” MODEL Display the device’s model ID. BAC VER. Display the version of the BAC processor. LANGUAGE Set the menu language of the operating display. -

Page 15: Installation

Installation Installation Unpacking Procedure Scope of Delivery Unpack the device. CAUTION Glass breakage due to the incorrect handling of the device! Do not lift the device by the Item Quantity draft shield. Only lift the device by its base. Install the device at the intended installation site. Device If the device is stored temporarily: Observe the Weighing pan... -

Page 16: Acclimatizing The Device

Installation Acclimatizing the Device When a cold device is brought into a warm environment: The temperature difference can lead to condensation from humidity in the device (moisture formation). Moisture in the device can lead to malfunctions. Procedure Allow the device to acclimatize for approx. 2 hours at the installation site. -

Page 17: Getting Started

Check the power Select the country-specific supply cable for damage, e.g. cracks in the insulation. power plug adapter. The If required: Contact VWR Service. power plug adapter must Check whether the country-specific power plug be suitable for use with the matches the power connections at the installation site. -

Page 18: System Settings

System Settings System Settings Setting the Calibration and Adjustment Performing System Settings 7.2.1 Setting Internal Calibration and Adjustment (Only Model I-1x) Default settings can be adjusted for the device and the applications in order to align with the ambient conditions The following functions can be set for the internal and individual operating requirements. -

Page 19: Parameter List

System Settings Parameter List 7.3.1 “SETUP”/”BALANCE” Menu Parameter Setting values Explanation AMBIENT V.STABLE Sets the ambient conditions to “very stable”: Activates a fast change in the weight values in the event of a load change with a high output rate. Recommended for the following work environment: −... -

Page 20: Setup"/"Gen.serv." Menu

System Settings Parameter Setting values Explanation WT.UNIT GRAMS*, KILOGR., − The device displays the weight in the selected unit. CARATS, POUNDS, − The availability of units depends on national legislation and is therefore OUNCES, TROY. country-specific. OZ., HKTAEL, SNGTAEL, TWNTAEL, GRAINS, PENYWT., MILLIGR., PTS./LB, CHNTAEL.,... -

Page 21: Device"/"Rs232" Menu

System Settings 7.3.3 “DEVICE”/”RS232” Menu Parameter Setting values Explanations DAT.REC. XBPI Extended range of commands to control numerous balance functions with binary protocol for direct communication with the device. SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the use of ESC commands from a PC to control the basic balance functions with ASCII protocol. -

Page 22: Device"/"Usb" Menu

System Settings 7.3.4 “DEVICE”/”USB” Menu Parameter Setting values Explanations DAT.REC.** XBPI Extended range of commands to control numerous balance functions with binary protocol for direct communication with the device. SBI* Enables SBI communication. The data is output to a PC or control unit. Enables the use of ESC commands from a PC to control the basic balance functions with ASCII protocol. -

Page 23: Data.out."/"Com. Sbi" Menu

System Settings Parameter Setting values Explanation EXT.KEY PRINT Assigns the print function to the external key. CAL. Assigns the calibration and adjustment function selected under [CAL./ADJ.] to the external key. Assigns the [Back] function to the external key. ENTER Assigns the [Confirm] function to the external key. ZERO Assigns the [Zero] function to the external key. -

Page 24: Data.out."/"Prnt.par." Menu

System Settings 7.3.7 “DATA.OUT.”/”PRNT.PAR.” Menu Parameter Setting values Explanation ACTIVAT. MAN. NO Manual without stability: The print process can be started manually at any time. MAN.AFTR* Manual after stability: After pressing the [Print] button, the print command is only executed once stability is achieved. INTERV.N. -

Page 25: Data.out."/"Pc.direc." Menu

System Settings 7.3.8 “DATA.OUT.”/”PC.DIREC.” Menu (only PC.TABL.) Parameter Setting values Explanations DEC.SEP. POINT* Sets a point as a decimal separator. COMMA Sets a comma as a decimal separator. OUT.FORM. TXT+NUM.* Exports text and numbers. ONLY.NUM. Only exports numbers. * Factory setting 7.3.9 “APPLIC.”/”WEIGH”... -

Page 26: Applic."/"Anim.wg" Menu

System Settings 7.3.12 “APPLIC.”/”ANIM.WG” Menu Parameter Setting values Explanation ACTIVIT. CALM Sets the intensity of the “Animal activity” to “calm”. Recommended for minor movements of the sample, e.g. caused by placement on the weighing pan. ACTIVE* Sets the intensity of the “Animal activity” to “active”. Recommended for medium movements of the sample, e.g. -

Page 27: Info" Menu

Operation 7.3.15 “INFO” Menu Parameter Setting values Explanation VERSION Displays the version number of the control module. SER. NO. Displays the serial number of the device. Model Displays the type designation of the device. BAC VER. Displays the version number of the weight sensor. * Factory setting 7.3.16 “LANGUAG.”... -

Page 28: Leveling The Balance Using

Operation Leveling the Balance Using Calibrating and Adjusting the Level Indicator the Device Internally (Only Model I-1x) Unevenness at the installation site of the device may result in incorrect weighing results. Leveling compensates for unevenness at the installation site. Requirements −... -

Page 29: Externally Calibrating And Adjusting

Operation Externally Calibrating and Printing Results of the Adjusting the Device Calibration and Adjustment Process Material Calibration and adjustment weight The results of the calibration and adjustment process can be printed in a GLP printout. Requirements Procedure − The weighing pan is unloaded. Set the GLP printout in the menu (setting parameters, −... -

Page 30: Setting Or Changing An Application

Operation Setting or Changing an 8.10.3 Running the “COUNT” Application Application The „COUNT“ application is used to determine the number of parts that have nearly the same piece weight. As the basis for this application, the balance measures the Procedure weight of a manually counted number of parts (reference quantity) and determines the individual average piece In the “APPLIC.”... -

Page 31: Cleaning And Maintenance

Cleaning and Maintenance Cleaning and 9.1.2 Dismantle the Round Draft Shield, Weighing Pan, and Associated Maintenance Components Material: 1 soft support base Detaching the Draft Shield Requirements 9.1.1 Detaching the Analytical Draft Shield, − The device is switched off. Weighing Pan, and Associated −... -

Page 32: Installing The Draft Shield

If this relates to a device without a shield disk: Install Software Update the pan support and the weighing pan. For a software update, contact VWR Service. Slowly slide the side panels and the upper panel into the frame rails. -

Page 33: Malfunctions

A previously forgotten weight was removed after starting the device. An error exists in the Contact VWR Service. weighing system or in the device electronics. COMM.ERR. The device is not No communication exists... -

Page 34: Troubleshooting

Malfunctions Warning message Fault Cause Remedy Chapter, page ERR 10 Taring is not The device cannot be To release the tare memory: possible. manually tared because an Exit the application program application program has with the [Back] button. the tare memory reserved. ERR 11 The weight value The weight value is... -

Page 35: Decommissioning

Decommissioning Decommissioning 13.2 Returning the Device and Parts Defective devices or parts can be sent back to VWR. Returned devices must be clean, decontaminated, and 11.1 Decommissioning the Device packed correctly, e.g. in their original packaging. Transport damage as well as measures for subsequent... -

Page 36: Technical Data

15.2 Contamination Type, Overvoltage Category (Device) Unit Value Pollution level according to IEC 61010-1 Overvoltage category according to IEC 60664-1 15.3 Power Supply 15.3.1 Power Supply Device Unit Value Input voltage 15 (±10 %) Power consumption, max. Only by VWR power supply unit Operating Instructions... -

Page 37: Power Supply Unit

Technical Data 15.3.2 Power Supply Unit Unit Value Type: VWR power supply unit Primary Voltage 100 – 240 (±10 %) Frequency 50 – 60 Current consumption, maximum Secondary Voltage 15 (±5 %) Current, maximum 0.53 Short-circuit protection Electronic Protection class according to IEC 60950-1... -

Page 38: Warm-Up Time

Pin 5: Internal ground Pin 6: Not assigned Pin 7: Clear to Send (CTS) Pin 8: Request to Send (RTS) Pin 9: Universal key 15.8.2 Specifications for the USB-C Interface Communication: USB UTL Connectable devices: VWR printers, PC Operating Instructions... -

Page 39: Device Dimensions

Technical Data 15.9 Device Dimensions 2 5 3 ± 2 3 1 7 ± 2 1 6 5 ± 1 usable height 49mm 2 5 3 ± 2 3 1 7 2 5 3 ± 2 ± 2 3 1 7 ±... -

Page 40: Metrological Data

Technical Data 15.10 Metrological Data 15.10.1 Models PBA224 | PBA124 | PBP623 | PBP423 Model Unit Value Value Value Value Readability | Scale interval (d) Maximum capacity (Max) Repeatability At approx. maximum load, typical value Linearity deviation Limits ± mg Sensitivity drift between +10 °C and ±... -

Page 41: Accessories

Web Resources Visit the VWR website at vwr.com for: − Complete technical service contact information − Access to the VWR Online Catalogue, and information about accessories and related products − Additional product information and special offers Contact us: For information or technical assistance contact your local VWR representative or visit vwr.com. -

Page 42: Warranty

The customer is responsible for applying for and obtaining the necessary regulatory approvals or other authorizations necessary to run or use the product in its local environment. VWR will not be held liable for any related omission or for not obtaining the required approval or authorization, unless any refusal is due to a defect of the product. - Page 44 Email: vwr_india@vwr.com Tel.: +351 21 3600 770 Email: info.pt@vwr.com China Ireland / Northern Ireland VWR (Shanghai) Co., Ltd VWR International Ltd / VWR International Singapore Bld.No.1, No.3728 Jinke Rd, (Northern Ireland) Ltd VWR Singapore Pte Ltd Pudong New District Orion Business Campus...

Need help?

Do you have a question about the avantor Premium Balance Analytic PBA and is the answer not in the manual?

Questions and answers