Subscribe to Our Youtube Channel

Summary of Contents for KSB HPK Series

- Page 1 Thermal Oil / Hot Water Pump Bearing Assemblies P02as to P08s Installation/Operating Manual...

- Page 2 All rights reserved. The contents provided herein must neither be distributed, copied, reproduced, edited or processed for any other purpose, nor otherwise transmitted, published or made available to a third party without the manufacturer's express written consent. Subject to technical modification without prior notice. © KSB SE & Co. KGaA, Frankenthal 27/10/2021...

-

Page 3: Table Of Contents

Contents Contents Glossary .............................. 6 General.............................. 7 Principles ................................ 7 Installation of partly completed machinery.................... 7 Target group.............................. 7 Other applicable documents.......................... 7 Symbols ................................ 7 Key to safety symbols/markings........................ 8 Safety .............................. 9 General................................ 9 Intended use .............................. 9 Personnel qualification and training....................... 9 Consequences and risks caused by non-compliance with this manual ............ 10 Safety awareness ............................ 10 Safety information for the operator/user ..................... 10 Safety information for maintenance, inspection and installation .............. 10... - Page 4 Contents Electrical connection ............................ 34 5.8.1 Setting the time relay ........................ 35 5.8.2 Earthing .............................. 35 5.8.3 Connecting the motor ........................ 35 Checking the direction of rotation........................ 36 Commissioning/Start-up/Shutdown.................... 37 Commissioning/Start-up .......................... 37 6.1.1 Prerequisites for commissioning/start-up .................. 37 6.1.2 Filling in lubricants.......................... 37 6.1.3 Shaft seal ............................ 38 6.1.4 Priming and venting the pump...................... 40 6.1.5...

- Page 5 Contents Trouble-shooting.......................... 68 Related Documents .......................... 70 General assembly drawing with list of components .................. 70 Version with gland packing ........................... 73 EU Declaration of Conformity ...................... 74 Certificate of Decontamination...................... 75 Index .............................. 76 5 of 80...

-

Page 6: Glossary

Glossary Glossary Back pull-out design The complete back pull-out unit can be pulled out without having to remove the pump casing from the piping. Back pull-out unit Pump without pump casing; partly completed machinery Certificate of decontamination A certificate of decontamination is enclosed by the customer when returning the product to the manufacturer to certify that the product has been properly drained to eliminate any environmental... -

Page 7: General

In the event of damage, immediately contact your nearest KSB service facility to maintain the right to claim under warranty. 1.2 Installation of partly completed machinery To install partly completed machinery supplied by KSB refer to the sub-sections under Servicing/Maintenance. -

Page 8: Key To Safety Symbols/Markings

1 General Symbol Description ⇨ Result of an action Cross-references ⇨ Step-by-step instructions Note Recommendations and important information on how to handle the product 1.6 Key to safety symbols/markings Table 3: Definition of safety symbols/markings Symbol Description DANGER DANGER This signal word indicates a high-risk hazard which, if not avoided, will result in death or serious injury. -

Page 9: Safety

2 Safety 2 Safety All the information contained in this section refers to hazardous situations. DANGER In addition to the present general safety information the action-related safety information given in the other sections must be observed. 2.1 General ▪ This operating manual contains general installation, operating and maintenance instructions that must be observed to ensure safe operation of the system and prevent personal injury and damage to property. -

Page 10: Consequences And Risks Caused By Non-Compliance With This Manual

2 Safety 2.4 Consequences and risks caused by non-compliance with this manual ▪ Non-compliance with these operating instructions will lead to forfeiture of warranty cover and of any and all rights to claims for damages. ▪ Non-compliance can, for example, have the following consequences: –... -

Page 11: Unauthorised Modes Of Operation

2 Safety ▪ When taking the pump set out of service always adhere to the procedure described in the manual. (ð Section 6.1.13, Page 45) (ð Section 6.3, Page 48) ▪ Decontaminate pumps which handle fluids posing a health hazard. (ð Section 7.3, Page 56) ▪ As soon as the work has been completed, re-install and re-activate any safety- relevant devices and protective devices. -

Page 12: Monitoring Equipment

If the pump is to be operated at a higher temperature, the data sheet is missing or if the pump is part of a pool of pumps, contact KSB for the maximum permissible operating temperature. 2.9.3 Monitoring equipment The pump (set) must only be operated within the limits specified in the data sheet and on the name plate. -

Page 13: Transport/Storage/Disposal

3 Transport/Storage/Disposal 3 Transport/Storage/Disposal 3.1 Transport DANGER The pump (set) could slip out of the suspension arrangement Danger to life from falling parts! ▷ Always transport the pump (set) in the specified position. ▷ Never attach the suspension arrangement to the free shaft end or the motor eyebolt. -

Page 14: Storage/Preservation

4. Always complete and enclose a certificate of decontamination when returning the pump. Indicate any safety measures and decontamination measures taken. (ð Section 11, Page 75) NOTE If required, a blank certificate of decontamination can be downloaded from the following web site: www.ksb.com/certificate_of_decontamination 14 of 80... -

Page 15: Disposal

3 Transport/Storage/Disposal 3.4 Disposal WARNING Fluids handled, consumables and supplies which are hot and/or pose a health hazard Hazard to persons and the environment! ▷ Collect and properly dispose of flushing fluid and any fluid residues. ▷ Wear safety clothing and a protective mask if required. ▷... -

Page 16: Description Of The Pump (Set)

2955 1/min Mat. No. 01220221 ZN 3804 - E 37 X 52 Fig. 5: Name plate (example) Type series, size Customer-specific information (optional) KSB order number and order item Flow rate number Speed Year of construction Head 16 of 80... -

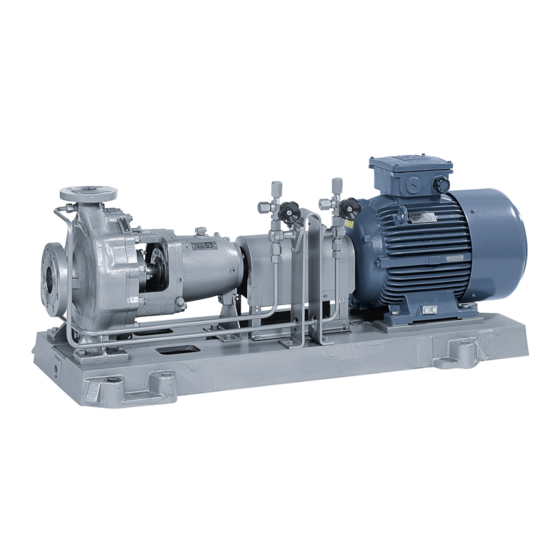

Page 17: Design Details

4 Description of the Pump (Set) 4.5 Design details Design ▪ Volute casing pump ▪ Back pull-out design ▪ Horizontal installation ▪ Single-stage ▪ Technical requirements to ISO 5199 ▪ Dimensions and ratings to ISO 2858 complemented by pumps of nominal sizes DN 25, DN 200 and above Pump casing ▪... - Page 18 4 Description of the Pump (Set) Mechanical seal with external circulation Circulation from discharge nozzle (operating mode "E") Uncooled, single, balanced mechanical seal ▪ Circulation from discharge nozzle to seal cover ▪ Venting via circulation line in the discharge nozzle Mechanical seal with air-cooled heat Circulation IN/OUT exchanger...

- Page 19 4 Description of the Pump (Set) Mechanical seal with jacket cooling Cooling liquid IN/OUT (operating mode "BM") Cooled shaft seal with single, balanced mechanical seal ▪ Cooling of seal chamber via seal housing ▪ Venting via clearance gap Mechanical seal with jacket and seat ring Cooling liquid IN/OUT cooling (operating mode "BG")

-

Page 20: Configuration And Function

4 Description of the Pump (Set) Bearings used Table 8: Bearing design KSB designation FAG designation SKF designation B-TVP-UA BECBP B.G 8 B-TVP-UA 80 BEC86P Table 9: Reinforced bearing assembly Bearing bracket Rolling element bearing Pump end Motor end P02as NU307 2 x 7307 BG... -

Page 21: Noise Characteristics

4 Description of the Pump (Set) Design The pump is designed with an axial fluid inlet and a radial or tangential outlet. The hydraulic system runs in its own bearings and is connected to the motor by a shaft coupling. Function The fluid enters the pump axially via the suction nozzle (6) and is accelerated outward by the rotating impeller (7). -

Page 22: Dimensions And Weights

4 Description of the Pump (Set) Drive ▪ Surface-cooled IEC frame three-phase squirrel-cage motor Coupling ▪ Flexible coupling with or without spacer Contact guard ▪ Coupling guard ▪ Baseplate (to ISO 3661), cast or welded, for pump and motor, in torsion-resistant design ▪... -

Page 23: Installation At Site

5 Installation at Site 5 Installation at Site 5.1 Safety regulations DANGER Excessive temperatures in the shaft seal area Explosion hazard! ▷ Never operate a pump (set) with gland packing in potentially explosive atmospheres. NOTE Operating pump sets with gland packings in combination with a frequency inverter / variable speed system is not recommended. -

Page 24: Installation On The Foundation

5 Installation at Site 5.3.1 Installation on the foundation Fig. 7: Fitting the shims Bolt-to-bolt distance Shim Shim if (L) > 800 mm Foundation bolt ü The foundation has the required strength and characteristics. ü The foundation has been prepared in accordance with the dimensions given in the outline drawing/general arrangement drawing. -

Page 25: Installation Without Foundation

5 Installation at Site 5.3.2 Installation without foundation Fig. 8: Adjusting the levelling elements 1, 3 Locknut Adjusting nut Machine mount ü The installation surface has the required strength and characteristics. 1. Position the pump set on the machine mounts (4) and align it with the help of a spirit level (on the shaft/discharge nozzle). - Page 26 5 Installation at Site NOTE Installing check and shut-off elements in the system is recommended, depending on the type of plant and pump. However, such elements must not obstruct proper drainage or hinder disassembly of the pump. ü Suction lift lines have been laid with a rising slope, suction head lines with a downward slope towards the pump.

-

Page 27: Permissible Forces And Moments At The Pump Nozzles

5 Installation at Site CAUTION Aggressive flushing liquid and pickling agent Damage to the pump! ▷ Match the cleaning operation mode and duration of flushing and pickling to the casing materials and seal materials used. 5.4.2 Permissible forces and moments at the pump nozzles The permissible resultant forces have been determined according to: Forces and moments at the pump nozzles... - Page 28 5 Installation at Site Suction nozzle Discharge nozzle Suction nozzle Discharge nozzle [Nm] [Nm] yTens yCompr 40-160 1750 1150 1400 1800 1100 1100 1150 40-200 1750 1150 1400 1800 1100 1100 1150 40-250 1750 1150 1400 1800 1100 1100 1150 40-315 1750 1150...

-

Page 29: Auxiliary Connections

5 Installation at Site Pump model HPK-EY/SY Table 12: Forces and moments at the pump nozzles Suction nozzle Discharge nozzle Suction nozzle Discharge nozzle [Nm] [Nm] yTens yCompr 80-400 4900 3200 3900 5100 2300 1400 2850 1900 3000 3600 2700 1850 1900 1450 1000 100-400 4900 3200... -

Page 30: Enclosure/Insulation

5 Installation at Site 5.5 Enclosure/insulation DANGER Risk of potentially explosive atmosphere due to insufficient venting Explosion hazard! ▷ Make sure the space between the casing cover/discharge cover and the bearing cover is sufficiently vented. ▷ Never close or cover the perforation of the bearing bracket guards (e.g. by insulation). - Page 31 5 Installation at Site Fig. 11: Non-spacer-type coupling, checking the coupling alignment Straight edge Gauge Fig. 12: Spacer-type coupling, checking the coupling alignment Straight edge Gauge Fig. 13: Double Cardan spacer-type coupling, checking the coupling alignment Straight edge Gauge 31 of 80...

-

Page 32: Aligning The Pump And Motor

5 Installation at Site Table 13: Permissible alignment offset of coupling halves Coupling type Radial offset Axial offset [mm] [mm] Non-spacer-type coupling (ð Fig. 11) ≤ 0,1 ≤ 0,1 Spacer-type coupling (ð Fig. 12) ≤ 0,1 ≤ 0,1 Double Cardan coupling (ð Fig. 13) ≤ 0,5 ≤ 0,5 ü The coupling guard and its footboard, if any, have been removed. 1. -

Page 33: Motors With Adjusting Screw

Risk of injury by rotating shafts! ▷ Always operate the pump set with a coupling guard. If the customer specifically requests not to include a coupling guard in KSB's delivery, then the operator must supply one! ▷ Observe all relevant regulations for selecting a coupling guard. -

Page 34: Electrical Connection

Risk of injury by rotating shafts! ▷ Always operate the pump set with a coupling guard. If the customer specifically requests not to include a coupling guard in KSB's delivery, then the operator must supply one! ▷ Observe all relevant regulations for selecting a coupling guard. -

Page 35: Setting The Time Relay

5 Installation at Site WARNING Incorrect connection to the mains Damage to the power supply network, short circuit! ▷ Observe the technical specifications of the local energy supply companies. 1. Check the available mains voltage against the data on the motor name plate. 2. -

Page 36: Checking The Direction Of Rotation

5 Installation at Site 5.9 Checking the direction of rotation DANGER Temperature increase resulting from contact between rotating and stationary components Explosion hazard! Damage to the pump set! ▷ Never check the direction of rotation by starting up the unfilled pump set. ▷... -

Page 37: Commissioning/Start-Up/Shutdown

6 Commissioning/Start-up/Shutdown 6 Commissioning/Start-up/Shutdown 6.1 Commissioning/Start-up 6.1.1 Prerequisites for commissioning/start-up Before commissioning/starting up the pump set, make sure that the following conditions are met: ▪ The pump set has been mechanically connected as specified. ▪ The pump set has been properly connected to the power supply and is equipped with all protection devices. -

Page 38: Shaft Seal

6.1.3.1 Mechanical seal for hot water Due to the complex conditions in hot water systems, the use of mechanical seals not approved by KSB shall not be covered by KSB's scope of warranty. 38 of 80... - Page 39 6 Commissioning/Start-up/Shutdown The following seal designs are used for hot water applications: (ð Section 4.5, Page 17) ▪ Mechanical seal with external circulation ▪ Mechanical seal with air-cooled heat exchanger 6.1.3.2 Mechanical seal for thermal oil DANGER Improper sealing! Severe burns! Damage to the environment! ▷...

-

Page 40: Priming And Venting The Pump

6 Commissioning/Start-up/Shutdown 6.1.4 Priming and venting the pump DANGER Risk of potentially explosive atmosphere by incompatible fluids mixing in the auxiliary piping Risk of burns! Explosion hazard! ▷ Make sure that the barrier fluid or quench liquid are compatible with the fluid handled. -

Page 41: Cooling Of The Shaft Seal

6 Commissioning/Start-up/Shutdown The cooling liquid quantities indicated are based on Δt = 15 °C (max.). In the case of deviations, the cooling liquid requirement changes in direct proportion to the change in the temperature difference. for Δtx = Q x (15 : Δtx) cooling water cooling water 6.1.6 Cooling of the shaft seal... -

Page 42: Heating Up/Keeping Warm The Pump (Set)

6 Commissioning/Start-up/Shutdown Bearing bracket Speed 2900 rpm 1450 rpm P05s, P05as P06s, P06as P08s 6.1.9 Heating up/keeping warm the pump (set) CAUTION Pump blockage Damage to the pump! ▷ Prior to pump start-up, heat up the pump as described in the manual. Observe the following when heating up the pump (set) and keeping it warm: ▪... -

Page 43: Checking The Shaft Seal

6 Commissioning/Start-up/Shutdown DANGER Excessive temperatures due to dry running or excessive gas content in the fluid handled Explosion hazard! Damage to the pump set! ▷ Never operate the pump set without liquid fill. ▷ Prime the pump as per operating instructions. (ð Section 6.1.4, Page 40) ▷... - Page 44 6 Commissioning/Start-up/Shutdown DANGER Excessive temperature of barrier fluid (pumps with double mechanical seal) Explosion hazard! Excessive surface temperature ▷ For pumps with double mechanical seal, make sure that the barrier fluid's temperature does not exceed 60 °C. NOTE When new plants are commissioned and a large amount of foreign matter is in the system, short service lives of the mechanical seals are to be expected during the initial phase of plant operation.

-

Page 45: Shutdown

6 Commissioning/Start-up/Shutdown Not enough leakage: Slightly loosen the nuts at the gland follower. No leakage: Immediately switch off pump set! Loosen the gland follower and repeat commissioning. Checking the leakage After the leakage has been adjusted, monitor the leakage for about two hours at maximum fluid temperature. -

Page 46: Operating Limits

6 Commissioning/Start-up/Shutdown 6.2 Operating limits DANGER Non-compliance with operating limits for pressure, temperature, fluid handled and speed Explosion hazard! Hot or toxic fluid could escape! ▷ Comply with the operating data specified in the data sheet. ▷ Never use the pump for handling fluids it is not designed for. ▷... -

Page 47: Fluid Handled

6 Commissioning/Start-up/Shutdown Table 19: Frequency of starts Motor rating Maximum frequency of starts [kW] [Starts/hour] ≤ 12 ≤ 100 > 100 CAUTION Re-starting while motor is still running down Damage to the pump (set)! ▷ Do not re-start the pump set before the pump rotor has come to a standstill. 6.2.3 Fluid handled 6.2.3.1 Flow rate Unless specified otherwise in the characteristic curves or in the data sheets, the... -

Page 48: Shutdown/Storage/Preservation

6 Commissioning/Start-up/Shutdown CAUTION Impermissibly high density of the fluid handled Motor overload! ▷ Observe the information about fluid density in the data sheet. ▷ Make sure the motor has sufficient power reserves. 6.2.3.3 Abrasive fluids Do not exceed the maximum permissible solids content specified in the data sheet. When the pump handles fluids containing abrasive substances, increased wear of the hydraulic system and shaft seal are to be expected. - Page 49 6 Commissioning/Start-up/Shutdown NOTE If the equipment has been out of service for more than one year, replace all elastomer seals. 49 of 80...

-

Page 50: Servicing/Maintenance

7 Servicing/Maintenance 7 Servicing/Maintenance 7.1 Safety regulations DANGER Improper cleaning of coated pump surfaces Explosion hazard by electrostatic discharge! ▷ When cleaning coated pump surfaces in atmospheres of Explosion group IIC, use suitable anti-static equipment. DANGER Sparks produced during servicing work Explosion hazard! ▷... -

Page 51: Servicing/Inspection

NOTE All maintenance work, service work and installation work can be carried out by KSB Service or authorised workshops. For contact details please refer to the enclosed "Addresses" booklet or visit "www.ksb.com/contact" on the Internet. - Page 52 7 Servicing/Maintenance DANGER Risk of potentially explosive atmosphere inside the pump Explosion hazard! ▷ The pump internals in contact with the fluid to be handled, including the seal chamber and auxiliary systems, must be filled with the fluid to be handled at all times.

-

Page 53: Inspection Work

For HPKE/EY models, casing wear rings are only available as a variant. NOTE If the clearances given are exceeded by more than 1 mm (referring to the diameter) replace the affected components or restore the original clearance by means of a casing wear ring. Contact KSB. 53 of 80... -

Page 54: Lubrication And Lubricant Change Of Rolling Element Bearings

+175 °C HD 20W/20 SAE Cleveland) Solidification point -15 °C (pour point) Application Higher than permissible bearing temperature temperature At least once a year For ambient temperatures below -10 °C use a different suitable type of lubricating oil. Contact KSB. 54 of 80... - Page 55 7 Servicing/Maintenance 7.2.3.1.3 Oil quantity Table 24: Oil quantity Bearing bracket Oil quantity P02as P03s, P03as P04s, P04as P05s P05as P06s P06as P08s 7.2.3.1.4 Changing the oil WARNING Lubricants posing a health hazard and/or hot lubricants Hazard to persons and the environment! ▷...

-

Page 56: Drainage/Cleaning

7 Servicing/Maintenance 7.3 Drainage/cleaning WARNING Fluids handled, consumables and supplies which are hot and/or pose a health hazard Hazard to persons and the environment! ▷ Collect and properly dispose of flushing fluid and any fluid residues. ▷ Wear safety clothing and a protective mask if required. ▷... -

Page 57: Preparing The Pump Set

7 Servicing/Maintenance DANGER Insufficient preparation of work on the pump (set) Risk of injury! ▷ Properly shut down the pump set. (ð Section 6.1.13, Page 45) ▷ Close the shut-off elements in the suction line and discharge line. ▷ Drain the pump and release the pump pressure. (ð Section 7.3, Page 56) ▷... -

Page 58: Removing The Impeller

7 Servicing/Maintenance 7.4.5 Removing the impeller ü The notes and steps stated in (ð Section 7.4.1, Page 56) to (ð Section 7.4.4, Page 57) have been observed/carried out. ü The back pull-out unit is kept in a clean and level assembly area. 1. Undo impeller nut 922 (right-hand thread). 2. -

Page 59: Reassembling The Pump Set

7 Servicing/Maintenance 8. Carefully drive shaft 210 together with angular contact ball bearing 320.02 and the inner race of cylindrical roller bearing 322.01 out of the bearing bracket towards the drive end. 9. Remove support disc 550.23 of angular contact ball bearing 320.02 from bearing bracket 330. -

Page 60: Installing The Bearings

7 Servicing/Maintenance CAUTION Contact of O-ring with graphite or similar material Fluid could escape! ▷ Do not coat O-ring with graphite or similar material. ▷ Use animal fats or lubricants based on silicone or PTFE. ▪ Assembly adhesives – For gaskets, avoid the use of assembly adhesives if possible. –... -

Page 61: Fitting The Shaft Seal

7 Servicing/Maintenance 12. Insert support disc 550.23 of angular contact ball bearing 320.02 into bearing bracket 330. 13. Carefully insert pre-assembled shaft 210 with angular contact ball bearing 320.02 and the inner ring of cylindrical roller bearing 322.01 into bearing bracket 330 from the drive end. - Page 62 7 Servicing/Maintenance 7.5.3.2 Packing the gland Fig. 18: Gland packing chamber Table 25: Gland packing chamber Bearing Gland packing chamber bracket Ø d Ø d P02as 8 x 8 4 rings and a second P03s, P03as 10 x 10 stuffing box P04s, P04as 10 x 10 ring P05s, P05as...

-

Page 63: Fitting The Impeller

7 Servicing/Maintenance Fitting a gland packing made of pure graphite Fig. 19: Packing arrangement Table 26: Number of packing rings Bearing bracket P02as, P03s, P03as, P05s, P05as, P06s, P08s P04s, P04as P06as in mm Number of packing rings ü The old packing rings have been removed. ü... -

Page 64: Fitting The Back Pull-Out Unit

7 Servicing/Maintenance 7.5.5 Fitting the back pull-out unit WARNING Back pull-out unit tilting Risk of crushing hands and feet! ▷ Suspend or support the bearing bracket at the pump end. ü The notes and steps stated in (ð Section 7.5.1, Page 59) to (ð Section 7.5.4, Page 63) have been observed/carried out. ü... -

Page 65: Tightening Torques For The Impeller Nut

7 Servicing/Maintenance Thread Material of stud/hexagon nut C35E+Qt/C 35 A4-70/A4-70 1.7709+QT/1.7258+QT 1.6772/1.6722 YK/Y A4-70/A4-70 GA/G MM/MM (M3k) Stamp mark on stud/hexagon nut 131,7 161,5 272,0 280,5 572,0 7.6.2 Tightening torques for the impeller nut Observe the following tightening torques for impeller nut (922): Table 28: Tightening torques for the impeller nut Bearing bracket Tightening torques... -

Page 66: Interchangeability Of Pump Components

7 Servicing/Maintenance Part No. Description Number of pumps (including stand-by pumps) 6 and 7 8 and 9 10 and more 320.02 Angular contact ball bearing 25 % (set) 322.01 Cylindrical roller bearing 25 % 502.01 Casing wear ring 50 % 524.01 Shaft protecting sleeve 50 %... - Page 67 7 Servicing/Maintenance Description Part. No. 65-160 P03s, P03as 80-160 65-200 80-200 100-200 32-250 40-250 50-250 65-250 80-250 40-315 80-315 100-250 P04s, P04as 125-250 150-250 65-315 80-315 100-315 125-315 80-400 100-400 125-400 200-250 P05s, P05as 150-315 200-315 250-315 150-400 200-400 150-500 200-500 250-400 P06s,...

-

Page 68: Trouble-Shooting

If problems occur that are not described in the following table, consultation with the KSB service is required. A Pump delivers insufficient flow rate B Motor is overloaded... - Page 69 In the case of persistent overloading, turn down impeller. ✘ - Density or viscosity of fluid handled Contact KSB. higher than stated in purchase order ✘ ✘ - Gland follower over-tightened or cocked Correct. ✘ ✘...

-

Page 70: Related Documents

9 Related Documents 9 Related Documents 9.1 General assembly drawing with list of components 903.18 902.04 411.10 411.18 920.04 322.01 550.23 400.02 360.02 940.02 902.02 914.01 400.01 932.01 932.02 320.02 914.02 421.02 901.31 920.02 903.03 903.02 411.03 411.02 903.04 411.04 502.01 411.31 561.01... - Page 71 9 Related Documents 902.04 411.10 322.01 550.23 400.02 360.02 940.02 920.04 901.31 161 914.01 400.01 932.01 932.02 320.02 914.02 421.02 903.03 903.02 411.03 411.02 903.04 411.04 502.01 411.31 561.01 903.01 902.01 903.46 411.01 940.01 920.01 507.01 421.01 411.46 901.04 920.21 930.01 411.32 902.02...

- Page 72 9 Related Documents Part. No. Comprising Description Volute casing 411.01/.02/.03/.04/.10 Joint ring Casing wear ring 502.01 Parallel pin 561.01 902.01 Stud 903.01/.02/.03/.04 Screw plug 920.01 Hexagon nut Casing cover Joint ring 411.18/.19 463.01 Drip plate 550.01 Disc 902.02 Stud Screw plug 903.18/.19 920.02 Hexagon nut...

-

Page 73: Version With Gland Packing

9 Related Documents Part. No. Comprising Description Joint ring Lip seal Casing wear ring 502.01 502.01 561.01 Parallel pin 507.01 507.01 Thrower 524.01 524.01 Shaft protecting sleeve 411.32 Joint ring Disc Grooved pin Constant level oiler Vent Guard Hexagon head bolt Stud Screw plug Hexagon socket head cap screw... -

Page 74: Eu Declaration Of Conformity

10 EU Declaration of Conformity 10 EU Declaration of Conformity Manufacturer: KSB SE & Co. KGaA Johann-Klein-Straße 9 67227 Frankenthal (Germany) The manufacturer herewith declares that the product: KSB order number: ....................▪ is in conformity with the provisions of the following directives / regulations as amended from time to time: –... -

Page 75: Certificate Of Decontamination

11 Certificate of Decontamination 11 Certificate of Decontamination Type: ..........................Order number / ..........................Order item number Delivery date: ..........................Application: ....................................................Fluid handled Please tick where applicable ⃞ ⃞ ⃞ ⃞ ⃞ Corrosive Oxidising Flammable Explosive Hazardous to health ⃞... -

Page 76: Index

Index Index Abrasive fluids 48 Impeller type 17 Installation Applications 9 Installation on a foundation 24 Auxiliary connections 29 without foundation 25 Installation at site 23 Intended use 9 Bearing assembly 19 Interchangeability of pump components 66 Bearing temperature 52 Keeping warm 42 Certificate of Decontamination 75 Key to safety symbols/markings 8 Clearance gaps 53 Commissioning 37 Configuration 20 Maintenance 51... - Page 77 Index Spare part Ordering spare parts 65 Spare parts stock 65 Special accessories 22 Start-up 43 Storage 14, 48 Temperature difference 42 Temperature limits 11 Tightening torques 64, 65 Transport 13 Warnings 8 Warranty claims 7 Water cooling 40 77 of 80...

- Page 80 KSB SE & Co. KGaA Johann-Klein-Straße 9 • 67227 Frankenthal (Germany) Tel. +49 6233 86-0 www.ksb.com...

Need help?

Do you have a question about the HPK Series and is the answer not in the manual?

Questions and answers