Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Shanghai Diesel Engine D Series

- Page 2 SC9DF 型柴油机 使用保养说明书 Operation and Maintenance Manual SC9DF Diesel Engine 上海柴油机股份有限公司 Shanghai Diesel Engine Co., Ltd. 2017 年 9 月 September of 2017...

- Page 3 告诫 为降低人员受伤和财产损失的可能性,降低柴油机性能恶化及柴油机早期磨损或损坏的 可能性,请务必认真遵守本手册中所给出的安全须知和操作规范,尤其是操作警告和注意事 项。 本手册中给出的警告部分内容是必须严格遵循,否则会引起烧伤、截肢、致残、窒息、 其他人身伤害或死亡的可能;注意部分内容是提醒操作者必须按正确的方法操作,以避免柴 油机零部件损坏或柴油机性能恶化。这些“警告”和“注意”并不周全,上海柴油机股份有 限公司不可能,也不能给出违反这些安全须知和操作规范而产生的所有潜在的危险后果。 产品报修、技术咨询、投诉与建议 产品报修、技术咨询、投诉与建议,请与上柴“易+人”呼叫中心联系,365×24 小时为 您提供快捷、专业、真情的服务。全国免费服务热线 400-820-5656。 产品报修,请务必提供如下信息: 柴油机型号 柴油机订货号 柴油机机号 设备采购日期 较详细的故障描述 联系人地址与电话...

-

Page 4: Table Of Contents

目录 1 引言 Ⅰ.致用户和操作者 ............................1 Ⅱ.用户反映产品质量情况须知 ........................1 Ⅲ.产品售后服务承诺 ............................1 Ⅳ. 安全注意事项 ............................1 Ⅴ. 使用保养注意事项 ............................ 3 第一章 概述 ................................5 1.1 柴油机的型号识别 ............................5 1.2 简写和缩写定义 ............................6 1.3 柴油机铭牌 ..............................7 1.4 柴油机外形图 .............................. 8 第二章... -

Page 6: Ⅰ.致用户和操作者

引言 Ⅰ.致用户和操作者 感谢您选择使用上海柴油机股份有限公司的柴油机产品! SC9DF 型柴油机是上海柴油机股份有限公司在本公司 SC9D 型柴油机(D 系列 9 升二气门非电控柴油机)基础上与国 外著名发动机咨询公司采用先进的设计理念和手段新开发的电控四气门大功率柴油机,可满足国Ⅲ、国Ⅳ、国Ⅴ排放标 准。动力强劲、经济可靠、操作维修方便,是各种汽车及非道路用车的理想动力。 本手册主要叙述该型柴油机基本型的技术规格、使用和保养注意事项,以帮助用户熟悉本产品并正确使用和保养本 产品。用户在柴油机使用前应认真阅读本手册中的有关内容和要求。由于产品性能和结构在不断改进,本手册中所列技 术规格和图例说明与您在使用中的实物可能略有不同,我公司在今后再版时会不断予以补充完善,不再专门通知用户, 谨请注意。在本产品的使用保养中,如有任何疑问请随时联系上柴“易+人”呼叫中心(400-820-5656) ,以获得技术咨 询或技术指导。 上海柴油机股份有限公司(上柴公司)的产品采用最新技术和高质量零部件。维修保养时,建议使用上柴公司品牌 的服务备件。上柴公司授权的维修站遍布全国各地,提供维修服务和备件供应,维修人员经过专业培训。 如柴油机转让或出售,本说明书应跟随柴油机转交给新的用户。 Ⅱ.用户反映产品质量情况须知 为便于我公司了解和分析产品质量问题及其产生故障的原因,及时改进产品质量,更好地为用户服务,谨请用户在 反映产品质量时说明下列事项: 1)发生故障的时间和地点; 2)柴油机出厂编号(机号) 、型号、订货号、发货日期、收货者确切地址; 3)柴油机使用条件、工作累计时间(小时数或公里数) 、工作状态(功率、转速) 、使用的燃油和机油牌号; 4)被驱动设备的特性(型号、消耗功率、结构特点等) ; 5)故障现象描述; 6)要求赔偿或检修的零件或部件,应随同损坏过程记录或说明寄到或带到本公司,以便进行分析。如用户发现问题较 多或问题特别严重时,应保持现场,并及时告知,我公司派员共同分析之。 对柴油机质量问题的处理按照质量保修手册有关规定。 Ⅲ.产品售后服务承诺 为做好产品售后的服务工作,减小因产品出现质量问题给用户造成损失,上柴公司建立了 24 小时报修处理制度。 用户在全国范围内拨打... - Page 7 帽或其他保护用品。 ●发动机的废排气中含有一氧化碳等对人体有害的成分,在通风不良的场所运行时,有废排气中毒的危险。如发动机在 室内运行,废气必须排出至室外,并确保排气管的连接部位等不能有废排气漏泄。 ●排气系统零部件如安装保护装置或隔热罩,则不可将其拆除;暴露在外部的转动零部件如安装保护罩,也不可将其拆 除,否则容易造成人员伤害。 ●溢出外面的燃油、润滑油或冷却液应擦净。燃油、发动机润滑油或冷却液着火后会引发火灾危险。将有油或冷却液的 抹布存放在防火容器中,不得将其放在发动机上。 ●应清除掉发动机上或周围的灰尘、泥土和异物等。这也是引起火灾或发动机过热的原因。 ●起动发动机前,应确保发动机周围没人员,发动机上无工具或其他物品。起动开关等挂有“禁止起动”警示标牌时, 绝对不能起动发动机。 ●发现燃油、润滑油或排气漏泄时,应立即采取阻止漏泄的措施。 燃油、润滑油飞溅到发动机的高温部件上,或废排 气接触到可燃物品时会引起火灾,引起人身事故或机损事故的危险。 ●不得用手检查发动机三漏,高温高压燃油、润滑油和冷却液会伤害人体。在检查高压燃油管泄漏时应特别小心,因为 燃油在高压下能注入皮肤并导致人身伤害或伤亡。应使用厚板检查是否有燃油泄漏,发现燃油漏泄时,应避免与喷出的 燃油直接接触。 ●检测燃油、润滑油、冷却水或蓄电池电解液时,如需要用灯照明,必须使用防爆照明器具,以避免发生引火燃爆的危 险。 ●处理任何与燃油系统相关的组件或在其附近工作时,不得吸烟,也不得使用明火。燃油蒸汽可能会点燃,引起零部件 损坏或人身事故的危险。 ●发动机运行时,切勿对燃油系统中任何零件进行保养。 ●柴油在超高压下通过高压油管从喷射泵流到喷油器。故在发动机运行期间,切勿松动任何高压油管,不遵守此项警告 会造成严重烫伤事故。 ) ●共轨燃油系统在发动机运行中会产生高电压。在发动机运行时,不得触动喷油器电磁阀导线或电磁阀部件,不遵守此 项警告会造成严重触电事故。 ●当发动机长期停用或需要维修时, 应拆除发动机与蓄电池的连接导线, 若是空气起动马达起动, 应拆去空气连接管路, 以防止发动机意外起动。 同时必须在操作室或控制部位挂上 “禁止运行” 的标牌。 拆除蓄电池端子时, 一定要先从(-) 端 子侧开始。安装时一定要先从(+) 端子侧开始。 ●蓄电池的两端子之间不得用工具等金属物接触,不得将蓄电池正负极端短路,有燃爆的危险。 ●蓄电池端子的连接应牢靠。端子松动时,因接触不良产生打火时,有引爆的危险。损伤的电缆、电线会引起火灾。在...

-

Page 8: Ⅴ. 使用保养注意事项

液盖即压力盖,使冷却系统卸压,然后进行添加。刚停机时的冷却水的温度很高,端盖打开的话,蒸汽或热水喷出有烫 伤的危险。检查冷却液液面、添加冷却液或更换冷却液后应注意拧紧加液盖。 ●发动机运行时,进、排气系统温度高,不可用手触摸排气管、排气尾管、增压器、中冷却器进气管、膨胀水箱等高温 零部件。发动机运行时,冷却水温度很高,不可打开散热器加液盖。如果打开散热器加液盖,蒸汽或热水喷出有烫伤的 危险。 ●风扇胶带断裂时,应立即停机,否则发动机会产生过热、膨胀水箱内的冷却液形成蒸汽喷出,有引起烫伤的危险。 ●排出润滑油,或更换润滑油滤油器时,不得用手直接操作。高温的润滑油或部件会烫伤手上的皮肤。 ●在拆卸或松开任何管路、固定接头、接口或有关零部件之前,应先释放这些零部件所属系统的压力,如空气系统、冷 却系统、润滑系统或燃油系统中的压力。否则,高压燃油、润滑油和冷却液会伤害人体。 ●发动机运行中,不得接近转动部位。在转动件的周围不得放置容易被卷入的物体。身体或工具等被转动件卷入后,会 发生严重的人身事故。 ●在调整发动机及其驱动装置之前务必停止发动机运行。卷入转动部件内会引起重大的事故。 ●使用适当的发动机盘车方法,不得利用风扇部位盘动发动机曲轴,否则会造成严重的人身伤害或风扇叶片损坏。 ●保养时使用的盘车工具,使用后必须取下。盘车工具插在发动机上,不仅会损坏发动机,还会引起人身事故。 ●使用过的润滑油可能含有致癌成分,且能引起再生毒性。应避免吸入润滑油蒸汽或长时间与其接触。用适当安全可靠 的方法处理废油。 ●为防止窒息或冻伤,在拆除空调致冷剂(氟利昂)管路时,一定要穿戴防护衣并且必须在通风良好的环境中进行。为 保护环境,致冷系统必须使用专门的设备进行倒空或灌装,以防止氟利昂扩散到大气中。应回收和循环使用致冷剂。 ●为保护环境,更换润滑油和润滑油滤清器、燃油滤清器或冷却液时,排出的润滑油或冷却液、被更换的润滑油滤清器 或燃油滤清器,不能随便废弃,应按相关环境保护法规处置。废弃的蓄电池也应按相关环境保护法规处置。 Ⅴ. 使用保养注意事项 在使用、定期维护保养发动机前,应仔细阅读和了解全部的发动机使用保养注意事项和警告。 下面的使用保养注意事项和警告必须遵守,否则会造成发动机故障或损坏。 ●认真阅读本手册,严格遵守本手册中规定的操作步骤及保养规程。 ●应严格遵守本手册规定,进行日常维护和四级保养,并做好定期保养记录。 ●应按本手册规定,使用恰当的燃油、润滑油和冷却液。 ●发动机的冷却系统在任何气候下都应采用本手册规定的冷却液或冷冻液。 ●加注润滑油时,不同规格的润滑油不得混用。 ●起动发动机前,必须检查冷却液、润滑油、燃油是否足够。 ●切记发动机必须空载起动。 ●对新机或大修后的发动机,使用前须经 60 小时磨合运行。 ●不允许在不带空气滤清器情况下运行发动机,以免发动机发生早期磨损。 ●如发动机在室内运行,应始终保持机房内的通风良好。发动机吸入空气量不足时,会引起发动机温度上升、输出功率 不足和性能下降;如需要,必须配备机房通风设备。 ●发动机运行时,应经常观察其运行状态和所有仪表的显示值。如发现异常情况或遇紧急情况应采取紧急停车措施,并 排除故障,防止因缺水过热或润滑油压力过低而导致使发动机运动件咬合。 ●当冷却液温度低于 60℃时,严禁发动机高速高负荷运行。... - Page 9 ●严禁发动机超负荷运行。 ●发动机出现过热必须停机时,不能在停机后立即注入冷却水,否则会损坏气缸盖等零部件。 ●发动机发生异常停机后,不能立即再起动。在发出异常报警的同时停机时,必须查明故障的原因并排除故障后才能再 次起动。如果不作故障处理继续运行的话,有可能引起更加重大的事故发生。 ●当由于某种原因发动机的润滑油压力异常下降时,应立即停机,检查润滑油系统的各个部分,确认故障原因。在低油 压状态下继续运行的话,会引起发动机轴承烧损等事故。 ●起动刚修复的发动机时,应作好切断 ECU 电源的准备。一旦发生异常,应立即断电。 ●共轨燃油系统在发动机运行中会产生高电压。当发动机运行时,不得触动喷油器电磁阀导线或电磁阀部件,否则会导 致电磁阀损坏。 ●ECU、共轨管、高压油泵和喷油器为精密部件,严禁用户自行检修,否则本公司将不承担相关的服务承诺。电控系统 各部件的检修必需由我公司维修站专业人员进行。 ●避免在装有电子设备的发动机或设备上进行焊接,如必须话,则焊接前,应切断设备电源,断开电子设备与线束连接。 不可带电插拔线束,并用保护套盖住 ECU、传感器等电子设备的插槽,以避免焊接产生的颗粒和火花溅入;不得用手 接触 ECU 等电子设备插槽的金属管脚。 应将电焊机地线点尽可能靠近焊接焊处, 避免焊接电流穿过 ECU 等电子零部件, 以保护电子零部件免受损。 ●不允许随意对线束进行插拔;如需插拔,必须断电后进行,以免失效。 ●检查胶带张力及其它驱动装置时,发动机应处于停车状态。 ●不得用撬棒将传动胶带从带轮上拆下或安装到带轮上,因为这样做可能会破坏胶带内部的增强纤维。应手工拆卸和安 装。 ●如果传动胶带被润滑油、燃油或其它有害液体沾染,则必须更换,并消除污染源。不得使用溶剂清洁胶带。 ●如果正时胶带或传动胶带润滑油、燃油或其它有害液体沾染,则必须更换,并消除污染源。不得使用溶剂清洁胶带。 ●传动胶带存放或搬运时,应确保其弯曲直径不小于25 mm,不得挂在挂钩上。 ●传动胶带带轮各处表面必须光滑,以延长胶带寿命。因此在安装胶带之前,应确保带轮表面无粗糙表面或毛刺,且转 动自如。 ●蓄电池有一定的使用寿命,到一定的时期必须更换。 ●如调温器失灵应及时更换,不得随意拆除不用。 ●禁止用水直接喷淋发动机进行清洗。 ●注意不要让雨水等从排气管口或进气管口进入。不得在发动机运行中清洗发动机。清洗剂( 水) 有可能被吸入发动机 的内部。发动机的燃烧室内进水的话,发动机起动时发动机受水压作用有可能导致内部的损坏,引起重大的事故。...

-

Page 10: 第一章 概述

第一章 概述 1.1 柴油机的型号识别 柴油机(除国内国 3 以上电站以及出口电站机型)型号表示下列含义: □ □ □ 排放标准:4—国 4 排放 用途:Q、G、D、C 、C 柴油机功率/马力 四气门电控 柴油机系列 柴油机排量/L 上柴动力 注:Q—汽车、G—工程机械、D—电站、C —船用主机、C —船用辅机 例:SC9DF340Q4 代表上柴动力 D 系列 9 升电控四气门 340 马力国Ⅲ车用柴油机... -

Page 11: 简写和缩写定义

国内国 3 排放标准以上电站和出口电站机型发动机型号表示下列含义: 配置变化:1, 2, 3,… 排放阶段 用途:G代表发电用 发动机排量(保留1位小数) 进气方式 省略 柴油发动机 天然气发动机 系列代号 发动机气缸数 注:进气方式分三种:T 增压,TA 增压水空中冷和 TAA 增压空空中冷 例:6DTAA8.9-G33 表示 D 系列 6 缸总排量 8.9L 增压空空中冷第 III 阶段排放标准第 3 种配置电站用发动机。 1.2 简写和缩写定义 电控高压共轨系统 千瓦 电子控制单元 升 燃油压力调节阀 兆帕 喷油电磁阀... -

Page 12: 柴油机铭牌

1.3 柴油机铭牌 柴油机铭牌标明了您所购买的柴油机的主要技术数据和信息, 是用户购买维修零件和我公司进行售后技术服务的 主要依据。希望用户将这些信息和数据记录到您的柴油机或所配设备的工作日志中。在日后联系维修和反映质量问题 时,及时提供这些信息,有助于正确解决您所反映的问题。请保护好标牌不受损坏。铭牌位于柴油机缸盖罩壳顶面。 下面是铭牌的 3 种样式举例: △注意:未经我公司许可,用户不得随意更换柴油机铭牌! -

Page 13: 柴油机外形图

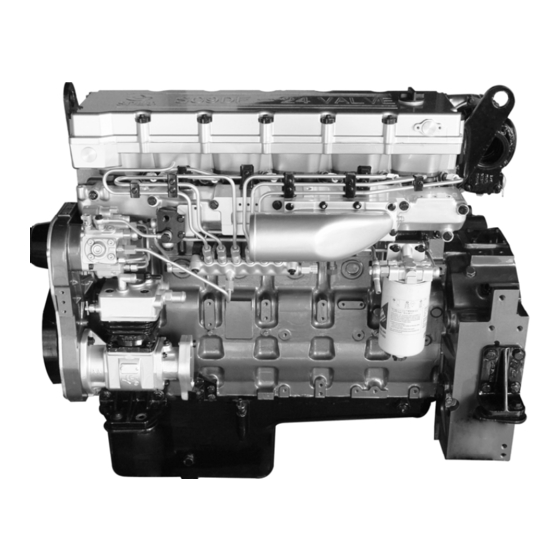

1.4 柴油机外形图 外形图仅为示例,不同车型所配柴油机配置要求不同,会导致外形有差异。 SC9DF375Q3 柴油机外形图 进气侧视图... - Page 14 排气侧视图 第二章 柴油机的主要技术和性能规格 顶面视图...

-

Page 15: 第二章 柴油机的主要技术规格和参数

第二章 柴油机的主要技术规格和参数 2.1 主要技术规格 SC9DF/6DTAA8.9 机型 型式 四冲程、水冷、直列、增压中冷 8.82 活塞总排量/L 缸径/mm 行程/mm 缸数 每缸气门数 进气方式 增压中冷(空空中冷) 16.4:1 压缩比 燃油系统 电控高压共轨 发火顺序 1-5-3-6-2-4 曲轴旋转方向(面向飞轮端) 逆时针 起动方式 电起动 最大净功率/ kW 240~340 额定功率/ kW 176~251 标定转速/(r/min) 1900~2200 净重/kg 680~780,880~980(柴油机装配承重油底壳) 1371 长/mm 外形尺寸 宽/mm 1372(带空气滤清器)... - Page 16 系统容量/L ≈30 冷却系统 调温器 开启温度/℃ 全开温度/℃ ≥10 升程/mm 水箱压力盖压力/kPa 冷却液容量(不包括水箱及外接管路)/L 进排气系统 允许最大进气阻力/kPa 4.5/5.5(二级);5.2/6.0(三级) (标定工况,干净空滤/脏空滤) 允许的最大排气温度/C 700(涡轮进口) 燃油系统 燃油输油泵吸油最大阻力/kPa 燃油回油最大阻力/kPa 燃油进油温度/°C ≤60 冷起动系统 无辅助起动装置时最低起动温度/°C 加预热装置时最低起动温度/°C 电器系统 推荐的最小蓄电池容量 24V 系统: 900 (320) -18℃冷起动电流/A(备用容量电流/A) 640 (240) 0℃冷起动电流/A(备用容量电流/A) 起动电机 电压/V 功率/kW 发电机 电压/V 28/14 电流/A 55、110 或...

-

Page 17: 其它技术要求

2.3 其它技术要求 2.3.1 燃油 警告:不准用汽油或酒精与柴油混合使用,这种混合物会引起爆燃。 本系列柴油机使用的柴油质量指标应不低于我国 GB 19147 车用柴油标准规定,下面列出该标准的主要指标。 车用柴油主要规格(GB 19147) 项 十六 馏 出 温 度℃ 运动 钢片 水分 含硫 密度 灰分 机 凝 冷滤 闪点 目 烷值 粘度 腐蚀 % 量 (50 ℃ % 械 点 点 (闭 (v/ v) (m/m) (20℃) - Page 18 2.3.2 润滑油 为确保柴油机的正常运行和长寿命、改善柴油机的排放,SC9DF 型柴油机规定使用上柴公司 D 系列柴油机专用机 油或 CH-4 级及以上级别的机油,在无法购买到上柴专用机油的情况下,可使用满足美国石油协会(API)要求的 CH-4 级及以上等级的润滑油。 不同粘度等级的柴油机油所适用的环境温度范围为下图所示。 适合环境温度 机油粘度等级 最低 最高 -40℃ 25℃ 0W-20 -40℃ 30℃ 0W-30 -40℃ 35℃ 0W-40 -35℃ 25℃ 5W-20 -35℃ 30℃ 5W-30 -35℃ 35℃ 5W-40 -30℃ 30℃ 10W-30 -30℃ 35℃ 10W-40 -25℃...

- Page 19 却液具有防冻、防腐、导热性好、稳定性好、环保等特点。 名称 件号 冰点/℃ 沸点/℃ 上柴有机型(防冻)冷却液 F/LQY-45 如选其它品牌防冻液, 或用水和乙二醇的混合液作为柴油机冷却系统的却液时, 冷却液中的硅酸盐 (无水硅酸钠) 、 氧化物及醋酸的含量分别不得高于 1 000 ppm、5 ppm 和 100 ppm,否则可能导致冷却系统零件表面积垢,堵塞散热器 和引起水泵密封圈泄漏。 调整水和乙二醇的混合比例可得到不同冰点(即凝固点)的防冻冷却液,一般情况下,所选择的防冻液的冰点应 比柴油机使用地区最低气温低 10℃左右。 对于大多数气候,乙二醇与水的体积比与冰点的关系如下,推荐水和乙二醇的比例为 50:50 乙二醇:水 10:90 20:80 30:70 40:60 50:50 55:45 60:40 65:35 冰点/℃ -3.8 -7.5 -14.1 △注意:任何气候下都使用防冻液作为发动机的冷却液。 △注意:必须每隔...

- Page 20 (2)从密封包装袋中取出一条试纸,将试纸条顶端试片浸入刚取出的冷却液中浸泡 5 秒后取出, 并将试纸与色版颜色表对比,观察试纸的颜色,即可确定冷却液样品中的 DCA4 添加剂浓度,然后按色版要求把冷却液 中的添加剂溶入调配到标准浓度。 (3)测试完毕,清洗接水杯,请密封好剩余试纸放在干燥阴凉处保存,以便下个周期再用(一般 每半个月进行测试一次) 。 DCA4 添加剂含量正确的标准色卡 冷却液中 DCA4 添加剂标准浓度 6 克/每升冷却液,可接受范围 3 克/升至 12 克/升之间。过低 或过高将对零部件有很大影响。 每升冷却液中 DCA4 状况 需要采取的保养措施 <3 g ●更换水过滤器 ●按冷却系统容量每升水补充 3 克 DCA4 添加剂 ●更换水过滤器 12 g ●不需要 ●放出 50%冷却液或防冻液(用塑料桶盛装,待下个周期补充冷 18 g 却液用)...

-

Page 21: 柴油机主要螺栓螺母拧紧扭据和方法

2.4 柴油机主要螺栓螺母拧紧扭据和方法 表 1 主要紧固螺栓扭据规格 序号 名称(每台数量) 螺纹规格 最后扭紧力矩/N·m 扭紧方法 125±5 N·m 第一次: 50 N·m M16-4h6h 主轴承盖螺栓 最后转角 第二次:120~130 N·m 210°±5° 第三次:转角210°±5° 115±5 N·m 第一次: 50 N·m M14-4h6h 气缸盖螺栓 最后转角 第二次:115±5 N·m 240°±5° 第三次:转角240°±5° 60±5 N·m 第一次:60±5 N·m M12×1.25-4g6g 连杆螺栓 最后转角... - Page 22 空压机紧固螺母 77±7 112±10 飞轮壳紧固螺栓 45±4 增压器紧固螺栓 80±8 发电机皮带轮螺母 13/1″M16 燃油滤清器 接触后旋转3/4-1圈 24±3 燃油滤清器进出油接头螺母 45±3 高压油管接头螺母 10±2 高压油泵回油铰接螺栓 18±2 高压油泵进油铰接螺栓 16±2 高压共轨回油铰接螺栓 20±3 燃油滤清器传感器 77±6 吊板紧固螺栓 45-60 N·m、或3/4-1圈 机油滤清器 80±4 油底壳放油螺塞 80±4 油底壳加热器螺塞 80±4 机油调压阀 45±4 机油吸油管(法兰) 序号 名称(每台数量) 螺纹规格 最后扭紧力矩/N·m 扭紧方法...

- Page 23 4 推荐力矩拧紧。 表 2 一般螺塞和标准螺栓的近似拧紧力矩 性能等级 10.9 扭矩/N·m 扭矩/N·m 螺栓直径/mm 铸铁 铝 铸铁 铝 注:上表中扭矩数据仅适应于螺栓、螺母的螺纹部分进行适当润滑的情况。 表 3 锥形螺塞的推荐扭紧力矩 扭矩/ N·m 螺 塞 规 格 螺纹 有效螺纹外径 铸铁或钢 铝 1/16 10.4 13.7 17.3 21.6 26.7 33.5 42.2 48.3 表 4 管接头铰接螺栓的推荐扭紧力矩 规格...

-

Page 24: 第三章 柴油机的运行操作

第三章 柴油机的运行操作 在使用柴油机之前,应根据具体的使用环境和条件,选用适当规格的机油、燃油和冷却液。选用的机油、燃油和冷 却液的技术规格应符合 2.3 之规定。 正确合理的使用将会使你的柴油机获得更长的寿命、更良好的工作性能和经济性。 3.1 柴油机的起动 3.1.1 常规起动 检查油门操作是否灵活。 脱开所有的从动装置,如果装有变速箱,将其置于空档。 等待预热指使灯熄灭。 发动车时不需要脚踏油门。 △注意:为防止损坏起动马达,当环境温度≥-15℃时,起动时间不得超过 15 秒;当环境温度<-15℃时,起动时 间不得超过 30 秒,两次起动之间应间隔至少 2 分钟(仅对电起动马达) 。 每次起动时间一般为 2 至 3 秒。 如果三次起车之后仍不能起动,检查预热装置和电控喷油系统。 柴油机起动后,将以 700 转/秒转速怠速运行。在低温环境下,柴油机怠速会自动提升,加快暖车,一般当水温达 到... -

Page 25: 柴油机的运行

打开油门。 按 3.1.1(常规起动)或 3.1.2(低温起动)的起动程序起动柴油机。 3.2 柴油机的运行 3.2.1 新柴油机磨合 新的或大修后的柴油机,在正式使用前须经 60 小时或约 2 000 公里的磨合并更换机油后,方可投入全负荷使用, 以改善柴油机各运动部件的工作状况、 提高柴油机的运行可靠性和延长使用寿命。 磨合应视柴油机用途和拖载方式的不 同,考虑具体磨合方案。原则上随着磨合时间的增加分阶段逐步提高柴油机的转速和负载。在整个磨合期内负荷应是标 定功率的 50%~80%,转速应不大于标定转速的 80%。 柴油机在磨合期及磨合后的正常工作期,均不宜长时间处于怠速运行或低负荷运行。柴油机怠速连续运行时间不得 超过 10 分钟,以避免因积碳而引起早期磨损或影响柴油机性能。 3.2.2 常规运行 柴油机在低于最大扭矩的转速下,全油门持续运转时间不应超过 1 分钟。 ● 在柴油机运行过程中应经常注视机油压力和冷却水温度,参阅第 2 章“柴油机主要技术规格和参数” ,若运行参数 不符合规定时,应停车检查原因,必要时应进行修理。 △注意:在冷却液温度低于 60C 或高于 100C 情况下连续运转,将有损于柴油机。 ●... -

Page 26: 柴油机的停车

△注意:使用制动器请遵循以下原则 打开制动器开关前,请确保发动机已经暖车;开关转换请遵循由“低”到“高”的顺序。 湿滑路面千万不要打开制动器,否则制动器工作可能使车辆打滑失控。 不同的路况选择合适的制动档位,保证您的车子有足够的减速能力以控制车速在合适速度。发动机在高转速 时制动器的制动能力更强,所以可以根据选择较低的档位,但是千万不要使发动机超速(建议您在上坡的时 候选择和下坡时一样的档位) 。 通常路面状况变化很快,请相应选择制动档位。如果制动器起作用时车辆出现打滑,就应该关掉制动器,直 到路面状况改善再打开。再次打开制动器的时候,也要遵循由“低”到“高”的顺序。 3.4 柴油机的停车 ● 满负载运行后,在停车前,柴油机应逐渐降低转速和负荷,并须在怠速运转 3~5 分钟,使增压器转速大幅下降, 使发动机逐步均匀冷却,以保护增压器和柴油机。 ● 将柴油机起动钥匙开关置于“OFF”位。 ● 除非迫不得已,不得在高负荷运行中紧急快速停车,否则会因出现过热而产生严重故障。 3.5 柴油机工作范围 △注意: 柴油机能成功地在最大扭矩转速以上的过渡工况上以全油门工作。 这与推荐的良好的经济运行方法是一致 的。在最大扭矩转速以下长时间全油门工作将缩短发动机寿命以致大修,造成柴油机严重损坏,这种情况被认作滥用柴 油机。 △注意:在换档过程中会产生柴油机低于最大扭矩转速运转,这是因为传动齿轮之间的传动比不同。但是柴油机在 低于最大扭矩转速情况下以全油门工作绝不能超过 1 分钟。 △注意:柴油机转速超过 2500 转/分会导致柴油机严重损坏。当从陡坡上下滑时,变速箱和柴油机相结合使用(不 允许挂空档)用或用脚踏刹车来控制车辆和柴油机速度;有排气制动功能时,可采用排气制动功能。... -

Page 27: 第四章 柴油机的维护保养

第四章 柴油机的维护保养 4.1 维护保养表 建议按照“维护保养表”保养 SC9DF 型柴油机。若柴油机经常在环境温度低于-18C 或高于 38C 情况下运行, 或者柴油机在多尘环境或在频繁停车情况下工作时,须适当缩短保养周期。 柴油机检查更换计划表 每 10000 km 每 20000 km 每 40000 km 每 80000 km 日常 或每 3 个月 或每 6 个月 或每 12 个月 或每 2 年 保养内容 保养 或每 250 小时 或每... - Page 28 D 系列柴油机维护保养周期表 适用范围 高速/公路用车(牵引、载货) 工程用车(公路自卸车、搅拌 工程机械/路面机械/农机 车、汽车吊) 保养周期 首保 定期保养 首保 定期保养 首保 定期保养 3000km 250h 250h 每 20000Km/6 个 每 500h/6 个月 每 500h/6 个 月 月 保养内容 更 换 机 更换机油、 机滤、 更换机油、 更换机油、 机滤、 更 换 机 更换机油、...

-

Page 29: 日常检查及保养内容

4.2 日常检查及保养内容 柴油机预防性保养,是从每天了解其本身及其系统的工作状态开始。 在起动之前,需先进行日常维护保养: 检查机油液面; 检查冷却液液面; 检查传动胶带; 检查冷却风扇; 排除燃油精滤油上水分离器中的水和沉淀物 目测检查泄漏; 检查是否有松动或损坏部件,特别是燃油和进、排气系统; 检查发动机烟色; 检查故障灯是否正常。 在起动运行柴油机时应注意柴油机是否有任何异常变化,如机油压力,功率波动,冷却液、机油或燃油消耗,冷却 液或机油温度,排烟等。如有异常应及时向维修部门报告,查找原因排除故障。 △注意:为防止线束短路,柴油机线束、传感器部分禁止用高压水枪直接冲洗。若发现线束部分有水,应用冷风吹 干后才能起动柴油机。 4.2.1 检查机油液面 检查油面高度需在柴油机停车(至少 5 分钟)后进行,使机油有 充分的时间流回油底壳。当油面低于油尺下液面记号或高于上液面记 号时,绝不允许起动柴油机。 油尺低位至高位上下液面油量差约为 4 升。 4.2.2 检查冷却液面 打开散热器或膨胀水箱的加水 口盖或液面检查 口闷头检查冷却液面。... - Page 30 警告:需等柴油机内冷却液温度降至 50C 以下时,方可拧开散热器 加水口盖或液面检查口闷头。 柴油机刚停车就立即拧开,带压力的高温水和蒸汽会喷出伤人! 需慢慢地拧开加水口盖或冷却液检查口闷头以使冷却系统逐渐减压。 注入柴油机的冷却液及其添加剂浓度应符合第 2 章规定。防冻冷 却液必须在注入柴油机之前先混合好,因为防冻液传热能力与水不 同,若直接注入柴油机,在冷却液未混合好之前,会引起过热。 警告:采用普通柴油机防冻液(无防锈防腐功 腐蚀)时,若 防冻液不加 DCA4 添加剂,缸套会产生穴蚀,将严重影响缸套使用寿 命。 若柴油机出气孔和放水孔锈蚀堵塞, 会出现气阻, 使柴油机过热, 造成冬天水放不掉引起机体冻裂等严重事故。 冷却液注入冷却系统应注满至散热器或膨胀水箱加水口或液面 检查口的底面为止。必须慢慢地灌注冷却液以防止产生气阻,须等 2 至 3 分钟以便让空气能充分地排出。 4.2.3 检查传动胶带 用肉眼检查传动胶带。检查胶带是否有纵横交叉的裂纹。沿胶带 宽度方向的横向裂纹是允许的。 但不允许出现纵向 (沿胶带长度方向) 和横向贯穿的裂纹。若胶带磨损或出现材料剥落应予更换。...

-

Page 31: 每隔 10 000 公里、250 小时或 3 个月的保养内容

4.2.4 检查冷却风扇 要求每天都要用肉眼检查风扇有无裂纹、铆钉松动、叶片松动和 弯曲等毛病。应确保风扇安装可靠。必要时应拧紧紧固螺栓,更换损 坏的风扇。 警告:风扇叶片损坏会造成伤人的严重事故。绝 不允许拖拉和撬动风扇,更不能借风扇转动柴油机。 4.2.5 排除精滤器上油水分离器中的水和沉淀物 应每天排除燃油精滤器上油水分离器中的水和沉淀物。打开油水 分离器底部阀门,排除水和沉淀物,直到清洁的燃油流出为止,然后 再关紧阀门。 如果配置燃油粗滤器,粗滤器有油水分离功能。当燃油粗滤器上 水储存罐中的水位达到一定高度时,水位传感器将信号提供给水位指 示灯,提醒驾驶员或操作员及时排水。旋松粗滤器底部放水阀门约 3 圈半, 排除水和沉淀物, 直到清洁的燃油流出为止, 然后再关紧阀门。 不要用力拧紧,手感紧即可。 4.3 每隔 10 000 公里、250 小时或 3 个月的保养内容 在完成日常保养的基础上,再增加下列保养项目: 更换机油和机油滤清器; 检查空气滤清器; 检查进气系统; 检查进气中冷器; 检查电控系统线束和传感器。 4.3.1 更换机油和机油滤清器... - Page 32 △注意:不要在柴油机冷态时放机油。因为在冷态时,悬浮在机油中的杂质颗粒已沉积到油底壳底部并粘附在油底 壳内表面,不能随机油一起排出。机油温热时杂质颗粒悬浮在机油中,此时放机油,杂质颗粒易排出。 (2)清洁放油螺塞安装面,更换新垫片,然后装上放油螺塞,拧紧力矩为 56-64 N·m。 (3)清洁机油滤清器外表面,用工具拆下机油滤清器并报废。 (4)清洁滤清器座密封面,不得有旧的 O 型密封圈残留。 (5)安装新的机油滤清器前,应从滤清器周边 8 个小孔注入清洁机 油,注满滤清器内腔,油面离螺纹孔下端 3-15 mm。并在密封圈密 封表面上涂一薄层凡士林或清洁机油,用以形成润滑膜。 △注意:不得从滤清器中心孔注入机油。 (6)手旋滤清器直至密封圈接触到滤清器座安装面, 再用工具再拧紧 40~45 N·m 或 3/4 圈至 1 圈。 (7)打开加油口盖,用清洁的机油注入柴油机至接近油尺“FULL” 刻线(高油面记号) 。 本柴油机系统机油容量 30 L(SC9DF) (8)起动柴油机并怠速运转,检查机油滤清器和放油螺塞是否漏油。 (9)停车,约等 5 分钟让机油有充分的时间流回油底壳,然后检查机油液面高度。如需要,则添加至接近油尺“FULL” 刻线(高油面记号) 。 (10)安装加油口盖,手感拧紧即可。 机油更换周期 维护保养表中给出的机油更换周期是就一般柴油机而言的,对于不同用途的柴油机、其更换机油的周期是有所不...

- Page 33 长途客车 月累计行驶大于 2 800 km 的汽车 运垃圾、废料的卡车 混凝土拌和车、自卸汽车 10 000 短途往返客车 校车 消防车 游览车 14 000 箱式送货卡车 汽车起重机 10 000 场内货物搬运机械 铺路机、起重机、推土机、反向铲、铲运机 × 注:本表中以公里、小时或月为单位规定更换周期,以先到为准。 △注意:即使柴油机正在使用中,也不能将机油更换周期延长超过上表推荐的数值。 4.3.2 检查空气滤清器 空气滤清器阻力超过下列数值时,应更换空气滤清器元件: 增压和增压中冷机型:6.2 kPa。 △注意:空气滤清器阻力应在柴油机标定工况时检查。 如果空气滤清器装有保养指示器,应定时检查,若红 按钮 色标志已上升至检查口位置,应更换空气滤清器元件。 更换空气滤清器元件后,在保养指示器顶部上的按钮 开关便复位。...

- Page 34 警告:绝不允许不带空气滤清器情况下开动柴油机。 进气空气必须滤清以防止灰尘、垃圾进入柴油机造成柴 油机早期磨损。 4.3.3 检查进气系统 检查进气胶管是否有裂缝或穿孔,夹箍是否松动,如有发现应 予以拧紧或更换,确保进气系统不漏气,否则会造成柴油机损坏。 4.3.4 检查和保养中冷器 用肉眼检查进气中冷器进出气室是否有裂缝、 穿孔或其它损坏。 检查中冷器管子、散热片以及焊缝是否有开裂、脱焊以及其它 的损坏。 如果检查发现由于增压器失效或其它的原因造成机油或垃圾进 入进气中冷器,则该中冷器必须从设备上拆下进行清洗。 △注意:不允许用带腐蚀性的清洁剂清洗进气中冷器,否则会严 重损坏中冷器。 用溶剂沿着气流流动方向冲刷中冷器内腔。在冲刷过程 中,应震动或用橡皮榔头轻轻敲击中冷器以促使积在里面的垃 圾冲刷出来。 用溶剂将中冷器内的机油和垃圾完全冲洗完毕后, 应用热...

-

Page 35: 每隔 20 000 公里、500 小时或 6 个月的保养内容

的肥皂水冲洗残留在中冷器内的溶剂,最后须用清水更完全冲刷一遍。顺着进气方向用压缩空气吹干中冷器内腔。 4.3.5 电控系统线束和传感器检查 检查电控系统线路的使用情况,目视检查线束是否有断裂 痕迹,磨损裸露或烧灼现象,必要时更换线束,检查传感器接 插件状态。 4.4 每隔 20 000 公里、500 小时或 6 个月的保养内容 在完成日常保养和前一个周期性保养项目的基础上,再增加下列保养项目: 更换燃油滤清器; 燃油系统放气; 检查防冻液和冷却液添加剂浓度; 调整气门间隙。 4.4.1 更换燃油滤清器 将燃油滤清器座周围清理干净。 拆下燃油滤清器并擦净滤清 器座的密封表面。... - Page 36 将干净的柴油注满新的燃油滤清器, 并用清洁的机油润滑橡 胶密封圈。 按燃油滤清器表面印制的说明安装燃油滤清器。 △注意:为防止燃油泄漏,必须按说明拧紧燃油滤清器,但 不宜拧得过紧,以免损坏燃油滤清器。 4.4.2 燃油系统放气 在燃油喷射泵进油腔上装有溢流阀, 如果按本说明书规定更换燃油滤清器, 进入燃油系统的少量空气可以自动地被 排出。 但出现下列情况时,燃油系统需进行人工排气: 在装燃油滤清器时其内腔未注满柴油; 更换燃油喷射泵; 更换燃油管或高压燃油管连接松动; 初始起动或起动后柴油机没有继续运行; 燃油箱中的柴油吸空。 松开燃油精滤器上的放气螺塞,按动手揿泵输送柴油,直到 螺塞处流出的柴油没有空泡为止,然后再拧紧螺塞。 国 III 机型燃油滤清器座 国Ⅳ及国Ⅴ机型部分机型上的燃油滤清器座上设有自动放气 机构,无需手工拆卸放气螺塞,燃油滤清器中的残留空气可经通 过放气阀自动将空气排至油箱释放掉。 国Ⅳ及国Ⅴ机型燃油滤清器座...

- Page 37 4.4.3 检查防冻液浓度和冷却液添加剂浓度 用冰点仪检查防冻液的浓度。在任何气候条件下,都使用必 要添加防冻液。因为加入防冻液后可提高冷却液的沸点,同时又 降低了其凝固点,从而扩大了柴油机冷却液运行温度范围。 防冻液浓度应控制在使冷却液冰点比当地最低气温低 10C 左右。防冻液与水的体积比与冰点的关系见 2.3.3 节说明。 如采用 DCA4 添加剂,则其浓度检查按 2.3.3 规定。 4.4.4 调整气门间隙 调整气门间隙前需拆卸气缸盖罩壳和它上面的相关的零部 件;拆下飞轮壳上观察窗盖板。 将盘车工具插入飞轮壳盘车孔并与飞轮齿圈啮合,慢慢地转 动曲轴,使飞轮壳上的指针对准飞轮上“0”刻线,然后检查第 1 缸进排气门是否关闭, 即进排气门推杆是否可以自由转动。 如能自 由转动,则第 1 缸活塞处于压缩上止点;否则,转动曲轴 360, 使第 1 缸活塞处于压缩上止点。 用气门间隙规检查和调整气门间隙检查和调整气门间隙时, 柴油机应在冷至 60C 以下: 进气门间隙:0.30 mm; 排气门间隙:0.50 mm。 △注意:当厚薄规在摇臂和气门桥之间滑动时,...

-

Page 38: 每 40 000 公里、1 000 小时或 1 年的保养内容

在减振器上标明记号并转动曲轴 360CA。 再按步骤 B 所示检查和调整指定的各气门的间隙。 拧紧摇臂锁紧螺母后,再复查各气门的间隙时间隙数值不 应有变化。 锁紧螺母拧紧扭矩:45 Nm。 复原缸盖罩壳及其它附件。 4.5 每 40 000 公里、1 000 小时或 1 年的保养内容 在完成日常保养和前面各个周期的保养项目的基础上,再增加下列保养项目。 检查传动胶带张紧度; 检查张紧轮轴承; 检查风扇轴承。 4.5.1 检查传动胶带张紧度 检查胶带张紧状况。在胶带的最大跨距处测量其挠度。最大 挠度不应大于 9.5~12.7 mm。... -

Page 39: 每隔 80 000 公里、2 000 小时或 2 年的保养内容

如有胶带张紧力测量仪,亦可在胶带最大跨距处测量其张力,张力极限为 360~480 N。 4.5.2 检查张紧轮轴承 检查传动胶带是否损坏, 转动张紧轮, 检查张紧轮轴承是 否异常检查张紧轮固定螺栓是否松动,其扭紧力矩为 45 Nm。 △注意:张紧轮应转动自如,不得有任何卡住或 径向/轴向窜动现象。 4.5.4 检查风扇轴承 转动风扇检查轴承是否有异常。 △注意:转动风扇不得有振动和过大的轴向窜动 现象。 4.6 每隔 80 000 公里、2 000 小时或 2 年的保养内容 在完成日常保养和前面的各个周期性保养项目的基础上,再增加下列保养项目: 清洗冷却系统,更换冷却液; 检查曲轴扭振减振器; 检查空气压缩机。 4.6.1 清洗冷却系统 为确保柴油机冷却和防腐效果,必须定期清洗冷却系统,即使采取滤清和定期保养的冷却液,也必须两年更换和清 洗一次,否则必须适当缩短更换和清洗周期。冷却系统清洗步骤:... - Page 40 排放冷却液 警告:必须等到冷却液温度低于 50C 后方可拆下 散热器上的加水盖,否则热的冷却液喷雾会造成严重的伤人事 故。 打开散热器和柴油机冷却水泵上的放水阀, 排放冷却系统中 的冷却液。对于大多数用途,系统中的冷却液容量约为 25~30 L。 检查胶管是否损坏、 夹箍是否松懈或损坏, 如需要应予更换。 检查是否有泄漏、损坏和积灰。如果需要,应予以清洗和修理。 将碳酸钠清洗液注满柴油机冷却系统。 注:清洗液浓度为每 23 升的水中加 0.5 kg 的碳酸钠。 △注意:冷却系统清洗过程中,不要装上散热器加 水盖;并在散热器不加盖情况下运行柴油机。...

- Page 41 △注意:在灌注清洗剂过程中,必须将冷却水腔 中的空气排出。先打开进气中冷器上的放气阀(如果有的话),需 慢慢地注入清洗剂以免产生气阻。需等 2 至 3 分钟以便让空气充 分排出。清洗剂须加至散热器加水口或液面检查口的底部。 起动柴油机在冷却液温度大于 80C 情况下运行 5 分钟。 停车 并排尽清洗剂。 向冷却系统注满清水。 △注意:为确保注满清水,柴油机和进气中冷 器必须放气。不要装散热器加水盖,这时也不要装新的冷却水滤 清器。 起动柴油机在冷却液温度大于 80C 情况下运行 5 分钟。 停车并排尽清水。 △注意:如果排出的清水仍很脏,必须继续注入 清水清洗,直到放出的冷却水干净为止。...

- Page 42 冷却系统灌注冷却液 △注意:绝不允许不加添加剂只用水作冷却液, 这样会因锈蚀造成柴油机严重事故。 防冻冷却液的配制参照 2.4 节说明, 务必在注入前在机外预先 与水混合好。 △注意:在灌注冷却液期间,必须将冷却水腔中的 空气排出, 为此须把进气中冷器上的放气阀(如果有的话)打开。 必 须慢慢地注入冷却液, 以防产生气阻, 须等 2 至 3 分钟让空气能充 分地排出。冷却液应灌注到散热器的加水口或液面检查口的底部。 装好散热器加水口压力盖,起动柴油机运行直到出水温度达 80C 后,检查冷却系统是否有泄漏现象。 停车后待冷却液温度降至 50C 以下时, 打开散热器加水口压 力盖,复查冷却液面,如有必要,需再补入适量的冷却液。 4.6.2 检查曲轴扭振减振器 检查扭振减振器内圈(B)和外圈(C)上的刻线(A)是否移动,若 两刻线错位大于 1.6 mm,则应更换该减振器。...

- Page 43 检查减振器橡胶元件是否老化。如果发现有碎片状橡胶脱落 或橡胶圈低于金属表面距离大 于 3.2 mm,则应更换该减振器。 检查减振器内圈对于外圈是否有向前移动的现象,如有发现 应更换该减振器。 4.6.3 检查空气压缩机 所有的空气压缩机都引入少量的机油来润滑活塞环和运动 部件。当这些机油在空气压缩机正常运行温度下使用超过一定时 间后,会产生结胶或积碳,若不进行下列的检查,空气压缩机的 活塞环将会受到高的运行温度和压力的影响而失去密封性。 检查空气压缩机出气管 放掉制动空气储气筒内的压力空气。 从空气压缩机上拆下 出气管。...

- Page 44 测量空气压缩机出气管内孔的积碳层总厚度, 若总的积碳 厚度(×+×)大于 2 mm,应清洗和检查空压机气缸盖、阀门组 件以及出气管。如有必要,应予以更换。 若总的积碳层厚度大于规定值, 需继续往前检查空压泵与 压缩空气储气筒之间的出气接管,直到积碳层厚度小于规定值 为止。清洗或更换积碳层厚度大于规定值的接管或接头。 检查空气压缩机进气阀 警告:拆开卸载阀体螺钉时,应向下按住卸 载阀体,否则卸载阀弹簧突然释放会将它弹起伤人。 仔细检查卸载阀是否积炭,若严重积炭,应清除并清洗干 净。并应检查空压机缸头和进、排阀部件,必要时更换有关部 件。...

-

Page 45: Scr 系统的维护保养

若卸载阀是干净的或仅轻微的积炭, 可以在卸载阀体上装上 新的 O 形密封圈和在卸载阀体中孔内装上新的 Y 形密封圈。 在卸载阀帽外表面涂以防咬合剂。 在卸载阀体 O 形圈外表面涂以清洁的 15W-40 机油。 将卸载 阀部件装入空压机气缸盖,并拧紧卸载阀体的压紧螺栓。 扭矩:14 Nm。 4.7 SCR 系统的维护保养 国 IV、国 V 发动机 SCR 后处理系统使用的是 32.5%的尿素水溶液,即添蓝。用户需严格按照排放法规要求及时补 充尿素溶液, 避免因添蓝不足导致系统出现故障报警, 进而限制发动机扭矩。 SCR 后处理在使用维护时应注意下列事项: (1)冬季加注添蓝一定不要加得太满,液位指示刚满即可。因为当气温低于-11℃,添蓝会结冰膨胀。若加的太满,... - Page 46 膨胀空间不足会导致添蓝罐胀裂。 (2)因停机后添蓝泵会继续吹扫 30 秒,将管路中残留的添蓝吹出去,以防止结晶堵塞,所以应在钥匙开关关闭 30 秒后再断开整车电源。 (3)添蓝罐的体积由添蓝用量决定,对于欧 4 系统,用量相当于燃油消耗量的 5%,对于欧五系统,用量相当于 燃油消耗量的 7%。添蓝罐最高液位应保证添加尿素溶液至 100%。当液位计显示添蓝溶液消耗到 20%时,需要添加添蓝 溶液;如液位显示为 0 时,MIL 灯将点亮,发动机会限扭。 (4)每年发动机进行保养时打开添蓝罐底部放水螺塞进行清洗,放出罐内沉淀;不定期检查如发现通气阀或加液 口处出现白色结晶,可用清水冲洗,也可用湿布擦拭;通气阀如发现堵塞,可旋下用清水清洗或更换,2~3 年更换罐内 滤网;不定期检查插件及管路接头是否良好。 (5)严禁用其他溶液替代添蓝溶液加入添蓝罐,否则将损坏 SCR 后处理系统,也会因 NOx 超标而使发动机限扭。...

-

Page 47: 第五章 故障判断与处理及故障代码

第五章 故障判断与处理及故障代码 正确的操作、认真的按规定进行日常及定期检查保养,才能有效的消除故障。对于柴油机使用过程中的任何异常情 况都应引起重视,及时向维修部门报告和咨询。该说明书列举了一些典型的柴油机故障、可能的原因和一些可以接受的 解决方法。若故障不明或是不能修理以及本节中未列出的问题,请及时与上柴“易+人”呼叫中心联系(全国免费服务 热线 400-820-5656) ,以便进行诊断和修理。 ●柴油机不能起动 ●柴油机突然熄火 ●柴油机功率不足 ●燃油消耗量过高 ●机油消耗量过高 ●柴油机过热 ●机油压力过高 ●机油压力过低 ●排气管冒黑烟 ●柴油机冷却液温度过低 ●柴油机运转声音异常 ●柴油机振动大 ●发电机不充电或充电不足 5.1 柴油机起动困难或不能起动 可能原因 排除方法 起动线路松动或腐蚀 清洗和拧紧线路接头 起动电机运行不正常 电瓶充电不足 充电或更换电瓶 起动电机和电器系统故障 请咨询授权维修服务站 启动程序不对 参看本书 3.1 节正确启动 预热设备操作不当(需要时) 使用正确的预热步骤 起动电机运行正常 进气系统受阻 检查进气系统管路是否通畅... -

Page 48: 燃油消耗量过高

高压燃油管或接头泄漏 检查泄漏,如有必要拧紧/更换接头或高压燃油管 燃油系统进空气 燃油系统放气并检查进油管泄漏 进气或排气系统受阻 检查进排气系统阻力,检查空滤器,必要时更换 喷油或配气定时不正确 请咨询授权维修服务站 增压器损坏 检查增压压力,若太低更换增压器 喷油器喷孔堵塞,雾化不良 检查、清洗或更换喷油器 环境温度太高或在高海拔地区运行 在高海拔地区或环境温度太高的情况下,柴油机功率将下降, 使用时应适当降低负荷 检查柴油机故障指示灯是否点亮 请咨询授权维修服务站 5.4 燃油消耗量过高 可能原因 排除方法 燃油泄漏 检查燃油系统的管路密封性,如有松动请拧紧 燃油品质低劣 使用推荐的合格燃油 辅助装置故障引起的附加载荷 检查辅助装置和车辆零件(参看车辆制造商的规定) 进气系统阻力增大 检查空滤器滤芯,如有必要进行更换 检查故障指示灯是否点亮 请咨询授权维修服务站 5.5 机油消耗量过高 可能原因 排除方法 柴油机外表漏油 检查柴油机外部的管路、密封垫片、油封等是否有泄漏,更换 损坏的零部件 机油油面过高 检查机油油面,必要时调整 使用了不合适的机油... -

Page 49: 机油压力过高

水泵故障 拆检水泵 空气或燃气进入冷却系统 检查水路的是否有泄漏和松动 水温传感器或水温表损坏 检查传感器和水温表 调温器故障 更换调温器 5.7 机油压力过高 可能原因 排除方法 压力表失灵 检查压力表功能 发动机运转温度过低 参看冷却液温度过低 机油规格不正确,机油粘度过稠 检查/换用合格机油 旁通在关闭位置卡死 检查/更换旁通阀 5.8 机油压力过低 可能原因 排除方法 机油油面过低 调整机油油面 机油规格不正确,机油粘度过稀 检查/换用合格机油 机油管路接头松或油道闷头脱落 检查机油外泄现象 机油被水稀释 寻找稀释的原因,调换机油 机油压力调节阀故障 检查/更换压力调节阀 机油压力表故障 检查机油压力表 机油滤清器堵塞 检查/调换滤清器 柴油机轴、轴瓦类零件磨损 更换磨损的轴或轴瓦 5.9 排气管冒黑烟... -

Page 50: 柴油机噪声过大

温度传感器故障 检查/校验传感器 温度表失效 校验温度表,必要时更换 调温器损坏 更换调温器 5.11 柴油机噪声过大 可能原因 排除方法 传动胶带啸叫声 检查胶带传动系统 进气和排气泄漏 检查/修理泄漏 气门间隙过大 检查/调整气门间隙 涡轮增压器噪声 检查叶轮与壳体是否擦碰 柴油机机油过少 检查/添加机油 传动齿轮噪声 请咨询授权维修服务站 5.12 柴油机振动大 可能原因 排除方法 柴油机支撑(包括隔振垫)松动或损坏 检查/更换柴油机支撑(包括隔振垫) 风扇损坏或附件故障 检查/更换故障零件 曲轴扭振减振器故障 检查/更换故障零件 驱动系统部件的磨损和不平衡 按部件制造厂的规格检查/更换 运动部件松动或损坏 请咨询授权维修服务站 5.13 发电机不充电或充电不足 可能原因 排除方法 蓄电池的接头松动或腐蚀... -

Page 51: 柴油机 故障代码表

5.14 柴油机 故障代码表 国 III、国Ⅳ、国 V 柴油机故障代码表 序号 故障代码 故障说明 故障闪码 环境温度传感器信号过低 P0072 环境温度传感器信号过高 P0073 共轨压力超过最高限制 P0088 共轨压力传感器性能失效(包括漏油) P0093 进气温度传感器信号过低 P0112 进气温度传感器信号过高 P0113 与 DCU 连接的 CAN 总线开路 U1155 水温传感器信号过低 P0117 水温传感器信号过高 P0118 油门踏板传感器#1 常闭 P0120 油门踏板传感器#1 常开 P0121 油门踏板传感器#1 信号过低 P0122 油门踏板传感器#1 信号过高... - Page 52 CAN#2 节点出错 U1001 冷却液位过低 P2560 供油泵保护 P2293 曲轴转角传感器脉冲数目错误 P0336 曲轴转角传感器无脉冲信号 P0337 凸轮轴转角传感器脉冲数目错误 P0341 凸轮转角传感器无脉冲信号 P0342 凸轮转角和曲轴转角传感器无脉冲信号 P0385 车速传感器信号无效 P0501 车速传感器信号频率短路或开路 P0502 车速传感器信号频率过高 P0503 机油压力传感器信号过低 P0522 机油压力传感器信号过高 P0523 机油压力过低 P0524 预热继电器对地短路 P0541 预热继电器开路或对电源短路 P0542 蓄电池电压过低 P0562 蓄电池电压过高 P0563 FLASH 校验和错误 P0601 QR 码错误...

-

Page 53: Scr 后处理系统故障代码

供油泵失效(流量不足) P1218 压力限制器打开 P1219 共轨压力低于目标值的控制下限 P1221 油泵负压超过第一等级限值 P1222 油泵负压超过第二等级限值 P1223 发动机停车开关粘黏常开 P1530 巡航开关电路失效 P1565 怠速开关粘黏常开 P2163 QR 码没有写入 P1602 倒档开关开路或对地短路 P1676 倒档开关对电源短路 P1677 排气制动阀输出开路或对地短路 P1681 排气制动阀输出对电源短路 P1682 缸内制动#1 电磁阀输出开路或对地短路 P1683 缸内制动#1 电磁阀输出对电源短路 P1684 缸内制动#2 电磁阀输出开路或对地短路 P1685 缸内制动#2 电磁阀输出对电源短路 P1686 后处理系统一般故障 P1D17 后处理系统严重故障... - Page 54 后处理系统一般故障 P1D17 后处理系统严重故障 P1D18 尿素箱空故障 P1D19 尿素计量泵空气电磁阀开路 P2059 尿素计量泵空气电磁阀短路 P2061 NOx 传感器置于空气中 P2214 尿素计量泵驱动单元故障 P3009 尿素计量泵内部 EEPROM 模块故障 P3010 尿素计量泵内部加热器故障 P3043 尿素计量泵压缩空气和尿素流量低 P3056 NOx 传感器 CAN 通讯故障 可自恢复 U1000 泵 CAN 通讯故障 可自恢复 U1001 与 ECU 的 CAN 线通讯故障 U1002...

-

Page 55: 附录 维护保养记录

附录 维护保养记录 维护保养记录 柴油机编号 车辆 VIN 号 柴油机型号 用户名称 设备名称/编号 公里(小时) 日期 实际里程 保养内容 保养者 备注 或时间间隔... - Page 56 Warnings and cautions in this manual are not complete because Shanghai Diesel Engine Co., Ltd. (SDEC) has no possibility and is not able to foresee all potential risks resulted from the failures to follow the safety cautions and operation instructions.

- Page 57 Table of Contents Introduction ............................... 1 1.1 To the Owner and Operator ......................1 1.2 Scope ............................1 1.3 Notices for Engine Quality Feedback ..................1 1.4 Safety Notes ..........................1 1.5 Operation and Maintenance Notes ....................4 1.6 Warning Signs on the Engine ...................... 6 2 About Engine ............................

-

Page 58: Introduction

Since this manual ensures proper engine operation and maintenance, it should be given to the new owner when the engine is traded or sold. 1.2 Scope This manual is for the operation and maintenance of all models of D series electronically controlled diesel engine for application of agricultural equipment. 1.3 Notices for Engine Quality Feedback... - Page 59 ●Be sure to work in a safe place, and be prepared for potential danger at any time. ●When working on the engine, remain alert at all times. Never work on the engine when physically or mentally fatigued. ●Do not smoke when working on the engine. ●Smoking is not allowed during fuel refilling, otherwise, fuel steam can cause fire easily.

- Page 60 ●The connection of the battery cable posts must be secured. Explosion may happen due to poor connection. Damaged wires or cables will cause fire. Check and replace them before reconnecting the wires and cables. ●Do not use fire, nor make welding near the battery(s) because battery can produce flammable hydrogen and oxygen. Do not use the battery(s) when its electrolyte is lower than the minimum level.

-

Page 61: Operation And Maintenance Notes

environment protection regulations when changing oil, oil filter, fuel filter or coolant. And discarded battery(s) must be also properly disposed. 1.5 Operation and Maintenance Notes Read and understand all notes and warnings before use and maintenance of the engine. Following notes and warnings must be followed to prevent the engine from fault or damage. ●Read this manual carefully, and be in strict accordance with operation instructions and maintenance procedures specified in this manual. - Page 62 ●Do not plug a harness in and out without necessary. If necessary, plug it in and out when power is off to avoid its malfunction. ●Do not connect the jumper starting cables or charging cables to the wiring of the electronic control system. This can cause electrical damage to the control system.

-

Page 63: Warning Signs On The Engine

1.6 Warning Signs on the Engine There are warning signs as below on the engine. They must be strictly observed to avoid personal injure or engine damage. 1) Warning signs 2) Caution sign 3) Reminding sign Tighten the cap in the direction of the arrow. -

Page 64: About Engine

Four-valve, electronic-controlled Engine series Engine displacement/L Shangchai Power Note: Q-Vehicle, G-Construction machinery, D-Generation, C - Marine engine; C - Marine auxiliary Example: SC9DF340Q4 represents Shangchai Power D series 9-liter electronic-controlled four-valve vehicle diesel engine of 340 PS compliant with China IV... -

Page 65: Acronym And Abbreviation Definitions

Note: Air inlet mode is divided into three type:T means Turbo,TA means Turbo with water-air intercooler and TAA means Turbo with air-air intercooler. Example: 6DTAA8.9-G33 represents D series six cylinder 9-liter air-air intercooler turbo NO.3 spec diesel engine for power station compliant with China III. -

Page 66: Engine Nameplate

Newton meter Parts per million (number) r/min Revolutions per minute 1.3 Engine nameplate The engine nameplate indicates the main technical data and information: model, order number, serial number, date of production, rated power and rated speed, which are a major basis for you to purchase service parts and for SDEC to conduct after-sale technical service. -

Page 67: Engine Outlines

1.4 Engine Outlines Below are the outlines of SC9DF375Q3 Diesel Engine Note: The figs below are for only reference. Outlines differ from one application to another due to different configurations. Exhaust outlet Fuel inlet joint Fuel return Fuel inlet joint Air compressor air outlet Air compressor... - Page 68 Coolant outlet Air Bleed joint Z3/4 Warm coolant tl t Drive pulley Coolant inlet Starter motor Coolant drain Oil filter M16×1.5Oil temp. sensor Oil drain plug Exhaust side view Compressor Compressor outlet Coolant filter control Turbine outlet Oil filler Engine air inlet Top view...

-

Page 69: Chapter 2 Main Specifications And Parameters

Chapter 2 Main Specifications and Parameters 2.1 Main specifications SC9DF/6DTAA8.9 Type Four stroke, water-cooled, in-line Displacement (L) 8.82 Bore (mm) 114×144 stroke (mm) Number of cylinders Number of valves per cylinder Aspiration turbocharged and charge air cooled (air-to-air intercooler) Compression ratio 16.4 Fuel injection equipment High-pressure common rail... -

Page 70: Main Parameters

2.2 Main parameters SC9DF/6DTAA8.9 Lubrication system Oil pressure (kPa) At idle (Min. allowance) ≥100 At rated speed (Min. allowance) ≥300 Oil sump capacity (L) (oil dipstick “high”-“low”) 26.5 - 22.5 Total system capacity (L) About 30 Cooling system Thermostat Start-to-open temperature (℃) Full-open temperature (℃) Lift (mm) ≥10... - Page 71 Cold start current at -18C (A) (Reserve capacity current (A)** (320) Cold start current at 0C (A) (Reserve capacity current (A)** (240) Starter motor Voltage (V) Power (kW) Alternator Voltage (V) 28/14 Current (A) 55, 110 or 140@280V150A@/14V Rated power (kW) 1, 1.5, 3 or 4@28V/2@14V * Two sets of 12V batteries are installed in series, and each cold start current is calibrated at -18C.

-

Page 72: Other Technical Requirements

2.3 Other technical requirements 2.3.1 Fuel Warning: Gasoline or alcohol is not allowed to be used with diesel, as their mixture may cause detonation. The quality of diesel fuel used for this engine should be not less than the requirement of national standard GB 19147. Main fuel specifications specified in the standard are as follows. - Page 73 2.3.2 Lube oil SDEC-designated special lubricating oil for D series diesel engine or oil of grade CH-4 and above is required for the SC9DF diesel engine in order to ensure its normal operation and long service life and improve its emissions. If the above engine oil is not available, oil of CH-4 grade or above meeting the requirements of American Petroleum Institute (API) can serve as an alternative.

- Page 74 with good low-temperature characteristics shall be used. △Caution: The oil with low viscosity is helpful to startup the engine. Due to abrasion, continuous use can affect the service life of the engine, so try not to use or limit the use of such oil. △Caution: Use of lube oil with bad quality will cause much high oil consumption, early wear, or even piston scuffing.

- Page 75 Ratio of ethylene 10:90 20:80 30:70 40:60 50:50 55:45 60:40 65:35 glycol and water Freezing point, °C -3.8 -7.5 -14.1 The recommended ratio of water and ethylene glycol is 50:50. △Caution: anti-freezing liquid is mandated for the engine as coolant for any climate. △Caution: It is required to discard or replace engine coolant every 385,000 km, 6,000 hours or 2 years (whichever comes first) in order to remove those harmful chemical sediments.

- Page 76 DCA4 powder is recommended. The coolant filter can be helpful to keep correct content of DCA4 in coolant and can also remove impurity in coolant. So it is required to change the filter periodically. △ Caution: Replacement of coolant filter is required every 8,000 km, 250 hours or 3 months, whichever comes first.

-

Page 77: Main-Bolt And -Nut Tightening Torque And Methods

2.4 Main-bolt and -nut tightening torque and methods Table 1 Torque specification for main fastening bolts Name Thread spec. Final torque Tightening method First: 50 N·m 125±5 N·m Main bearing cap bolts M16-4h6h Second: 120-130 N·m Final angle 210°±5° Third: angle 210°±5° First: 50N·m Cylinder head bolts 115±5 N·m... - Page 78 filter High pressure fuel pipe joint 45±3 N·m nuts Fuel pump fuel return banjo 10±2 N·m bolts Fuel pump fuel inlet banjo bolt 18±2 N·m High pressure common rail fuel 16±2 N·m return banjo bolt Fuel filter sensor 20±3 N·m Lifting plate bolts 77±6 N·m 45-60 N·m or additional...

- Page 79 Cast iron Aluminum Cast iron Aluminum Note: the torque values given in the above table only applies to the threads of bolts and nuts that have been properly lubricated. Table 3 Recommended tightening torque for tapered screw plugs Specification of screw plug Torque/ N·m Effective thread Thread diameter...

- Page 80 Table 4 Recommended tightening torque for banjo bolts Specification M81 M101 M121.25 M141.5 M161.5 M181.5 M201.5 M221.5 Torque/N·m Note: The torque described above is applicable to bolts made of steel, cast iron or aluminum substrate.

-

Page 81: Chapter 3 Operation Of Engine

Chapter 3 Operation of Engine Oil, fuel and coolant with suitable specifications shall be chosen according to specific application environment and conditions before running the diesel engine. The selected oil, fuel and coolant shall comply with technical specifications as given in the Article 2.3. Correct and reasonable application will enable the engine to have a longer service life, a better work performance and a high economical efficiency. -

Page 82: Operation

protections and specific warm-up time shall be provided. The lube oil, fuel and coolant must be used properly according to different temperature ranges of local areas where the engine is operated. 3.1.3 Starting after long time out of operation When the engine has been out of use for more than 30 days, check the oil level and make supplement before starting. -

Page 83: Operation And Control Of Engine Brake

Most failures will develop with a symptom. Observe the change of engine performance and sound of abnormality, or check if one of following signs occurs. If so, it is necessary to repair it. -misfire -abnormal smoke -abnormal vibration -power loss -abnormal noise -oil consumption increases -sudden change of oil pressure or coolant temperature... -

Page 84: Stopping

3.4 Stopping After full-load operation and before shutdown, gradually reduce the engine speed and load, and run the engine for 3~5 minutes at the idle to let turbocharger speed fall considerably and let the engine cool down gradually and evenly so as to protect the turbocharger and engine. -

Page 85: Chapter 4 Maintenance Of Engine

Chapter 4 Maintenance of engine 4.1 Maintenance schedule It is recommended to maintain the SC9DF electronically controlled diesel engine according to the "Maintenance Schedule". The maintenance interval shall be shortened appropriately in case that the diesel engine is always operating in an area with ambient temperature lower than -18℃... - Page 86 harness Check oil separator ● ● ● Checking anti-freeze ● ● ● concentration Checking/adjusting valve ● ● ● clearance Checking belt tensioner ● ● Checking belt tension ● ● Checking fan bearing ● ● Checking turbocharger ● Checking vibration damper ●...

- Page 87 Maintenance Interval for D Series Diesel Engines Scope On-road vehicles (tractors, Engineering Trucks (road tippers, Construction, road building trucks) truck mixers, truck cranes) and agriculture machines Maintenance First time Regular First time Regular service First time Regular interval service service...

-

Page 88: Daily Check And Maintenance Items

4.2 Daily check and maintenance items Preventative maintenance work starts with understanding daily working conditions of the engine itself and its systems. Daily maintenance shall be made before starting the engine: Check oil level; Check coolant level; Check drive belt;... - Page 89 4.2.2 Check coolant level Coolant inlet Open the water filler cap or remove the plug on the inspection Inspection port port on the radiator or expansion tank to check the coolant level. Warning: The coolant filler cap or inspection port plug of the cooler can be unscrewed only after the engine Coolant coolant temperature falls below 50°C.

- Page 90 The coolant fluid shall be added into the cooling system until the level reaches bottom surface of the coolant filler cap or inspection port of radiator or expansion tank. It shall be filled slowly in order to avoid air block, and wait for 2-3 min to allow the air to be exhausted fully.

-

Page 91: Maintenance Content Every 10,000 Km, 250 Hours Or 3 Months

close the valve fully. The primary fuel filter is used for the engine has a function of fuel and water separation. When water in the water container of the primary fuel filter reaches a certain level, the water-level sensor will send a signal to the water-level indicator light, reminding driver or operator to drain the water timely. - Page 92 (5) Before installing a new oil filter, fill it with clean oil from 8 peripheral holes. The oil level should be 3-15mm below the threaded hole. Apply a light film of Vaseline or clean lubricating oil to the O-ring on the new filter to form a lubricating film. △Caution: Do not add oil from the central hole of the filter.

- Page 93 Truck mixers, tippers Shuttle buses School buses Fire trucks Sightseeing buses 14,000 Box type delivery trucks Crane trucks 10,000 Onsite goods transportation machinery Pavers, cranes, bulldozers × Backhoes, carry-scrappers Note: The change interval in this table is in month, or hour, whichever comes first. △Caution: Even if the engine is under use, the replacement period of lube oil should by no means be prolonged beyond the above recommended intervals.

- Page 94 Warning: It’s prohibited to start the engine without air filter. Intake air must be filtered to prevent dust and dirt from entering the diesel engine in order to avoid early wear. 4.3.3 Check air intake system Check the air intake hose to see whether there is crack or perforation, or its clamp is loose;...

- Page 95 If oil or dirt is found in the intercooler due to turbocharger fault or other causes, remove and clean the intercooler. △Caution: Do not wash the intercooler with corrosive detergent; otherwise, the intercooler will be damaged seriously. Use the solvent to wash the inner chamber of the intercooler in air flow direction.

-

Page 96: Maintenance Content Every 20,000 Km, 500 Hours Or 6 Months

4.4 Maintenance content every 20,000 km, 500 hours or 6 months Following maintenance items shall be completed in addition to daily maintenance and the previous periodical maintenance: Replace fuel filter; Prime fuel system; Check anti-freeze content and coolant additive concentration. ... - Page 97 4.4.2 Prime fuel system There is an overflow valve in the fuel inlet chamber of the fuel injection pump, and a small amount of air shall be discharged freely if the fuel filter is replaced as per in the instruction in the manual.

- Page 98 temperature range of the engine coolant is extended. The anti-freeze content shall be controlled to make the coolant ice point lower than local min. temperature by about 10℃, Refer to Section 2.3.3 for relationship between the volume ratio of ethylene glycol and water and ice point. If being applied the content of DCA4 additive shall be checked as per Section 2.3.3.

- Page 99 Check and adjust the clearances of the valves in the way specified in Step A when the piston of the cylinder 1 TDC on compression stoke (I stands for intake valve; E exhaust valve). Recheck all the valve clearances after tightening the adjusting screw locknuts.

-

Page 100: Maintenance Content Every 40,000 Km, 1,000 Hours Or 1 Year

4.5 Maintenance content every 40,000 km, 1,000 hours or 1 year The following maintenance items shall be completed in addition to daily maintenance and the previous periodical maintenance items: Check belt tension; Check tensioner bearing; Check fan bearing. 4.5.1 Check belt tension Measure the deflection of the belt at its maximum span. -

Page 101: Maintenance Content Every 80,000 Km, 2000 Hours Or 2 Years

4.5.3 Check fan bearing Rotate the fan to check whether the shaft bearing works normally. △Caution: The fan shall be free of vibration and without excessive axle movement. 4.6 Maintenance content every 80,000 km, 2000 hours or 2 years The following maintenance items shall be completed in addition to daily maintenance and the previous periodical maintenance items: ... - Page 102 Open the drain valves on the radiator and the engine water pump, and discharge the coolant in the cooling system. For most engine applications, the coolant volume in the system is about 25-30 L. Check whether the hose(s) has been damaged and the clamp(s) loosened or damaged, and replace them if necessary.

- Page 103 △Caution: Air must be discharged from the cooling system water Ethylene chamber when filling clean agent. First open the air glycol bleeding valve (if applicable) in the intercooler, and slowly fill the detergent to avoid air block. Wait for 2 to 3 minutes to allow air to be exhausted fully.

- Page 104 Start Start the engine and run it for 5 minutes after the coolant temperature goes higher than 80℃. Stop the engine and discharge all clean water. Coolant temperature △Caution: If the discharged water is very dirty, continue to fill clean water to water the system until discharged water becomes clean.

- Page 105 4.6.2 Check vibration damper Check whether the scribed lines (A) on inner ring (B) and outer ring (C) of the vibration damper are out of alignment. Replace the damper if misplacement of the above two scribed lines exceeds 1.6 mm. Check whether the rubber part of the damper has aged or not.

- Page 106 Check the air outlet pipe of the air compressor Discharge the compressed air in the brake air reservoir. Remove the air outlet pipe from the air compressor. Measure the total thickness of carbon deposit inside the air Inner diameter of exhaust pipe outlet pipe of the air compressor.

- Page 107 Carefully check the unloading valve to see whether there is carbon deposit, and if so, remove and clean them. Check the compressor cylinder head inlet/outlet valve components, and replace relevant components if necessary. It is allowed to install a new-seal ring on the unloading valve body and a new Y-ring into its bore if the unloading valve clean or there is light carbon deposit.

-

Page 108: Maintenance Of Scr System

4.7 Maintenance of SCR system Aqueous solution of 32.5% urea or AdBlue is adopted for the SCR system of the engine models that are compliant with China IV and China V. It is required to supplement AdBlue timely according to the national emissions regulation to avoid the SCR system failure due to lack of AdBlue, resulting in torque restriction. -

Page 109: Chapter 5 Troubleshooting Guidelines And Diagnosis Codes

Chapter 5 Troubleshooting Guidelines and Diagnosis Codes Only when correct operation and regular maintenance is done as required in this manual can failure(s) be eliminated effectively. Any abnormal condition during the engine operation shall deserve attention and be eliminated timely. Some typical engine failures, possible causes and acceptable solutions are listed in this manual. -

Page 110: Sudden Misfire

Air enters the fuel system Discharge the air 5.2 Sudden misfire Possible Causes Correct The fuel is contaminated Replace with clean and qualified fuel Air enters the fuel system Prime the fuel system There is fuel leakage at high-pressure fuel Check the line for leakage, tighten and replace relevant parts if necessary line Low pressure fuel pipe or fuel filter is... -

Page 111: Fuel Consumption Is Too High

incorrect The turbocharger is damaged Check the turbocharger for pressure, replace it if its pressure is too low The injector orifice is blocked, resulting in Check and clean the injector or replace it poor atomization The ambient temperature is too high, or In the case of operation in the high-altitude area or at extra-high ambient the engine operates in high-altitude area temperature, the engine’s power will decline. -

Page 112: Oil Pressure Is Too High

The oil leaks from the turbocharger and Check the turbocharger inlet and outlet for oil trace enters the intake and exhaust pipes The internal parts of the engine are over Consult the authorized service station or provider worn so that the seal becomes ineffective 5.6 Oil pressure is too high Possible causes Correction... -

Page 113: Engine Is Overheating

5.8 Engine is overheating Possible causes Correction Check the cooling system for leakage, add coolant and discharge air Coolant is insufficient completely The radiator pressure cap has failure Check the radiator cap The engine is overloaded Reduce load The radiator is covered with excessive Check the radiator and clean it if necessary dust The wind guide ring of the radiator is... -

Page 114: Coolant Temperature Is Too Low

5.10 Coolant temperature is too low Possible causes Correction Too much cold air flow through the Check the fan and fan clutch, refer to the instructions by the fan clutch radiator manufacturer The radiator shutter is stuck at maximum Check the shutter and replace it if necessary opening The temperature sensor is failed Check and calibrate the sensor... -

Page 115: Alternator Cannot Be Charged Or Fully Charged

Driving system components become Check and replace them when necessary worn and imbalance The moving parts inside the engine are Consult the authorized service station or provider loose or damaged 5.13 Alternator cannot be charged or fully charged Possible causes Correction The battery connector becomes loose or Clean and tighten the battery connector... -

Page 116: Engine Diagnosis Codes

5.14 Engine Diagnosis codes Engine compliant with China III,China IV and China V emissions regulation P code Explanation SVS lamp P0072 Ambient Air Temp. Sensor Signal Too Low P0073 Ambient Air Temp. Sensor Signal Too High P0088 Common rail pressure exceeds hi upper limit P0093 C/Rail Press. - Page 117 U0155 Can Bus-Line Open From METER U1001 CAN2 Node Error P2560 Coolant Level Low P2293 Supply pump protection P0336 Number of NE sensor pulse error P0337 Crank Sensor No Pulse P0341 Number of G sensor pulse error P0342 Cam Sensor No Pulse P0385 Crank &...

-

Page 118: Scr System Diagnosis Code (Compliant With China Iv & V Emissions Regulation)

P1190 Supply pump control valve(suction control valve) stuck P1217 Supply pump exchange P1218 Supply pump malfunction(insufficient flow) P1219 P/L(pressure limiter) activated P1221 C/R press. falls below the control limit of the target press. P1222 Fuel Filter diagnosis level 1 P1223 Fuel Filter diagnosis level 2 P1530 Engine Stop switch stuck closed... - Page 119 P1D13 Urea Tank Level Sensor Short P1D14 Urea Tank Level Sensor Open Circuit P1D17 SCR Control Failure Level1 P1D18 SCR Control Failure Level2 P1D19 Urea Tank Empty P2059 Urea Pump Solenoid Open Circuit P2061 Urea Pump Solenoid Short Circuit P2214 Nox Sensor in Air P3009 Urea Pump Drive Unit...

-

Page 120: Appendix Maintenance Record

Appendix Maintenance record Maintenance Record Diesel Engine Serial No. Vehicle VIN No. Diesel Engine Model User Name Equipment Name/Number Km (hrs) Date Actual Mileage Maintenance Content Maintainer Remark: Or Time Interval...

Need help?

Do you have a question about the D Series and is the answer not in the manual?

Questions and answers