Summary of Contents for Fortress Building Products Fe26 AXIS

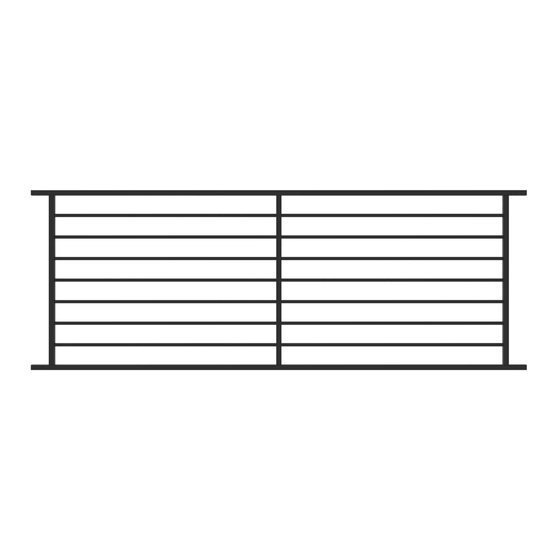

- Page 1 INSTALLATION INSTRUCTIONS AXIS HORIZONTAL STEEL RAILING AXIS INSTALLATION...

-

Page 2: Table Of Contents

TABLE OF CONTENTS English Introduction.................3 Universal Bracket (UB)..........4 Collar Bracket (CB)..........20 Angled Bracket (UB & CB)........23 Stair Bracket (SSB) ..........31 Care & Maintenance/Warranty......40 AXIS INSTALLATION... -

Page 3: Introduction

INTRODUCTION READ INSTRUCTIONS COMPLETELY BEFORE STARTING INSTALLATION It is the responsibility of the installer to meet all code and safety requirements, and to obtain all required building permits. The deck and railing installer should determine and implement appropriate installation techniques for each installation situation. Fortress Railing Products and its distributors shall not be held liable for improper or unsafe installations. -

Page 4: Universal Bracket (Ub)

Required Tools Goggles Safety Tape Speed Level Touch-Up Gloves Measurer Square Tool Paint T-25 #2 Phillips Drill Bits: Spring 1/16”, 3/16”, 3/8”, [2mm, 5mm,10mm] Driver Bit Head Bit Extender Punch Drill Clamp Metal Cutting Miter Saw Hand Rubber or Portable Band saw Grinder Mallet Pencil File Wood 2” x 4” UNIVERSAL BRACKET Axis: Universal (UB) Bracket Installation Ball Cap Pressed Dome Cap UB-04 Cup... - Page 5 Universal Bracket (UB-04) Post Configuration Axis Rail Panel Height Installed Panel Height* Required Post 34” [864mm] 37-3/4” [956mm] 39-1/2” [1003mm] 40” [1016mm] 43-3/4” [1111mm] 45-1/2” [1156mm] *Installed heights include a 3-3/4” [96mm] space between deck surface and bottom edge of bottom rail. UNIVERSAL BRACKET: POST MOUNTING *If using Fortress Evolution Framing, contact Fortress for instructions. Note: It’s recommended to install brackets into post before Post Mounting. Reference page 7 for Bracket Installation steps. Step 1: Install Wood Blocks 1. Install Wood Block level with top of joist. As shown in...

- Page 6 Step 2: Position Base Plate 1. Position the edge of the base plate a minimum of 1/2” [13mm] from the inside edge of rim joist. As shown in Fig. 1. Fig. 1 1/2” [13mm] 1/2” [13mm] Step 3: Max Post Spacing • 6’ panel maximum post spacing is 69-3/4” [1772mm]. • 8’ panel maximum post spacing is 93-3/4” [2381mm]. Note: • Using the maximum post spacing will help minimize the amount of required panel cuts. • DO NOT exceed the maximum post spacing. Fig. 1 6’ panel maximum post spacing is 69-3/4” [1772mm]. 8’ panel maximum post spacing is 93-3/4” [2381mm]. Step 4: Mount Posts 1. Mark mounting hole locations and pre-drill a 3/8” [10mm]...

- Page 7 Note: • Post Base Plate holes MUST be positioned a minimum 1/2” [13mm] from edge of deck board. • Use only 3/8” [10mm] Hex Head Galvanized Bolts. Lag Screws should NOT be used. Secure each post with four bolts. Fig. 1 Fig. 2 Step 5: Check Mounted Posts 1. Shim post as needed to ensure post is level. Fig. 2 Fig. 1 Shim post as needed to ensure post is level Deck Board 1/2” Wood Block Joist / Blocking UNIVERSAL BRACKET: BRACKET INSTALLATION *Fe26 Posts are also available with pre-attached UB-04 brackets.

- Page 8 Fig. 1 UB-04 Bracket Hole Locations Pre-drill Dimensions: Pre-drilling with a 3/16”[5mm] drill bit is required 34” [864mm] Panel 1/2” [13mm] 1/2” [13mm] 37” [940mm] 4” [102mm] 40” [1016mm] Panel 1/2” [13mm] 1/2” [13mm] 4” [102mm] 43” [1092mm] *Dimension A positions bottom edge of rail 3-3/4” [96mm] above deck surface. *Dimension A is measured from the bottom surface of post base. Fig. 2 Step 2: Pre-Drill and Install Brackets Tip: • It’s important to double check dimensions to confirm accuracy of bracket hole locations before drilling.

- Page 9 Fig. 1 Fig. 2 Fig. 3 Fig. 4 UNIVERSAL BRACKET: CUTTING DOWN PANELS Step 1: Measure The Panel Opening Length 1. Measure the distance of the panel opening. As shown in Fig. 1. 2. Confirm that the measurements for the top brackets are the same as the bottom brackets. Note: • Measure from the back wall of the bracket to the back wall of the bracket on other post. As shown in Fig. 2. AXIS INSTALLATION...

- Page 10 • T-25 Thread Cutting Screws are packaged in a plastic bag and secured to the panel. DO NOT discard screws. Fig. 1 Fig. 2 DO NOT measure from post Measure the panel opening Measure from back of bracket Check measurement with top Step 2: Mark Rail & Picket Cut Points 1. Position the panel on a flat surface, preferably a table. 2. To ensure rails are symmetrical, take the measurement found in step 1 and divide it in half. 3. Find and mark the center of the rail. 4. From the previously marked center, measure out the divided length in each direction. As shown in Fig. 1.

- Page 11 Tip: • Be sure to have upright positioned correctly when marking cut points. Fig. 1 Center of Rails Mark Here Mark Here Half of Panel Length Mark Here Mark Here Fig. 2 Fig. 3 Panel length DO NOT REMOVE marking OPPOSITE UPRIGHT Fig. 4 Fig. 5 Rail cut mark on inside edge Reference marks on outside face of picket...

- Page 12 Fig. 6 Fig. 7 Rail Cut mark Reference mark Straightened Picket Cut mark - 1/4” [6mm] Step 3: Cut Rails & Pickets 1. Cut top and bottom rails using a Portable Band Saw, Circular Saw or Grinder with a cutoff disc. Be sure to follow cut marks on top and side faces. As shown in Fig. 1. 2. Use a circular saw or hand grinder to cut pickets. Tip: • Be sure to support rails and pickets when making cuts. • When cutting pickets, clamp a straight wood 2” x 4” [60mm x 102mm] to create a straight edge for the circular saw to follow. As shown in Fig. 2. •...

- Page 13 Fig. 2 Clamped wood 2” x 4” [60mm x 102mm] Step 4: Clean Rails & Pickets 1. Use a file to smooth cut edges. As shown in Fig. 1. 2. Remove any metal shavings and dust with a brush or rag. 3. Make sure surfaces to be painted are clean. Fig. 1 Step 5: Apply Spray Paint To Cut Areas 1. Using a piece of cardboard as a mask, apply the 1 coat of Fortress zinc based touch-up paint. 2. Allow to dry before applying second coat. 3. Apply the 2 coat of Fortress zinc based touch-up paint. 4. Allow to dry and install. Fig. 1 AXIS INSTALLATION...

- Page 14 Step 6: Install Uprights 1. Insert uprights into the cut panel. As shown in Fig. 1. 2. Starting on one end, use a rubber mallet to fully seat upright on to rails and pickets. As shown in Fig. 2. Fig. 1 Fig. 2 Step 7: Cut Opposite Side Of Panel 1. Repeat steps 1 - 6 for the opposite side of panel. Step 8: Test Fit Panel 1. Once both uprights are inserted, test fit the panel to confirm length. As shown in Fig. 1. 2. Confirm inside face of post to inside face upright spacing. CANNOT exceed 4” [ 102mm]. Fig. 1 Step 9: Install Set Screws 1. Once panel length is confirmed, measure 1/2” from inside edge of upright and mark screw hole. As shown in Fig. 1.

- Page 15 Side View Fig. 1 Fig. 2 Centerline of rail 1/2” [25mm] UNIVERSAL BRACKET: PANEL INSTALLATION Step 1: Determine The Top & Bottom Of Panel 1. Use the Manufacturing Date Code (MDC) Stamp to determine the bottom of the panel. The MDC Stamp can be found on the bottom inside face of the middle upright. As shown in Fig. 1. Tip: • The bottom of the panel can also be determined by the spot welds. Spot welds on the panel should face down and be on the under side of the rails. As shown in Fig. 2. Fig. 1 Fig. 2 Spot MDC welds on Stamp under side of rails...

- Page 16 Fig. 2 Fig. 1 T-25 Thread Cutting 3/16” Screws [5mm] Hole Step 3: Install Panel 1. Install cut panel to ensure proper fit. As shown in Fig. 1. Fig. 1 Step 4: Attach Panel To Bottom & Top Brackets 1. Pre-drill holes for screws using a 3/16” [5mm] drill bit. 2. Install screws into bottom & top brackets. As shown in Fig. 1. Note: • Only one screw per bracket is needed to secure the bracket to the panel. • Screws should be installed on the same side of brackets. Fig. 1 AXIS INSTALLATION...

- Page 17 Step 5: Attach I-support To Deck (Optional) 1. Fasten I-support to deck surface with the supported T-25 Wood screws. As shown in Fig. 1. Tip: • Pre-drill with a 1/16” [2mm] drill bit. Fig. 1 UNIVERSAL BRACKET: POST BASE COVER, BRACKET CAP & PRESSED DOME/BALL CAP INSTALLATION Step 1: Install Post Base Cover 1. Separate the two-piece base plate cover. Hold one side parallel to the post base plate. As shown in Fig. 1. 2. Place 2nd half of the post base cover on the opposite side of the post. Hold 2nd piece slightly under the 1st piece. As shown in Fig. 2. 3. Twist the 2nd cover ¼ turn and move piece until both half’s touch. As shown in Fig. 3.

- Page 18 Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig. 5 AXIS INSTALLATION...

- Page 19 Step 2: Install Bracket Caps 1. Bracket Caps snap over Bracket Cups. As shown in Fig. 1 & 2. Fig. 1 Fig. 2 Step 3: Install Pressed Dome Cap 1. Pressed Dome Caps & Ball Caps are press fit into place. As shown in Fig. 1 & 2. Fig. 1 Fig. 2 AXIS INSTALLATION...

-

Page 20: Collar Bracket (Cb)

COLLAR BRACKET Axis: Collar Brackets (CB-04) Installation Ball Cap Pressed Dome Cap CB-04 3-3/4” [96mm] I-Support Axis: 69-1/2”[1766mm] or 93-1/2” [2375mm] Base Cover 2” X 2” & 3” X 3” [51mm x 51mm] & [76mm x 76mm] Iron Posts with base Collar Bracket (CB-04) Post Configuration Rail Panel Axis Height Installed Panel Height* Required Post 34” [864mm] 37-3/4” [959mm] 39-1/2” [1003mm] 40” [1016mm] 45-1/2” [1156mm] 43-3/4” [1111mm] *Installed heights include a 3-3/4” [96mm] space between deck surface and bottom edge of bottom rail. COLLAR BRACKET: POST MOUNTING • Reference Post Mounting instructions on page 5. - Page 21 COLLAR BRACKET: BRACKET INSTALLATION Step 1: Mark Bracket Hole Locations • Reference Bracket hole marking instructions on page 7. Fig. 1 CB-04 Bracket Hole Locations Pre-drill Dimensions: Pre-drilling with a 3/16”[5mm] drill bit is required 34” [864mm] Panel 3-3/16” [81mm] 30-3/4” [781mm] 2-3/16” [56mm] 40” [1016mm] Panel 3-3/16” [81mm] 36-13/16” [935mm] 2-3/16” [56mm] *Dimension A positions bottom edge of rail 3-3/4” [96mm] above deck surface. *Dimension A is measured from the bottom surface of post base. Fig. 2 Step 2: Pre-Drill Bracket Holes • Reference Bracket hole pre-drilling instructions on page 8, step 2.

- Page 22 COLLAR BRACKET: PANEL INSTALLATION Step 1: Install I-Support On Bottom Rail • Reference I-support installation step on pages 15 & 16. Step 2: Install Panel 1. Slide CB-04 Brackets over each end of the bottom and top rails. Make sure that all set screw holes face the desired direction. As shown in Fig. 1. 2. Secure Brackets into pre-drilled Bracket holes on post with provided T-25 Drive Thread-Cutting Screws. 3. Pre-drill Bracket Set Screw holes on bottom Rail using a 3/16” [5mm] drill bit. 4. Secure Bracket to Rail with provided T-25 Drive Thread-Cutting Screws. As shown in Fig. 2. Use low speed setting on drill. Fig. 1 Fig. 2 Set Screw Step 3: Attach I-Support To Deck •...

- Page 23 ANGLE BRACKET Axis: Angled Bracket Installation Options Universal Bracket (UB-04) With Angle Adapter Ball Cap Pressed Dome Cap UB-04 Cap UB-04 Angle Adapter UB-04 Cup 3-3/4” [96mm] I-Support Axis: 69-1/2”[1766mm] or 93-1/2” [2375mm] 2” X 2” & 3” X 3” Base Cover [51mm x 51mm] & [76mm x 76mm] Iron Posts with base Universal Bracket (UB-04) with Angle Adapter Post Configuration Rail Panel Axis Height Installed Panel Height* Required Post 34” [864mm] 37-3/4” [959mm] 39-1/2” [1003mm] 40” [1016mm] 43-3/4” [1111mm] 45-1/2” [1156mm] *Installed heights include a 3-3/4” [96mm] space between deck surface and bottom edge of bottom rail.

-

Page 24: Angled Bracket (Ub & Cb)

Universal Bracket (UB-04) with Angle Adapter Stair Angled Bracket Cap Bracket Base Chicago Bolt Male Chicago Bolt Female Angled Bracket Cup Stair *Bracket & Stair adapters Bracket Adapter are sold separately. Collar Bracket Side Adjustable (CBS-04) Ball Cap Pressed Dome Cap CBS-04(ADJ) 3-3/4” [96mm] I-Support Axis: 69-1/2”[1766mm] or 93-1/2” [2375mm] Base Cover 2” X 2” & 3” X 3” [51mm x 51mm] &... - Page 25 Collar Bracket Side Adjustable (CBS-04) Chicago Bolt Female Angled Bracket Base Angled Bracket Cup Chicago Bolt Male ANGLE BRACKET: POST MOUNTING • Reference Post Mounting instructions on page 5. Note: IT’S RECOMMENDED TO INSTALL BRACKETS ON TO POST BEFORE POST MOUNTING. ANGLE BRACKET: BRACKET INSTALLATION (UB-04 or CBS-04) Note: THE BRACKET INSTALLATION INSTRUCTIONS COVER BOTH UB-04 & CB-04, ONLY USE STEPS SPECIFIC TO BRACKET BEING INSTALLED. Step 1: Mark Bracket Hole Locations (UB-04 or CBS-04) 1. Mark the centerline of each post with a pencil.

- Page 26 Fig. 1 UB-04 With Angle Adapter Bracket Hole Locations Pre-drill Dimensions: Pre-drilling with a 3/16”[5mm] drill bit is required 34” [864mm] Panel 4-3/16” [106mm] 37-3/16” [945mm] 1”-3/16”[30mm] 40” [1016mm] Panel 4-3/16” [106mm] 43-3/16” 1097mm] 1”-3/16”[30mm] *Dimension A positions bottom edge of rail 3-3/4” [96mm] above deck surface. *Dimension A is measured from the bottom surface of post base. Fig. 2 UB-04 With Angle Adapter Fig. 3 CBS-04 Bracket Hole Locations Pre-drill Dimensions: Pre-drilling with a 3/16”[5mm] drill bit is required 34”...

- Page 27 Fig. 4 CBS-04 Bracket Step 2: Pre-drill Angle Bracket Holes Tip: • It’s important to double check dimensions to confirm accuracy of bracket hole locations before drilling. 1. Use Spring Punch to mark the holes. As shown in Fig. 1. 2. Pre-drill bracket holes with a 3/16” [5mm] drill bit. As shown in Fig. 2 & 3. 3. Remove the bolt from the Angle Bracket Assembly. Fig. 1 Fig. 2 Pre-Drill with a 3/16” [5mm] drill bit 1”-3/16”...

- Page 28 Step 3: Install UB-04 With Angle Adapter 1. Attach Angle Adapter Base piece to the posts with supplied T-25 Thread-Cutting Screws. Use low speed setting on drill. As shown in Fig. 1. 2. Assemble Angle Adapter Body piece & Base piece. As shown in Fig. 2. 3. Attach UB-04 Bracket to Angle Adapter using T-25 Thread-Cutting Screws. As shown in Fig. 3. Tip: • Use a Bit Extender for an easier screw fastening process. Fig. 1 Fig. 2 Fig. 3 Step 4: Install CBS-04 Bracket 1. Attach Angle Bracket Base piece to the posts with supplied T-25 thread-cutting screws. Use low speed setting on drill. As shown in Fig. 1. 2. Assemble Angle Bracket Body piece & Base piece. As shown in Fig. 2. Tip: • Use a Bit Extender for an easier screw fastening process. AXIS INSTALLATION...

- Page 29 Fig. 1 Fig. 2 Step 5: Determine Panel Length 1. Check to ensure that all posts are square and straight. Shim posts as required. 2. Ensure that the Angle Bracket Cups are approximately aligned. 3. With another person’s help, measure the distance from the inside back of one cup to the inside back of the other cup. This will be the panel length. As shown in Fig. 2 & 3. Fig. 1 UB-04 With Angle Bracket CBS-04 Fig. 2 DO NOT measure from post Measure from...

- Page 30 Fig. 3 DO NOT measure from post Measure from back of bracket CBS-04 Bracket ANGLE BRACKET: CUTTING DOWN PANELS • Reference pages 9 - 15 for panel cutting steps. ANGLE BRACKET: PANEL INSTALLATION • Reference UB-04 panel installation steps on pages 15 - 17 and CB-04 panel installation steps on page 22. ANGLE BRACKET: POST BASE COVER, BRACKET CAP & PRESSED DOME/BALL CAP INSTALLATION •...

-

Page 31: Stair Bracket (Ssb)

STAIR BRACKET Axis: Stair Bracket Installation Simplified Stair Bracket (SSB-04) Ball Cap LT Bracket & Cap Pressed SB Bracket Dome & Cap ST Bracket & Cap LB Bracket & Cap 2” X 2” & 3” X 3” [51mm x 51mm] & [76mm x 76mm] Iron Posts with Base Cover Simplified Stair Bracket Back View Front View Each bracket base Each bracket cup of the SSB’s has of the SSB’s has a stamped letter... - Page 32 Simplified Stair Bracket (SSB-04): LT Stair Stair Bracket Base Bracket Cap Chicago Chicago Bolt Male Bolt Female Stair Bracket Cup Simplified Stair Bracket (SSB-04): SB Stair Chicago Bracket Base Bolt Male Chicago Bolt Female Stair Bracket Cap Stair Bracket Cup Simplified Stair Bracket (SSB-04): ST Stair Bracket Cap Stair Bracket Base Chicago...

- Page 33 STAIR BRACKET: BRACKET INSTALLATION Bracket Options • When installing SSB brackets, Identify the 4 brackets (LT, ST, LB and SB) by the letters stamped in each part. • Reference the installed panel image at the top of pages 31 & 32 for placement of each SSB bracket. Step 1: Bottom Bracket Installation 1. Position wood 2” x 4” [60mm x 102mm] between posts. As shown in Fig. 1. 2. Position bottom brackets centered flat on post & wood 2” x 4” [60mm x 102mm]. Use pencil to mark top edge of bracket location on post. As shown in Fig. 2. 3. Disassemble the bracket by removing the barrel and screw. Reference the bracket options on page 32. 4. Place bracket base on previous top edge mark. Center the base on the post and use pencil to add marks for two screw hole locations. As shown in Fig. 3.

- Page 34 Fig. 3 Step 2: Bottom Bracket Installation Continued 1. Use Spring Punch to mark the holes. As shown in Fig. 1. 2. Drill out bracket hole with a 3/16” [5mm] drill bit. As shown in Fig. 2. 3. Use T-25 screws to attach the base to the post. Begin with bottom hole then top. As shown in Fig. 3. 4. Keep bracket base centered as you install second screw. 5. Insert barrel & screw to re-assemble bracket. 6. Tighten barrel & screw. As shown in Fig. 4. Note: • Lower Post may need to be unmounted to install bracket then remounted. Fig. 1 Fig. 2 AXIS INSTALLATION...

- Page 35 Fig. 3 Fig. 4 Step 3: Top Bracket Installation 1. Position wood 2” x 4” [60mm x 102mm] on stairs in line with bottom brackets. 2. Place panel on top of wood 2” x 4” [60mm x 102mm] next to bottom brackets. As shown in Fig. 1. 3. Rake the panel until center upright is parallel to the post or level and positioned as close to final installation position as possible. 4. Clamp the panel to the post. Be sure to clamp at four touch points to keep panel in position. As shown in Fig. 2. 5. Position bracket parallel with top rail & flat centered on post. Make sure inside bottom of bracket is flush with bottom of rail. As shown in Fig. 3. 6. Use pencil to mark top edge of bracket location on post.

- Page 36 Fig. 1 Clamp Fig. 2 Fig. 3 Mark top and side location of Stair Bracket on post Position Clamp bottom of Clamp Bracket flush with bottom of rail Clamp Fig. 4 Step 4: Top Bracket Installation Continued • Reference bottom bracket installation step 2 on pages 34 & 35. Tip: • For both top brackets (LT & ST), install the top screw first. AXIS INSTALLATION...

- Page 37 STAIR BRACKET: POST MOUNTING • Reference Post Mounting instructions on page 5. Note: IT’S RECOMMENDED TO INSTALL BRACKETS ON TO POST BEFORE POST MOUNTING. STAIR BRACKET: CUTTING DOWN PANELS (SSB-04 BRACKET) Step 1: Determine The Top & Bottom Of Panel 1. Use the MDC Stamp to determine the bottom of the panel. The MDC Stamp can be found on the bottom inside face of the middle upright. As shown in Fig. 1. Fig. 1 MDC Stamp Step 2: Measure & Mark Panels Where Cuts Will Be Made 1. Position wood 2” x 4” [60mm x 102mm] on stairs in line with bottom brackets.

- Page 38 7. From the reference marks, subtract 4” [102mm] and mark cut points on the top and bottom rails. As shown in Fig. 2. 8. Measure distance from rail cut mark to the end of the rail. As shown in Fig. 3. Write the dimension on paper for future reference. 9. Using a rubber mallet, remove one of the uprights from the panel. As shown in Fig. 4. DO NOT Remove the opposite upright. 10. Use previously found measurement (Fig. 3.) to mark picket cut points. Measure from the end of picket inward and mark the cut points. As shown in Fig. 5. 11. Place the removed upright on top of loose rails & pickets. 12. Position the back edge of upright in line with the previously marked rail reference marking and flush with the rails. As shown in Fig. 6. 13. Confirm rail & picket cut marks before cutting the panel. 14. Using a square, straighten cut point markings on top and side faces of rails and pickets. As shown in Fig. 7.

- Page 39 Fig. 4 Fig. 5 Cut mark Fig. 6 Fig. 7 Cut mark DO NOT REMOVE OPPOSITE UPRIGHT Reference mark Rail Reference mark Step 3: Continue Stair Panel Cutting & Clean Steps 1. Reference steps 3 - 9 on pages 12 - 15 for the remaining panel cutting and cleaning steps. STAIR BRACKET: PANEL INSTALLATION • Reference panel installation steps on pages 15 - 17. STAIR BRACKET: POST BASE COVER, BRACKET CAP & PRESSED DOME/BALL CAP INSTALLATION •...

-

Page 40: Care & Maintenance/Warranty

CARE & MAINTENANCE Care And Maintenance Of Fortress Railing Products Powder-Coated Products And Surfaces: • Immediately after installation of your Fortress Railing Products, clean powder-coated products and surfaces with a solution of warm water and non-abrasive, pH neutral detergent solution. Surfaces should be thoroughly rinsed after cleaning to remove all residues. All surfaces should be cleaned using a soft cloth or sponge. • Ensure construction materials such as concrete, plaster, and paint splashes are removed immediately before they have a chance to dry. Failure to remove these materials may cause damage to the powder-coated surfaces. • The frequency of cleaning depends in part on the standard of appearance and also the requirements to remove deposits that may cause damage to the powder coating after prolonged exposure. Fortress recommends cleaning in three to... - Page 41 AXIS INSTALLATION...

- Page 42 JOIN THE REVOLUTION. FortressBP.com | 866.323.4766 © 2021 Fortress Building Products. Unless otherwise noted, all proprietary names are trademarks of Fortress Iron, LP. All rights reserved. AXIS INSTALLATION 03/2021...

Need help?

Do you have a question about the Fe26 AXIS and is the answer not in the manual?

Questions and answers