Table of Contents

Advertisement

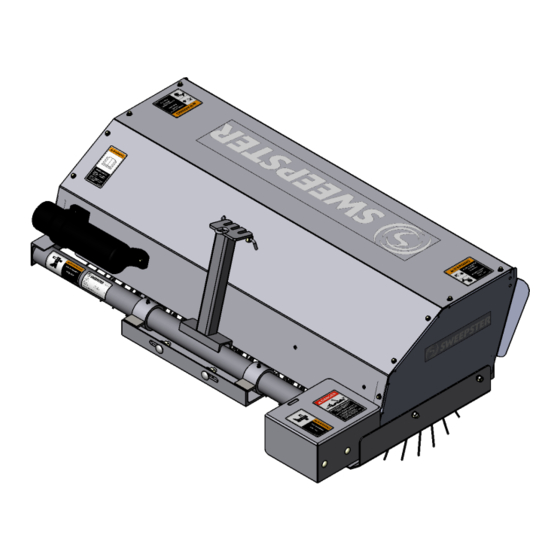

OPERATOR'S AND PARTS MANUAL

Mechanical Windrow Sweepers

Serial Number: ___________________

Model Number: ___________________

800-456-7100 I www.paladinattachments.com

51-3000

M24 Series

L4800, MRM & CTM

2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©

Manual Number: 51-3000

Release Date: January 2014

Rev. 1

1

Advertisement

Table of Contents

Summary of Contents for paladin Sweepster M24 Series

- Page 1 OPERATOR’S AND PARTS MANUAL M24 Series L4800, MRM & CTM Mechanical Windrow Sweepers Serial Number: ___________________ Manual Number: 51-3000 Release Date: January 2014 Model Number: ___________________ Rev. 1 800-456-7100 I www.paladinattachments.com 2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright © 51-3000...

- Page 2 NOTES 51-3000...

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ............................4 SAFETY STATEMENTS ..........................4 GENERAL SAFETY PRECAUTIONS......................5-6 SAFETY SIGNS & LABELS .........................7 INSTALLATION & ADJUSTMENTS ......................8-15 OPERATION ............................16-17 STORAGE ..............................17 MAINTENANCE ............................18-21 TROUBLESHOOTING ..........................22-23 BRUSH HEAD ASSEMBLY ........................24-25 DRIVE ASSEMBLIES 1-WAY ........................26-33 DRIVE ASSEMBLIES 2-WAY ........................34-43 GEARBOXES ............................44-47 MANUAL ANGLE KIT ..........................48 OPTION - DIRT DEFLECTORS ......................49-50... -

Page 4: Introduction

INTRODUCTION SAFETY STATEMENTS Purpose of Sweeper DANGER! THIS STATEMENT IS USED WHERE SERIOUS INJURY OR This sweeper is designed solely for the use in DEATH WILL RESULT IF THE construction cleanup, road maintenance and similar INSTRUCTIONS ARE NOT operations. Use in any other way is considered FOLLOWED PROPERLY. -

Page 5: General Safety Precautions

GENERAL SAFETY PRECAUTIONS GENERAL SAFETY PRECAUTIONS WARNING! PROTECT AGAINST FLYING WARNING! READ MANUAL PRIOR TO DEBRIS INSTALL Always wear proper safety glasses, Improper installation, operation, goggles or a face shield when driving or maintenance of this equipment pins in or out or when operation could result in serious injury or causes dust, flying debris, or any other death. - Page 6 GENERAL SAFETY PRECAUTIONS GENERAL SAFETY PRECAUTIONS CONTINUED CONTINUED • Wear safety glasses, protective • Wear the protective clothing clothing, and use a sound piece of equipment specified by the tool cardboard or wood when manufacturer. searching for hydraulic leaks. DO NOT USE YOUR HANDS! WARNING! SAFELY OPERATE EQUIPMENT SEE ILLUSTRATION.

-

Page 7: Safety Signs & Labels

SAFETY SIGNS & LABELS 1. 50-0147 4. 50-0721 3. 50-0236 Serial Tag Location 2. 50-0115 5. 50-0722 Item Part Description 50-0147 Decal, Frequency of Lube, Weasler 50-0115 Decal, Danger, Rotary 7. 41043 Driveline 6. 50-0726 50-0236 Decal, Gearbox, Hubcity, Check Oil SAFETY SIGNS &... - Page 8 INSTALLATION Mounting Assembly NOTE: If the mounting assembly includes angles Install the mounting assembly (figure 1) on the and an input shield, place angles on the tractor by the following instructions enclosed with holes before installing hardware. those parts. Then proceed to Drive Assembly or Brush Head Assembly if your sweeper has a 4.

- Page 9 INSTALLATION Brush Head Assembly 1. After installing the mounting and drive assemblies, position the brush head assembly (figure 1) in front of the drive assembly. 2. Fasten the brush head assembly to the drive assembly using 2, 1/2-13 x 1 1/2 inch carriage bolts, flat washers, lock washers and nuts.

- Page 10 INSTALLATION Spring-Chain Assembly, Transport Chain, Lift Cable Follow the instructions that match your sweeper. Spring-Chain Assembly & Transport Chain Refer to figures 1 and 2. 1. Connect 2, 26-link chains and 2 springs to form a loop. 2. Place chains in the outside slots in the drive assembly upright and in the brush head assembly upright.

- Page 11 INSTALLATION 6. Raise the brush head assembly using the lift system. If the brush head assembly raises 4 inches (101mm) off the ground, the lift cable is properly adjusted; otherwise, go to the next step. 7. Adjust the cable. • If the brush head assembly does not raise enough, decrease the amount of cable figure 4...

- Page 12 INSTALLATION 8. Raise the brush head assembly using the lift system. If the brush head assembly raises 4 inches (101mm) off the ground, the lift cable is properly adjusted; otherwise, go to the next step. 9. Adjust the cable. • If the brush head assembly does not raise enough, decrease the amount of cable between the uprights.

- Page 13 INSTALLATION 4. Place a shackle on the rod end of the cylinder; then, attach the shackle to the brush frame upright. 5. Place a shackle on the barrel end of the cylinder and attach the chain to the shackle. Then, attach the chain to the center slot in the drive mounting assembly upright.

-

Page 14: Installation & Adjustments

INSTALLATION / ADJUSTMENTS NOTICE! AVOID WIRE DAMAGE. Keep wires away from hot and/or moving parts. 5. Connect the red wire to the tractor power supply. Connect the yellow wire to a good ground, preferably the battery ground or tractor frame (figure 6). - Page 15 ADJUSTMENTS the measurements are equal. Tighten the hardware. • If they are equal, go to step 6 (2-way sweepers) or the sweeper is level (1-way sweepers). 6. 2-way sweepers only - Swing the brush head assembly to the right. Measure from each end of Swept Area the brush frame to the ground.

-

Page 16: Operation

OPERATION Before each use Sweeping Preform daily maintenance as indicted in To sweep: Maintenance: Schedule. 1. Manual Angle Kit Only - Swing the brush head Run the prime mover and sweeper at a slow idle. assembly the direction that you want to direct Check for loose hardware or other problems and debris. -

Page 17: Storage

OPERATION Operating Tips Heavy Debris NOTICE! AVOID SWEEPER DAMAGE. Do not Travel slowly - less than 5mph (8kph) ram into piles. Use a dozer blade for this type of job. Sweep a path less than the full width of the sweeper. -

Page 18: Maintenance

MAINTENANCE Maintenance Record Use this log to record maintenance performed on the sweeper. Date Maintenance Procedure Performed by Comments Performed 51-3000... - Page 19 MAINTENANCE Schedule Part Schedule Every 8 Every 40 When Daily Hours Hours Necessary Brush Head Assembly - Check brush pattern; adjust as necessary. (See Adjustments: Brush Height) Level brush head. (See Adjustments: Leveling) Drive Chain - Lubricate with oil or chain lubricant. Drive Shaft - Lubricate universal joints with high- quality grease.

- Page 20 MAINTENANCE Replacing Brush Sections 1. Remove the front bolt from inside the right- hand side of the brush frame. This allows you to remove the shield and right mounting bracket (figure 1). 2. Remove the rear screw from the right-hand side of the brush frame.

- Page 21 MAINTENANCE 9. Place the retainer halves on the brush and reinstall the screws. 10. Position the brush in front of the brush hood. 11. Reinstall the drive chain on the core sprocket. 12. Slide the brush into the left-hand side of the brush frame.

-

Page 22: Troubleshooting

TROUBLESHOOTING Brush Head Assembly Problem Possible Cause Possible Solution Remove gearbox, switch breather Gearboxes with 3 shafts - gearbox cap and plug, and remount flipped gearbox Brush rotates wrong direction Gearboxes with 2 shafts - incorrect Contact SWEEPSTER for gearbox replacement Adjust;... - Page 23 TROUBLESHOOTING Constant Velocity (CV) Drive Shaft Problem Possible Cause Possible Solution Drive shaft too long Adjust drive shaft length; replace parts End and/or inboard yoke Axial forces too high - running Clean and grease profile tubes; replace ears spread above recommended rpm parts;...

-

Page 24: Brush Head Assembly

BRUSH HEAD ASSEMBLY Item Part Description Item Part Description 01-0550 Core, 4 ft 08-0006 Bearing, 1 Round, with Collar 01-0209 Core, 5 ft 08-0034 Bearing, 7/8 Hex, with Hole 01-0640 Core, 6 ft 08-0037 Bearing, 7/8 Hex, without Hub 06-0238 Sprocket, 50B, 12 x 7/8 Hex 11-1804 Plate, Retainer, Section, Set... - Page 25 BRUSH HEAD ASSEMBLY 51-3000...

-

Page 26: Drive Assemblies 1-Way

DRIVE ASSEMBLIES 1-WAY Assemblies 11-1727 & 11-1728 Item Part Description 11-3001 Frame, Drive, 1-Way 05-0003 Gearbox, Right-Hand, 7/8 Round-7/8 Round (11-1727) 05-0004 Gearbox, Left-Hand, 3/4 Round-3/4 Round (11-1728) 05-1076 U-Joint, H7, Rectangular, 3/4 Round 11-1684 Arm, Lift 07-0196 Pin, Clevis, 1/2 x 2 11-7289 Cable, 3/16 x 32 07-0214... - Page 27 DRIVE ASSEMBLIES 1-WAY Assemblies 11-17224 & 11-17229 Item Part Description 05-1113 Gearbox, 1:1, Left-Hand (11-17229) 05-1114 Gearbox, 1:1, Right-Hand, (11-17224) 11-9216 Frame, Drive, 1-Way 13-2823 Shield, Drive, Extension, 1-Way 11-9214 Shield, Drive, Input 11-9215 Shield, Drive, Output 05-0926 U-joint, H7, Rectangular, 1 Round 11-1585 Shaft, Rectangular, 9 11-1590...

- Page 28 DRIVE ASSEMBLIES 1-WAY Item Part Description 05-0656 U-Joint, H7, Rectangular, 7/8 Round, 3/16 Keyway 05-0763 Fitting, Zerk, 1/4-28 05-1145 Gearbox, 3:1, T-Style, 3-Shaft, Left-Hand/Right-Hand 07-0156 Washer, Flat, 1/2 07-0196 Pin, Clevis, 1/2 x 2 07-0209 Clip, Hairpin, 16ga x 1 3/8 07-0210 Clip, Hairpin, 14ga x 1 3/4 07-0214...

- Page 29 DRIVE ASSEMBLIES 1-WAY Assembly 11-17142 51-3000...

- Page 30 DRIVE ASSEMBLIES 1-WAY Item Part Description 03-0011 Hose, 1/4 x 36, 1W, 1/4MP 03-0898 Fitting, Adapter, HP, 9/16MOR, 1/4FP 03-1053 Fitting, Elbow, HP, 45º, 1/4MP, 1/4FPS 03-1851 Cylinder, 1.75 x 4 x 9, 9/16 O-Ring (09/23/09 & Before) 03-5719 Cylinder, 1.75 x .75 x 4, 3.5K (09/24/09 & After) 05-0656 U-Joint, H7, Rectangular, 7/8 Round, 3/16 Keyway 05-0763...

- Page 31 DRIVE ASSEMBLIES 1-WAY Assembly 11-17390 51-3000...

- Page 32 DRIVE ASSEMBLIES 1-WAY Item Part Description 05-0926 U-Joint, H7, Rectangular, 1 Round 05-1112 Gearbox, 3:1, Left-Hand 07-0209 Clip, Hairpin, 16ga x 1 3/8 07-0223 Fitting, Zerk, Straight, NPT 07-0237 Spring, Tension, 1-13/32 x 6 07-0387 Chain, 3/16, 26 Links 07-1709 Pin, Clevis, 1/4 x 4 1/2 07-1714 Screw, Cap, 5/16-18 x 1...

- Page 33 DRIVE ASSEMBLIES 1-WAY Assemblies 11-17186 & 11-17187 51-3000...

-

Page 34: Drive Assemblies 2-Way

DRIVE ASSEMBLIES 2-WAY Item Part Description 05-0655 U-Joint, H7, Hex, Rectangular 05-0668 Gearbox, 4:1, Right-Hand (11-17100) 05-0669 Gearbox, 4:1, Left-Hand (11-17101) 05-1075 U-Joint, H7, Rectangular, 3/4 Round 07-0066 Screw, Cap, 5/8-11 x 2 07-0108 Bolt, Carriage, 3/8 x 3/4 07-0196 Pin, Clevis, 1/2 x 2 07-0201 Pin, Clevis, 5/8 x 2... - Page 35 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17100 & 11-17101 51-3000...

- Page 36 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17102 & 11-17103 Item Part Description 11-2461 Frame, Swing 13-0848 Plate, Swing, 2-Way, 3/8 05-0733 U-Joint, H3, Rectangular, Round, 3/4, Long Slip 11-2460 Shield, U-Joint, 2-Way 05-0668 Gearbox, Double, 4:1, Right-Hand (11-17102) 05-0669 Gearbox, Double, 4:1, Left-Hand (11-17103) 07-0201 Pin, Clevis, 5/8 x 2 10.

- Page 37 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17333 & 11-17334 Item Part Description 13-2200 1 Frame, Swing 05-1112 Gearbox, 3:1, Left-Hand 11-6493 Shield, Gearbox 13-2204 1 Handle, Stop 07-0203 1 Pin, Spring, Lock, 3/16 x 2 1/4 07-0319A 1 Spring, Hitch, Quick 07-1374 1 Washer, .625 x 1 07-0387 2 Chain, 3/16, 26 Links...

- Page 38 DRIVE ASSEMBLIES 2-WAY Item Part Description 1. 05-0983-1 Shaft, CV, 1 Round, 7/8 Hex, Output, 38 1/4 Extended 05-1112 Gearbox, 3:1, Left-Hand 07-3436 Screw, Cap, 5/16-18 x 3/4 07-1714 Screw, Cap, 5/16-18 x 1 07-2116 Screw, Cap, 3/8-16 x 1 1/4 07-0066 Screw, Cap, 5/8-11 x 2 07-3275...

- Page 39 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17177 & 11-17182 51-3000...

- Page 40 DRIVE ASSEMBLIES 2-WAY Item Part Description 1. 05-0983-1 Shaft, CV, 1 Round, 7/8 Hex, Output, 38 1/4 Extended 05-1113 Gearbox, 1:1, Left-Hand (11-17371) 05-1114 Gearbox, 1:1, Right-Hand (11-17372) 07-0018 Screw, Cap, 3/8-16 x 1 07-0066 Screw, Cap, 5/8-11 x 2 07-0203 Pin, Spring, Lock, 3/16 x 2 1/4 07-0209...

- Page 41 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17371 & 11-17372 51-3000...

- Page 42 DRIVE ASSEMBLIES 2-WAY Item Part Description 05-1114 Gearbox, 1:1, Right-Hand 05-0983 Shaft, Telescoping, CV, 1 Round 7/8 Hex, Output, 42 1/4 Extended 07-4052 Screw, Cap, 3/8 x 3/4 07-0018 Screw, Cap, 3/8-16 x 1 07-2116 Screw, Cap, 3/8-16 x 1 1/4 07-0066 Screw, Cap, 5/8-11 x 2 07-3279...

- Page 43 DRIVE ASSEMBLIES 2-WAY Assemblies 11-17198 & 11-17231 51-3000...

-

Page 44: Gearboxes

GEARBOXES Gearbox 05-0004 Gearbox 05-0003 1:1 Ratio, Left Hand 1:1 Ratio, Right Hand Item Parts Description Item Parts Description 05-0573 Screw 05-0573 Screw 05-0559 Housing 05-0559 Housing 05-0560 Gear 05-0560 Gear 05-0575 Shaft, Output, Left Hand 05-0561 Shaft, Output, Right Hand 05-0576 Shaft, Input, Left Hand 05-0562... - Page 45 GEARBOXES Gearboxes 05-0668 & 05-669 (shown) 4:1 Ratio, Stacked Item Part Description Item Part Description 17. 05-0770 Shim 05-0759 Shaft, Output 18. 05-0763 Fitting, Zerk 05-0766 Seal 19. 07-0795 Key, Woodruff, Hard #11 05-0745 Housing 20. 05-0744 Housing 05-0757 Snap Ring 21.

- Page 46 GEARBOXES Gearboxes 05-1113 (left) & 05-1114 (Right) Gearbox 05-1112 1:1 Ratio 3:1 Ratio, Left Hand Item Part Description Item Part Description 05-1158 Shaft, Cross 05-1137 Shaft, Pinion 05-1159 Shaft, Pinion 05-1157 Shaft, Cross (for 05-1113) 05-1160 Gear, Standard Bevel, 42T 05-1156 Shaft, Cross (for 05-1114) 05-1161...

- Page 47 GEARBOXES Gearbox 05-1145 3:1 Ratio, 3 Shaft Item Part Description 05-0776 Shaft, Cross 05-0799 Shaft, Pinion 05-0974 Gears, Set 05-0974 Gears, Set 05-1162 Cup, Bearing 05-1163 Cup, Bearing 05-1164 Cone, Bearing 05-1165 Cone, Bearing 05-1166 Cone, Bearing 10. 05-1175 Ring, Snap 11.

-

Page 48: Manual Angle Kit

MANUAL ANGLE KIT Assembly 11-5819 Item Part Description 13-4194 Tube, Link, In 13-4193 Tube, Link, Out 07-0210 Clip, Hairpin, 14ga x 1 3/4 07-2105 Pin, Lock, 3/8 Square Bail 51-3000... -

Page 49: Option - Dirt Deflectors

OPTION - DIRT DEFLECTORS Installation 1. Clamp the extension plate to the front of the hood, centered from left to right. The top edge of the extension plate must be 2 inches (51mm) from the bend in the hood. 2. Transfer punch holes from the extension plate to the hood. - Page 50 OPTION - DIRT DEFLECTORS Item Part Description 07-1714 Screw, HHC, Gr8, 5/16-18 x 1 07-3273 Washer, Lock, Split, Medium, 5/16, 4 ft 07-3273 Washer, Lock, Split, Medium, 5/16, 5,6 ft 07-3275 Washer, Flat, Gr8, 5/16, 4 ft 07-3275 Washer, Flat, Gr8, 5/16, 5,6 ft 07-3278 Nut, Hex, Gr8, 5/16-18, 4 ft 07-3278...

-

Page 51: Option - Hydraulic Angle Kit

OPTION - HYDRAULIC ANGLE KIT Installation Figure 1 shows the kit fully installed. NOTICE: AVOID DAMAGE TO THE SWING CYLINDER. Remove the manual angle T-pin before installing the hydraulic angle kit. 1. Remove the T-pin from the swing assembly by driving out the roll pin and lifting the pin. - Page 52 OPTION - HYDRAULIC ANGLE KIT To order, ask for kit 11-4191 Replacement Parts for 03-5719: 46072 Seal Kit 114406 Cylinder Rod Item Part Description 03-2092 Fitting, Elbow, HP, 90º, 9/16MOR, 3/8MFS 03-2159 Fitting, Adapter, HP, 3/8MFS, 1/4MP 03-2270 Hose, 3/8 x 72, 2W, 3/8FFS, 3/8FFS 03-3381 Cylinder, Hydraulic, 1 3/4 x 4 x 9 (09/23/09 &...

-

Page 53: Option - Hydraulic Lift Kits

OPTION - HYDRAULIC LIFT KITS Installation Figure 1 shows the lift kit fully installed. 1. Remove the transport chain and/or electric lift, if installed. 2. Attach adapter fittings to both cylinder ports, and install elbow fittings on adapter fittings. Then, attach hoses to the elbow fittings and install quick coupler fittings on the hoses. - Page 54 OPTION - HYDRAULIC LIFT KITS To order, ask for kit 11-9250 Replacement Parts for 03-5719: 46072 Seal Kit 114406 Cylinder Rod Item Part Description 03-0011 Hose, 1/4 x 36, 1W, 1/4MP 03-0898 Fitting, Adapter, HP, 9/16MOR, 1/4FP 03-1053 Fitting, Elbow, HP, 45º, 1/4MP, 1/4FP 03-1423 Fitting, Quick Coupler, Male, 1/4FP 03-1851...

- Page 55 OPTION - HYDRAULIC LIFT KITS Installation Figure 1 shows the lift kit fully installed. 1. Remove the electric actuator and wiring if installed on the drive assembly. 2. Place the lift plate on the pin welded to the lift linkage. Clamp the plate. Center mark the hole.

- Page 56 OPTION - HYDRAULIC LIFT KITS For 11-17100 & 11-17101 To order, ask for kit 13-3149 Replacement Parts for 03-5719: Item Part Description 46072 Seal Kit 114406 Cylinder Rod 03-0011 Hose, 1/4 x 36, 1W, 1/4MP 03-1423 Fitting, Quick Coupler, Male, 1/4FP 03-1851 Cylinder, 1 3/4 x 4 x 9, 9/16 O-Ring (09/23/09 &...

-

Page 57: Bolt Torque Specifications

BOLT TORQUE SPECIFICATIONS NOTE - Nylock nuts are utilized when greater resistance to vibrating loose is required, and greater operating temperatures are not a factor. In addition, like lock nuts, nylock nuts have a safety feature that if the bolt does vibrate loose, the nut will remain on the screw. Install nylock nuts to the standard torque shown above. -

Page 58: Hydraulic Torque Specifications

HYDRAULIC TORQUE SPECIFICATIONS Face Seal: Assembly, Tube to Fitting NOTICE - Face seal fittings have the most reliable sealing method and therefore, should be used whenever possible. Installation 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or foreign materials. 2. - Page 59 HYDRAULIC TORQUE SPECIFICATIONS Straight Thread O-ring Fitting: Assembly, Fitting to Port NOTE - Straight thread o-ring fittings are utilized to adapt hydraulic systems to motors, pumps, cylinders, and valves. Installation (Adjustable Fitting) 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or any foreign materials. 2.

-

Page 60: Glossary

GLOSSARY lift cylinder - means of raising the brush head angle or angle assembly - portion of the sweeper assembly hydraulically. that allows the brush head assembly to angle. BP - black pipe. lps - liters per second. M - male. brush head assembly - assembly that includes the core, hood, and brush frame. - Page 61 GLOSSARY section - single brush wafer. section set - replacement brush wafers. sprinkler system - system that sprays water ahead of the sweeper used to reduce dust. sprinkler tank - assembly that includes the water reservoir and mounting used in a sprinkler system. stands - devices designed to keep the components off the ground when the sweeper is dismounted.

-

Page 62: Warranty

Period, which is the period that begins on the fi rst to occur of: (i) the date of initial purchase by an end-user, (ii) the date the product is fi rst leased or rented, or (iii) the date that is six (6) months after the date of shipment by Paladin Light Construction as evidenced by the invoiced shipment date (the “Commencement Date”) and ends on the date...

Need help?

Do you have a question about the Sweepster M24 Series and is the answer not in the manual?

Questions and answers