WEICHAI WP10 Series Operation And Maintenance Manual

Industrial power diesel engine

Hide thumbs

Also See for WP10 Series:

- Operation and maintenance manual (33 pages) ,

- Operation and maintenance manual (49 pages)

Advertisement

Table of Contents

- 1 Table of Contents

- 2 Ⅰ. Operation and Maintenance for Industrial Power WP10 Series Land Diesel Engines

- 3 Schematic for WP10 Series Land Diesel Engines

- 4 Schematic for WP10 Series Marine Diesel Engines

- 5 Fuel, Lubricating Oil and Coolant Used for Diesel Engines

- 6 Diesel Engine Installation and Connection

- 7 Precautions and Operational Requirements for Diesel Engine

- 8 Maintenance Specifications for Industrial Engines

- 9 Maintenance Specifications for Main Accessories of Diesel Engine

- 10 Common Failure Analysis and Troubleshooting

- 11 Ⅱ. User Service Guide

- 12 Weichai Power Product Warranty Card

- 13 Service Registration Form

- 14 Repairs Instruction

- 15 Diesel Engine "Three-Guaranty" Warranty Specification

- 16 Weichai Industrial Engine Spare Parts "Three-Guaranty" Warranty Specification

- Download this manual

Advertisement

Table of Contents

Summary of Contents for WEICHAI WP10 Series

- Page 1 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine...

- Page 2 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine PREFACE Industrial power covers six industries: land generation power, marine generation power, emergency marine generation power, pump power, air compressor power and fixation power for other purposes.

- Page 3 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Notice Before delivery, this series of diesel engines have already been tested, strictly following the test codes. Therefore, never dismantle the lead sealing on the throttle to raise its openness; never dismantle or impact the rotor of turbocharger which belongs to the sophisticated parts;...

- Page 4 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Please select the specified fuel and oil grades which will be filled into the diesel engine (it is suggested to use the Weichai special oil sold at all service stations of Weichai).

-

Page 5: Table Of Contents

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine CONTENTS Ⅰ. Operation and maintenance for industrial power WP10 series land diesel engines ..6 Schematic for WP10 series land diesel engines..............6 Schematic for WP10 series marine diesel engines ............7 1. -

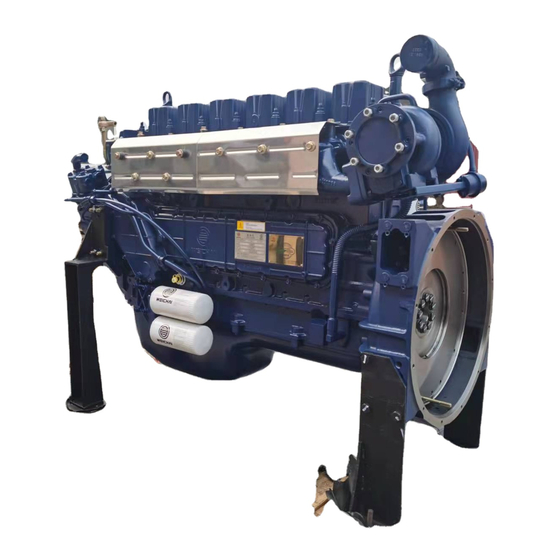

Page 6: Ⅰ. Operation And Maintenance For Industrial Power Wp10 Series Land Diesel Engines

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Ⅰ . Operation and maintenance for industrial power WP10 series land diesel engines Schematic for WP10 series land diesel engine... -

Page 7: Schematic For Wp10 Series Marine Diesel Engines

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine water jacket exhaust manifold Schematic for WP10 series marine diesel engine... -

Page 8: Fuel, Lubricating Oil And Coolant Used For Diesel Engines

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 1 Fuel, lubricating oil and coolant used for diesel engines 1.1 Oil 1.1.1 Quality grade Refer to the quality and feature to divide the oil into API and GB standards. - Page 9 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 1.2. Fuel 1.2.1 The diesel engine uses the light diesel as the fuel; 1.2.2 Quality grade Sulfur content in the fuel with specified grade should not be higher than 1%.

- Page 10 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Coolant classification Coolants are classified into two grades according to the engine loads: a. Coolant for light engine load b. Coolant for heavy engine load 1.3.2 Correct selection of coolant...

- Page 11 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Suggestion: It is recommended to use the Weichai Power heavy-load engine coolant which is sold at all the service stations of Weichai at the unified national sale price.

-

Page 12: Diesel Engine Installation And Connection

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 2 Diesel engine installation and connection Before installation of diesel engine, the installers should carefully read the on-board documents to be familiar with the diesel engine structure and installation requirements. - Page 13 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine If the wire is to be used, the inclination angle of the two wires from the vertical direction must be kept within 20 degree. Diesel engine installation 2.4.1 During installation, the sufficient space should be reserved at the...

- Page 14 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Fig. B All accessories should be symmetrically arranged at the both sides of diesel engine to prevent the crankshaft from being subject to the one-way tension.

- Page 15 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Exhaust pipe outside connected is made of steel pipe, should be flexibly connected to the supercharger of diesel engine. The inside diameter of extended exhaust pipe should be more than 120mm. Moreover, the extended exhausted pipe should not be bent as possible as you can, and should be reliably fixed without any vibration.

-

Page 16: Precautions And Operational Requirements For Diesel Engine

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 3 Precautions and operational requirements for diesel engine 3.1 Preparation for operation 3.1.1 Unsealing After the diesel engine is unpacked, user should firstly refer to the packing... - Page 17 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 3.1.3 Filling fuel The filled diesel fuel should meet the specifications. Keep the diesel fuel clean, and the diesel fuel should be sedimentated for 72h or more and then filled into the fuel tank through the built-in mesh.

- Page 18 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 3.2. Operation precautions 3.2.1 Before startup of engine, firstly crank the crankshaft by a few circles to ensure there is no obstacle. Then refer to stipulated methods and...

- Page 19 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine leaked. Switch off the main power switch to deenergize the diesel engine for avoidance leakage of electricity. In winter or cold regions, if the diesel engine is not used for long time and...

-

Page 20: Maintenance Specifications For Industrial Engines

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 4. Maintenance specifications for industrial engines Maintenance intervals and specifications of industrial engines are suitable for P4, P6, 10L, 12L, 13L and Baudouin series. 4.1 Maintenance intervals and specifications of industrial engines 4.1.1 Maintenance intervals of industrial diesel engines... - Page 21 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 4.1.3 Inspection and maintenance works for diesel engine Initial Routine Items WD1 WD2 WD3 WD4 maintenance checking Replace oil and oil filter ▲ ▲ ▲...

- Page 22 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 4.1.5 Maintenance Instruction In case of any failure within the period of “three- guaranty”, timely call 400- 618-3066, and then the call center will range Weichai special service center for inspection and repair at once.

- Page 23 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Maintenance Items Maintenance content mileage Replace the service kit of voltage stabilizer; clean the mixer, electronic throttle and clean maintenance the injection valve. Check the high-voltage wire of spark plug maintenance and it is suggested to replace it.

-

Page 24: Maintenance Specifications For Main Accessories Of Diesel Engine

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 5 Maintenance specifications for main accessories of diesel engine 5.1. Use and maintenance of fuel injection pump 5.1.1 Preparation for operation Before installing the fuel injection pump, check whether the pump model is correct, if not, replace it. - Page 25 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine new fuel injection pump before being put into use should be filled with proper lubricant, because it can’t be lubricated before engine provides the lubricant. Refer to the engine maintenance interval to service the fuel injection pump by loosening the bolts at the back housing of it to drain the used lubricant.

- Page 26 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine The oil from the supercharger flows out from the main oil passage of engine, lubricates and cools the supercharger, then return back to the lower portion of crankcase.

- Page 27 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine outlets on the thermostat: one is connected to the radiator and the other to the inlet of coolant pump which is also called as short circulation. When coolant hits 80±...

- Page 28 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine also can lead to abovementioned failures. Reliable fixing: generator should be correctly and reliably fixed on the engine. The bolts should be matched with the mounting hole of generator, and the pulley groove should share the same plane with the driving roller groove.

- Page 29 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine generator can output electricity, which otherwise can burn the testing bulb or diode. With the rectifier connected with stator winding, it is prohibited to use a megger or 220V AC power supply to check for insulation of generator.

- Page 30 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine cover wear. If needed, replace the oil pump. If the oil pressure is over high, dismantle and check the pressure- limiting valve, specially, whether the pressure-limiting valve can be open.

- Page 31 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine -- The filter element is damaged. -- After the filter element is cleaned, it still gives alarm. -- To replace the element after being cleaned for 3-6 times, select high- quality ones, which can ensure the reliability of diesel engine.

- Page 32 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine If the diesel engine is not in use, do drain the water in the fresh-water cooler, which otherwise is harmful to parts in fresh-water cooler, especially in winter.

- Page 33 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine obtained. Then the actual position defection is operationally amplified by PIDⅡ governor, and then converted into the current control manner which can output the drive current to the executor and accordingly change the motion displacement of executor.

- Page 34 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine negative pole of power supply is grounded, the negative pole of battery should be grounded at the negative pole of battery rather than at the negative pole (1 pin) of controller.

- Page 35 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine executor for a few times for feeling whether the motion is smooth. Maintenance every 2000h: remove and clean the speed sensor probe on which the dirt may be accumulated. Open the sight glass cover on the mid of governor to check whether the fasteners or pins attached coupling to the rack of oil pump are loosened, if so, timely tighten it.

-

Page 36: Common Failure Analysis And Troubleshooting

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 6. Common failure analysis and troubleshooting 6.1 Unable to start the diesel engine Cause Troubleshooting Operation causes The starting pressure in the air bottle (1) For the air starter, the air pressure should frequently stay at 2MPa. - Page 37 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Cause Troubleshooting Others (1) Intake valves and exhaust valves Grind or readjust the valve clearance. are leaked. Check each cylinder gasket, and then (2) Cylinder leaked.

- Page 38 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Cause Troubleshooting (4) Diesel fuel filter is clogged; the fuel pressure in the fuel supply pump is Check, clean, adjust or replace insufficient, the check valve of fuel supply pump is fractured or worn;...

- Page 39 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 6.3 Exhaust system smokes Cause Troubleshooting Gray-white smoke Increase the coolant temperature (1) Diesel engine temperature is very low. at the inlet of engine. Remove the exhaust pipe or (2) Cylinder leaks water.

- Page 40 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Each journal severely rubs with bearing bush on crankshaft, making knocking noise along the Repair or replace it overall length of diesel engine. The compression ratio...

- Page 41 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine lead to knocking of cylinder. The fuel injectors have different amount of fuel Check and adjust it distribution and injection time. Air enters the fuel system.

- Page 42 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 6.8 Diesel engine overheats Cause Troubleshooting Refer to the section 6.6 in this Coolant is insufficient. chapter. Decrease the coolant inlet Inlet temperature of coolant is very high.

-

Page 43: Ⅱ. User Service Guide

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine II. User Service Guide Weichai Power Product Warranty Card (for users) Name Content Name Content Model Name Order No. Zip code Number Address Purchasing date... -

Page 44: Service Registration Form

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Service Hotline: 400 Free Service Hotline: 400-6183066 800 Free Hotline: 800-8603066 Customer Service Center: 0536-8235369 (fax) Customer Service Center Complaint: 0536-2297322 Service Registration Form (filled by the service staff) -

Page 45: Repairs Instruction

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Repairs instruction 1. “Domestic Repair” Domestic users could call for 400 618 3066 or 800 860 3066 for repair. Customer Service Center 800 and 400 hotlines are available for 24h, providing quick and effective high-quality service. -

Page 46: Diesel Engine "Three-Guaranty" Warranty Specification

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Diesel engine “Three-guaranty” warranty specification 1 "Three-guaranty” principle 1.1 Under the normal use and maintenance, Weichai Power will free repair or maintain the damaged parts caused by its quality during “Three- guaranty”... - Page 47 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 1500h, whichever comes first High-pressure fuel Cylinder head Cylinder liner pump Seawater –fresh- Oil cooler Oil pump water heat exchanger Piston Seawater pump Fresh-water pump...

- Page 48 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Rocker shaft Hand oil pump Cooling nozzle Oil sump All kinds of gears All kinds of bearings Oil pressure-limiting Intercooler Starting valve valve Air bottle head and...

- Page 49 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Plunger assembly in Fuel injection nozzle Belt high-pressure fuel assembly pump All kinds of spin-on Clamp elements Note: If the timer is fault, the “Three-guaranty” period should be calculated referring to 10h each day.

- Page 50 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Solenoid valve All kinds of sensors Ignition coil Relay Harness Ignition cable The following parts, as wear parts, are out of “Three-guaranty” Spark plug Fuel filter assembly Note: If the timer is fault, the “Three-guaranty”...

-

Page 51: Weichai Industrial Engine Spare Parts "Three-Guaranty" Warranty Specification

Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine Weichai industrial power engine spare parts “Three-guaranty” warranty specification Weichai power promise of quality warranty and “Three-guaranty” for spare parts: Under the normal use and maintenance, Weichai Power will free repair or maintain the damaged parts caused by its quality within the “Three-... - Page 52 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 1.3 For the essential and common parts, the warranty period is 3months The following parts belong to essential and common parts Cylinder head Gear shaft...

- Page 53 Operation and Maintenance Manual and User Service Guide for Industrial Power WP10 Series Diesel Engine 1.4 For the basis parts, the warranty period is 12 months In case of any failure within “Three-guaranty” period, the market manager of Maintenance and Service Center should take the picture of it at site and determine the work-hour cost.

Need help?

Do you have a question about the WP10 Series and is the answer not in the manual?

Questions and answers