Table of Contents

Advertisement

Quick Links

®

SPM

Well Service Pumps & Flow Control Products

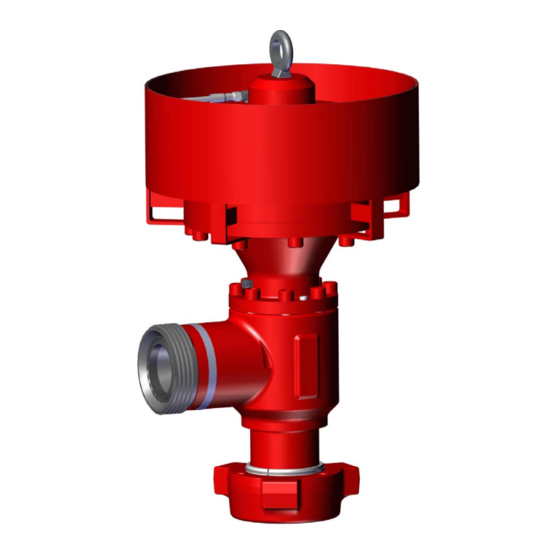

Full Bore Emergency Unloading Valve

Operating and Maintenance Instructions

Copyright © 2014, S.P.M. Flow Control, Inc.. All rights reserved. S.P.M. Flow Control, Inc. is the owner of the copyright and all confidential information in this

document, which must not be copied in whole or in part, in any form or by any means, and the information in it must not be used for any purpose other than the specific

purpose for which it has been provided without the prior written consent of the copyright owner. SPM, SAFETY IRON, SAFETY HAMMER, SUR-DROP, DESTINY,

STAMPEDE, VERIBAND, DURALAST and GLADIATOR are trademarks and/or registered trademarks of S.P.M. Flow Control, Inc.. WEIR is a trademark and/or

registered trademark of Weir Engineering Services Limited. Certain features of some of the products disclosed in this document may be protected worldwide by patents

pending and registered in the name of S.P.M. Flow Control, Inc..

Document P/N:

1A23392

Release Date

11/4/2014

Advertisement

Table of Contents

Summary of Contents for Weir SPM

- Page 1 SPM, SAFETY IRON, SAFETY HAMMER, SUR-DROP, DESTINY, STAMPEDE, VERIBAND, DURALAST and GLADIATOR are trademarks and/or registered trademarks of S.P.M.

-

Page 2: Product Description

Available in 3”, this valve offers pressure ranges from 1000 – The SPM Unloading Valve should be installed in a branch 15000 psi. The valve is best suited for over pressure on the high-pressure pump line (Fig. 1). The valve should protection in a “slick water”... -

Page 3: Description Of Operation

DO NOT USE FOR H2S SERVICE. Particulates, abrasives and contaminants will not preclude Weir SPM does offer a separate series of H2S service the valve from opening at the appropriate set pressure. unloading valve. Contact your Weir SPM... - Page 4 Some wear in this area is expected. Any damage result if these areas are not smooth. to this surface that extends deeper than .10" renders the 5. Use only Weir SPM relief valve parts on Weir SPM relief part unusable and it should be replaced. valves.

- Page 5 6.) Spider 12 : cartridge should be replaced. Visually inspect the fluid discharge areas for erosion and corrosion. Some wear in these areas is expected. Any FIG. 4 WEIR SPM REPAIR KITS Ref. No./FIG 5 Part No. Complete Internal Parts Kit 4L23547...

- Page 6 VII. Service: (Con’t) 4. Install seals 26 31 27 & 20 into flange 1 . 5. Install rod and piston assembly into flange 1 . Install 8.) Wear Sleeve 14 and Nozzle 16 : entire package into body 2 . Be certain that wear The fit between the wear sleeve, nozzle and main seal sleeve 14 passes fully through main seal assembly 5 .

- Page 7 predicted gas pressure does not produce the desired set VIII. Setting and Adjusting pressure, you may have to adjust the regulator 8 up or Pressure: down. The unloading valve is direct acting. The pressure set on Some of the factors affecting performance include the nitrogen regulator is directly related to the relief ambient and liquid temperature, and gas media used (air pressure.

-

Page 8: Troubleshooting Guide

Always follow existing company procedure concerning identifying equipment for inspection, and removing equipment from service. The following is intended as a general guide in helping resolve most problems encountered in repairing clapper check valves. If problems are not covered here please contact Weir SPM for assistance at (817) 246-2461. SYMPTOM... -

Page 9: Safety Information

INTO THE HANDS OF THE OPERATOR. FAILURE TO READ, UNDERSTAND AND FOLLOW THE OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL COULD RESULT IN SEVERE PERSONAL INJURY OR DEATH. Weir SPM 7601 Wyatt Drive Tel: (817) 246 2461 Fort Worth Fax (817) 246 6324 TX 76108 www.weiroilandgas.com © 2011 Weir SPM V.1 02/11...

Need help?

Do you have a question about the SPM and is the answer not in the manual?

Questions and answers