Brady BP-IP300 Operation/Configuration Manual

Ip printer

Hide thumbs

Also See for BP-IP300:

- Specifications (2 pages) ,

- Service manual (30 pages) ,

- Manual (75 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Brady BP-IP300

- Page 1 Operator/ Configuration Manual Edition 07/07...

-

Page 2: United States

No part of this manual nor any translation may be reproduced or transmitted in any form or by any means, for any purpose other than the purchaser’s personal use, without the express written permission of Brady. United States Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. - Page 3 Brady’s high quality specialized materials. To gain the full benefit of the system, material and ribbons from Brady are programmed with the ability to communicate with the printer and software.

-

Page 4: Table Of Contents

Industry Canada ... 1 Taiwan ... 1 Europe ... 1 Table of Contents ... i Brady IP™ Printer Operator/Configuration Manual ... 1 Copyright ... 1 Safety and the Environment ... 2 About the Printer ... 2 Intended Use of the Printer ... 2 Safety ... -

Page 5: Table Of Contents

Custom Material ... 16 Standard Mode... 16 Gap Sensors ... 17 Reflective Sensor ... 18 Brady Mode... 18 Standard Mode ... 18 Reading the LCD Display ... 27 Feeding the Label — Peel-Off Mode... 28 Feeding the Label — Tear-Off Mode... 29 Powersave Mode... - Page 6 Font List ... 40 Device List ... 41 ASCII Dump Mode ... 42 Test Grid... 44 Label Profile ... 45 Setup Menu... 47 Local Settings ... 47 Machine Parameters ... 48 Print Parameters ... 50 Interfaces ... 52 Security ... 53 Firmware ...

- Page 7 Table of Contents Please use this page for your individual notes...

-

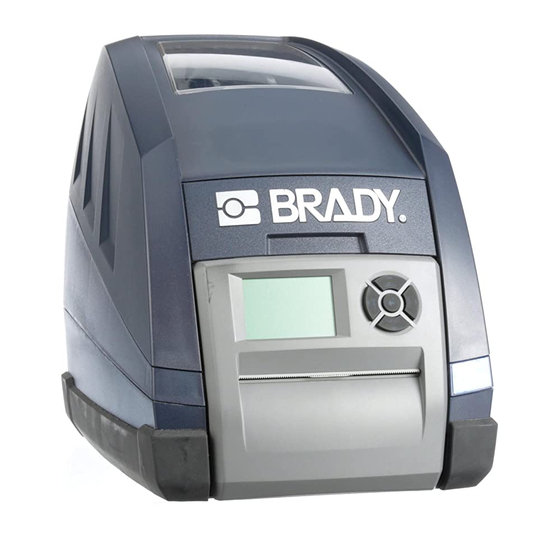

Page 8: Brady Ip™ Printer Operator/Configuration Manual

Copyright This manual is copyrighted with all rights reserved. No portion of this manual can be copied or reproduced by any means without the consent of Brady Worldwide Inc. While every precaution has been made to ensure accuracy in the preparation of this document, Brady assumes no liability to any party for any losses or damage caused by errors or omissions or by statements resulting from negligence, accident or any other cause. -

Page 9: Safety And The Environment

Safety and the Environment Please read and understand this manual before using the Brady IP Printer for the first time. This manual describes all of the main functions of the Brady IP Printer. The functions actually available depend on the version ordered. -

Page 10: Safety

Brady IP™ Printer Operator/Configuration Safety The Brady IP Printer is configured for voltages of 100 to 240 V ~, 50 to 60 ■ Hz. Connect only to a grounded power outlet. The Brady IP Printer may only be used in a dry environment, do not expose ■... -

Page 11: Unpacking The Brady Ip Printer

Stress Free System Setup Stress Free System Setup is available, free of charge, in North America. Brady’s Stress Free System Setup helps you set up your new printer and software. To schedule a free phone setup assistance appointment, call 1-800-643-8766 and select Menu Option 4. -

Page 12: Installation

Printer Overview VIEW A 2 3 4 VIEW B 1. RS-232 port 2. USB port 3. Two USB master ports for keyboard or scanner 4. Ethernet port 5. CompactFlash card slot 6. Power connection socket 7. PC card slot, type II 8. -

Page 13: Printer Location

(Figure 1, 6). 2. Plug the power cable into a grounded 100 to 240 V~, 50 to 60 Hz power source. NOTE: The Brady IP Printer senses the voltage type and automatically adjusts for the power source. NOTICE NOTICE... -

Page 14: Interface Connections

3. Connect the printer to the computer using the supplied USB cable, an RS-232 cable or an Ethernet cable (refer to Interface Connections on page 7). 4. If you do not have BradySoft, LabelMark or IdentiLab software installed on your computer, refer to Software Installation on page 13. 5. -

Page 15: Usb Connection

Installation USB Connection 1. Ensure that the Brady IP Printer is turned off. 2. Connect the printer to the computer using the supplied USB cable. The USB cable connects to the printer at the USB port (Figure 2, 2) and to a USB port on the computer. -

Page 16: Multiple Printers

Hardware Wizard will appear. (At this point the Plug and Play process should have created a new USB virtual port. The Brady IP printer driver will be added in later steps.) Cancel the New Hardware wizard. If using Windows XP, skip ahead to step 1. - Page 17 Installation 1. Ensure the Product CD is in the CD drive. Select Run from your computer’s start menu. Choose the drive where the Product CD is located. Choose Setup\Setup.exe. Choose OK. 2. Choose your language. Figure 6, Choose Setup Language Dialog Box Figure 4, Printers Window Figure 5, Run Dialog Box...

- Page 18 Installation 3. Choose the printer. Figure 7, Choose Printer Dialog Box 4. Choose the appropriate port. Figure 8, Choose Printer Port Dialog Box...

-

Page 19: Rs-232 Or Ethernet Printer Driver

Installation 5. Click Yes. Figure 9, Read Only File Detected Dialog Box 6. Choose to restart your computer. Figure 10, Restart Printer Dialog Box 7. Once your computer has restarted, ensure the added printer is powered on and connected to your computer. Check to make sure the new printer driver is not offline by choosing Start | Settings | Printers and right clicking on the printer icon. -

Page 20: Software Installation

On-line Status Monitor The On-line Status Monitor provides printer status information. From the Options menu, you can select Warn if no Brady Smart Supply, Always on top or Unit of Measure (inches or mm). The Help menu provides links to Brady Online. -

Page 21: Media Setup

THT printer. Refer to Standard Mode on page 16. The LCD display shows: The Brady logo in the top, left corner which indicates that the printer is ■ operating in Brady mode. -

Page 22: Typical Ready Display

If you are not using Brady-brand supplies but LabelMark, IdentiLab or BradySoft labeling software, the software will ask if metallized material is installed when the printer cannot read a Brady IP enabled Supply. If you answer “yes,” the software will request selection of a part number from a list prior to operation. -

Page 23: Sleeving Material

LCD display. This is true for only IP-enabled material (not compatible). Refer to Gap Sensors on page 17. Set the gap sensor switch to the setting displayed and the printer will operate in Brady mode. Refer to Brady Mode on page 14. -

Page 24: Label Sensors

These sensors are controlled by a switch setting (Figure 13, 3). The switch can be set to the left or to the right. All Brady IP enabled material will instruct the user, via the front LCD display, which position to set the switch. For non-standard material, set the sensor to position 2. -

Page 25: Reflective Sensor

(Figure 14, 2).) Brady Mode 1. The LCD will indicate Brady mode (Figure 14, 1) and show sensor placement information (Figure 14, 2). 2. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and press the green print module release button (Figure 1, 15). - Page 26 Figure 14, Adjusting the Reflective Sensor 1. Designates printer in Brady mode 2. Sensor position Figure 15, Reflective Sensor Label R60XX 3. Sensor window 4. Sensor knob 5. Scale Installation View A...

-

Page 27: Device Types

Device Types The Brady IP Printer has a Peel-off function and a Tear-off function. Driver Settings 1. When in Start | Settings | Printers, right click on the IP printer. Choose Properties, then Printing preferences. Then choose Paper/ Output; paper size. -

Page 28: Peel-Off Mode

Figure 17, Custom Settings Dialog Box Peel-Off Mode The Brady IP Printer enables label output in Peel-off mode. In this mode, a label is printed, separated from the liner and presented to the user. The printer pauses until the label is removed. After the label is removed, the printer prints the next label and the cycle continues. -

Page 29: Tear-Off Mode

Label stock is loaded as described in Feeding the Label — Tear-Off Mode on page 29. After printing, the strip label is detached by hand. The Brady IP Printer is equipped with a tear bar for this purpose. -

Page 30: Loading The Ribbon And Material

Loading the Ribbon and Material Loading the Ribbon Do not use a ribbon for direct thermal printing. When inserting a ribbon, ensure that the coated side faces the labels, otherwise the printhead can become dirty. 1. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and press the green print module release button (Figure 1, 15). - Page 31 Loading the Ribbon and Material 2. Push the old ribbon spindle (Figure 18, 2) slightly to the right to release tension on the spindle and pull the left side of the spindle (Figure 18, 1) toward you. Discard used ribbon. 3.

-

Page 32: Loading The Material

There are electrical contacts located under the side tabs (Figure 20, 1) on both sides of the material supply holder. Be careful not to damage these electrical contacts or the Brady IP Printer will be unable to read the material identification tag on the labels. - Page 33 3. Press and hold the green tab (Figure 20, 3) on the material supply holder and slide the end piece (Figure 20, 4) outward. 4. Slide the Brady labeling material roll onto the material supply holder. Make sure material roll is installed with label printable side (up) towards printhead (Figure 20, 6).

-

Page 34: Reading The Lcd Display

Reading the LCD Display The use of Brady-brand supplies and LabelMark, BradySoft or IdentiLab labeling software allows access to the full operation of Brady mode. For detailed information about Brady mode, refer to Brady Mode on page 14. The LCD display should read Ready and display the type of material loaded into the printer as well as the type of ribbon loaded. -

Page 35: Feeding The Label - Peel-Off Mode

Loading the Ribbon and Material Feeding the Label — Peel-Off Mode 1. Pressure roller (engaged) 2. Pressure roller (disengaged) 3. Pressure roller 1. Load the labels on the material supply holder. Refer to Loading the Material on page 25. 2. Position the label strip between the label guides (Figure 21, 2) and turn the adjustment wheel (Figure 21, 1) to snug the guides just up against the label strip. -

Page 36: Feeding The Label - Tear-Off Mode

5. Feed the label backing (Figure 23, 4) out between the control panel and the printer. 6. Make sure that there is enough slack in the label strip so the printer can be closed without pulling the label strip backward. 7. -

Page 37: Synchronizing The Paper Feed

Synchronizing the Paper Feed After the label stock has been inserted, the printer will calibrate automatically if Brady IP enabled materials are used. If materials other than Brady IP enabled are used, calibration is performed manually. Select the material type in the software. -

Page 38: Control Panel

The user can control many printer operations with the control panel. These options include: Starting, interrupting, continuing and cancelling print jobs (refer to Key ■ Functions on page 36). Setting print speed, interface configuration, language and time of day (refer ■... - Page 39 Control Panel...

- Page 40 Control Panel...

-

Page 41: Control Panel Structure

(Figure 25, 2) with five integrated keys. The graphic display indicates the current status of the printer, label and/or ribbon numbers, if Brady-brand materials are used, the print job, faults and the printer settings in the menu. The key functions depend on the current printer status. The key pads (for example, menu or feed) light up white in Print mode. -

Page 42: Printing Label' State

‘Printing label’ state The printer is currently processing an active print job. Data can be transmitted for a new print job. The new print job will start when the previous one has finished. The display shows the message Printing label and the number of the printed label in the print job. -

Page 43: Key Functions

Control Panel Key Functions The up, down, left and right arrows are used for navigating in the menu. ■ key corresponds to the Enter key on a computer keyboard. It ■ confirms: - Selection of a menu item. - Entry of a parameter. - Help information in the event of a fault. -

Page 44: Short Status

Revision of the CPU Serial number of the PCB CPU Resolution of the installed thermal printhead Previously printed paper lengths Previously printed paper length (thermal print) IP address of the Brady IP Printer when connected to a network Control Panel keys. Example IP/300 Firmware V1.00... -

Page 45: Test

Control Panel Test Overview The printer is equipped with different test functions providing information about: The most important configuration parameters. ■ The fonts available in the printer. ■ The hardware components and connected peripheral devices. ■ The print image quality and state of the thermal printhead. ■... -

Page 46: Status Print

Status Print The Status print function prints a test image containing information on the configuration and status of the printer. The printout occurs using the heat level and print speed specified in the Setup > Print param. menu. NOTE: Continuous media is most suitable for this function. 1. -

Page 47: Font List

Control Panel Font List The Font list function prints the most important parameters of the fonts available in the printer. The table contains both the original fonts and user-loaded fonts. NOTE: Continuous media is most suitable for this function. 1. Press the menu key. 2. -

Page 48: Device List

Device List The Device list function prints out the most important information on hardware components of the printer and connected devices. NOTE: Continuous media is most suitable for this function. 1. Press the menu key. 2. Select Test > Device list menu. 3. -

Page 49: Ascii Dump Mode

Control Panel ASCII Dump Mode ASCII Dump mode offers the option of checking incoming control sequences at the interface when working with direct programming. The incoming commands at the printer are printed out as text. In addition, a corresponding error message is printed out immediately after an error occurs. The printout is started after four lines have been received. - Page 50 Control Panel Figure 30, Sample ASCII Dump Mode...

-

Page 51: Test Grid

Control Panel Test Grid The Test grid function prints out the geometric pattern on a background grid. This allows you to assess the evenness of the print quality. NOTE: Continuous media is most suitable for this function. 1. Press the menu key. 2. -

Page 52: Label Profile

Label Profile The Label profile function carries out a longer label advance. It saves the values measured by the label sensor here and then prints them out in two diagrams. The printout is used to check label detection in conjunction with the optical properties of the label medium. - Page 53 Control Panel Figure 33, Typical Label Profile Graph Description of Label Profile Graph 1 Direction of paper flow at which the label start was detected 2 Type of peripheral device connected 3 Information for the firmware developer 4 Width of the negative derivative in motor increments 5 Stroke between start and end of the negative derivative 6 Scale factor for the derivative diagram 7 Service information for adjusting the label sensor...

-

Page 54: Setup Menu

Setup Menu Local Settings Press the menu key. Select Setup > Local settings. Parameter Meaning Sets the display language and the Country country-specific date and time formats. Adapts the time display on the printer to the time Timezone zone in relation to UTC (Universal Time Coordinated). -

Page 55: Machine Parameters

Control Panel Machine Parameters Press the menu key. Select Setup > Machine param. Parameter Meaning Shifting of the entire print image perpendicular to Printhead the direction of paper flow. pos. X The absolute shifting is limited by the margins of the print zone. - Page 56 Parameter Meaning Delay time between removing the label from the >Backfeed peel position and the backfeed of the label. delay Limitation of the print speed in the Peel-off mode to > Limit 100 mm/s. peel-off spd. Brightness of the LCD display from 1 to 10. Brightn.

-

Page 57: Print Parameters

Control Panel Print Parameters Press the menu key. Select Setup > Print param. Parameter Meaning Heating value to compensate for different Heat level thermal behavior of printheads. Changing this value is necessary if the printing intensity has changed after replacing the printhead. To adapt the printing intensity when using different media, print speeds or printing contents, you should change the heat level in... - Page 58 Parameter Meaning Method for detecting the starting end of the Label label. sensor Gap sensor: Detection using changes in the transparency between the label and label gap. Bottom-Reflect: Detection using reflex marks on the bottom of the material and notched material. Positioning the label medium for tearing off at Tear-off the Tear-off plate.

-

Page 59: Interfaces

Control Panel Parameter Meaning On: With faulty barcode contents or size Barcode specifications, printing is interrupted. error Off: Printing is not interrupted if an error occurs. If barcode contents are faulty, the printer attempts to replace the incorrect data with valid characters (e.g. zeros). If barcode size specifications are faulty, a gray area is printed instead of the barcode. -

Page 60: Security

On: Dynamic issuing of IP address by the DHCP server Off: Direct issuing of the IP address by the operator IP address of the Brady IP Printer. Only valid > IP with DHCP = Off. Subnet mask (classification and address range) >... -

Page 61: Firmware

Firmware upd.: Copy a firmware file from a computer connected to one ■ of the interfaces of the Brady IP Printer. Refer to Firmware Update via Interface on page 54. Brady Support can provide additional information about current firmware available on the Brady website. -

Page 62: Firmware Update From Memory Card

Firmware Update from Memory Card 1. Format CompactFlash memory card in printer. The directories “fonts,” “images,” “labels” and “misc” are created on the memory card. 2. Copy the firmware file to the “misc” directory in a CompactFlash drive. 3. Insert the prepared memory card into the printer. 4. -

Page 63: Error Messages During Firmware Update

Control Panel Error Messages During Firmware Update If an error occurs during the update, one of the following error codes is shown in the display: Error Meaning code Checksum error. /b may have been forgotten in the COPY command or the file is defective. -

Page 64: Calibration For Standard Material

Calibration for Standard Material Heat Settings for Print Darkness With the use of Brady material, the heat settings in the setup print parameters menu may vary greatly. Setting the heat excessively high can result in not only melting the ribbon but also damaging the printhead. If your material does not have a recommended heat setting, it is recommended that you set the heat at -20, which is the lowest possible value. -

Page 65: Print Sample Label

Control Panel Print Sample Label A sample label is imbedded in the firmware and can be printed through the test menu. Figure 34, Sample Print Label... -

Page 66: Print Setting Label

Control Panel Print Setting Label To validate the settings, print the configuration label. Figure 35, Configuration Label... -

Page 67: Cleaning And Simple Maintenance

Cleaning and Simple Maintenance Cleaning and Simple Maintenance Disconnect power to the printer before starting any maintenance work. It is important to clean the thermal printhead regularly. This guarantees a consistently good printed image and will prevent premature wear of the printhead. - Page 68 Cleaning and Simple Maintenance • Do not use sharp objects to clean the printhead. • Do not touch the protective glass layer on the printhead. Risk of injury from the hot printhead. Ensure that the printhead has cooled down before starting cleaning.

-

Page 69: Basic Troubleshooting Guide

Basic Troubleshooting Guide Basic Troubleshooting Guide Troubleshooting Chart Problem Transfer ribbon creases. Print image has smears or voids. Printer does not stop after transfer ribbon runs out. Printer prints a sequence of characters instead of the label format. Printer transports label media, but transfer ribbon does not move. -

Page 70: Error Messages With Corrective Actions

Error Messages with Corrective Actions Error messages ADC malfunction Barcode error Barcode too big Battery low Buffer overflow FPGA malfunction Head error Head open Head too hot Invalid Label Invalid Ribbon Basic Troubleshooting Guide Cause Possible hardware issue. Recycle power to the printer. If the Barcode content is invalid, for example alphanumeric characters... - Page 71 Basic Troubleshooting Guide Error messages Invalid setup Memory overflow Multiple Label Tags Found, Remove Extras Multiple Ribbon Tags Found, Remove Extras Multiple Tags Read Remove Extra Tags Network Error, No Link No Label Detected No label size Cause The Setup menu is incorrectly configured.

- Page 72 Error messages Cause Supply missing RFID tag. Verify compatible supply has No Ribbon Detected Printer is configured to No SMTP server send error messages to the server but the IP address of the recipient can not be found. Ribbon does not match Not a Primary ribbon Recommended...

- Page 73 Basic Troubleshooting Guide Error messages Protocol error Ribbon too Narrow for Label Voltage error Wrong revision Cause Printer has received an unknown or invalid command from the computer. Ribbon is smaller than the width of the installed supply. An incorrect voltage is detected.

-

Page 74: Additional Support

Additional Support Technical Support Numbers/Online Help For Repair or Technical Assistance, find your regional Brady Tech Support office by going to: In the Americas: www.bradyid.com ■ In Europe: www.bradyeurope.com ■ In Asia: www.bradycorp.com ■ Repair and Replacement Parts Brady Corporation offers Repair and Replacement Services. Contact Brady Technical Support for repair and replacement information. - Page 75 For Repair or Technical Assistance, find your regional Brady Tech Support office by going to: In the Americas: www.bradyid.com ■ In Europe: www.bradyeurope.com ■ In Asia: www.bradycorp.com ■...

Need help?

Do you have a question about the BP-IP300 and is the answer not in the manual?

Questions and answers