Table of Contents

Advertisement

Operation Manual

SYNERGY 0.5

LOW PROFILE

TURNTABLE STRETCH

WRAPPER

SERIAL NUMBER

Please refer to the serial number in all correspondence with Highlight or

any Highlight Distributor. This identifies your machine and will help in

our ability to quickly and efficiently respond to your needs.

OPERATION MANUAL NUMBER: SYN0.5LPSTD2013 / JULY-2015 / JAN-2019

Advertisement

Table of Contents

Summary of Contents for Highlight Synergy 0.5

- Page 1 TURNTABLE STRETCH WRAPPER SERIAL NUMBER Please refer to the serial number in all correspondence with Highlight or any Highlight Distributor. This identifies your machine and will help in our ability to quickly and efficiently respond to your needs. OPERATION MANUAL NUMBER: SYN0.5LPSTD2013 / JULY-2015 / JAN-2019...

-

Page 2: Table Of Contents

Troubleshooting Guide ....................40 Power Problems ......................41 Turntable Problems ......................42 Technical References ................... 43 Recommended Spare Parts ................... 44 Mechanical Drawings...................... 45 Electrical Drawings ......................51 Notes ......................54 Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 3: Table Of Figures

Figure 3: Film Loading/Threading Diagram ................ 32 Figure 4: Top View of Package, Film Cut Location ............34 Figure 5: Side View of Package, Film Tear Angle .............. 34 Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 4: General Information

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual General Information... -

Page 5: Safety Messages

Notes This symbol indicates an area or subject of special merit, emphasizing equipment’s capabilities, common errors operation maintenance, or other special instructions that can provide benefits to users. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 6 Warning! Loose clothing must NOT be worn while the machine is in operation. Stay clear of moving parts while the machine is running. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 7: Introduction And Warranty

Introduction and Warranty Introduction Thank you for your purchase of a Synergy 0.5 Turntable Stretch Wrapper! Designed for the high volume industrial user the Synergy 0.5 offers the flexibility to precisely adjust the level of film stretch to match the load-holding requirements. - Page 8 1. Machine Serial Number 2. Date of Purchase 3. Symptoms of any problems Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 9: Revision History

Revision Comment Date of Revision Initial Release April 2011 Updated turntable drawing – ref 2008 Oct 2013-RDU Updated Film Diagram July 2015-WBK Tension Knob Assembly added Jan 2019-JMR Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 10: Specifications

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Specifications... -

Page 11: Specifications

Off the Shelf Components Turntable 4,000 lbs Maximum Turntable Load Capacity 12 RPM Maximum Turntable Speed 1/2 HP 3-Phase AC Motor 1/2 HP AC Frequency Drive Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

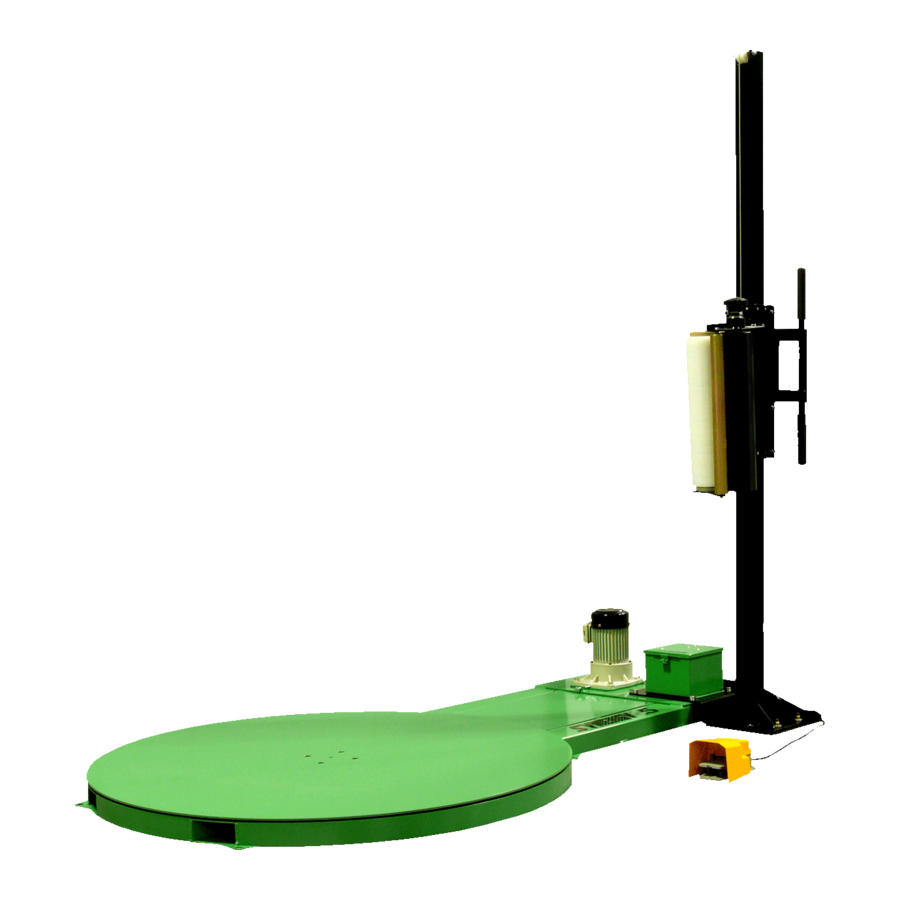

Page 12: System Overview Prints

Refer to the Technical References section of the manual for more detailed information. Figure 1: Synergy 0.5 Low Profile, Side View Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 13: Installation & Adjustments

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Installation & Adjustments... -

Page 14: Machine Placement

Upon receiving, please do the following: 1. Inspect the entire machine for visual damage during shipment. If found, immediately report this damage to the trucking line. Highlight Industries, Inc. has taken every precaution during the packaging and loading of this equipment, however, it is YOUR RESPONSIBILITY to inspect for damage before installation. -

Page 15: Machine Set-Up

1. Using a volt meter, check the AC voltage coming to the machine and insure the proper voltage is present. 2. Plug the machine in and turn the Power Switch ON. Power should now be applied to the AC frequency drives. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 16: Frequency Drive Adjustments

Keypad Description: 1. Value LED. When illuminated it indicates when a numeric value is being displayed. 2. Charge LED. When illuminated it indicates when drive capacitors are fully charged. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 17 Using the wheel, scroll to “COnF” and press the wheel again; this will access different sets of parameters. Using the wheel, scroll to “FULL” and press the wheel; this will give the user access to the complete parameter set. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 18 – Freewheel stop control Obr – Auto-Adapted deceleration CtL – Controlled stop on mains phase loss tUn – Auto-tuning in progress FSt – Fast stop active nLP – No line power Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 19 Synergy 0.5 Turntable Stretch Wrapper Operation Manual Programming Functions All functions have been Highlight factory set and tested. The factory settings listed in this manual are the drive manufacturer’s factory setting, not the Highlight Industries factory settings. Refer to the Electrical Schematic Drive Parameters page of the Technical References section for the Highlight factory settings.

- Page 20 Frequency Loop Gain: 0-100% Adjusts the slope of the speed increase. A lower number decreases oscillations. Motor Auto Tuning: nO/YES/dOnE nO Automatically tunes the drive to the motor profile Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 21 Stt- Type of Stop: rNP – Ramp Stop FSt – Fast Stop nSt - Freewheel Reverse Direction Assignment: nO – Function inactive L1H – Input L1 active high Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 22 Flying Restart (Catch on the fly): Restarts the motor at the estimated speed the motor is already going. nO – Function inactive YES – Function active tHt- Motor Thermal Current varies Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 23 Check the state of the mechanism Connect line chokes Reduce the Switching Frequencies (SFr) Check the ground connection of drive, motor cable, and motor insulation Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 24 Check the process and the parameters of the drive to be in phase Motor overload Triggered by excessive motor Check the setting of the motor current thermal protection, check the motor load Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 25 Check the SoMove connecting SLF2 SoMove Communication interruption with Communication SoMove cable. Check the time-out SLF3 HMI Communication Communication interruption with the Check the terminal connection external display terminal Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 26 Line supply too low Undervoltage Check the voltage and the Transient voltage dip parameters of Undervoltage Phase Loss Menu USb Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 27: Pre-Operation Adjustments

Once all parameters are entered into the drive press ESC until you see RDY then press the dial once, you will see REF, press the dial once again, you will see a number value, turn the dial clockwise until the number stops at 100. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 28: Load Compression Testing

6. Attach the scale provided in the Highlight Field Test Kit FTK-4000 kit to the center of the package by pushing the pointed end of the hook all the way through the stretch film. -

Page 29: Optional Scale Package

Step 9: Replace the screws on the back cover and retighten the scale swivel grips on the side. Step 10: The scale is now ready to use. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 30 Places the scale in a Zero Calibration routine. See See below. Calibration below. F17: Span Places the scale in a Span Calibration routine. See See below. Calibration below. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 31 Highlight Industries, Inc. calibrates the scale before shipment using known weights. The values stored in these settings are custom per scale and machine. Do not change these values unless directed to do so by Highlight personnel. Step 1: Navigate the scale menu to parameter “F 16.”...

-

Page 32: Operation Instructions

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Operation Instructions... -

Page 33: Film Loading

3. Follow the diagram below and thread the film tail all the way through the rollers. 4. After threading, grab the film tail, pull it out, and attach to the load. Figure 3: Film Loading/Threading Diagram Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 34: Machine Operating Instructions

Synergy 0.5 Turntable Stretch Wrapper Operation Manual Machine Operating Instructions Simply step on the foot pedal to start the turntable rotating. Pressing on the footswitch again will turn the turntable off. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 35: Film Cutting

To cut the film a film knife can be used or an operator can tear the film at a 45- degree angle to itself. Figure 4: Top View of Package, Film Cut Location 45 deg Pull Figure 5: Side View of Package, Film Tear Angle Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 36: Maintenance

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Maintenance... -

Page 37: Preventative Maintenance

4. Check for oil leaks around the speed reducers. 5. Check for dry seals at the bearings. 6. Check for loose electrical connections and for frayed cords and cables. Replace immediately any damaged cords and cables. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 38 Replace chain guards when preventative maintenance is complete. Miscellaneous Pivot and Rotating Bearings All other bearings not mentioned previously should be greased bi-monthly using Mobile EP- 2 or equivalent. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 39: Maintenance Schedule

All pivot bearings Mobil EP-2 grease thereafter. Note For additional maintenance information about specific components on the machine, refer to the components operation manuals shipped inside the main enclosure. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 40: Trouble-Shooting

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Trouble- shooting... -

Page 41: Troubleshooting Guide

4. Have a multi-meter nearby to be able to check for voltages and continuity on different portions of the machine circuitry. 5. Use the schematics provided in this manual to trace wiring and find components on the sub panel. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 42: Power Problems

The drive circuit breaker is off. Frequency Drive replace if necessary. is not on. Check wiring to the Frequency The drive has malfunctioned. Drive, or replace if necessary. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 43: Turntable Problems

Refer to the Electrical Schematics in the Technical References The parameters in the Frequency section of this manual for Drive are not set properly. Highlight Industries, Inc. factory drive settings. Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... -

Page 44: Technical References

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Technical References... -

Page 45: Recommended Spare Parts

Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Recommended Spare Parts The table below provides the recommended spare parts list for the Synergy 0.5 Turntable Stretch Wrapper. Machine HLI Part Section Number Item Description L.P Turntable 305357 GEARMOTOR, 1/2 HP L.P Turntable... -

Page 46: Mechanical Drawings

Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Mechanical Drawings Low Profile System Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 47 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Low Profile Turntable Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 48 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Tower Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 49 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 50 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Film Carriage Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 51 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 52: Electrical Drawings

Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Electrical Drawings Electrical Schematics Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465... - Page 53 50 Hz Detected Fault Reset Assignment Automatic Restart Max Automatic Restart Time 5 min Flying Restart Motor Thermal Current PLATE This table represents the Electrical Schematics Page 2 Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 54 Technical References Synergy 0.5 Turntable Stretch Wrapper Operation Manual Electrical Enclosure Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

-

Page 55: Notes

Highlight Industries, Inc. Synergy 0.5 Turntable Stretch Wrapper Operation Manual Notes... - Page 56 Notes Synergy 0.5 Turntable Stretch Wrapper Operation Manual Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

- Page 57 Notes Synergy 0.5 Turntable Stretch Wrapper Operation Manual Highlight Industries, Inc. ● 2694 Prairie SW, Wyoming, Mi 49519 ● 1-800-531-2465...

Need help?

Do you have a question about the Synergy 0.5 and is the answer not in the manual?

Questions and answers