Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pulsar Measurement Greyline TTFM 6.1

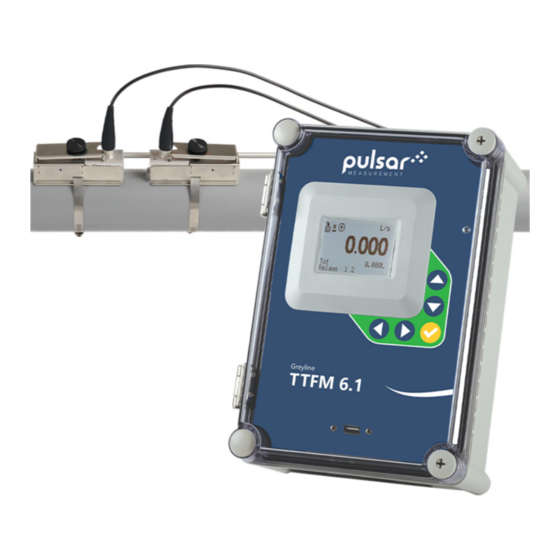

- Page 1 PULSAR MEASUREMENT Greyline TTFM 6.1 Instruction Manual Manual Rev 2.0...

- Page 2 Note: This page has been left blank intentionally.

-

Page 3: Table Of Contents

PULSAR MEASUREMENT CONTENTS CONNECTIONS: ................................................4 KEYPAD SYSTEM ................................................6 MENU SYSTEM ................................................. 7 ICONS ....................................................8 MESSAGE ICON ................................................9 STATUS ....................................................9 PASSWORD ..................................................11 MENU SELECTIONS ..............................................11 UNITS/MODE ................................................. 12 SET UP ....................................................14 CALIBRATION ................................................. 17 RELAY PARAMETERS .............................................. -

Page 4: Connections

TTFM 6.1 INSTRUCTION MANUAL CONNECTIONS: POWER INPUT: The standard model requires AC power input between 100 to 240 VAC 50/60Hz 10VA. No adjustments are necessary for voltages within this range. Connect L (Live) N (Neutral) and AC Ground. Optional DC input model requires 9-32 VDC/10 Watts. Connect to + and - terminals. Optional Thermostat and Heater modules are available rated for specifically 115 VAC or specifically 230 VAC. - Page 5 PULSAR MEASUREMENT 100-240 VAC Meter CONNECTIONS SENSOR SERIAL COMMUNICATION OPTION RS-485 Output EXTRA RELAYS OPTION RLY3 RLY4 RLY5 RLY6 POWER INPUT – 4-20mA HEATER OPTION RLY2 RLY1 SENSOR...

-

Page 6: Keypad System

TTFM 6.1 INSTRUCTION MANUAL KEYPAD SYSTEM The diagram on page 7 shows the TTFM 6.1 menu system. Arrows show the four directions to leave a menu box. Pressing a corresponding keypad arrow will move to the next item in the direction shown. Move the cursor (highlighted) under numerals and increase or decrease numerals with the ... -

Page 7: Menu System

PULSAR MEASUREMENT MENU SYSTEM --Units/Mode-------- Mode Flow Linear Volume Multiplier Decimal Velocity ft/s Flow USG/m Decimal emperature Setup------ ------- Senso SE16B Angle 37° Fluid Water Temp Mode Fixed Temp 77.0 F Pipe 4.5000 in Wall 0.2500 in Lining... -

Page 8: Icons

TTFM 6.1 INSTRUCTION MANUAL ICONS from main page to view Message waiting. Press Data logging Data logging USB file download File download completed. Download Error. TTFM Echo OK. TTFM - Low Signal / No Echo , Empty Pipe or high Aeration TTFM - No Sensors Attached / Wrong Settings... -

Page 9: Message Icon

PULSAR MEASUREMENT MAIN DISPLAY USG/m 0.00 The Main Display shows the units selected from the Units/Mode menu, flow rate or velocity rate being measured, totalizer, totalizer multiplier, and relay states. The TTFM 6.1 will go to this display after start-up. - Page 10 TTFM 6.1 INSTRUCTION MANUAL Status (cont.) --Status------------ Velocity 0.00 ft/s Displays the expected fluid speed of sound Exp. SOS Flow 0.00 USG/m measurement, in units that match the Velocity. The Min Flow 4.00 USG/m expected speed of sound is based on the pipe, fluid, Signal Strength 100% Exp.

-

Page 11: Password

PULSAR MEASUREMENT 24 HR LOG Press from the Main Display to view a formatted flow report. Press to scroll down one day or repeatedly to scroll to a specific date. Up to 365 days will be stored. Newest date will overwrite the oldest. Press to return to the Main Display. -

Page 12: Units/Mode

TTFM 6.1 INSTRUCTION MANUAL UNITS/MODE --Units/Mode-------- Mode Flow Linear At Mode, press the and then the or to select Flow or Velocity. Flow Volume mode displays the flow rate in engineering units (e.g. gpm, litres/sec, etc.) Multiplier Decimal Press the ... - Page 13 PULSAR MEASUREMENT UNITS/MODE (cont.) --Units/Mode-------- Mode Flow Linear At Flow, press the and then the or to select the engineering units Volume for flow rate. Press to store your selection then to the next menu item.

-

Page 14: Set Up

TTFM 6.1 INSTRUCTION MANUAL SET UP Setup------ ------- Senso SE16B Angle 37° Press or to position curser at Setup, and to enter. Use or to Fluid Water position cursor before each menu item and to enter. When settings are Temp Mode Fixed Temp... - Page 15 PULSAR MEASUREMENT SET UP (cont.) Setup------ ------- Senso SE16B Angle 37° When Lining = Other, enter speed of sound of liner (consult Fluid Water factory). Temp Mode Fixed Temp 77.0 F When Lining ≠ None, enter liner thickness. Thick Pipe 4.5000 in...

- Page 16 TTFM 6.1 INSTRUCTION MANUAL SET UP (cont.) Setup------ ------- After sensor, angle, fluid, and pipe material are defined, this Senso SE16B Sens pace Angle 37° displays the calculated sensor spacing. Also called the Fluid Water separation distance. The sensors will be set to this Temp Mode Fixed dimension when installed on the pipe, as described later in...

-

Page 17: Calibration

PULSAR MEASUREMENT CALIBRATION --Calibration------- Mode Flow 20mA 500.00 USG/m Press or to position curser at Calibration menu, and to enter. Use or 0.00 USG/m to position cursor before each menu item and to enter. When settings are... - Page 18 TTFM 6.1 INSTRUCTION MANUAL CALIBRATION (cont.) --Calibration------- Mode Flow 20mA 500.00 USG/m Damping 0.00 USG/m Choose between OFF, FIR (Default), or LOW PASS. LOS Time 10 sec Mode Min Flow 4.00 USG/m Damping Mode When measured flows are outside the Window of the Percent running average, the FIR filter will reduce the damping Window...

-

Page 19: Relay Parameters

PULSAR MEASUREMENT RELAY PARAMETERS --Relay Parameters-- Relay Function Flow Press or to position curser at Relay Parameters, and to enter. Use or 1000 USG 0.000 USG to position cursor before each menu item and to enter. When settings are completed press ... -

Page 20: Data Logging

Press or to select the logging interval. Press to store Interval the setting. Pulsar Measurement recommends choosing an interval which will give you as much resolution as required and no more. Choosing too often of an interval for what is required will result in larger data files, which may take a long time to download to USB. - Page 21 Install Greyline Logger on your PC or laptop. Select File/Open/Instrument Log (.log) to open the log file from your USB flash drive. Greyline Logger Software is available for download on the Pulsar Measurement website, www.pulsarmeasurement.com/downloads. Data can also be converted to .CSV via Greyline Logger software.

-

Page 22: Communication (Optional)

Files: Communicator. The files are included in the USB drive provided with your TTFM 6.1 meter. You may also request the files from Pulsar Measurement by calling or emailing us at info@pulsarmeasurement.com. Warning: The TTFM 6.1 and associated DDs are pending certification from the Fieldcomm Group. - Page 23 PULSAR MEASUREMENT COMMUNICATION (Optional) (cont.) Choose MODBUS or HART. Protocol Device address for the TTFM. Valid range: 001-247 Address (Default: 001). This number should be unique across the (Modbus) bus. Press or to scroll, to select digits, and press ...

-

Page 24: Special Functions

TTFM 6.1 INSTRUCTION MANUAL SPECIAL FUNCTIONS --Special Functions- Language English Analog Out 4-20mA Press or to position curser at Special Functions, and to enter. Use or Backlight High to position cursor before each menu item and to enter. When settings are Reset Totalizer Neg. - Page 25 4-20mA This function should only be used when instructed by a Capture WF Backlight High Pulsar Measurement representative to do so. The Reset Totalizer Neg. Totals function captures the ultrasonic signal so that it can be Rev. Flow evaluated by Pulsar Measurement.

- Page 26 TTFM 6.1 INSTRUCTION MANUAL SIMULATION Press or to position curser at Simulation, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu. Changes made in the Simulation menu exercise the 4-20mA output, digital display and control relays.

-

Page 27: Typical Se16A Sensor Installation

PULSAR MEASUREMENT TYPICAL SE16A SENSOR INSTALLATION 2 or 4 Cross Separation Distance SEPARATION* DISTANCE Reference Transducer Transducer * Shown in Setup menu after sensor, fluid and pipe parameters are entered. ‘ ’ Separation distance is measured from transducer face to transducer face. -

Page 28: Typical Se16B Sensor Installation

TTFM 6.1 INSTRUCTION MANUAL TYPICAL SE16B SENSOR INSTALLATION 2 Cross Separation Distance SEPARATION* DISTANCE TRANSDUCER TRANSDUCER 1 Cross Separation Distance SEPARATION* DISTANCE TRANSDUCER TRANSDUCER Setup * Shown in menu after sensor, fluid and pipe parameters are entered. ‘ ’ TMK-B1 transducer mounting kit shown. Sensor spacing method is consistent with TMK-B21 and TMK-B22 kits, but the brackets will be different. -

Page 29: Typical Se16C Sensor Installation

PULSAR MEASUREMENT TYPICAL SE16C SENSOR INSTALLATION 2 Cross Separation Distance SEPARATION* DISTANCE 0 i nc h 1 Cross Separation Distance SEPARATION* DISTANCE Setup *Shown in ‘ ’ menu after sensor, fluid and pipe parameters are entered. TMK-C1 transducer mounting kit shown. Sensor spacing method is consistent with TMK-C1 or TMK-C2 kits. - Page 30 TTFM 6.1 INSTRUCTION MANUAL SE16A Pipe Preparation and Bracket Mounting Prepare an area 2" wide by 10" long (50mm x 250mm) for the track mounting bracket by removing loose paint, scale and rust. The objective of site preparation is to eliminate any discontinuity between the sensor and the pipe wall, which would prevent acoustical coupling.

- Page 31 PULSAR MEASUREMENT SE16B Pipe Preparation and Bracket Mounting Prepare an area 2" wide by 4" long (50mm x 100mm) for each sensor bonding by removing loose paint, scale and rust. The objective of site preparation is to eliminate any discontinuity between the sensor and the pipe wall, which would prevent acoustical coupling.

- Page 32 TTFM 6.1 INSTRUCTION MANUAL SE16C Pipe Preparation and Bracket Mounting Prepare an area 2" wide by 4" long (50mm x 100mm) for each sensor bonding by removing loose paint, scale and rust. The objective of site preparation is to eliminate any discontinuity between the sensor and the pipe wall, which would prevent acoustical coupling.

- Page 33 PULSAR MEASUREMENT SENSOR COUPLING For permanent bonding, the following are recommended: IMPORTANT: Coupling tape is recommended for installations where the sensors cannot easily be accessed in the future to reapply coupling compound, or in installations where the coupling compound may wear away faster than normal (>250 deg F or where submersion is frequent).

- Page 34 TTFM 6.1 INSTRUCTION MANUAL Transducer Installation in Wet Locations (SE16B and SE16A) The TTFM 6.1 Transit Time Flowmeter transducers are rated for accidental submersion up to 10 psi (0.75 bar). The flowmeter will continue to operate and measure flow accurately during periods of submergence. Plastic seal jackets on the cables, as well as the BNC connectors, must be filled with coupling compound to provide additional moisture protection for the BNC cable connectors.

-

Page 35: Sensor Mounting

PULSAR MEASUREMENT SENSOR MOUNTING LOCATION The position of the sensor is one of the most important considerations for accurate flow measurement. The same location guidelines apply to Transit Time as most other flow meter technologies. VERTICAL OR HORIZONTAL PIPE - Vertical pipe runs are acceptable, and the transducers can be mounted in any orientation around the pipe. -

Page 36: Or 4 Cross Installation Overview - Se16A Transducers Tmk-A1 Kit

TTFM 6.1 INSTRUCTION MANUAL SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given and is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 37 PULSAR MEASUREMENT 2 or 4 CROSS INSTALLATION OVERVIEW – SE16A Transducers TMK-A1 Kit (Cont.) 3. Apply a small amount of coupling compound on the first transducer and place this transducer in the “reference” position. This is the position where the face of the transducer aligns with the 0 inch or 0 mm mark on the built-in ruler.

- Page 38 TTFM 6.1 INSTRUCTION MANUAL 2 or 4 CROSS INSTALLATION OVERVIEW – SE16A Transducers TMK-A1 Kit (Cont.) 4. Apply a small amount of coupling compound on the second transducer and place this transducer at the separation distance provided in the Setup menu of the TTFM. Tighten this transducer down using the built-in tightening bracket.

-

Page 39: Or 4 Cross Installation Overview - Se16B Tmk-B1 Kit

PULSAR MEASUREMENT SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given, and it is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 40 TTFM 6.1 INSTRUCTION MANUAL 2 OR 4 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 3. Use alignment bar to ensure the brackets are parallel. Completion of steps 2 & 3 is shown below. 4. Mark the position of the permanent bracket on the pipe. This is the bracket that will not be adjusted and will be used as the reference for the separation distance and alignment.

- Page 41 PULSAR MEASUREMENT 2 OR 4 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 5. Measure the separation distance from the mark you created in step 4 and create a new mark on the pipe at the separation distance. It may be useful to mark your tape measure (included with every meter) at the separation distance point before marking the pipe.

- Page 42 TTFM 6.1 INSTRUCTION MANUAL 2 OR 4 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) Proper coupling compound or tape application: Finished installation, ready for cable connection: 7. Coupling compound only: If you need to make fine adjustments (±0.25”) to the spacing at this point, you may do so by loosening the hose clamps slightly and sliding the brackets while the transducers are installed inside them.

-

Page 43: Cross Installation Overview - Se16B Transducers Tmk-B1 Kit

PULSAR MEASUREMENT SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given, and it is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 44 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 2. Install one of the stainless steel mounting brackets on the pipe. This will be the stationary bracket not being rotated to the opposite side of the pipe. For a horizontal pipe, position the bracket at 3 or 9 o’clock. Hold the level up to the top of the bracket to ensure the angle is correct.

- Page 45 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 4. Mark the position of the bracket on the pipe. Mark both where the front of the bracket is, as well as the center of the bracket. 5. Measure the separation distance from the marks you created in step 4 and create new marks on the pipe at the separation distance.

- Page 46 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 6. Using the mylar sleeve included with the installation kit, wrap it around the pipe, keep it taut, and with the Sharpie, draw a line anywhere the sleeve overlaps: 7.

- Page 47 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) 8. Position the marked mylar back on the pipe, with the overlap marks on the center line of the transducer bracket that will be rotated to the other side of the pipe. Be sure the mylar is parallel with the face of the transducer.

- Page 48 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) Sand the pipe at this position if it needs to be prepped because of scale or rust. After prepped, move the bracket to this 1 cross mark, and tighten it in place. Apply coupling compound to the transducers and place them in the brackets: Tips for installing transducers: Be sure the red knob on the brackets are loosened completely.

- Page 49 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B1 Kit (Cont.) Finished installation: 10. Coupling compound only: If you need to make fine adjustments (±0.25”) to the spacing at this point, you may do so by loosening the hose clamps slightly and sliding the brackets while the transducers are...

-

Page 50: Or 4 Cross Installation Overview - Se16B Transducers Tmk-B21 Or Tmk-B22 Kit

TTFM 6.1 INSTRUCTION MANUAL SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given and is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 51 PULSAR MEASUREMENT 2 OR 4 CROSS INSTALLATION OVERVIEW - SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 2. Install the spacer bar onto the right bracket as shown below: 3. Insert the spacer bar into the left bracket and position the bracket at the separation distance referenced...

- Page 52 TTFM 6.1 INSTRUCTION MANUAL 2 OR 4 CROSS INSTALLATION OVERVIEW - SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 4. Place the bracket assembly on the pipe, tighten it in place with the two hose clamps: 5. Apply coupling compound to the transducers and install them in the brackets. Tips for installing transducers: Be sure the tightening Philips screw on the top of the bracket is loosened completely.

- Page 53 PULSAR MEASUREMENT 2 OR 4 CROSS INSTALLATION OVERVIEW - SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) Proper coupling compound or tape application: Finished installation, ready for cable and conduit connection: 6. Coupling compound only: If you need to make fine adjustments (±0.25”) to the spacing at this point, you may do so by loosening the hose clamps slightly and sliding the brackets while the transducers are installed inside them.

-

Page 54: Cross Installation Overview - Se16B Transducers Tmk-B21 Or Tmk-B22 Kit

TTFM 6.1 INSTRUCTION MANUAL SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given, and it is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 55 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 2. Install the spacer bar onto the right bracket as shown below: 3. Insert the spacer bar into the left bracket and position the bracket at the separation distance referenced...

- Page 56 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 4. Place the bracket assembly on the pipe, tighten it in place with the two hose clamps. For a horizontal pipe, position the bracket at 3 or 9 o’clock. Hold the level up to the top of the bracket to ensure the angle is correct.

- Page 57 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 6. Using the mylar sleeve included with the installation kit, wrap it around the pipe, keep it taut, and with the Sharpie, draw a line anywhere the sleeve overlaps: 7.

- Page 58 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 8. Position the marked mylar back on the pipe, with the overlap marks on the center line of the transducer bracket that will be rotated to the other side of the pipe. Be sure the mylar is parallel with the face of the transducer.

- Page 59 PULSAR MEASUREMENT 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) 9. Sand the pipe at this position if it needs to be prepped because of scale or rust. After prepped, move the bracket to this 1 cross mark, and tighten it in place. Apply coupling compound to the transducers and...

- Page 60 TTFM 6.1 INSTRUCTION MANUAL 1 CROSS INSTALLATION OVERVIEW – SE16B Transducers TMK-B21 or TMK-B22 Kit (Cont.) With the transducer hovering, tighten the screws on the bracket until tight. The transducer will be level with the surface of the pipe, and no coupling will have moved from inserting the transducer in the bracket.

-

Page 61: Cross Installation Overview - Se16C Transducers Tmk-C1 Or Tmk-C2 Kit

PULSAR MEASUREMENT SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given, and it is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 62 TTFM 6.1 INSTRUCTION MANUAL 3. Use the built-in alignment bar with ruler to set the bracket spacing to the separation distance provided in the Setup menu. One transducer is placed at the 0”/0mm reference position, and the other at the separation distance from the Setup menu.

- Page 63 PULSAR MEASUREMENT 4. Tighten the assembly in place with the two hose clamps 5. Apply coupling compound or tape to the transducers, insert them into the brackets, and tighten them in place with hand screws. Tips for installing transducers: Be sure the tightening screw on the top of the bracket is loosened completely before attempting to insert the transducers.

-

Page 64: Cross Installation Overview - Se16C Transducers Tmk-C1 Or Tmk-C2 Kit

TTFM 6.1 INSTRUCTION MANUAL SEPARATION DISTANCE (Sensor Spacing Distance) Separation distance is automatically calculated by the TTFM 6.1 based on parameters entered in the Setup menu. Sens Space is a parameter where this distance is given, and it is located in the Setup menu. Document this value for the following transducer installation procedure. - Page 65 PULSAR MEASUREMENT 2. Install the stainless steel mounting brackets on the pipe. Position them at approximately the correct separation distance. Exact measurement is not required at this time. Tip: Use a 5/16” nut driver to tighten the hose clamps. 3. Use the built-in alignment bar with ruler to set the bracket spacing to the separation distance provided in the Setup menu.

- Page 66 TTFM 6.1 INSTRUCTION MANUAL 4. Tighten the assembly in place with the two hose clamps. For a horizontal pipe, position the bracket at 3 or 9 o’clock. Hold the level up to the top of the bracket to ensure the angle is correct. For vertical pipes, the bracket can be at any orientation about the pipe.

- Page 67 PULSAR MEASUREMENT 6. Using the mylar sleeve included with the installation kit, wrap it around the pipe, keep it taut, and with the Sharpie, draw a line anywhere the sleeve overlaps: 7. Lay the mylar sleeve flat, and use the tape measure to measure half way between the two marks created...

- Page 68 TTFM 6.1 INSTRUCTION MANUAL 8. Position the marked mylar back on the pipe, with the overlap marks on the center line of the transducer bracket that will be rotated to the other side of the pipe. Be sure the mylar is parallel with the face of the transducer.

- Page 69 PULSAR MEASUREMENT 10. Coupling compound only: If you need to make fine adjustments (±0.25”) to the spacing at this point, you may do so by loosening the hose clamps slightly, and sliding the brackets while the transducers are installed inside them. Tighten hose clamps when done.

-

Page 70: Sensor Mounting/Coupling Recommendations

TTFM 6.1 INSTRUCTION MANUAL SENSOR MOUNTING/COUPLING RECOMMENDATIONS... -

Page 71: Enclosure Installation

PULSAR MEASUREMENT ENCLOSURE INSTALLATION Locate the enclosure within 25 ft (7.6 m) of the sensors (up to 100 ft - 30 m optional). The enclosure can be wall mounted with the four mounting screws (included) or panel mounted with Option PM Panel Mount kit from Pulsar Measurement. -

Page 72: Field Troubleshooting

Ensure 4-20mA Shield connected to Instrument Ground stud. Adjust setting. Calibration / Min Flow Contact Pulsar Measurement for further assistance. Follow Drive manufacturers wiring and Grounding instructions Variable Speed Drive interference Relocate Flowmeter electronics, Sensor and wiring away... - Page 73 Ensure 4-20mA Shield connected to Instrument Ground quality. stud. Contact Pulsar Measurement for further assistance. Laminar flow profile due to high viscosity fluid requires High viscosity fluid an adjustment to Cal Const.

- Page 74 TTFM 6.1 INSTRUCTION MANUAL SENSOR CABLE & TRANSDUCER RESISTANCE TEST Unplug the green sensor terminal from the Transit Time board with the sensor wires still connected and the BNC end of the cable is connected to the transducer. With a multimeter, perform resistance checks for each set of wires.

-

Page 75: Common Questions And Answers

PULSAR MEASUREMENT COMMON QUESTIONS AND ANSWERS The pipe vibrates. Will it affect the flow meter? Common vibration frequencies are far lower than the sonic frequencies used by the flow meter, and will not normally affect accuracy or performance. However, applications where very weak Transit Time signal is present (when sensitivity is adjusted to maximum and signal strength is low), accuracy may be affected by pipe vibration, or the flow meter may show readings under no-flow conditions. - Page 76 ISO 9000 or similar quality management systems may require periodic and verifiable recalibration of flow meters. TTFM 6.1 Flow Meters may be returned to Pulsar Measurement for factory calibration and issue of a new NIST traceable certificate. Refer to the ‘Product Return Procedure’ section of this manual for return instructions.

-

Page 77: Applications Hotline

Obtain an RMA Number from Pulsar Measurement - Before shipping a product to the factory please contact Pulsar Measurement by telephone, fax or email to obtain an RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or credit. - Page 78 If a product manufactured by Pulsar should prove defective within the first year, return it freight prepaid to Pulsar Measurement along with a copy of your invoice. This warranty does not cover damages due to improper installation or handling, acts of nature, or unauthorized service.

- Page 79 PULSAR MEASUREMENT ENCLOSURE HEATER AND THERMOSTAT - Option TH Instruments can be factory-equipped with an Enclosure Heater and Thermostat or the module can be customer- installed. The Thermostat is factory set to turn ON at 40°F (4.5°C) and OFF at 60°F (15.5°C). Power consumption is 15 Watts.

- Page 80 TTFM 6.1 INSTRUCTION MANUAL POWER INPUT OPTION 9-32VDC TTFM 6.1 Flow Meters may be ordered factory-configured for 9-32VDC power input, or a 9-32VDC Power Input card can be installed in the place of the 100-240VAC card in the field. CONNECTIONS: POWER INPUT: Connect 9-32VDC to the + and - terminals.

-

Page 81: Specifications

PULSAR MEASUREMENT SPECIFICATIONS 7.4 / 188 mm " Flow Rate Range: ±0.07 to 40 ft/sec (±0.02 6.46 / 164 mm " 5.12 / 130 mm " to 12 m/sec) Pipe Size: ½” to 48” (15 to 1200 Accuracy: ±1% of flow rate from 1.5 to 40 ft/sec, ±0.015... - Page 82 TTFM 6.1 INSTRUCTION MANUAL SE16A Transit Time Sensor Pipe Diameter: 0.5” To 6” (15 to 150 mm) Operating Temperature: -40° to 300°F (-40° to 150°C) Exposed Materials: 316SS, Ultem Operating Frequency: 2.56 MHz Sensor Cable: 25 ft (7.6 m) Optional 50 ft (15 m) or 100 ft (30 m) available, extendable up to 500 ft (150 m) with JB2X optional junction box.

- Page 83 PULSAR MEASUREMENT SE16C Transit Time Sensor Pipe Diameter: 4” to 48” (100 mm to 1200 mm) Operating Temperature: -40° to 300°F (-40° to 150°C) Exposed Materials: 316SS, Ultem Operating Frequency: 640 kHz Sensor Cable: 25 ft (7.6 m) Optional 50 ft (15 m) or 100 ft (30 m) available, extendable up to 500 ft (150 m) with JB2X optional junction box.

-

Page 84: Pipe Charts

TTFM 6.1 INSTRUCTION MANUAL PIPE CHARTS Note: Not all pipe types allowed in programming have charts below. Pipe dimensions will need to be acquired from pipe markings or the pipe manufacturer in such cases. Carbon Steel & PVC Pipe Pipe Pipe Schedule Standard Extra Heavy... - Page 85 PULSAR MEASUREMENT Stainless Steel, Hastelloy "C" & Titanium Pipe Pipe Pipe Schedule 5 S (a) Schedule 10 S (a) Schedule 40 S Schedule 80 S Size O.D. I.D. WALL I.D. WALL I.D. WALL I.D. WALL ½ 0.840 0.710 0.065 0.674 0.083...

- Page 86 TTFM 6.1 INSTRUCTION MANUAL Cast Iron Pipe - ASA Standard Pipe Pipe Class 50 Class 100 Class 150 Class 200 Class 250 Class 300 Class 350 Size O.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D.

- Page 87 PULSAR MEASUREMENT Copper Tubing Pipe Copper & Brass Pipe Aluminum Size O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL ½” 0.625 0.527 0.049 0.625 0.545 0.040 0.625 0.569 0.028 ¾” 0.875 0.745 0.065 0.875...

- Page 88 TTFM 6.1 INSTRUCTION MANUAL C900/C905 PVC AWWA Water Distribution Pipe (Blue) DR14 DR18 DR-21 DR25 Pipe Size Wall Wall Wall Wall 4.80 0.343 4.114 0.267 4.266 0.192 4.416 6.90 0.493 5.914 0.383 6.134 0.276 6.348 9.05 0.646 7.758 0.503 8.044 0.362 8.326 11.10...

-

Page 89: Appendix C - Liquid Speed Of Sound

PULSAR MEASUREMENT APPENDIX C – Liquid Speed of Sound Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Acetic anhydride (22) 1.082 (20ºC) 1180 Acetic acid, anhydride (22) 1.082 (20ºC) 1180 Acetic acid, nitrile 0.783 1290 Acetic acid, ethyl ester (33) 0.901... - Page 90 TTFM 6.1 INSTRUCTION MANUAL Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Carbitol 0.988 1458 Carbon dioxide (26) 1.101 (-37ºC) 7.71 Carbon disulphide 1.261 (22ºC) 1149 Carbon tetrachloride(33,35,47) 1.595 (20ºC) 2.48 Carbon tetrafluoride (14) 1.75 (-150ºC) 875.2 6.61 Cetane (23)

- Page 91 PULSAR MEASUREMENT Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Diethylenimide oxide 1.00 1442 1,2-bis(DiFluoramino) butane (43) 1.216 1000 1,2bis(DiFluoramino)- 2-methylpropane 1.213 (43) 1,2bis(DiFluoramino) propane (43) 1.265 2,2bis(DiFluoramino) propane (43) 1.254 2,2-Dihydroxydiethyl ether 1.116 1586 Dihydroxyethane 1.113...

- Page 92 TTFM 6.1 INSTRUCTION MANUAL Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Formic acid, amide 1.134 (20ºC) 1622 Freon R12 Furfural 1.157 1444 Furfuryl alcohol 1.135 1450 Fural 1.157 1444 2-Furaldehyde 1.157 1444 2-Furancarboxaldehyde 1.157 1444 2-Furyl-Methanol 1.135 1450...

- Page 93 PULSAR MEASUREMENT Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Mesityloxide 0.85 1310 Methane (25,28,38,39) 0.162 405(-89.15ºC) 17.5 Methanol (40,41) 0.791 (20ºC) 1076 2.92 Methyl acetate 0.934 1211 o-Methylaniline (46) 0.999 (20ºC) 1618 4-Methylaniline (46) 0.966 (45ºC)

- Page 94 TTFM 6.1 INSTRUCTION MANUAL Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Oil (Sperm) 0.88 1440 Oil, 6 1509 2,2-Oxydiethanol 1.116 1586 Oxygen (45) 1.155 (-186ºC) Pentachloro-ethane (47) 1.687 1082 Pentalin (47) 1.687 1082 Pentane (36) 0.626 (20ºC) 1020 n-Pentane (47)

- Page 95 PULSAR MEASUREMENT Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. Pyridine 0.982 1415 Refrigerant 11 (3,4) 1.49 828.3 3.56 Refrigerant 12 (3) 1.516 (-40ºC) 774.1 4.24 Refrigerant 14 (14) 1.75 (-150ºC) 875.24 6.61 Refrigerant 21 (3) CHCl 1.426 (0ºC)

- Page 96 TTFM 6.1 INSTRUCTION MANUAL Substance Form Index Specific Gravity Sound Speed v/°C - m/s/°C Δ m/sec. 1,1,1-Trifluoro-2-Chloro-2-Bromo-Ethane HClBrF 1.869 1,2,2-Trifluorotrichloro- ethane (Freon 113) F-CClF 1.563 783.7 3.44 d-1,3,3-Trimethylnor- camphor 0.947 1320 Trinitrotoluene (43) 1.64 1610 Turpentine 0.88 1255 Unisis 800 0.87 1346 Water, distilled (49,50)

- Page 97 PULSAR MEASUREMENT Appendix D Sonic Velocity Relative to Temperature of Pure Water Temp °F Temp °C Velocity ft/s Temp °F Temp °C Velocity ft/s Temp °F Temp °C Velocity ft/s -17.8 4240 100.0 37.8 5003 200.0 93.3 5080 -16.7 4267 102.0...

- Page 98 TTFM 6.1 INSTRUCTION MANUAL Sonic Velocity Relative to Temperature of Pure Water Temp °F Temp °C Velocity m/s Temp °F Temp °C Velocity m/s Temp °F Temp °C Velocity m/s -17.8 1292.45 100.0 37.8 1525.03 200.0 93.3 1548.38 -16.7 1300.64 102.0 38.9 1526.99...

- Page 99 PULSAR MEASUREMENT...

- Page 100 TTFM 6.1 INSTRUCTION MANUAL www.pulsarmeasurement.com service@pulsarmeasurement.com Copyright © 2020 Pulsar Measurement Ltd.. Registered Address: 1 Chamberlain Square CS, Birmingham B3 3AX Registered No.: 3345604 England & Wales Rev 2.0...

Need help?

Do you have a question about the Greyline TTFM 6.1 and is the answer not in the manual?

Questions and answers