Advertisement

Quick Links

The Thermal Conductivity Detector (TCD) is the most universal detector available. Depending on the

compound, the TCD responds with a detection range of 0.01% to 100% (100-1,000,000ppm). The SRI

TCD consists of four filaments housed in a stainless steel detector block. The TCD detector block is installed

in its own thermostatically-controlled oven for stability. The TCD oven is mounted on the right rear of the

column oven. The TCD filament control switch and the bridge terminal block to which the filament leads are

connected are located to the immediate right of the detector oven. Since the four TCD filaments can be

damaged or destroyed if energized in the absence of carrier gas flow, a TCD filament protection circuit is

provided in all TCD-equipped SRI GCs.

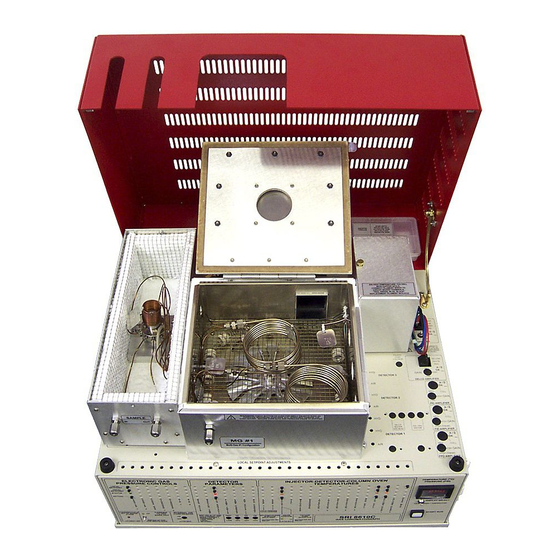

TCD Detector on an SRI GC

Overview

TCD Detector on

an SRI 310 GC

TCD detector oven setpoint (trimpot)

Color-coded TCD

filament leads are

connected to the

bridge terminal block

TCD filament current

control switch

Thermal Conductivity Detector - TCD

TCD detector

body

Insulation

TCD detector

housing

Color-coded

filament leads

DETECTORS

TCD Detector

(paired with an

FID detector) on

an SRI 8610 GC

TCD Detector on an SRI GC with

detector cover and top/front

insulation removed for clarity

Advertisement

Summary of Contents for Sri TCD

- Page 1 TCD responds with a detection range of 0.01% to 100% (100-1,000,000ppm). The SRI TCD consists of four filaments housed in a stainless steel detector block. The TCD detector block is installed in its own thermostatically-controlled oven for stability. The TCD oven is mounted on the right rear of the column oven.

- Page 2 Electronic Pressure Controller module, flows through the polishing filter, through the reference side of the TCD bridge, then through the injection port to the column, and from the column to the sample side of the TCD bridge. After the flow passes through the sample cell, it is directed back out of the TCD oven and into the column oven through the TCD detector outlet, where it may be routed to a subsequent detector or to vent.

-

Page 3: Thermal Conductivity Detector - Tcd

Initial Hold Ramp Final 15.00 0.00 TCD noise averages 10µV frompeak to peak Factory Test Run of a TCD-equipped SRI GC Sample: natural gas standard, 1mL sample loop Columns: 1m Molecular Sieve, 2m Silica Gel Events: Time Event 0.00 ZERO 0.050... - Page 4 DETECTORS Thermal Conductivity Detector - TCD Expected Performance TCD Room Air Analysis Column: 3’ Silica Gel Carrier: Helium at 10mL/min Sample: 0.5cc room air, direct injection TCD current: LOW TCD temperature: 100 Temperature Program: Initial Hold Ramp Final 4.00 0.00...

-

Page 5: General Operating Procedure

Thermal Conductivity Detector - TCD General Operating Procedure 1. Check to make sure that the TCD filament current is switched OFF. Plug in and turn on your GC. Allow the TCD detector oven to reach temperature (100 C) and stabilize. With the “Display Select” switch in the UP position, press on the TCD Temperature Actual button on the front control panel to read the TCD cell temperature. - Page 6 3.5 to 4.5 volts is typical when using high current; low current will display 2.5-3.5 volts (note: the LED displays 4 volts as “400,” 3.5 as “350,” etc.). Any value lower than these indicates a potential problem in the TCD...

- Page 7 SRI TCD detector replacement parts Standard TCD filament with rubber O-ring gasket 8670-9120 High temperature TCD filament with copper gasket 8690-9123 (filament part #s are also listed on the top of the TCD oven in your SRI GC)

- Page 8 Thermal Conductivity Detector - TCD Replacing the TCD Filaments SRI TCD detectors are made to last a long time without ever replacing the filaments. However, any TCD filaments that fail the diagnostic ohmeter test mentioned previously will have to be replaced. While they share the same outer assembly, there are a few differences between the high temperature TCD detector block and the standard TCD block.

- Page 9 Gently remove the white insulation to reveal the detector block. 6. The TCD filaments are secured in the detector block by two plates, each of which is held in place with three hexagonal head screws. Holding the detector block with one hand, use an Allen wrench to unscrew and remove the hexagonal head screws from one of the filament securing plates.

- Page 10 B. High temperature TCD detector block access The high temperature TCD assembly is the same as the standard: outer housing around an inner clamshell case. The high temp detector block uses gland nuts and copper gaskets to secure the four filaments in its two cells.

- Page 11 Secure the clamshell with its two screws. 8. Reconnect the TCD detector gas inlets and outlets. 9. Replace the inner clamshell and its insulation inside the detector housing that is permanently mounted on the column oven wall.

Need help?

Do you have a question about the TCD and is the answer not in the manual?

Questions and answers