Summary of Contents for SPX Cooling Technologies MARLEY Geareducer Series

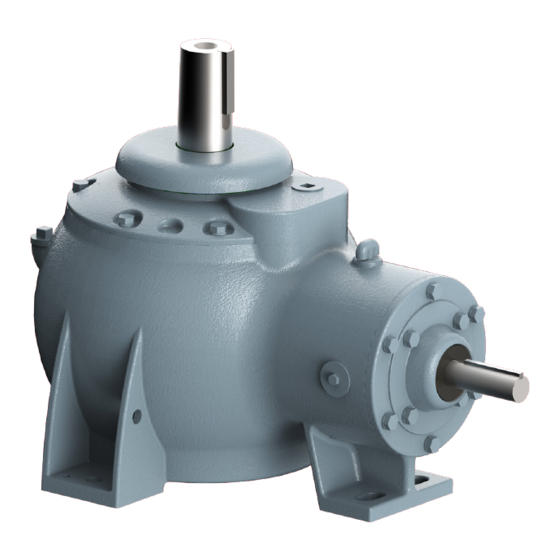

- Page 1 u s e r m a n u a l Geareducer models 1800 - 2000 ® O P E R AT I O N - M A I N T E N A N C E – R E PA I R Z0493651_A ISSUED 02/2017 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT...

-

Page 3: Protection Against Corrosion

operation and service instructions Oil Level Check and Fill Vent Drain Plug Figure 1 Service Fittings Protection Against Corrosion Initial Operation Geareducer® units ship from the factory with a protective coating of Check to be sure that the Geareducer is filled with oil and that epoxy enamel paint on all unmachined parts and with rust-proofing there are no visible oil leaks. - Page 4 operation and service instructions Lubricants If lubricants other than Marley factory lubricants are used, they must not contain any additives (such as detergents or EP additives) which To insure maximum performance and service life, it is recommended are adversely affected by moisture and could reduce the service Marley factory lubricants be used in all Marley Geareducers.

-

Page 5: Scheduled Maintenance

operation and service instructions Scheduled Maintenance Protection Against Corrosion Warning—Make certain that mechanical equipment is inoperable Check Geareducer exterior yearly and touch up with epoxy paint if during periods of maintenance—or during any situation of possible required. If your Geareducer is equipped with an oil gauge and drain endangerment to personnel. -

Page 6: Parts List

parts list WATER SLINGER BEARING RETAINER DOWEL PIN COVER AIR VENT GEAREDUCER CASE PINION CAGE PINION CAGE BOTTOM CAP Figure 2... - Page 7 parts list Complete Geareducer Assembly. Ring Gear Hub. 100 Spiral Bevel Gear Set. 101 Set of matched spiral bevel gears including integral pinion shaft with key. Gear ratios as follows: 4.80 to 1 3.75 to 1 2.71 to 1 4.09 to 1 3.27 to 1 5.375 to 1 102 Ring gear attaching hardware.

-

Page 8: Field Repair

field repair General Pinion Cage Disassembly Remove pinion cage cap* from pinion cage. Geareducers can be repaired in the field—however, major repairs require the use of a fully equipped machine shop. When field repair Remove O-rings* (503 and 504). or replacement of parts is necessary, the following procedure is Slide seal off of pinion shaft and remove O-ring (505). - Page 9 field repair Assembly Install locknuts and lockwasher (103 and 104). Tighten nuts Before assembling a new pinion gear in the pinion cage, check on bearing cone until 5 to 15 in·lbƒ (565-1695 mN·m) of match numbers on pinion gear and spiral bevel ring gear to be bearing preload is obtained.

- Page 10 field repair Installation of Fan Shaft Gear Setting Procedure Press ring gear hub (5) and the upper and lower bearing The proper mounting of the gear set is essential to obtain long cones (411 and 412) on the fan shaft (201). Install ring gear life and smooth operation of the gears.

-

Page 11: Final Assembly

field repair Final Assembly Remove bottom cap and apply a bead of sealant to the bottom cap flange inboard of the bolt holes. Reinstall the bottom bearing retainer cap and tighten the cap screws to 20 ft·lbƒ (27 N·m). Install O-ring (502) in water slinger. Install water slinger on fan shaft (201). - Page 12 Geareducer U S E R M A N UA L SPX COOLING TECHNOLOGIES, INC. 7401 WEST 129 STREET Z0493651_A (M00-1218C) ISSUED 02/2017 OVERLAND PARK, KS 66213 USA COPYRIGHT © 2017 SPX CORPORATION In the interest of technological progress, all products are subject to design 913 664 7400 | spxcooling@spx.com...

Need help?

Do you have a question about the MARLEY Geareducer Series and is the answer not in the manual?

Questions and answers