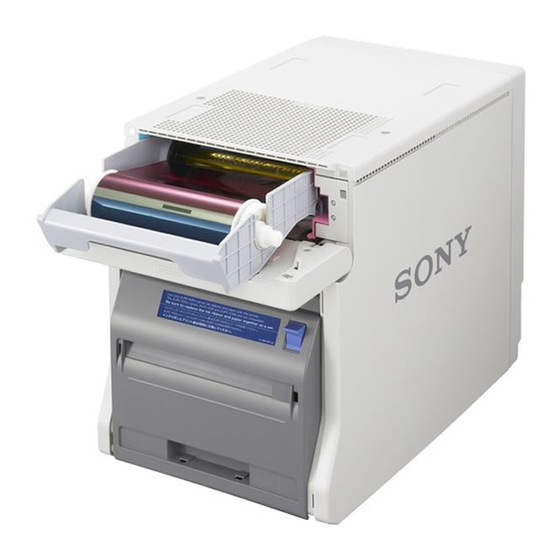

Sony UP-DR200 Service Manual

Digital photo printer

Hide thumbs

Also See for UP-DR200:

- Brochure & specs (16 pages) ,

- Specifications (2 pages) ,

- Operating instructions manual (31 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sony UP-DR200

- Page 1 DIGITAL PHOTO PRINTER UP-DR200 SERVICE MANUAL 1st Edition...

- Page 2 Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres. Pour toute réparation faire appel à une personne compétente uniquement. UP-DR200...

-

Page 3: Table Of Contents

4-6-2. Head Home Sensor and Head Position Sensor ..4-4 1-7. Cleaning the Interior ............. 1-24 4-6-3. Head arm Home Sensor and 1-8. Recommended Power Cord .......... 1-27 Head Arm Position Sensor ........4-5 1-9. Unleaded Solder ............1-27 UP-DR200... - Page 4 Error Contents and Possible Causes ....... 6-2 6-3. Error Log (ERROR LOG) Information ......6-9 6-4. Printing Image Defects ..........6-10 7. Spare Parts 7-1. Notes on Repair Parts ............1 7-2. Exploded Views ..............2 7-3. Packing Materials & Supplied Accessories ..... 23 UP-DR200...

-

Page 5: Manual Structure

Manual Structure Purpose of this manual This manual is the Service Manual of the Digital Photo Printer UP-DR200. This manual contains the installation, service overview, adjustment for parts replace- ment, mechanical operation description, circuit description, service mode, trouble- shooting, spare parts, block diagrams, and frame wiring. -

Page 7: Service Overview

MA-168 board CN-3049 board SE-934 board MEC-36 board KY-632 board SU-135 board SE-936 board SE-931 board SU-137 board LE-351 board SE-926 board SU-134 board SE-928 board SE-933 board SU-138 board SE-929 board SE-935 board SE-930 board LE-350 board SE-932 board UP-DR200... -

Page 8: Main Parts And Sensor Location

Cutter unit Supply motor Paper path sensor Supply sensor Head position sensor Ribbon mark sensor Takeup sensor Paper door sensor Pinch position sensor Head arm position sensor Paper edge sensor Paper FG sensor Paper size sensor Ribbon door sensor UP-DR200... -

Page 9: Removing/Installing The Cabinet

3. Remove the stepped screw, then remove the side panel (R) assembly in the direction of the arrow. 3. Attach the top panel assembly in the reverse order of Stepped screw steps 1 and 2. Side panel (R) assembly UP-DR200... -

Page 10: Rear Panel Assembly

BVTT3 x 6 Stepped screws Rear panel assembly Harnesses Harnesses Harnesses 5. Install the MEC-36 board in the reverse order of steps 1 to 4. Stepped screws 2. Attach the rear panel assembly in the reverse order. UP-DR200... -

Page 11: Board

KY-632 board 5. Install the MA-168 board in the reverse order of steps 1 to 4. BVTT 3 x 6 Flexible flat cable CN101 7. Install the KY-632 board in the reverse order of steps 1 to 6. UP-DR200... -

Page 12: Replacing The Main Parts

4. Disconnect the harness from the connector (CN421) MA-168 on the SE-934 board. board Harness CN421 SE-934 board Ribbon door Hook Heat sink block lock cover assembly BVTT3 x 6 5. Install the SE-934 board in the reverse order of steps 1 to 4. UP-DR200... -

Page 13: Paper Door Assembly

Paper door assembly ribbon roller (CH). 6. Attach the paper door assembly in the reverse order of Ribbon roller (CH) steps 1 to 5. Discharging brush Paper eject guide cover UP-DR200... -

Page 14: Paper Holder (Main) Assembly

. When removing the paper holder (main) assembly, make sure that the door lock cam position is as shown in the illustration. UP-DR200... -

Page 15: Ribbon Door Lock Assembly

4. Disconnect the harness from the connector (CN242) Pinch motor assembly 3 x 6 on the SU-138 board. 5. Remove the four screws, then remove the cutter unit. 7. Attach the pinch motor assembly in the reverse order of steps 1 to 6. UP-DR200... -

Page 16: Supply Drive Assembly

14. Attach the supply drive assembly in the reverse order Rail cover of steps 1 to 13. BVTT 3 x 6 Harness CN241 Harness SU-138 board CN242 E2.3 E2.3 Bearing flanges E2.3 Brake link lever subassembly *1: Bearing flange *2: Bearing (630) Bearing (630) 1-10 UP-DR200... -

Page 17: Takeup Drive Assembly

Harness PS2.6 x 5 Takeup drive assembly BVTT 3 x 6 13. Attach the takeup drive assembly in the reverse order of steps 1 to 12. Takeup drive assembly Parallel pin Cam drive gear E3.0 Worm gear E3.0 1-11 UP-DR200... -

Page 18: Paper Eject Guide Assembly

3 x 6 CN462 CN-3049 board CN464 11. Attach the paper eject guide assembly in the reverse order of steps 1 to 10. 11. Attach the paper holder stay assembly in the reverse order of steps 1 to 10. 1-12 UP-DR200... -

Page 19: Vertical Guide Assembly

(R) flanges Helical extension CN431 spring E5.0 SE-935 board Harness E2.3 Parallel pins Bearing (630) E2.3 BVTT 3 x 6 Bearing Paper drive gear E2.3 flange Return roller gear Bearing (630) Bearing flange Paper feed plate (R) subassembly 1-13 UP-DR200... - Page 20 Paper feed plate (L) subassembly Bearing flange Paper feed roller E2.3 Helical E2.3 extension E2.3 spring E2.3 Paper feed roller bracket (L) Bearing flanges Paper lever shaft Bearing (630) Bearing flange Helical extension spring Paper levers Helical extension spring 1-14 UP-DR200...

-

Page 21: Return Guide Assembly

Bearing (6) SE-929 board 30. Attach the vertical guide assembly in the reverse order of steps 1 to 29. Bearing (6) Return guide assembly 14. Attach the return guide assembly in the reverse order of steps 1 to 13. 1-15 UP-DR200... -

Page 22: Platen Roller

9. Remove the two helical extension springs. extension spring 10. Remove the platen roller in the direction of the arrow. 11. Remove the four ball bearings from the platen roller. 12. Attach the platen roller in the reverse order of steps 1 to 11. 1-16 UP-DR200... -

Page 23: Capstan Roller

13. Attach the capstan roller in the reverse order of steps 1 pulley and parallel pin. to 12. 10. Remove the capstan spacer. 11. Remove the capstan roller in the direction of the arrow. 12. Remove the helical compression spring and two ball bearings from the capstan roller. 1-17 UP-DR200... -

Page 24: Pinch Roller

16. Remove the two snap rings, then remove the pinch roller assembly in the direction of the arrow. Bearing flange (7) Pinch roller E3.0 Ball bearing 18. Attach the pinch roller in the reverse order of steps 1 to 17. 1-18 UP-DR200... -

Page 25: Stepping Motor

. Before replacing the thermal head, be sure to check Section 2-1. 5. Attach the thermal head in the reverse order of steps 1 . Perform the cleaning of the thermal head periodically. to 4. (Refer to Section 1-7.) 1-19 UP-DR200... -

Page 26: Head Unit Assembly

SE-928 board Flexible flat cable E4.0 Bearing (6) MA-168 board 14. Attach the head unit assembly in the reverse order of CN901 steps 1 to 13. MEC-36 board CN15 CN13 Harnesses CN12 BVTT 3 x 6 CN201 Switching regulator 1-20 UP-DR200... -

Page 27: Pinch Cam/Head Cam

15. Attach the pinch cam and head cam in the reverse head cam (R) and parallel pin. order of steps 1 to 14. 14. Remove the two hooks, then remove the pinch cam (R), head cam (R) and parallel pin. 1-21 UP-DR200... -

Page 28: Switching Regulator

BVTT 3 x 6 Rear foot chassis PSW4 x 8 Ground wire Harness Harnesses CN101 Switching regulator CN201 CN202 CN203 BVTT 3 x 6 6. Attach the switching regulator in the reverse order of steps 1 to 5. 1-22 UP-DR200... -

Page 29: Dc Fan (For Inside)

6. Attach the DC fans (for inside) in the reverse order of steps 1 to 5. BVTT DC fans 3 x 10 Label side 6. Attach the DC fans (thermal head) in the reverse order of steps 1 to 5. 1-23 UP-DR200... -

Page 30: Filter

. As the cleaning sheet in not reusable, discard it after the first use. . If there is insufficient print paper remaining, an error may occur. If this occurs, replace the print paper and begin the cleaning process again. 1-24 UP-DR200... - Page 31 Affix the cleaning sheet vertically. To continue with roller cleaning, proceed to step 6. To end the cleaning process here, press the 7 button. The print paper used will be cut and ejected. Proceed to step 11. 1-25 UP-DR200...

- Page 32 After cleaning is finished, make sure that the cleaning sheet is completely ejected. If any part of the cleaning sheet remains, cut off all portions of the print paper on which the cleaning sheet is still affixed before further operation. 1-26 UP-DR200...

-

Page 33: Recommended Power Cord

This unit does not come with a power cord. Boards requiring use of unleaded solder are printed with a To get a power cord, please contact your local Sony Sales lead free mark (LF) indicating the solder contains no lead. -

Page 35: Adjustment For Parts Replacement

(3) Press the ←, →, ←, →, and EXEC keys 10. Turn off the power of this unit. 11. Replace the thermal head. (Refer to Section 1-6-17.) sequentially and check that “0” is displayed in the lower-right position of the LCD screen. UP-DR200... -

Page 36: Thermal Head Position Adjustment

1. Using a flat-bladed screwdriver, turn the protrusion of an adjustment frame to the take-up side by one scale until it is locked. 2. Adjust the head position adjustment mechanism on the opposite side in the same way as described above. UP-DR200... -

Page 37: Ribbon Mark Sensor (Le-352/Se-934 Board)

11. Press the MENU key when “READY” is displayed. 12. Select “<PRINT>” using ← and → keys. 14. Press the EXEC key and check printing. 13. Select an arbitrary pattern using ↑ and ↓ keys. 14. Press the EXEC key and check printing. UP-DR200... -

Page 38: Board

(4) Adjust the voltage of a thermal head using ← and Press the ← and → keys continuously until “S” is → keys. displayed in the upper-right position of the LCD (5) Press the EXEC key and print a test pattern (16 screen. STEP). UP-DR200... - Page 39 1. Connect this unit and PC using a USB cable. 2. Turn on the power of this unit. 3. Download the latest firmware to PC from the homep- age of Sony. URL: http://www.sony.net/Products/DP-driver/index.html 4. Double-click the downloaded file and upgrade the firmware according to the message on the screen.

-

Page 41: Mechanical Operation Description

IC tag. Initialization of cutter Thermal head moves Tag information of ribbon is read. to the print position. Pinch roller FEED Pinch roller and thermal head Plunger OFF move to the standby position. UP-DR200... -

Page 42: Print Operation

IC tag position of the pinch roller Ribbon Y cueing Paper is fed by cutting length & ribbon tag writing Paper is fed to the paper edge sensor. Moving to the pinch roller print position & second cutting Paper is fed to the print position. UP-DR200... -

Page 43: Main Parts Constitution

DC fan (for inside) Pinch roller Ribbon Ribbon door Paper feed roller Head unit Cutter unit Return roller DC fan (thermal head) Paper exit Switching regulator 6 !- MEC-36 board Roll paper Power switch 7

Need help?

Do you have a question about the UP-DR200 and is the answer not in the manual?

Questions and answers