Table of Contents

Advertisement

Models

15B-060K

15B-095K

15B-120K

15B-150K

15B-175K

15B-205K

15B-235K

C.S.A. Certified

For Natural Gas Or Propane

15B-K

Cast Iron Gas Fired Boilers

For Forced Hot Water

With Honeywell Control

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

Tested For 50 psi

ASME

Working Pressure

Manufactured by:

ECR International Inc.

2201 Dwyer Avenue, Utica, NY 13501

Tel. 800 325-5479

www.ecrinternational.com

PN 240012786 REV. C [11/15/2020]

Advertisement

Table of Contents

Summary of Contents for PENNCO 15B-060K

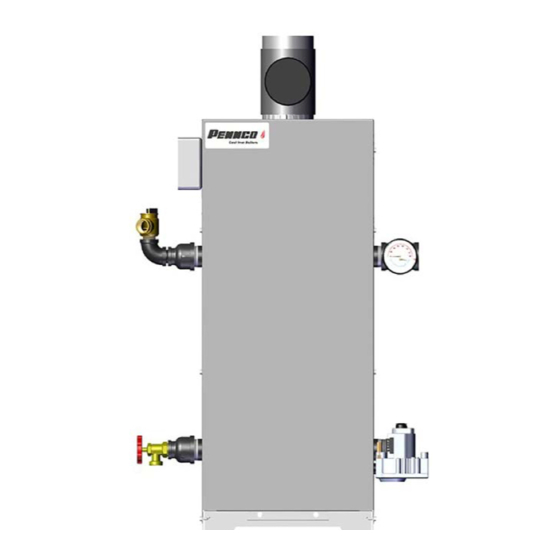

- Page 1 15B-K Cast Iron Gas Fired Boilers For Forced Hot Water With Honeywell Control INSTALLATION, OPERATION & MAINTENANCE MANUAL Models 15B-060K 15B-095K 15B-120K 15B-150K 15B-175K 15B-205K 15B-235K C.S.A. Certified Tested For 50 psi For Natural Gas Or Propane ASME Working Pressure Manufactured by: ECR International Inc.

- Page 2 VERIFY CONTENTS RECEIVED Fully Assembled Boiler Vent Damper Draft Hood Pump (Optional) *Black Iron Fittings *Drain Valve *ASME Safety Relief Valve *Tridicator (see parts list for sizes and use) Includes Essential Documents and Warranty 11x17 Wire Diagrams Document Package *Circulator Harness *Junction Box * Items found in parts box included with your boiler.

-

Page 3: Table Of Contents

TABLE OF CONTENTS 1 - Physical Data ........................4 2 - Safety Symbols And Warnings ....................5 3 - Locating The Boiler ......................7 3.1 Installation Requirements ....................7 3.2 Minimum Clearances To Combustible Construction ..............7 3.3 Recommended Clearances For Service ................. 7 3.3 Boiler Location Considerations .................... -

Page 4: Physical Data

1 - PHYSICAL DATA Model 15B-060K 15B-095K 15B-120K 15B-150K 15B-175K 15B-205K 15B-235K # Sections 13-³/8" 13-³/8" 16-1/4" 19" 21-7/8" 27-¹/2" 27-¹/2" A Width (Jacket) 700 mm 700 mm 340 mm 340 mm 411 mm 483 mm 555 mm 22" 27 -3/4"... -

Page 5: Safety Symbols And Warnings

2 - SAFETY SYMBOLS AND WARNINGS FOR YOUR SAFETY READ BEFORE OPERATING 2.1. Safety Information DANGER Boiler installation shall be completed by qualified agency. WARNING Fire, explosion, asphyxiation and electrical shock hazard. Improper installation could result in death or serious injury. Read this manual and understand all requirements before beginning installation. - Page 6 2 - SAFETY SYMBOLS AND WARNINGS WARNING WARNING Combustion chamber insulation in this product Fire, Explosion, Asphyxiation, Electrical shock contains ceramic fiber material. Ceramic fibers hazard! Flooding will result in damages such as can be converted to cristobalite in very high electrical problems, corrosion, inoperative parts, temperature applications.

-

Page 7: Locating The Boiler

3 - LOCATING THE BOILER 3.2 Minimum Clearances to Combustible WARNING Construction Fire hazard! Do not install boiler on carpeting. Minimum clearances to combustible construction are: Failure to follow these instructions could result in death or serious injury. 10 inches (254 mm) Front Alcove* CAUTION... -

Page 8: Boiler Location Considerations

3 - LOCATING THE BOILER 3.3 Boiler Location Considerations • System piping exposed to freezing conditions: Use • Ambient room temperature always above 32°F (0°C) to inhibited propylene glycol solutions certified by fluid prevent the potential of freezing. manufacturer for use with closed water heating system. Do not use automotive or ethylene glycol. -

Page 9: Connecting Supply & Return Piping

4 - CONNECTING SUPPLY & RETURN PIPING 4.1 Connection Locations 4.2 Safety Relief Valve Installation See Figure 4-1 • Boiler has one supply and one return tapping on each side (4 total). Boiler supplied with dust caps only. Discharge line shall be installed to relief valve outlet Remove all four (4) caps and plumb before filling boiler connection to avoid burns, scalding, or water damage due with water. -

Page 10: Flush And Rinse System

4 - CONNECTING SUPPLY & RETURN PIPING 4.4 Water Treatment WARNING Manufacturer recommends a water analysis be done on • Poison hazard. Ethylene glycol is toxic. Do not water used to fill the system. Treatment may be required use ethylene glycol. based on the analysis results. -

Page 11: Supply And Return Requirements

4 - CONNECTING SUPPLY & RETURN PIPING 4.5 Supply and Return Requirements Installation using circulators and zone valves are shown in Figures 4-2 through 4-7. For further piping Boiler used in connection with refrigeration system, information refer to AHRI Installation and Piping install so chilled medium is piped in parallel with boiler Guide. - Page 12 4 - CONNECTING SUPPLY & RETURN PIPING • Boiler installed above radiation level (or as required Do not expose boiler and piping to freezing by authority having jurisdiction). Integral low water Note temperatures. switch is provided in boiler. • Boiler used in connection with refrigeration system. 4.6 Special Conditions Install piping in parallel with boiler, with appropriate valves to prevent chilled medium from entering boiler.

- Page 13 4 - CONNECTING SUPPLY & RETURN PIPING PIPING LEGEND: BACK FLOW VALVE Figure 4-3 - Bypass Piping With Automatic Mixing Valve PURGE VALVE Back Flow Valve ASME RELIEF VALVE DRAIN VALVE PN 240012786, Rev. C [11/15/2020]...

- Page 14 4 - CONNECTING SUPPLY & RETURN PIPING PIPING LEGEND: BACK FLOW VALVE Figure 4-4 - Bypass Piping - Fixed Low Temp Only With Zone Valve ASME RELIEF VALVE Drain Valve Drain Valve Manually adjust until proper system temperature is reached. PN 240012786, Rev.

- Page 15 4 - CONNECTING SUPPLY AND RETURN PIPING PIPING LEGEND: BACK FLOW VALVE Figure 4-5 - Bypass Piping (4-Way Valve Option With Circulator On Supply side) Back Flow Valve ASME RELIEF VALVE Drain Valve PN 240012786, Rev. C [11/15/2020]...

- Page 16 4 - CONNECTING SUPPLY AND RETURN PIPING PIPING LEGEND: BACK FLOW VALVE Figure 4-6 - Single Zone System With DHW Priority Back Flow Valve ASME RELIEF VALVE Purge Drain Valve Valve PN 240012786, Rev. C [11/15/2020]...

- Page 17 4 - CONNECTING SUPPLY AND RETURN PIPING PIPING LEGEND: BACK FLOW VALVE Figure 4-7 - Multi Zone System With Zone Valves And DHW Priority (With Zone Valve) * Hot Water Supply Tempered Tank Sensor Optional Indirect DHW Tank T & P Relief Cold Valve to Water...

-

Page 18: Ventilation & Combustion Air

5 - VENTILATION & COMBUSTION AIR 5.1 Requirements B. Known Air Infiltration Rate. See Table 5-1 for space with boiler only. Use equation for multiple WARNING appliances. Do not use an air infiltration rate (ACH) Asphyxiation Hazard! Provide enough air openings greater than 0.60. -

Page 19: Vent System Modification

6 - VENT SYSTEM MODIFICATION 6.1 Removal Of Existing Boiler From Venting System Typical Masonry Chimney Requirements Figure 6-1 - When an existing boiler is removed from a common venting system, the system is likely too large for proper venting of appliances still connected to it. -

Page 20: Vent Installation

7 - VENT INSTALLATION Boiler series is classified as a Category I. Vent WARNING installation shall be in accordance with "Venting of Equipment," of the National Fuel Gas Code, ANSI Boiler and venting installations shall be performed Z223.1/NFPA 54, or "Venting Systems and Air Supply by a qualified expert and in accordance with the for Appliances,"... -

Page 21: Vent Damper Installation & Instructions

8 - VENT DAMPER INSTALLATION & INSTRUCTIONS 8.1 Vent Damper Fasten sections of vent pipe with sheet metal screws to make piping rigid. Support horizontal potions of vent Connecting The Vent Damper And Vent Connector system to prevent sagging. Use stovepipe wires every 5’ to Refer to page 4 for size and location of vent (flue opening). - Page 22 8 - VENT DAMPER INSTALLATION & INSTRUCTIONS Figure 8-2 - Vent Damper Placement Figure 8-3 - Vent Damper Position Indicator PN 240012786, Rev. C [11/15/2020]...

-

Page 23: Connecting Gas Service

9 - CONNECTING GAS SERVICE DANGER Table 9-1 Natural Gas Propane Min. Supply Pressure 5" w.c. 11" w.c. Fire Hazard. Do not use matches, candles, open flames, or other methods providing ignition source. Max. Supply Pressure 13.5" w.c. 13.5" w.c. Failure to comply will result in death or serious 10"... -

Page 24: Electrical

10 - ELECTRICAL WARNING Electrical shock hazard. Turn OFF electrical power supply at service panel before making electrical connections. Failure to do so could result in death or serious injury. 10.1 Electrical Wiring See wiring diagrams on the following pages for details. -

Page 25: Wiring Diagram

11 - WIRING DIAGRAM WARNING Modification, substitution or elimination of factory equipped, supplied or specified components may result in personal injury or loss of life. Figure 11-1 - Integrated High Limit & Electronic Ignition Control PN 240012786, Rev. C [11/15/2020]... - Page 26 11 - WIRING DIAGRAM Figure 11-2 - Integrated High Limit & Electronic Ignition Control PN 240012786, Rev. C [11/15/2020]...

-

Page 27: Lighting Instructions

12 - LIGHTING INSTRUCTIONS 12.2 Operating Instructions For Intermittent WARNING Pilot System If you do not follow these instructions STOP! Read the safety information to the left. exactly, a fire or explosion may result Set the thermostat to lowest setting. causing property damage, personal injury or loss of life. -

Page 28: Normal Sequence Of Operation

13 - NORMAL SEQUENCE OF OPERATION A. Power remains off until boiler water temperature WARNING drops below high limit setting. Burn Hazard. View port on burner door may be hot. B. Circulator continues to operate under this condition Wear personal protection when servicing this boiler. until thermostat is satisfied. -

Page 29: General Maintenance And Care Instructions

14 - GENERAL MAINTENANCE AND CARE INSTRUCTIONS 14.2 Clean Flue Gas Passageways WARNING Label all wires prior to disconnection when servicing Follow this procedure to clean flue gas passageways: controls. Wiring errors could cause improper and Remove burner tray from heat exchanger by dangerous operation. -

Page 30: General Maintenance

14 - GENERAL MAINTENANCE AND CARE INSTRUCTIONS 14.3 General Maintenance Figure 14-1 - Burner Tray BURNERS • Visually inspect main burner and pilot flames at start of heating season and again in mid-season. ◊ Main burner flame should have well defined inner blue mantel with lighter blue outer mantel. -

Page 31: Adjusting Gas Input

14 - GENERAL MAINTENANCE AND CARE INSTRUCTIONS 14.4 Adjusting Gas Input Adjust gas input to boiler by removing protective cap on pressure regulator and turning screw clockwise increase input and counterclockwise to decrease input. See Figure 12-1 page 27. Manifold pressures are taken at outlet side of gas valve. See page 23 for proper pressure recommendations. -

Page 32: Ratings & Data - Natural Gas & Propane Gas

Heating Net AHRI Air Cushion Input AFUE Diameter Altitude Model No. Sections Capacity Rating Water Tank BTU/HR Inches Input BTU/ BTU/HR BTU/HR 15B-060K 59,000 50,000 43,000 84.0 53,100 15B-095K 92,500 78,000 68,000 84.0 83,200 15B-120K 120,000 101,000 88,000 84.0 108,000... -

Page 33: Appendix A - Control Module

APPENDIX A - CONTROL MODULE A.3 Adjusting Settings WARNING To discourage unauthorized changing of settings, procedure If you do not follow these instructions to enter adjustment mode is required. exactly, a fire or explosion may result To enter adjustment mode, press UP, DOWN, and I buttons causing property damage, personal injury simultaneously for three seconds. -

Page 34: Operation

APPENDIX A - CONTROL MODULE A.5 Operation Control determines burner operation is required, module proceeds to start burner (see state codes list) Module continuously monitors boiler water temperature and and heats water in boiler until setpoint temperature is fires or shuts off burner based on this temperature data. achieved or thermostat is satisfied. - Page 35 APPENDIX A - CONTROL MODULE Table A1 conti. - Vent Damper Models Operation State Codes State Code Definition Explanation Order Number 2. Other possible state codes System is purging before ignition trial; includes Pilot Valve circuit diagnostics. On vent Pre-purge damper models, this is so quick it will typically be over before the display can flash this code, and therefore will rarely be visible.

-

Page 36: Boiler High Limit Temperature Controller

APPENDIX A - CONTROL MODULE A.7 Troubleshooting A.6 Boiler High Limit Temperature Controller • Following service procedures are provided as general • When water temperature reaches setpoint, controller guide. ends heating cycle. • On lockout and retry models, meter readings between •... - Page 37 APPENDIX A - CONTROL MODULE Table A7 - Troubleshooting Error Codes Error Display clearing ( once error condition has disappeared) Error Clears itself Up/down Cycle Code Definition Push when root key when Power Number Explanation Things to look for problem is status is solved displayed...

- Page 38 APPENDIX A - CONTROL MODULE Table A7 - Troubleshooting Error Codes - conti. Error Display clearing ( once error condition has disappeared) Error Clears itself Up/down Cycle Code Definition Push when root key when Power Number Explanation Things to look for problem is status is solved...

-

Page 39: Intermittent Pilot

APPENDIX A - CONTROL MODULE A.9 Intermittent Pilot Ignition System Checks STEP 1: Check ignition cable. • Verify ignition cable does not make contact with metal surfaces. • Verify only factory supplied Ignition cable (or approved replacement) is used. • Verify connections to ignition module and igniter or igniter-sensor are clean and tight. - Page 40 APPENDIX A - CONTROL MODULE STEP 3: Check spark ignition circuit. Recheck ignition sequence as follows. Disconnect ignition cable at SPARK terminal on module. — Adjust thermostat above room temperature. — Verify ignition sequence at burner. WARNING Electrical shock hazard. Ignition circuit generates over 10,000 volts.

-

Page 41: Appendix B - Vent Damper Installation

APPENDIX B - VENT DAMPER INSTALLATION WARNING Figure 1a - Horizontal Installations Flow Asphyxiation, burn hazard. Improper operation of vent damper may result in serious injury or death due to fire or to asphyxiation from poisonous gases Vent Damper To Boiler o Chimney such as carbon monoxide which is odorless and Install vent damper with actuator to sides of... -

Page 42: Vent Damper Harness - Molex Plugs

APPENDIX B - VENT DAMPER INSTALLATION B.3 Vent Damper Harness - Molex Plugs Figure 4 WARNING Follow all instructions regarding safety operational controls in this manual. Failure to follow these instructions could result in death or serious injury. When servicing controls, all wires must be Note labeled prior to disconnection. -

Page 43: Vent Damper Troubleshooting Guide

APPENDIX B - VENT DAMPER TROUBLESHOOTING B.4 Vent Damper Troubleshooting Guide Normal Sequence of Operation WARNING 24 VAC Power ON Damper Position Power Follow all instructions regarding safety operational 4 & 1 All times Open or Closed controls in this manual. Failure to follow these instructions could result in death or serious injury. - Page 44 I M P O R T A N T In accordance with Section 325 (f) (3) of the Energy Policy and Conservation Act, this boiler is equipped with a feature that saves energy by reducing the boiler water temperature as the heating load decreases. This feature is equipped with an override which is provided primarily to permit the use of an external energy management system that serves the same function.

Need help?

Do you have a question about the 15B-060K and is the answer not in the manual?

Questions and answers