Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for SCP SCIENCE NOVAWAVE

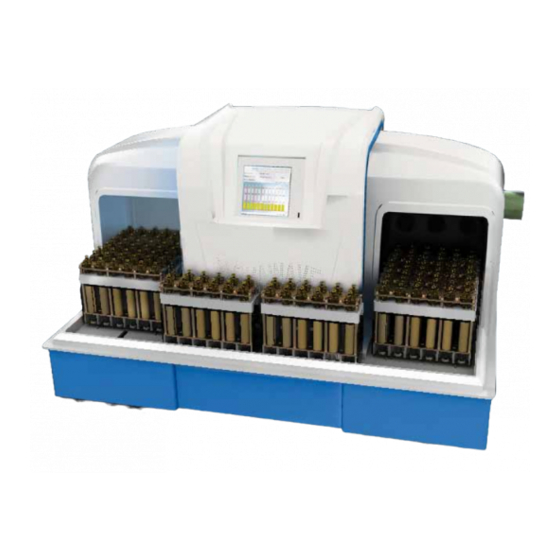

- Page 1 NOVAWAVE A new category of Automated Microwave Digestion User Manual...

- Page 2 Cat. # 010-600-032 Transporter Transfer Rack Stand Required to upgrade a 12 position polycarbonate support stand for vessels and NOVAWAVE SA to FA model. Transfer Rack. With Forced Air Cooling and (Qty: One) Auto-Venting stations. Cat. # 010-600-040 (Qty: One)

- Page 3 Fax: +86 (10) 58032302 Disclaimer: Products are supplied for laboratory use only. SCP SCIENCE presumes that only trained and qualified individuals, familiar with procedures suitable for the safe operation of these instruments, will handle them. Our customers are solely responsible for the safe operation, handling and use of these products.

-

Page 4: Table Of Contents

| Table of ConTenTs Table of Contents Introduction Cleaning of System Accessories Cleaning of Vessels Cleaning of Fluoropolymer Caps and Safety Caps Installation Pressure Cleaning the Tunnel Cautions, Notes and Symbols Cleaning the GUI Racks and Vessels Cleaning the Rack Software Operation Warranty &... - Page 5 12 dynamic microwave mini cavities are formed, delivering energy to each mini cavity according to the digestion method selected. In the NOVAWAVE FA model, when the rack exits the tunnel, the rack proceeds to the Cooling Station and a second rack enters the tunnel to begin its digestion sequence.

- Page 6 NOVAWAVE - A New Category of Automated Microwave Digestion Accessories Accessories for Quartz for Fluoropolymer Vessels Vessels Complete Rack 50 ml Complete Rack 75 ml Complete Rack 50 ml Complete Rack 75 ml Cal. Quartz Vessels Cal. Quartz Vessels Fluoropolymer Vessels...

- Page 7 NOVAWAVE should be installed on a stable lab counter top which provides easy access considering the height of the lab’s operators. The exhaust vent of the NOVAWAVE must be connected to a fume hood to prevent noxious fumes from entering the lab in the event of the venting of a digestion vessel.

- Page 8 NOVAWAVE - A New Category of Automated Microwave Digestion NOVAWAVE FA Place the NOVAWAVE SA in the position where you plan to use the system allowing at least 28 inches (72 cm) on each side for the Transporter. Use a straight edge to ensure the top of the Transporter is level with the bottom of the tunnel. This is accomplished by placing the straight edge in the tunnel parallel to the back wall of the tunnel.

- Page 9 Cautions, Notes and Symbols symbol Description symbol Description Voltage Mains on Alternating current Mains off Current Attention, consult accompanying documents Frequency Caution, hot surfaces Fast-acting fuse Protective conductor terminal Cautions, warnings and notes are included throughout this manual. CAUTION A caution is used to emphasize information pertaining to procedures that, if not strictly followed, may result in damage or destruction to the instrument or improper instrument operation.

- Page 10 10 | Racks & Vessels The round bottom quartz digestion vessel allows the analyst to place the vessel directly onto the balance for weighing samples with the tube support supplied. Once weighed, the digestion media may be added. The 75 ml vessel is calibrated at 45 ml for quick addition of the sample and 50 ml for acid addition as per EPA 3015.

- Page 11 Once the Safety Pressure Plate is in the correct position, tighten each of the Safety Pressure Caps until they do not turn. The rack is now ready to be inserted in the NOVAWAVE . Place the loaded rack onto the ‘IN Staging Table’. The locking mechanism should be oriented furthest from the door.

-

Page 12: Software Operation

Software Operation NOVAWAVE software has been designed with 3 levels of password protected operations allowing accessibility to various parts of the software by different individuals. This feature protects the laboratory from inadvertently changing or erasing important settings and / or data. - Page 13 USER LEVEL Button Administrator Operator Service Program Add Cycle Add Rack Delete Manual Start Show Keyboard Hide Keyboard Save Load Method Select Vessel Type Select Start Digestion Sample List Digestion Operational after the ‘Start Digestion’ button is pressed Stop Methods Delete Edit View...

-

Page 14: Programming A Run

NOVAWAVE - A New Category of Automated Microwave Digestion “Program” Run Cycle This is the tab where a digestion run is created. It starts by creating a ‘cycle’, where ‘racks’ are then added to the cycle. A cycle is used when programming several racks with the same method for all of the tubes per rack. It may also be used when a second digestion is required after the addition of a second reagent. - Page 15 NOVAWAVE - A New Category of Automated Microwave Digestion Select ‘Add rack’ up to 32 racks per cycle. Highlight the rack number in which the samples will be digested or extracted. The racks with a check mark will be saved to the list. To delete a rack, click on the rack number to delete.

- Page 16 NOVAWAVE - A New Category of Automated Microwave Digestion It is possible to add several ‘cycles’ with different rack ID’s for each cycle. It is also possible to use the same rack ID for each ‘cycle’ selected. By selecting Cycle 2, and selecting a...

-

Page 17: Sample Position

NOVAWAVE - A New Category of Automated Microwave Digestion After a method is selected, a vessel type needs to be selected for the system to operate correctly. Select one of the pre-programmed vessel types from the Vessel Type pull down tab. - Page 18 NOVAWAVE - A New Category of Automated Microwave Digestion Sample List Pos is the vessel position in the rack. Method is selected from the pull down methods tab. Type is vessel type select quartz or Teflon ® from the pull down tap.

- Page 19 NOVAWAVE - A New Category of Automated Microwave Digestion Vessel Type Select the from the pull down tab. Quartz is for either 50 ml and 75 ml Quartz Vessels. Teflon is for either 50 ml and 75 ml fluoropolimer vessel in quartz sleeves.

-

Page 20: Entering Sample Id

NOVAWAVE - A New Category of Automated Microwave Digestion Entering Sample ID Individual sample IDs can be entered by assigning them individually from the Sample IDs tab by clicking the Sample List button, or may be entered using the remote bar code reader from this page by selecting Rack #. The barcode reader plugs into the USB connection at the front panel. -

Page 21: Digestion

NOVAWAVE - A New Category of Automated Microwave Digestion Digestion Press OK when ready, start the diges- tion. Follow the prompts as they come up on the Touch Screen. Firmly push the rack into the tunnel until the rack en- gages with the ‘In Gear’... -

Page 22: Digestion Method Creation

NOVAWAVE - A New Category of Automated Microwave Digestion If a rack was in the tunnel prior to starting a digestion, the NOVAWAVE will move the current rack in the tunnel to the out position prior to allowing the next rack to be processed. - Page 23 NOVAWAVE - A New Category of Automated Microwave Digestion The green bars represent that the temperature has reached set point temperature and is in the ‘Time at Temperature’ state. The blue bars represent that the system has completed the digestion method for the particular position.

-

Page 24: Method Creation Methods

NOVAWAVE - A New Category of Automated Microwave Digestion Method Creation Methods This tab allows for the design of the heating profile desired to digests samples. Select New to create new heating profiles. Edit to make corrections to an existing method. - Page 25 NOVAWAVE - A New Category of Automated Microwave Digestion Upon clicking New, the program new method screen will appear. To add reagents click the Add button, then click the pull down tab to select the reagent that will be added to the digestion. Input the volume.

- Page 26 NOVAWAVE - A New Category of Automated Microwave Digestion Reagents list - adds other names for reagents. Add is used to populate the drop down list for reagent used. Delete is use to remove the reagent from the drop down list. Highlight the...

- Page 27 NOVAWAVE - A New Category of Automated Microwave Digestion With a NOVAWAVE SA unit the cooling of the rack may take place in the tunnel either By time or By temperature. Cooling is to determine where the first stage of cooling takes place. If...

- Page 28 NOTE In NOVAWAVE FA, there must be a sample in rack position 4 to monitor the cooling of the sample when it is located in the vessel NOTE venting position.

-

Page 29: Reports

NOVAWAVE - A New Category of Automated Microwave Digestion Reports The individual temperature profiles for all of the positions for this particular run may be accessed from this tab. Delete removes all of the information for the run shown. Comments - allows the user to add comments to each rack. -

Page 30: Utilities

NOVAWAVE - A New Category of Automated Microwave Digestion Utilities The Status tab is used to manually Initialize the system. The initialize command will verify the position of the doors, the applicators and whether or not a rack is in the tunnel. -

Page 31: Ir Calibration

NOVAWAVE - A New Category of Automated Microwave Digestion IR Calibration Read New Data once the thermopile calibrating device is connected, press this button to calibrate the NOVAWAVE. NOVAWAVE is factory calibrated, and should be calibrated every 6 months during a preventive maintenance visit by a trained Service Engineer. - Page 32 NOVAWAVE - A New Category of Automated Microwave Digestion The system shows its progress in real time. The system should only be calibrated in “quartz tubes. Teflon ® calibra- tion is done automatic- ally by the system after the calibration is completed for quartz.

-

Page 33: Users

NOVAWAVE - A New Category of Automated Microwave Digestion Users Users This window is used by Service to give or delete Administrator rights, or by Administrators to give or delete Operator rights and by Operators to change their password. To add a new user, click Add new... - Page 34 NOVAWAVE - A New Category of Automated Microwave Digestion Click on OK then select Change password. The following screen will pop up. Fill in the data required, then press OK. Apply changes is used to change from the ‘operator’ to ‘administrator’...

-

Page 35: Settings

NOVAWAVE - A New Category of Automated Microwave Digestion Settings This page is used to set the date and time for the appropriate geographic location. Language selects the language of your choice. Reports sets the number of days to purge your reports. -

Page 36: System

NOVAWAVE - A New Category of Automated Microwave Digestion System Used to change FA to SA Mode. The NOVAWAVE recognizes the current configuration FA or SA. The system displays information based upon the model diplayed in the Mode. Diagnostic The Log tab allows the service engineer to review the collected data for trouble shooting purposes. -

Page 37: Logout

NOVAWAVE - A New Category of Automated Microwave Digestion The Operations tab allows for NOVAWAVE SA and FA com- ponents to be tested. Logout Exit is used to return to the main screen, i.e. to change users level. Open Desktop is used for calibration at the touch Screen of NOVAWAVE. - Page 38 Safety Caps have been calibrated to appropriate settings in the factory. Calibration settings of the caps should only be adjusted by an authorized SCP SCIENCE technician. It is highly recommended that Safety Caps be tested and re-calibrated if necessary every 6 months.

-

Page 39: Warranty & Safety Information

2. There are no user-serviceable parts in this unit. The warranty is void if the instrument shows evidence of tampering or is subjected to excessive moisture, heat, corrosion or other misuse. 3. sCP sCIenCe shall not be responsible for any damage or losses, however caused, which may be experienced as a result of the improper installation or misuse of this product. -

Page 40: Safety Messages

MicroBlaze is updating GUI is shutting down If any of the safety messages are displayed in RED on the touch screen, please call your local distributor or contact SCP SCIENCE’s Service Department. Contact information is located at the back of this manual. - Page 41 NOVAWAVE - A New Category of Automated Microwave Digestion An Example of a Safety Message: Safety messages displayed during a digestion. By pressing the Stop sign, the message will be displayed. It will disappear in a few seconds. This channel has been shut down, but the rest of the channels will continue their digestions.

-

Page 42: Specifications

** Fuses are located behind the back panel on the Novawave. * All safety critical components used in the NOVAWAVE are CSA certified and UL Recognized. All polymeric materials used in the NOVAWAVE are UL Recognized and have the appropriate flammability rating. Vessels are tested to three times pressure venting maximum. - Page 43 Toxic or hazardous substances and elements Lead Mercury Cadmium Hexavalent Chromium Polybrominated Diphenyl Ether Part name (Pb) (Hg) (Cd) (Cr6+) (PBDE) Skins Frame Electronic boards Feet Wiring Harness Motors Gear Boxes Fasteners HV boards Magnetrons Applicators Co-axial cable Touch Screen Ribbon Cables Housings O: Indicates that the toxic or hazardous substance contained in all the...

-

Page 44: Troubleshooting

44 | Troubleshooting Messages may occur during system operation due to operator error or component failure. For further assistance, contact SCP SCIENCE Service Department or your local distributor. List of Error Messages: Error Message Description COM.ERROR Unrecognized packet. ERROR! ID=Stalled DESC= Section 1 (2,3,4) is stalled. FA Rack is stalled at B-F section. - Page 45 NOTES Version 0.15.1...

- Page 46 PETROLEUM AGRICULTURE GEOLOGY CONSUMER PROTECTION ENVIRONMENT Online: www.scpscience.com Email: sales@scpscience.com Providing Innovative Solutions to Analytical Chemists NORTH AMERICA / INTERNATIONAL EUROPE CHINA BRAZIL Tel.: (800) 361-6820/+1 (514) 457-0701 Tel.: +33 (0) 1 69 18 71 17 Tel.: +86 (10) 58032301 Tel.: +55 19 8194-8488 Fax: (800) 253-5549/+1 (514) 457-4499 Fax: +33 (0)1 60 92 05 67...

Need help?

Do you have a question about the NOVAWAVE and is the answer not in the manual?

Questions and answers