Table of Contents

Advertisement

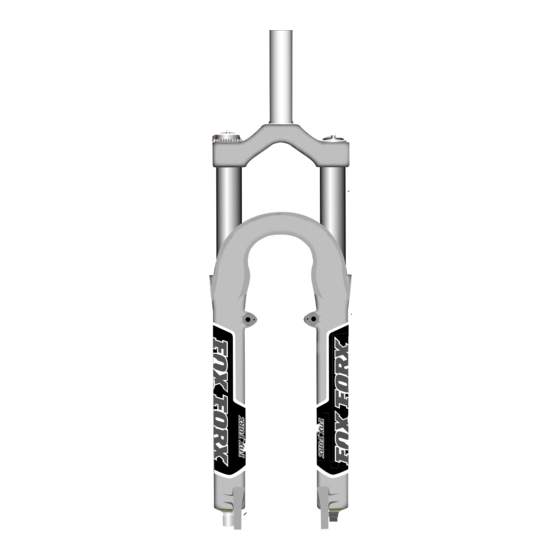

2002 FOX FORX Owners Manual

FLOAT 80R - FLOAT 80RL - FLOAT 80RLC

FLOAT 100R - FLOAT 100RL - FLOAT100RLC

Vanilla 100R - Vanilla 100RL - Vanilla 100RLC

Vanilla 125R - Vanilla 125RL - Vanilla 125RLC

FOX RACING SHOX

130 Hangar Way, Watsonville, CA 95076

831.768.1100 FAX 831.768.9342

E-Mail: service@foxracingshox.com

Website: www.foxracingshox.com

1

Advertisement

Table of Contents

Summary of Contents for FOX RACING SHOX FLOAT 80R

- Page 1 2002 FOX FORX Owners Manual FLOAT 80R - FLOAT 80RL - FLOAT 80RLC FLOAT 100R - FLOAT 100RL - FLOAT100RLC Vanilla 100R - Vanilla 100RL - Vanilla 100RLC Vanilla 125R - Vanilla 125RL - Vanilla 125RLC FOX RACING SHOX 130 Hangar Way, Watsonville, CA 95076 831.768.1100 FAX 831.768.9342...

- Page 2 FLOAT Forx Features One-piece Magnesium Lower Leg Double butted Aluminum Steerer PSC - Precision Steering Control CLS - Coil Lubrication System SDC - Shimmed Damping Control Rebound Adjustment FLOAT Air Spring Technology Adjustable Travel- 80&100mm Vanilla Forx Features One-piece Magnesium Lower Leg Double butted Aluminum Steerer PSC - Precision Steering Control CLS - Coil Lubrication System...

-

Page 3: Table Of Contents

Table of Contents Introduction ... 4 Contact Information ... 4 Service / Warranty ... 4 International Service Centers ... 4 Warranty Policy ... 5 Methods of Payment ... 5 Method of Shipping ... 5 Disclaimer ... 5 Consumer Safety ... 5 Important Safety Information ... -

Page 4: Introduction

Introduction Congratulations on choosing FOX FORX for your bicycle. In doing so, you have chosen the best suspension fork in the industry! All FOX Racing Shox products are designed, manufactured and assembled by the finest professionals in the industry. As a consumer and supporter of FOX Racing Shox products, you need to be aware of the importance of setting up your fork correctly to ensure maximum performance. -

Page 5: Warranty Policy

Warranty Policy The factory warranty period for your fork is one year from the original date of purchase of the bicycle or fork. A copy of the original purchase receipt must accompany any fork being considered for warranty service. Warranty is at the full discre- tion of FOX Racing Shox and will cover only defective materials and workmanship. -

Page 6: Important Safety Information

Important Safety Information 1. Verify that the brakes are installed and adjusted properly before riding the bicycle. Improperly installed or adjusted brakes can cause loss of control and serious or fatal injuries to the rider. Use only “V” - style or hydraulic cantilever brakes or disc brakes designed by the manufacturer for use on FOX FORX. -

Page 7: Tire Sizes

Tire Sizes FOX FORX will accept tires sizes up to 2.40 inches wide (e.g. WTB MotoRaptor 55/60, 26 x 2.40). Any tire larger than 26 x 2.30 must be checked for clearance by the following method. Determining Tire Size - With the tire installed and inflated on the Maximum Peak Tire Diameter = 343mm = 27.00 inch... -

Page 8: Service Intervals

Service Intervals Your FOX FORX will perform best if serviced at the regular intervals shown below. r e t e t I r e t r o i & l l i f ) y l s n I i t c Required Tools and Supplies Safety Glasses Bucket or Drain Pan... -

Page 9: General Set-Up Instructions

General Set-Up Instructions Fork Terminology Travel: The total amount the fork compresses. Sag: The amount the fork compresses with the rider sitting on the bike in a normal riding position. Compression Damping: This controls the rate at which the fork compresses Rebound Damping: This controls the rate at which the fork extends. -

Page 10: Float Forx

Changing your Coil Spring 1. With a 26mm 6-point socket wrench, loosen and remove the preload topcap. Remove the black spring spacers (two spacers for 125mm travel, 1 for 100mm travel, none for 80mm travel). Compress the fork slightly and remove the coil spring. -

Page 11: Damping Adjustment Guidelines

Damping Adjustment Guidelines Rebound Adjustment (R, RL, RLC) FOX FORX feature a rebound adjuster. This allows the rider to control the speed at which the fork extends after compression. The Rebound Adjustment Knob is the red knob located on top of the right fork leg. Turn it clockwise for slower rebound and counter-clockwise for faster rebound. -

Page 12: Changing Travel - Float Forx

Changing Travel - FLOAT Forx FOX FORX travel can be changed by rearranging the travel spacers as shown in the drawings below. After changing travel check the fork for proper operation before riding. If there is free movement in the fork or if it makes strange noises disassemble the fork and check for complete number and correct orientation of spacers. -

Page 13: Vanilla Forx

Changing Travel - Vanilla Forx FOX FORX travel can be changed by rearranging the travel spacers as shown in the drawings below. After changing travel check the fork for proper operation before riding. If there is free movement in the fork or if it makes strange noises disassemble the fork and check for complete number and correct orientation of spacers. -

Page 14: Changing Oil

Changing Travel - Vanilla Forx con’t 80mm Preload Topcap 25mm 20mm 20mm Vanilla Forx Travel Spacer Diagram Bushings Bushings should be checked annually for excessive wear. If fore and aft movement is detected between the upper tubes and lower legs, contact an Authorized FOX Racing Shox Service Center or FOX Racing Shox for further instructions. Grasp the lower legs at the drop outs (axle). - Page 15 Changing Oil con’t Step 1 - Remove the blue air cap from the top of the left fork leg. Let the air out of the fork. Refer to Pump Instructions for details about letting the air out with a pump. Remove left top cap with a 26mm socket 6-point socket wrench.

-

Page 16: Seals And Foam Rings

Changing Oil con’t Step 4 - Carefully pull the damper from the fork. It will still contain oil. Step 5 - Place the damper upright in a deep bucket and carefully cycle the shaft up and down several times to pump out the remaining oil.

Need help?

Do you have a question about the FLOAT 80R and is the answer not in the manual?

Questions and answers