Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Omni Base

- Page 1 Omni Base...

- Page 2 If differences are found between the contents of this manual and the actual machine operation, please communicate them to the Builder. CEC BASE IGM REV13...

-

Page 3: Table Of Contents

3.6 INAPPROPRIATE AND INCORRECT USE ................. 30 3.7 OTHER RISKS ........................30 TRANSPORT AND INSTALLATION .................... 33 4.1 HANDLING AND TRANSPORT ................... 33 4.2 PACKAGING ........................34 4.3 STOCKING.......................... 34 4.4 INSTALLATION ........................35 4.5 PRELIMINARY INSPECTIONS ................... 37 CEC BASE IGM REV13... - Page 4 5.2.2 CHAIN TENSIONING ....................41 5.3 ELECTRICAL PARTS MAINTENANCE ................41 5.4 EXTRAORDINARY MAINTENANCE ................... 43 5.5 CLEANING .......................... 43 DEMOLITION AND DISPOSAL ....................45 6.1 DISPOSAL OF PRODUCTION WASTE ................45 6.2 MACHINE DEMOLITION ..................... 45 CEC BASE IGM REV13...

-

Page 5: General Information

Wide experience and radical innovation have made the building of this cutting-edge, cost-effective wrapping machine possible. If you need information on use and maintenance, or if you wish to request spare parts, please give the identification data of the machine placed on the Builder plate. CEC BASE IGM REV13... -

Page 6: Certification

1.8 SYMBOLS AND TERMS The most important parts of the text are in bold and are signalled by the following symbols that are placed before them. CEC BASE IGM REV13... -

Page 7: Machine Identification

The machine is identified by means of the Builder plate located on the machine column. The following data are written on the plate. MACHINE MODEL sales@omnigroup.com.au www.omnigroup.com.au SERIAL NUMBER Ph : 1300 764 963 BUILDING YEAR MACHINE MASS (kg) ABSORBED POWER (kW) SUPPLY VOLTAGE (V) CAPACITY (kg) (MAXIMUM WEIGHT OF LOADING) CEC BASE IGM REV13... -

Page 8: General Safety Information

Carefully read the information reported in the manual and placed directly on the machine, especially safety information. Please read this manual carefully before using or servicing the machine. CEC BASE IGM REV13... - Page 9 Every intervention on the system or the equipment must be exclusively carried out by qualified electrical maintenance workers. Prevent water from dripping onto the electrical panel. CEC BASE IGM REV13...

- Page 10 The location of fire extinguishers and their operating instructions must be indicated in the departments. Make sure that the staff members know how to stop the machine in an emergency. CEC BASE IGM REV13...

- Page 11 Builder, referring to the data contained in this manual or written on the original plate. Do not clean or lubricate any parts of the machine when operating. Do not clean the machine with water nor aggressive products, even if diluted. CEC BASE IGM REV13...

-

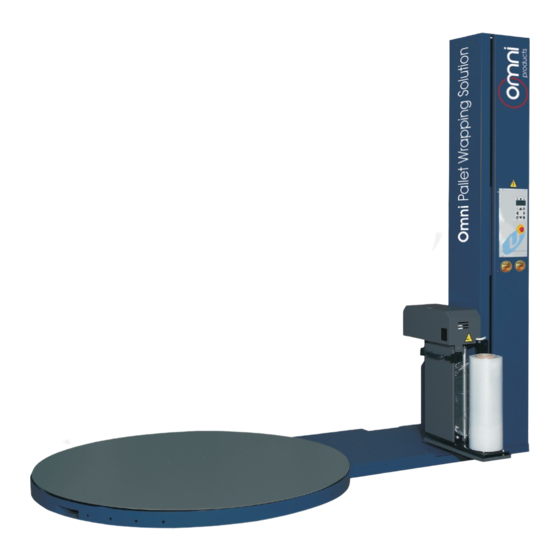

Page 12: Description Of The Machine

D. Film roll carriage: it holds and winds the stretch film coil. E. Control panel: it contains all the buttons for the control and running of the machine. It is located on the column. It is built according to the Directives and to the rules in force. CEC BASE IGM REV13... -

Page 13: Main Optional Groups

"fully lowered" position". In this way, the film can further wrap the lower part of the pallet. If the carriage rotation group is present, the direction of rotation of the table must be anti-clockwise. CEC BASE IGM REV13... - Page 14 C. Carriage with dynamic brake: it holds and winds the stretch film coil. It replaces the standard film roll carriage. D. Motorized top press: it allows to stabilize the load during the wrapping phase. It is controlled by the logic of the machine. CEC BASE IGM REV13...

-

Page 15: Accessories

The description and the operating instructions of additional accessories are enclosed to the main operating and maintenance “base” machine manual. 2.3 TECHNICAL DATA The following are the data and the technical characteristics for a correct installation. -

Page 16: Plates And Pictograms

INDICATES DANGER WARNING OF BEING TRAPPED OR DRAGGED DUE TO ROTATING PARTS INDICATES DANGER WARNING OF INJURIES DUE TO MOVING PARTS. INDICATES DANGER WARNING OF GETTING CUT. INDICATES THE REQUIREMENT TO READ THE GENERAL INFORMATION AND MAINTENANCE MANUAL. CEC BASE IGM REV13... - Page 17 INDICATES THE ROTATION DIRECTION OF THE TABLE The plates and pictograms must be located on the machine as shown in the pictures. CEC BASE IGM REV13...

- Page 18 Do not remove plates or pictograms. CEC BASE IGM REV13...

-

Page 19: Overall Dimensions Of The Machine

2.5 OVERALL DIMENSIONS OF THE MACHINE D 1500 table with standard carriage D 1650 table with standard carriage D 1800 table with standard carriage D 1650 table with pre-stretch carriage D 1800 table with pre-stretch carriage CEC BASE IGM REV13... -

Page 20: Necessary Space

CEC BASE IGM REV13... -

Page 21: Sound Emissions

If the machine is used according to the instructions for a correct use, the vibrations cannot cause any dangerous situations. 2.13 GAS, DUST AND FUME EMISSIONS If the machine is used according to the instructions for a correct use, there are no gas, dust or fume emissions, nor emissions of dangerous substances. CEC BASE IGM REV13... -

Page 22: Safety Devices

To restart the machine after an emergency stop, press the RESET button on the control panel. Before restarting the machine after an emergency stop, make sure that the danger has been removed. CEC BASE IGM REV13... -

Page 23: Safety Devices

It intervenes when an obstacle prevents the carriage from descending. By intervening it stops the carriage’s descent, causes a reverse and makes the carriage slightly go up, to allow obstacle removal. CEC BASE IGM REV13... -

Page 24: Protections And Fixed Repairs

Never modify or replace fixed repairs with repairs in other materials, or with a different form or function. The table rotation electric motor is covered with a casing fixed to the machine frame In the following pictures power motor is shown with and without fixed guard. CEC BASE IGM REV13... - Page 25 The moving mechanisms of the film roll carriage located inside the column are protected by two casings (A and B) fixed with screws, but just the lower one (B) must be removed to install the machine. CEC BASE IGM REV13...

-

Page 26: Safe Use Of The Machine

Should there be special working needs, please contact the Technical or Commercial Office of the Builder. Please remember that any changes must be authorized by the Builder in writing. CEC BASE IGM REV13... -

Page 27: Inappropriate And Incorrect Use

Therefore, operators need to: pay attention to the warning messages; maintain an adequate safety distance from the dangerous parts remain at a distance greater than 50 cm from the rotary table while the machine is in operation. CEC BASE IGM REV13... - Page 28 (e.g. noise, electromagnetic phenomena, etc.), but such risks are not to be excluded. THE CLIENT IS REQUIRED TO CARRY OUT A RISK ASSESSMENT, CONSIDERING THE MACHINE WORK, THE INSTALLATION PLACE, THE SURROUNDING ENVIRONMENT AND ANY INTERFERENCES WITH OTHER MACHINES. CEC BASE IGM REV13...

-

Page 29: Transport And Installation

Machine handling must always be carried out by experienced staff. While lifting and handling the machine, the whole area surrounding it must be considered DANGEROUS ZONE. Therefore, make sure that there are no people exposed to danger in the zone. CEC BASE IGM REV13... -

Page 30: Packaging

Should it be necessary to close the machine in a box (e.g. for sea or air transport), the box must have a perimeter base similar to the one of the machine, but 200 mm larger on all sides, with a capacity adequate to the machine weight, and with the appropriate identification pictograms stamped on (together with the indications “THIS SIDE UP”... -

Page 31: Installation

Then assemble the casing paying attention to close the dangerous parts of the column. Once the column is fixed it is possible to install the carriage. Use suitable lifting equipment. CEC BASE IGM REV13... - Page 32 STANDARD CARRIAGE CARRIAGE WITH DYNAMIC BRAKE PRE-STRETCH CARRIAGE WARNING! DO NOT LIFT THE CARRIAGE OFF THE ROLLER! Screw the brackets fixed to the carriage to the brackets and distance pieces fixed to the column. CEC BASE IGM REV13...

-

Page 33: Preliminary Inspections

During machine connection to the power grid, the system has to be cut off from the power supply, in compliance with the technical code of practice and the norms in force in the Country of use. CEC BASE IGM REV13... - Page 34 After all preliminary controls have been carried out and the electrical connection has been correctly performed, the machine can be connected to the power supply. Then, check that all machine parts and devices work correctly. CEC BASE IGM REV13...

-

Page 35: Maintenance

It is suggested that a sign be placed in a clearly visible position near the machine reading, "MACHINE IN MAINTENANCE". It is absolutely forbidden to run the machine in automatic mode with the fixed or mobile guards disassembled. CEC BASE IGM REV13... -

Page 36: Mechanical Parts Maintenance

Tighten all screws, bolts and lock nuts of every adjustable mechanical element following normal tightening values, without using any levers or hitting any spanners. 5.2.1 GREASING GREASING OF THE TABLE ROTATION COLUMN RACK GREASING CHAIN CEC BASE IGM REV13... -

Page 37: Chain Tensioning

Any modification must be registered and added to the documentation; check all the switches that disconnect the machine; to operate on power devices in danger conditions there must be more than one worker. Stop the machine power before operating on electric devices. CEC BASE IGM REV13... - Page 38 About every month or every 200 working hours, carry out a visual check of the following limit switches: of table rotation; of carriage going up and down. CEC BASE IGM REV13...

-

Page 39: Extraordinary Maintenance

Do not allow to unauthorized staff to access the machine Do not put your body, fingers or limbs into the machine openings when the machine is running. Do not clean the machine with aggressive products, even if diluted. CEC BASE IGM REV13... - Page 40 The hygienic state of the machine must be kept under strict control, particularly in specific parts: the packing phase, being at the end of the production cycle, must not compromise the hygiene degree maintained up to that moment. CEC BASE IGM REV13...

-

Page 41: Demolition And Disposal

Metal parts must be divided according to the type of metal for a correct recycling. To safeguard the health of people and the safety of objects, demolition operations must be carried out by trained staff with adequate equipment. CEC BASE IGM REV13... - Page 42 Omni Group has been Engineering to Perfection Packaging Solutions for over 25 years. The Omni Brand is renowned for providing quality and customised Packaging Solutions as a result of continual innovation and development to perfect its whole range. As specialists in pallet load containment and end of line packing solutions, you can rely on us as the industry experts.

Need help?

Do you have a question about the Base and is the answer not in the manual?

Questions and answers