Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for MJ Research PTC-100

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

- Page 2 PTC-100 Operations Manual Version 8.1 MJ Research™, Incorporated Boston • San Francisco • Tahoe • Copenhagen • Seoul Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 3 Copyright ©1997, MJ Research™, Incorporated. All rights reserved. PTC-100, PTC-100HB, 16MS Slide Block, Chill-out, Frame-Seal, Hot Bonnet, Microseal, Self-Seal, Slide Griddle, MJ Research marks and helix logo are trade and/or service marks belonging to MJ Research, Incorporated. 06107-AA Thermal cyclers can be used for a number of purposes, including the polymerase chain reaction (PCR).

-

Page 4: Table Of Contents

Contents Documentation Conventions ....................iv 1. Introduction ......................... 1-1 2. Layout and Specifications ..................2-1 3. Installation ........................3-1 4. Operation ........................4-1 5. Running Protocols ....................... 5-1 6. Programming ....................... 6-1 7. Editing Programs ......................7-1 8. Maintenance ......................... 8-1 9. -

Page 5: Documentation Conventions

Documentation Conventions Typographic Conventions The names of keyboard keys are in sans serif type and placed within double angle brackets: Example: «Proceed» Items in programming menus are italicized: Example: Select Edit from the Main Menu. Graphic Conventions The programming screens displayed in the LCD window are represented by a box containing two lines of text: Example: Enter... -

Page 6: Introduction

Introduction Meet the PTC-100 ......... 1-2 How to Use This Manual ......1-2 Important Safety Information ..... 1-2 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 7 Safe operation of the PTC-100 begins with a complete understanding of how the machine works. Please review this entire manual before attempt- ing to operate the PTC-100. Do not allow anyone who has not reviewed this manual to operate the machine.

-

Page 8: Layout And Specifications

Models Available ............. 2-4 Front View (Fig. 2-4) ..........2-4 Back View (Fig. 2-5) ..........2-5 PTC-100 with 16MS Slide Block (Fig. 2-6) ..2-6 Accessories ..........2-7 Temperature Probe (Fig. 2-7) ........2-7 Slide Griddle Adapter (Fig. 2-8) ....... 2-7 Specifications .......... -

Page 9: Models Available

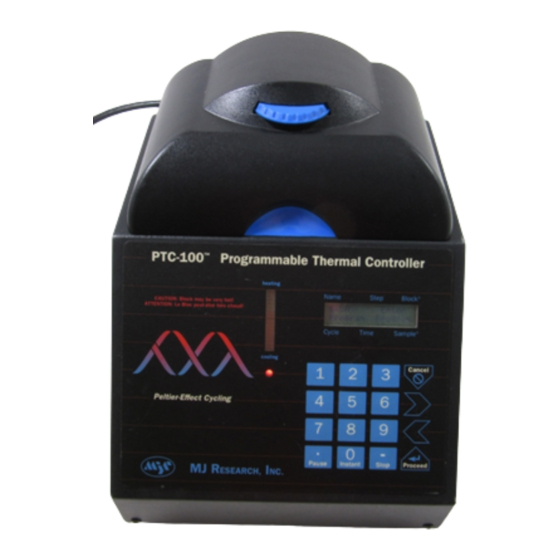

PTC-100 Operations Manual PTC-100 with Cold Lid Models Available 60-well block: holds 60 x 0.5ml tubes 96-well block: holds 96 x 0.2ml tubes or one 96-well microplate 96AgV gold/silver block: holds 96 x 0.2ml tubes or one 96-well microplate; block is gold- plated sterling silver for faster ramping speed 16MS Slide Block: holds sixteen 25 x 75mm slides and 24 x 0.2ml tubes (see p. -

Page 10: Back View (Fig. 2-2)

Layout and Specifications Back View (Fig. 2-2) Probe jack On-off switch Chart recorder jack Power cord jack Hot Bonnet jack (unused in this model) Parallel printer port Air intake vents Control Panel (Fig. 2-3) LCD window Cancel key Left and right selection keys Proceed key LED bar graph... -

Page 11: Ptc-100 With Hot Bonnet

PTC-100 Operations Manual PTC-100 with Hot Bonnet Models Available 60-well block: holds 60 x 0.5ml or 0.6ml microcentrifuge tubes 96-well block: holds 96 x 0.2ml tubes or one 96-well microplate 96AgV gold/silver block: holds one 96-well microplate or 96 x 0.2ml tubes; block is gold- plated sterling silver for faster ramping speed Front View (Fig. -

Page 12: Back View (Fig. 2-5)

Layout and Specifications Back View (Fig. 2-5) On-off switch Chart recorder jack Power cord jack Hot Bonnet jack (with cord plugged in) Parallel printer port Hot Bonnet cord Air intake vents Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 13: Ptc-100 With 16Ms Slide Block (Fig. 2-6)

PTC-100 Operations Manual PTC-100 with 16MS Slide Block (Fig. 2-6) Slide block Plastic pin Control panel Air exhaust vents Air intake vents Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 14: Accessories

Accessories Temperature Probe (Fig. 2-7) Allows machine to control reactions according to a representative sample’s temperature. Avail- able for the 60-well model of the PTC-100, with or without the Hot Bonnet. Probe jack Probe tube, with sensor inside Slide Griddle Adapter (Fig. 2-8) Allows machine to thermally cycle up to four 25 x 75mm glass slides. -

Page 15: Specifications

100 steps; maximum of 1600 steps among all programs 7.0kg Weight: Size: PTC-100 with cold lid, 24cm x 28cm x 23cm; PTC-100 with Hot Bonnet, 23cm x 28cm x 26cm Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 16: Installation

Installation Packing List ..........3-2 Setting Up the PTC-100 ........ 3-2 Environmental Requirements ....... 3-2 Power Supply Requirements ....... 3-3 Air Supply Requirements ......3-3 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 17 (see fig. 2-2), then plug the cord into an electrical outlet (see “Power Supply Requirements,” below). For the PTC-100 with Hot Bonnet, screw the Hot Bonnet power cord into its jack at the back of the machine (see fig. 2-5; finger-tightness is adequate).

- Page 18 Installation Power Supply Requirements The PTC-100 requires 100–240VAC, 50–60Hz, 850W, and a grounded out- let. The machine can use current in the specified range without adjust- ment, so there is no voltage-setting switch. Air Supply Requirements Air is taken in from vents at the rear and sides and on the bottom of the machine and exhausted from vents at both sides of the machine.

- Page 19 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 20 Operation Turning the PTC-100 On ....... 4-2 Using the Probe .......... 4-10 Customizing the Probe Vessel ........4-10 Adding the Oil ............4-11 Using the Control Panel ....... 4-2 Loading and Connecting the Probe ......4-12 Operation Keys ............4-2 Running a Protocol under Probe Control ....

-

Page 21: Turning The Ptc-100 On

• Stop: Terminates a running protocol. • Pause: Pauses a protocol during execution; accesses Japanese Katakana syllabary. • Instant Incubate: Initiates a program that sets up the PTC-100 as a simple incubator. Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 22: Operation

Opening and Closing the Lid Opening the 60-block PTC-100 with cold lid: Lift the lid (there is no latch) (fig. 4-1A, p. 4-4). Opening all other PTC-100s with cold lids: Gently push on the metal latch at the front of the lid (fig. -

Page 23: Microplates

Microseal ‘A’.) Figure 4-1 A, Opening the 60-well block PTC-100 with cold lid. B, Opening all other PTC-100s with cold lids. C, Opening the PTC-100 with Hot Bonnet. Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 24: Thin-Walled Vs. Thick-Walled Tubes

Operation Thin-Walled Vs. Thick-Walled Tubes The thickness of sample tubes directly affects the speed of sample heat- ing and thus the amount of time required for incubations. Thicker walled tubes delay sample heating since heat transfers more slowly through the tubes’... -

Page 25: Sealing With The Hot Bonnet And Caps Or Film

Sealing with the Hot Bonnet and Caps or Film The Hot Bonnet heated lid (available for all PTC-100 blocks except the 96U block and the 16MS Slide Block) maintains the air in the upper part of sample vessels at a higher temperature than the reaction mixture. -

Page 26: Adjusting The Hot Bonnet's Lid Pressure

Operation Caps, film, or mats must be used along with the Hot Bonnet to prevent evaporative losses. Tight-fitting caps do the best job of preventing vapor loss (and should be used for long-term storage of reaction products). Microseal ‘A’ film is a quick way to seal Multiplate and “Concord” microplates or large arrays of tubes. -

Page 27: Loading Sample Vessels

PTC-100 Operations Manual 4. Close the Hot Bonnet. Turn the thumbwheel clockwise to lower the Hot Bonnet’s inner lid onto the loaded tubes/microplate. The thumbwheel turns easily at first since the inner lid has not yet come into contact with anything. Stop turning the thumbwheel when you feel increased resistance, which indicates that the inner lid has touched the tubes/microplate. -

Page 28: Using Oil To Improve Thermal Contact

Slide Block. Using the Sponge Rubber Pad with the 96-well Block In PTC-100 models with the 96-well block and the cold lid, a sponge rub- ber pad may be used to help seat tubes or a plate into the block. Attach the magnetic backing of the pad to the inner surface of the lid. -

Page 29: Using The Slide Griddle

4 and 96°C. When a probe-control protocol is run, the PTC-100 controls the block’s temperature to keep the probe at the programmed temperature, using feedback information from the sensor. -

Page 30: Adding The Oil

Operation particularly important when the sample tubes have much thicker walls than the probe’s tube. Follow these steps to customize the probe vessel: 1. Uncap the probe tube. The sensor will come out when the lid is removed. 2. Remove the lid from the new probe tube. Add oil to the probe tube as described below under “Adding the Oil.”... -

Page 31: Loading And Connecting The Probe

PTC-100 Operations Manual Loading and Connecting the Probe Seat the probe tube in the center of the block. If oil is used to thermally couple samples to the block, it must also be used on the probe tube. Plug the probe into the jack at the back of the instrument (see fig. 2-2). - Page 32 Operation Select Y and press «Proceed». The following screen will be displayed: REMOVE YOUR SAMPLES Remove all samples from the block, then press «Proceed». The following screen will be displayed: Check Probe Prep Insert in Block_ If the probe is filled with the correct amount of oil and inserted into the block, press «Proceed».

-

Page 33: System Selection Chart

PTC-100 Operations Manual Appendix 4-A Tube, Microplate, and Sealing System Selection Chart Reaction vessel fits block without modification. ❍ Reaction vessel must be cut to fit. - l i i l s - f l l i f l a t... -

Page 34: Appendix 4-B: Safety Warning Regarding Use Of 35 S Nucleotides

Operation Appendix 4-B Safety Warning Regarding Use of Nucleotides Some researchers have experienced a problem with radioactive contamination when using S in thermal cyclers. This problem has occurred with all types of reaction vessels. The Problem When S nucleotides are thermally cycled, a volatile chemical breakdown product forms, prob- ably SO . - Page 35 PTC-100 Operations Manual contaminated on the outside after thermal cycling. Please be certain that you are using the appropriate detection methods and cleaning procedures for this isotope. Consult your radia- tion safety officer for his or her recommendations. If mild cleaning agents do not remove radioactivity, harsher cleaners may be used. Users have suggested the detergent PCC-54 (Pierce Chemical Co., Rockford, Illinois;...

-

Page 36: Running Protocols

Running Protocols Running a Protocol .......... 5-2 Running a Protocol on the PTC-100 with Hot Bonnet ..5-2 Running a Protocol under Probe Control ....... 5-2 Reading the Runtime Screen ......5-3 Reading the LED Bar Graph ......5-3 Reading the Protocol Completion Screen ..5-4 Manually Stepping Through a Protocol ... -

Page 37: Running A Protocol

Press one of the «Select» keys until the name of the protocol you wish to run is displayed, then press «Proceed». The protocol will begin running. QUIKSTEP? Running a Protocol on the PTC-100 with Hot Bonnet Select a protocol to run and press «Proceed». The following screen will be displayed:... -

Page 38: Reading The Runtime Screen

Running Protocols probe control. If probe control is not desired, select No and press «Proceed». The proto- col will begin running under block control. Reading the Runtime Screen During a protocol run, a runtime screen will be displayed: CUSTOM1 65.4 64.0 This screen lists the program name (CUSTOM1 in the example above), the protocol step that is running (3), the block temperature (65.4°C), the... -

Page 39: Reading The Protocol Completion Screen

PTC-100 Operations Manual when the block is heating, and the lower half lights up green when the block is cooling. The percentage of the column that lights up during ei- ther heating or cooling provides an instantaneous reflection of how much energy the heat pumps are using to either heat or cool the block. -

Page 40: Stopping A Running Protocol

Menu will be displayed. Note: Turning off the machine will not cancel a running protocol. Instead, the PTC-100 will assume that a power outage has occurred and will resume the protocol run when the machine is turned on again (see below). -

Page 41: Running An Instant Incubation

«Stop» (see “Stopping a Running Protocol”). Printing a Log of a Running Protocol If the PTC-100 is connected to a printer, it will print a log for a running protocol that includes • The machine’s serial number and software version •... -

Page 42: Printing A Record Of Actual Temperatures

To use the chart recorder, plug a miniature phone plug patch cord (3/32- inch twin conductor) into the chart recorder jack on the left side of the PTC-100 (fig. 2-2). Connect the other end to a chart recorder, being cer- tain to observe correct polarity (the tip is positive). - Page 43 PTC-100 Operations Manual Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 44 Programming The Elements of a Program ......6-2 Editing While Entering a Program ....6-11 Changing the Last Value Entered or Last Menu Option Chosen ........6-11 Desigining a New Program ......6-2 Changing All Values in the Step Being Entered ..6-11 Translating a Protocol into a Program .....

- Page 45 1. Temperature step (mandatory): Sets a temperature for the block and the length of time it is held at that temperature. The PTC-100 brings the block to this temperature at its maximum rate of heating or cooling, unless modifying instructions are added to the program.

-

Page 46: Programming

Block Control Block control is available for all models of the PTC-100. Under block con- trol, the temperature of samples always lags behind the temperature of the block. The duration of this time lag depends on the sample vessel and sample volume but typically is between 10 and 30 seconds. - Page 47 Tip: control because fewer variables are involved in the tempera- ture control feedback loop. Entering a New Program Programming the PTC-100 involves four steps: 1. Initiating the program 2. Naming the program 3. Entering the program’s steps 4. Entering the End step Each step involves typing in values from the keyboard or making selec- tions from a menu.

- Page 48 Programming Naming the Program Program names may be up to eight characters long and may consist of any combination of letters (Roman and Greek), numbers, punctuation marks, or Japanese Katakana. Press the right «Select» key to scroll forward and the left «Select» key to scroll backward through the alphabets and characters avail- able, which are presented in this order: Roman alphabet, selected Greek letters, punctuation marks, numbers.

- Page 49 PTC-100 Operations Manual The first line of this screen shows the number of the step being pro- grammed (1 is used in the example above). The second line of the screen allows a target temperature (in degrees Celsius) to be entered for the step.

- Page 50 Programming The first line of this screen shows the number of the step being pro- grammed (2 is used in the example above). The second line of the screen allows entry of the number of the step the program should cycle back to.

- Page 51 PTC-100 Operations Manual Type a temperature and press «Proceed». The number will be accepted, and a screen allowing entry of an incubation time will be displayed: Step 3 Min _ Type a number for Min and Sec. Press «Proceed» to automatically enter a value of 0.

- Page 52 Programming When the number has been typed, press «Proceed». The number will be accepted, and the Enter Menu will be displayed again. Use the Enter Menu to add another step to the program. Entering a Slope Step To enter a slope step, two values must be specified: •...

- Page 53 PTC-100 Operations Manual Note: Not all blocks will be able to ramp at the maximum program- mable speed of 1.5°/sec. See chapter 2, “Specifications,” to determine the maximum speed possible for a given block. Entering the End Step To enter the End step, select End from the Enter Menu, then press «Pro- ceed».

- Page 54 Programming Editing While Entering a Program Changing the Last Value Entered or Last Menu Option Chosen To change the last value entered or last menu option chosen, press «Can- cel». The choice just made will be cancelled, and another value may be entered or another menu option chosen.

- Page 55 PTC-100 Operations Manual After you have made all necessary changes, press the right «Select» key until the Enter menu is displayed for the next step in the program. Con- tinue entering the new program. Deleting an Incomplete Program To delete a program that you are in the process of entering, enter the End step and press «Proceed», which will store the program.

- Page 56 Programming Printing a Program The PTC-100 can print all the programs stored in the machine. To do this, follow the instructions under “Listing a Program” to enter List mode. If a printer is connected to the printer port, the List program screen will give...

-

Page 57: Editing Programs

Editing Programs Initiating Editing .......... 7-2 Editing the Program ........7-2 Editing Temperatures and Cycling Values ....7-2 Editing a Time Value ..........7-3 Editing a Slope Step ..........7-4 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 58 PTC-100 Operations Manual Initiating Editing To edit an existing program the machine must be in Edit mode. To enter Edit mode, select Enter Program from the Run-Enter Menu and press «Pro- ceed». The Main Menu will be displayed. Select Edit from the Main Menu and press «Proceed».

- Page 59 Editing Programs Note: Be careful when editing program values. Once a value is changed or deleted, you cannot make it reappear by pressing any key. To restore a value, you must retype it. You may find it helpful to write a value down before changing it, to minimize the chance that you will forget what it was.

- Page 60 PTC-100 Operations Manual Type the number 30, then press «Proceed». The number will be entered for the seconds element, and the cursor will move back to the first digit for the hours: CUSTOM1 94.0 00:00:30 Editing a Slope Step To edit a slope step you must retype both a sign (plus or minus) and a number.

-

Page 61: Maintenance

Maintenance Cleaning the Chassis and Block ....8-2 Cleaning the Air Vents ......... 8-2 Cleaning Radioactive or Biohazardous Materials Out of the Block ....8-2 Changing the Fuses ........8-2 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 62 PTC-100 Operations Manual Cleaning the Chassis and Block Clean the outside of the PTC-100 with a damp, soft cloth or tissue when- ever something has been spilled on it or the chassis is dusty. A mild soap solution may be used if needed.

- Page 63 Warning: Warning: Warning: The PTC-100 incorporates neutral fusing, which means that live power may still be available inside the unit even when a fuse has blown or been removed. Never open the PTC- 100. You could receive a serious electrical shock. Opening the unit will also void your warranty.

- Page 64 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 65: Troubleshooting

Troubleshooting Error Messages ........... 9-2 Problems Related to Protocols ..... 9-3 Problems Related to Machine Performance ........9-5 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 66 PTC-100 Operations Manual Error Messages i t c s ' k i v r n i c r i c i u c y r t f l a i t c t s i b i r . r o...

- Page 67 Troubleshooting Problems Related to Protocols i t c i t c i k r " d - r " r r e t l a i t f o i n i t a i i t - c u c - r a l 1 <...

- Page 68 PTC-100 Operations Manual i t c i t c s t c r - e i t c i s u i a t t o r . l o s n i t s i s ' l l o r...

- Page 69 Troubleshooting Problems Related to Machine Performance i t c n i t t o r . l o y l s h t i s i t t n i s t i t r o . ) y i h c r a t t o r .

-

Page 70: Appendix A: The 16Ms Slide Block

Appendix A Appendix A Appendix A Appendix A Appendix A Appendix A The 16MS Slide Block Description of the 16MS Slide Block The 16MS Slide Block can thermally cycle slides and tubes. The block consists of a vertical metal rack holding up to 16 standard 25 x 75mm slides (see fig. 2-6). Four removable thin plastic rods are inserted into holes drilled along the back of the rack. - Page 71 PTC-100 Operations Manual (especially a problem with two-slide preparations). Keep the bottoms of slides free of sealer, to avoid interposing anything between the slides and the bottom of the slide slots. Self-Seal reagent and Frame-Seal incubation chambers, available from MJ R...

- Page 72 Appendix A Maintaining the 16MS Slide Block Clean the 16MS Slide Block with a mild soap solution, water-based laboratory cleaner, or ethanol (95%) and a soft cloth. Avoid strongly alkaline cleaners and chlorinated solvents. Do not immerse the block in water. Remove extraneous materials from slide slots with a long-handled cotton swab, small glassware cleaning brush, or tongue depressor wrapped in laboratory tissue.

-

Page 73: Appendix B: Safety Warnings

Installation category II Electromagnetic Interference The PTC-100 has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the US FCC Rules. These limits are designed to provide a reasonable protec-... - Page 74 In addition, the PTC-100 design has been tested and found to comply with the EMC standards for emissions and susceptibility established by the European Union at time of manufacture.

-

Page 75: Appendix C: Factory-Installed Protocols

PTC-100 Operations Manual Appendix C Appendix C Appendix C Appendix C Appendix C Factory-Installed Protocols & , ° , ° ° 7 , ° , ° ° 7 , ° , ° ° 5 , ° , ° , °... -

Page 76: Appendix D: Warranties

MJ Research, Incorporated ship a repaired or replaced machine, or grant a refund of pur- chase price, to a user in a nation in which there was an authorized MJ Research distributor at the time of purchase. This warranty is not transferable from the original purchaser to a subsequent owner. - Page 77 All provisions of this warranty are voided if the product is resold, repaired, or modified by any- one other than MJ Research, Incorporated or an authorized distributor. Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 78: Appendix E: Shipping Instructions For Us Residents

5. Ship the machine (freight prepaid) to the following address. We recommend you purchase insurance from your shipper. Ship to: Repair Department MJ Research, Incorporated 590 Lincoln Street Waltham, MA 02451 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 79: Index

Index A A A A A F F F F F Accessories. See Probe, Slide Griddle FCC warning, B-2 Air supply requirements. See Setting up the Fuses, changing, 8-2 machine G G G G G B B B B B GoTo step, 6-2 Block control. - Page 80 MiniCycler Operations Manual M M M M M entering steps End step, 6-10 Manually stepping programs. See Program- extend step, 6-8 ming, Protocols GoTo step, 6-6 Menus increment step, 6-7 Enter Menu, 6-5 slope step, 6-9 Main Menu, 6-4 temperature step, 6-5 Run-Enter Menu, 4-2 indefinite holds, 6-10 Microplates, 4-4...

- Page 81 Index Sample vessels loading into block, 4-8. See also 16MS Slide Block sealing, 4-5 16MS Slide Block, 4-5 with Hot Bonnet and caps/film, 4-6 with oil or wax, 4-5 selecting 0.2ml tubes, 4-3 0.5ml tubes, 4-3 microplates, 4-4 thin-walled vs. thick-walled tubes, 4-5 Self-test, 4-2 Setting up the machine, 3-2 air supply requirements, 3-3...

- Page 82 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 83: Declaration Of Conformity

Declaration of Conformity DoC-1 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 84 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the PTC-100 and is the answer not in the manual?

Questions and answers