Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Aerotech BM Series

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

-

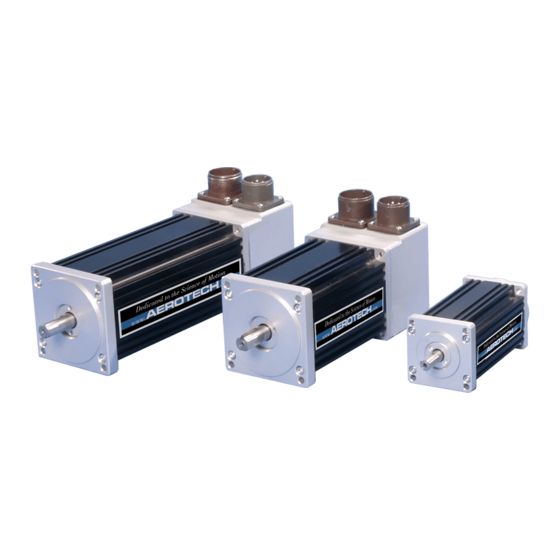

Page 2: Bm/Bms Brushless Motor Hardware Manual

BM/BMS Brushless Motor Hardware Manual Revision: 2.10.00... - Page 3 This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and may be trademarks of their respective companies.

-

Page 4: Table Of Contents

2.2.3. Over Current Protection 2.2.4. Hall-Effect Device and Thermistor Wiring 2.2.5. Wiring Guidelines 2.2.6. Thermal Protective Device (BMS Motors Only) 2.3. Hall-Effect Operation and Motor Phasing 2.4. Motor Heating 2.5. Maintenance Appendix A: Warranty and Field Service Appendix B: Revision History Index www.aerotech.com... -

Page 5: List Of Figures

Typical Thermal Sensor Resistance as a Function of Temperature Figure 2-2: Typical Thermistor Interface Circuit Figure 2-3: Hall Effect and Motor Phasing Figure 2-4: Test Setup Configuration Figure 2-5: Motor Lead Phasing with Oscilloscope Figure 2-6: Hall Phasing with Oscilloscope Figure 2-7: Example Torque Speed Curve www.aerotech.com... -

Page 6: List Of Tables

Feedback Connector Pinout (with Limits, -D25-9D, -9D-CMS, -5D, -FLB, -4TS) Table 2-17: Mating Connector Part Numbers for the -D25-XX Feedback Connector Table 2-18: Limit Connector Pinout (-D25-9D,-9D-CMS, -5D, -FLB, -4TS) Table 2-19: Mating Connector Part Numbers for the Limit Connector (-D25-xxx) www.aerotech.com... - Page 7 Table of Contents BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 8: Eu Declaration Of Conformity

BM/BMS Hardware Manual Declaration of Conformity EU Declaration of Conformity Manufacturer Aerotech, Inc. Address 101 Zeta Drive Pittsburgh, PA 15238-2811 Product Standard BM and BMS motors (excluding VAC6 versions) Model/Types BM75, BM130, BM200, BM250, BM500, BM800, BM1400, BMS35, BMS60, BMS100, BMS280, BMS465... - Page 9 Declaration of Conformity BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 10: Safety Procedures And Warnings

N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any time. All drawings and illustrations are for reference only and were complete and accurate as of this manual’s release. - Page 11 The motor relies on the drive package for all manners of fault protection. Aerotech, Inc. does not approve their motors for use in any other manner. 6. Equipment grounds must be in place and maintained to reduce the risk of potentially fatal or serious injury from electrical shock.

-

Page 12: Chapter 1: Overview

Overview Chapter 1: Overview N O T E : Aerotech continually improves its product offerings; listed options may be superseded at any time. All drawings and illustrations are for reference only and were complete and accurate as of this manual’s release. Refer to www.aerotech.com for the most up-to-date information. - Page 13 D-style 25-pin motor and feedback mating connector MCM1-3 Military style motor power mating connector (BM2000, BM3400, BM4500) Military style motor power mating connector (BM75, BM130, BM200, BM250, BM500, MCM-3 BM800, BM1400) MCF-3 Military style feedback mating connector Chapter 1 www.aerotech.com...

-

Page 14: Table 1-2: Bms Motor Options

2500 lines/rev TTL incremental encoder w/Hall tracks (-E2500H); not available for BM22 -E5000H 5000 lines/rev TTL incremental encoder w/Hall tracks (-E5000H); not available for BM22 1000 lines/rev 1 Vpp incremental encoder w/Hall tracks (-E1000ASH); not available for -E1000ASH BM22, BM2000, BM3400 or BM4500 www.aerotech.com Chapter 1... - Page 15 BMS280 or BMS465. Vacuum Preparation (Optional) Vacuum preparation to 10 Torr -VAC6 Accessories MC-HPD25-M High-power D-style motor mating connector MC-DB25-F D-style 25-pin mating connector MCM-3 Military style motor power mating connector MCF-3 Military style feedback mating connector Chapter 1 www.aerotech.com...

-

Page 16: Motor Specifications

5. Torque constant and motor constant specified at stall 6. Maximum winding temperature is 130 °C 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 17: Figure 1-1: Bm22 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-1: BM22 Torque Speed Curves Figure 1-2: BM75 Torque Speed Curves Figure 1-3: BM130 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 18: Table 1-4: Bm200, Bm250, And Bm500 Motor Specifications

5. Torque constant and motor constant specified at stall 6. Maximum winding temperature is 130 °C 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 19: Figure 1-4: Bm200 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-4: BM200 Torque Speed Curves Figure 1-5: BM250 Torque Speed Curves Figure 1-6: BM500 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 20: Table 1-5: Bm800 And Bm1400 Motor Specifications

5. Torque constant and motor constant specified at stall 6. Maximum winding temperature is 130 °C 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 21: Figure 1-7: Bm800 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-7: BM800 Torque Speed Curves Figure 1-8: BM1400 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 22: Table 1-6: Bm2000, Bm3400, And Bm4500 Motor Specifications

5. Torque constant and motor constant specified at stall 6. Maximum winding temperature is 155 °C 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 23: Figure 1-9: Bm2000 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-9: BM2000 Torque Speed Curves Figure 1-10: BM3400 Torque Speed Curves Figure 1-11: BM4500 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 24: Table 1-7: Bms35, Bms60, And Bms100 Motor Specifications

5. All performance and electrical specifications ±10% 6. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 25: Figure 1-12: Bms35 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-12: BMS35 Torque Speed Curves Figure 1-13: BMS60 Torque Speed Curves Figure 1-14: BMS100 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 26: Table 1-8: Bms280 And Bms465 Motor Specifications

5. All performance and electrical specifications ±10% 6. Maximum winding temperature is 100 °C (thermistor trips at 100 °C) 7. Ambient operating temperature range 0 °C - 25 °C; consult Aerotech for performance in elevated ambient temperatures 8. All Aerotech amplifiers are rated A ;... -

Page 27: Figure 1-15: Bms280 Torque Speed Curves

Overview BM/BMS Hardware Manual Figure 1-15: BMS280 Torque Speed Curves Figure 1-16: BMS465 Torque Speed Curves Chapter 1 www.aerotech.com... -

Page 28: Brushless Motor Dimensions

BM/BMS Hardware Manual Overview 1.2. Brushless Motor Dimensions The following figures show the outline dimensions of each model in BM series brushless motors. Figure 1-17: BM22 Model Dimensions (NEMA 17) www.aerotech.com Chapter 1... -

Page 29: Figure 1-18: Bm75, Bm130, Bm200 Model Dimensions (Nema 23)

Overview BM/BMS Hardware Manual Figure 1-18: BM75, BM130, BM200 Model Dimensions (NEMA 23) Figure 1-19: BM250, BM500 Model Dimensions (NEMA 34) Chapter 1 www.aerotech.com... -

Page 30: Figure 1-20: Bm800, Bm1400 Model Dimensions (Nema 42)

BM/BMS Hardware Manual Overview Figure 1-20: BM800, BM1400 Model Dimensions (NEMA 42) Figure 1-21: BM2000, BM3400, BM4500 Model Dimensions (NEMA 56) www.aerotech.com Chapter 1... -

Page 31: Figure 1-22: Bms35 Model Dimensions (Nema 17)

Overview BM/BMS Hardware Manual Figure 1-22: BMS35 Model Dimensions (NEMA 17) Figure 1-23: BMS60 and BMS100 Model Dimensions (NEMA 23) Chapter 1 www.aerotech.com... -

Page 32: Figure 1-24: Bms280 And Bms465 Model Dimensions (Nema 34)

BM/BMS Hardware Manual Overview Figure 1-24: BMS280 and BMS465 Model Dimensions (NEMA 34) www.aerotech.com Chapter 1... -

Page 33: Environmental Specifications

Exceeding environmental or operating specifications can cause damage to the equipment. Table 1-9: Environmental Specifications Operating: 0° to 25°C, consult Aerotech for operation outside of this range. Temperature: Storage: -20°C to 85°C Ambient conditions need to be such that condensation on the motor does not Humidity: occur. -

Page 34: Vacuum Operation

BM/BMS Hardware Manual Overview 1.4. Vacuum Operation Aerotech can specially prepare the BM/BMS for operation in vacuum environments. Aerotech offers two vacuum preparation options; one for low vacuum (for use in atmospheric pressures to 10 torr) and one for high vacuum (preparation for environments from 10 to 10 torr). - Page 35 Overview BM/BMS Hardware Manual This page intentionally left blank. Chapter 1 www.aerotech.com...

-

Page 36: Chapter 2: Assembly And Installation

25 pin D-style connector (no limits) Table 2-14 -D25-9D -D25-9D-CMS -D25-5D 25 pin D-style connector (with limits) Table 2-16 -D25-FLB -D25-4TS Table 2-3: Limit Connector Options Option Connector Description Pinout Table -D25-9D -D25-9D-CMS -D25-5D 9 pin D-style connector Table 2-18 -D25-FLB -D25-4TS www.aerotech.com Chapter 2... -

Page 37: Motor Connectors

Motor Phase C Frame Ground (motor protective ground) Backshell Motor Cable Shield P/N: MS3101A18-10P Table 2-5: Mating Connector Part Numbers for the Motor Power Connector (-MS Option) Mating Connector Aerotech P/N Third Party P/N Plug MCM00475 Amphenol MS3106A18 Insert MCM00495 Amphenol 9718-10S... -

Page 38: Table 2-8: Motor Power Flying Leads Pinout (-D25-Flb Option)

Motor Phase B Motor Phase C Reserved Frame Ground (motor protective ground) Table 2-11: Mating Connector Part Numbers for the -D25-5D Option Motor Power Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Sockets [QTY. 5] ECK00659... -

Page 39: Feedback Connectors

-BK Option Only: Brake + Reserved with -BK Option Only: Brake - (1) 24 VDC @ 1 A max Table 2-13: Mating Connector Part Numbers for the -MS Option Feedback Connector Mating Connector Aerotech P/N Third Party P/N Plug MCM00454 Amphenol MS3106A-20 Insert MCM00464... -

Page 40: Table 2-14: Feedback Connector Pinout (Without Limits, -D25 Option)

Common ground Reserved Reserved Reserved Reserved with -BK Option Only: Brake + Table 2-15: Mating Connector Part Numbers for the -D25 Option Feedback Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Connector ECK00300 FCI DB25S064TLF www.aerotech.com Chapter 2... -

Page 41: Table 2-16: Feedback Connector Pinout (With Limits, -D25-9D, -9D-Cms, -5D, -Flb, -4Ts)

Home limit Reserved Negative hardware limit (Counterclockwise/CCW) Reserved with -BK Option Only: Brake + Table 2-17: Mating Connector Part Numbers for the -D25-XX Feedback Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Connector ECK00300 FCI DB25S064TLF Chapter 2... -

Page 42: Table 2-18: Limit Connector Pinout (-D25-9D,-9D-Cms, -5D, -Flb, -4Ts)

Home limit Negative hardware limit (Counterclockwise/CCW) Reserved Common ground Reserved Reserved Table 2-19: Mating Connector Part Numbers for the Limit Connector (-D25-xxx) Mating Connector Aerotech P/N Third Party P/N 9-Pin D-Connector ECK00340 FCI DE09S064TLF Backshell ECK01021 Amphenol 17E-1724-2 www.aerotech.com Chapter 2... -

Page 43: External Motor Wiring

Fuse values should be selected according to the RMS current rating of the motor. For most applications slow-blow type fuses should be used. When the motor is part of an Aerotech system utilizing an Aerotech controller and drive, the “A ” continuous current rating of the motor must be used to set the motor over-current protection fault. -

Page 44: Hall-Effect Device And Thermistor Wiring

Do not introduce multiple paths to ground from a grounding point. Multiple paths to ground can create ground loops within the system. The use of EMI suppression devices may be necessary where the EMI environment warrants their use. www.aerotech.com Chapter 2... -

Page 45: Thermal Protective Device (Bms Motors Only)

W A R N I N G : The thermal protective device used in the motor must be incorporated in an external shutdown circuit to provide protection to the motor. Figure 2-1: Typical Thermal Sensor Resistance as a Function of Temperature Chapter 2 www.aerotech.com... -

Page 46: Figure 2-2: Typical Thermistor Interface Circuit

An excessive amount of current through the thermistor will cause its temperature to rise. False triggering will then occur. See Figure 2-2 for a typical interface circuit. Figure 2-2: Typical Thermistor Interface Circuit www.aerotech.com Chapter 2... -

Page 47: Hall-Effect Operation And Motor Phasing

Assembly and Installation BM/BMS Hardware Manual 2.3. Hall-Effect Operation and Motor Phasing Aerotech brushless motors are shipped from the factory with the correct motor phase to Hall effect relationship. Figure 2-3 shows the proper Hall effect to motor phasing for both clockwise (CW) and counterclockwise (CCW) motor rotation viewed as shown. -

Page 48: Figure 2-4: Test Setup Configuration

Note the peak of the sine wave of channel 3 in comparison to the peak of the sine wave of channel Aerotech phasing expects ØC to be the lead signal in time, ØB to follow it, and ØA to follow ØB. This means that whichever signal has been determined to lead the others in time is designated as the ØC winding. -

Page 49: Figure 2-5: Motor Lead Phasing With Oscilloscope

Move channel 1 of the oscilloscope to the second motor lead and repeat the steps given above. Note which Hall signal corresponds to the currently selected motor lead. Repeat the process for the 3rd motor lead until the desired relationships are attained and noted. Chapter 2 www.aerotech.com... -

Page 50: Figure 2-6: Hall Phasing With Oscilloscope

BM/BMS Hardware Manual Assembly and Installation Figure 2-6: Hall Phasing with Oscilloscope www.aerotech.com Chapter 2... -

Page 51: Motor Heating

The importance of motor overload and thermal protection devices as described in previous sections becomes apparent. An example torque speed curve is given in Figure 2-7. Figure 2-7: Example Torque Speed Curve Chapter 2 www.aerotech.com... -

Page 52: Maintenance

Motors should be wiped with a clean dry cloth to remove any grease, dirt, or other material that has accumulated on the motor. Fluids and sprays are not recommended for chance of internal motor contamination. Cleaning the motor labels should be avoided to prevent their removal. www.aerotech.com Chapter 2... - Page 53 Assembly and Installation BM/BMS Hardware Manual This page intentionally left blank. Chapter 2 www.aerotech.com...

-

Page 54: Appendix A: Warranty And Field Service

Aerotech makes no warranty that its products are fit for the use or purpose to which they may be put by the buyer, whether or not such use or purpose has been disclosed to Aerotech in specifications or drawings previously or subsequently provided, or whether or not Aerotech’s... - Page 55 Aerotech's approval. On-site Warranty Repair If an Aerotech product cannot be made functional by telephone assistance or by sending and having the customer install replacement parts, and cannot be returned to the Aerotech service center for repair, and if Aerotech determines the problem could be warranty-related, then the following policy applies:...

-

Page 56: Appendix B: Revision History

BM200: Section 1.1. 2.08.00 Updated connector pinouts: Section 2.1. 2.07.00 2.06.00 2.05.00 2.04.00 2.03.00 2.02.00 Revision changes have been archived. If you need a copy of this revision, contact Aerotech 2.01.00 Global Technical Support. 2.00.00 1.04 1.03 1.02 1.01 1.00 www.aerotech.com Appendix B... - Page 57 Revision History BM/BMS Hardware Manual This page intentionally left blank. Appendix B www.aerotech.com...

-

Page 58: Index

Mating Connector Part Numbers (Feedback BM2000 Model Dimensions (NEMA 56) Connector) BM2000 Motor Specifications Mating Connector Part Numbers (Limit Connector) BM22 Model Dimensions (NEMA 17) -D25-FLB Option BM22 Motor Specifications Feedback Connector Pinout BM250 Model Dimensions (NEMA 34) www.aerotech.com Index... - Page 59 BMS60 Model Dimensions (NEMA 23) Introduction BMS60 Motor Specifications Braycote® 602EF Limit Connector Pinout Brushless Motor Dimensions -D25-4TS Option -D25-5D Option Connector Pin Assignment -D25-9D-CMS Option -D25-9D Option Declaration of Conformity -D25-FLB Option Dimensions lubricants Dust Exposure vacuum operation Index www.aerotech.com...

- Page 60 Motor Phasing Motor Power Connector Pinout -D25 Option -D25-4TS Option Pinout -D25-5D Option Feedback Connector -D25-FLB Option -D25-4TS Option -D25 Option -D25-5D Option -MS Option -D25-9D-CMS Option Motor Specifications -D25-9D Option MS3101A18-10P -D25-FLB Option MS3101A20-29P -D25 Option -MS Option www.aerotech.com Index...

- Page 61 -D25-FLB Option Motor Power Connector -D25-4TS Option -D25-5D Option -D25-FLB Option -D25 Option -MS Option positive-temperature coefficient reduce EMI emissions Support Technical Support Temperature Test Setup Configuration thermistor 44-45 Thermistor Interface Circuit Torque Speed Curve vacuum vacuum guidelines Index www.aerotech.com...

- Page 62 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the BM Series and is the answer not in the manual?

Questions and answers