Chapters

Table of Contents

Summary of Contents for Anritsu MP2110A BERTWave

- Page 1 MP2110A BERTWave Operation Manual 18th Edition For safety and warning information, please read this manual before attempting to use the equipment. Keep this manual with the equipment. ANRITSU CORPORATION Document No.: M-W3831AE-18.0...

- Page 2 Ensure that you clearly understand the meanings of the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this manual.

-

Page 3: For Safety

● The performance-guarantee seal verifies the integrity of the equipment. To ensure the continued integrity of the equipment, only Anritsu service personnel, or service personnel of an Anritsu sales representative, should break this seal to repair or calibrate the equipment. Be careful not to break the seal by opening the equipment or unit covers. - Page 4 For Safety WARNING Falling Over ● This equipment should always be positioned in the correct manner. If the cabinet is turned on its side, etc., it will be unstable and may be damaged if it falls over as a result of receiving a slight mechanical shock.

- Page 5 Back-up Battery backup the memory. This battery must be replaced by service personnel when it has reached the end of its useful life; contact the Anritsu sales section or your nearest representative. Note: The battery used in this equipment has a maximum useful life of 2 years.

- Page 6 ● The USB flash drive may be damaged by static electric charges. ● Anritsu has thoroughly tested all external storage media such as USB flash drive, Hard disk drive and DVD drive. Users should note that external storage media may not have been tested by Anritsu, thus Anritsu cannot guarantee the performance or suitability of such media.

- Page 7 It is recommended to periodically back up all important data and programs to protect them from being lost accidentally. Anritsu will not be held responsible for lost data. To reduce the possibility of data loss, particular attention should be given to the following points.

- Page 8 For Safety CAUTION Use in a Residential This instrument is designed for an industrial environment. Environment In a residential environment this instrument may cause radio interference in which case the user may be required to take adequate measures. Use in Corrosive Exposure to corrosive gases such as hydrogen sulfide, sulfurous acid, Atmospheres and hydrogen chloride will cause faults and failures.

- Page 9 In addition, this warranty is valid only for the original equipment purchaser. It is not transferable if the equipment is resold. Anritsu Corporation shall assume no liability for damage or financial loss of the customer due to the use of or a failure to use this equipment, unless the damage or loss is caused due to Anritsu Corporation’s intentional or gross...

- Page 10 Anritsu Corporation Contact In the event of this equipment malfunctions, please contact an Anritsu Service and Sales office. Contact information can be found on the last page of the printed version of this manual, and is available in a separate file on the...

- Page 11 Notes On Export Management This product and its manuals may require an Export License/Approval by the Government of the product's country of origin for re-export from your country. Before re-exporting the product or manuals, please contact us to confirm whether they are export-controlled items or not. When you dispose of export-controlled items, the products/manuals need to be broken/shredded so as not to be unlawfully used for military purpose.

- Page 12 2012/19/EU (the “WEEE Directive”) in European Union. For Products placed on the EU market after August 13, 2005, please contact your local Anritsu representative at the end of the product's useful life to arrange disposal in accordance with your initial contract and the local law.

- Page 13 Anritsu electronic equipment, etc.). By using this Software, you shall be deemed to have agreed to be bound by the terms of this EULA, and Anritsu Corporation (hereafter Anritsu) hereby grants you the right to use this Software with the Anritsu specified equipment (hereafter Equipment) for the purposes set out in this EULA.

- Page 14 US embargoed countries or (b) to anyone financial or otherwise, due to your violation restricted by the Japanese export control of the terms of this EULA, Anritsu shall have regulations, or the US Treasury the right to seek proportional damages from Department's list of Specially Designated you.

- Page 15 Cautions Against Computer Virus Infection ● Copying files and data Only files that have been provided directly from Anritsu or generated using Anritsu equipment should be copied to the instrument. All other required files should be transferred by means of USB flash drive or CompactFlash media after undergoing a thorough virus check.

- Page 16 CE Conformity Marking Anritsu affixes the CE conformity marking on the following product(s) in accordance with the Decision 768/2008/EC to indicate that they conform to the EMC, LVD, and RoHS directive of the European Union (EU). CE marking 1. Product Model...

- Page 17 B: The equipment shall continue to operate as intended after the test. No degradation of performance or loss of function is allowed below a performance level specified by the manufacturer, when the equipment is used as intended. The performance level may be replaced by a permissible loss of performance.

- Page 18 4. Contact Name: Anritsu GmbH Address, city: Nemetschek Haus, Konrad-Zuse-Platz 1 81829 München, Country: Germany Name: ANRITSU EMEA Ltd. Address, city: 200 Capability Green, Luton Bedfordshire, LU1 3LU Country: United Kingdom xviii...

- Page 19 RCM Conformity Marking Anritsu affixes the RCM mark on the following product(s) in accordance with the regulation to indicate that they conform to the EMC framework of Australia/New Zealand. RCM marking 1. Product Model Model: MP2110A BERTWave 2. Applied Standards...

- Page 20 About Eco label The label shown on the left is attached to Anritsu products meeting our environmental standards. Details about this label and the environmental standards are available on the Anritsu website at https://www.anritsu.com.

-

Page 21: About This Manual

The manual set for the BERTWave Series consists of the following five operation manuals: MP2110A BERTWave Operation Manual (M-W3831AE) (This Manual) This manual is intended for those who use the MP2110A BERTWave, and explains the installation procedure, handling precautions, connector connection procedures, panel operations, maintenance procedures, specifications and various functions. - Page 22 • Windows file operations and the Windows Control Panel Manual Notation System The MP2110A BERTWave is referred to as the MP2110A in this manual. The user interface such as button and tab names are in bold. Example: PPG, System Menu The connector names on the panel are in Arial –...

-

Page 23: Table Of Contents

Table of Contents For Safety ............iii About This Manual ..........I Chapter 1 Outline ..........1-1 Introduction of BERTWave .......... 1-2 Configuration .............. 1-9 Features ..............1-16 Intended Use ............1-17 Technical Terms ............1-20 Abbreviations ............1-45 Chapter 2 Before Use ......... - Page 24 Chapter 4 Screen Operation ......4-1 Window Configuration ..........4-2 Data Input Method ............4-5 Setting System Menu ..........4-8 Multi-channel Signal Output ........4-19 Simultaneous Measurement Start and Stop at Multi-channels ............4-20 Linking Measurement Settings for Multiple Channels . 4-21 Displaying BER Measurement Results for Multiple Channels .............

- Page 25 Chapter 8 Maintenance ........8-1 Daily Maintenance ............8-2 Replacement of Optical Connector ......8-3 Optical Connector/Optical Adapter Cleaning ....8-5 Displaying Software Version........8-8 Updating Software ............8-9 Adding an Option License ......... 8-10 System Recovery Function ........8-12 Calibration ..............

-

Page 27: Chapter 1 Outline

Chapter 1 Outline This chapter explains the MP2110A BERTWave configuration, features, and technical terms used in this manual. Introduction of BERTWave ........... 1-2 1.1.1 MP2110A BERTWave ........1-3 1.1.2 MP2100B BERTWave ........1-8 Configuration ..............1-9 1.2.1 Standard Configuration ........1-9 1.2.2 Options ............ -

Page 28: Introduction Of Bertwave

Chapter 1 Outline 1.1 Introduction of BERTWave The BERTWave is a measuring instrument that combines the functions of a pulse pattern generator (PPG), bit error detector (ED) and sampling oscilloscope all-in-one instrument. The PPG is a digital signal generator that can edit the data rate, the voltage level of the pulse, and the pattern of data to be transmitted. -

Page 29: Mp2110A Bertwave

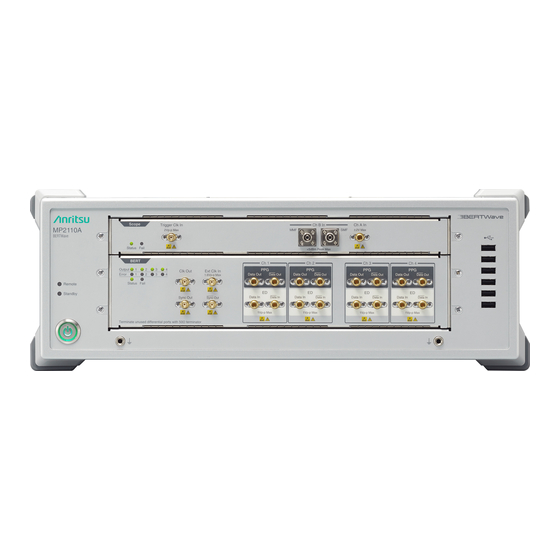

Introduction of BERTWave 1.1.1 MP2110A BERTWave MP2110A BERTWave (MP2110A) is a measuring instrument combining the BERT (Bit Error Rate Tester) and the sampling oscilloscope. It is used by connecting with the monitor, key board, and mouse as the same as PC. - Page 30 Chapter 1 Outline Scope: Sampling Oscilloscope BERT: Bit Error Rate Tester Figure 1.1.1-2 Front Panel of MP2110A The input connectors of the sampling oscilloscope can be selected by specifying the option. Table 1.1.1-1 Sampling Oscilloscope Input Connectors Channel A Channel B Channel C Channel D Options Number Electrical Optical Optical Electrical Optical Optical Optical Optical OpticalOptical...

- Page 31 Introduction of BERTWave BERT (Bit Error Rate Tester) uses PPG (Pulse Pattern Generator) and ED (Error Detector) together. The number of BERT channels can be selected by specifying the option. Table 1.1.1-2 Number of BERT Channels Option Number Number of Channels MP2110A-011 MP2110A-012 MP2110A-014...

- Page 32 Chapter 1 Outline By installing MP2110A-095 PAM4 Analysis Software, PAM4 waveform can be analyzed. Figure 1.1.1-3 Example of PAM4 Waveform Analysis...

- Page 33 Introduction of BERTWave By installing MP2110A-096 Jitter Analysis Software, jitter analysis result can be displayed. Figure 1.1.1-4 Example of Jitter Analysis...

-

Page 34: Mp2100B Bertwave

Figure 1.1.2-1 MP2100B External View MP2100B BERTWave is a space-saving measuring instrument that can operate using the 12.1-inch touch panel. The SFP slot and O/E converter can be added as the option. Refer to the following website for the MP2100B BERTWave information. https://www.anritsu.com/en-us/test-measurement/products/mp2100b... -

Page 35: Configuration

Configuration 1.2 Configuration 1.2.1 Standard Configuration The following table lists the standard configuration of the MP2110A. Table 1.2.1-1 Standard Configurations Model/ Item Product Name Q’ty Remarks Ordering No. Main unit MP2110A BERTWave Accessories POWER CORD Contained in accessory box. J1627A GND connection cable Z1364A MX210000A... - Page 36 Chapter 1 Outline Table 1.2.1-2 Connection Destination and Quantity of J0617B and Z0397A Option Number Connection Destination Q’ty MP2110A-030, MP2110A-040 Optical In SMF A, B, C, D MP2110A-039, MP2110A-049 Optical In MMF A, B, C, D MP2110A-022, MP2110A-032, Ch A In SMF, Ch A In MMF, MP2110A-042 Ch B In SMF, Ch B In MMF MP2110A-023, MP2110A-033,...

- Page 37 Configuration Table 1.2.1-4 Connection Destination and Quantity of J1341A Option Number Connection Destination Q’ty MP2110A-011 Ext Clk In, Clk Out, Sync Out×1, Data In×1, In×1 Data MP2110A-012 Ext Clk In, Clk Out, Sync Out×1, Data In×2, In×2 Data MP2110A-014 Ext Clk In, Clk Out, Sync Out×1, Data In×4, In×4 Data MP2110A-030,...

-

Page 38: Options

The MP2110A options are shown below. The numbers of the options installed are indicated on the label on the rear panel. For details of whether retro-fitted options or software options are included, please refer to the ordering information on the Anritsu website. https://www.anritsu.com/en-us/test-measurement/products/mp2110a 1-12... - Page 39 Configuration Table 1.2.2-1 MP2110A Option List Option Number Name MP2110A-011 1CH BERT* MP2110A-012 2CH BERT* MP2110A-014 4CH BERT* MP2110A-021 Dual Electrical Scope* MP2110A-022 Dual Optical Scope* MP2110A-023 Optical and Single-ended Electrical Scope* MP2110A-024 Precision Trigger* MP2110A-025 Optical Scope for Singlemode* MP2110A-026 Optical Scope for Multimode* MP2110A-030...

-

Page 40: Optional Accessories

Chapter 1 Outline 1.2.3 Optional Accessories Table 1.2.3-1 shows the optional accessories for MP2110A Contact us to confirm the specifications of the optical switch and programmable optical attenuator. Table 1.2.3-1 Optional Accessories Model/Order No. Name B0734A Carrying Case B0735A Rack Mount Kit G0307A Clock Recovery Module (<2.667G) G0342A... - Page 41 Fixed Optical Attenuator (1dB) J1825A Fixed Optical Attenuator (2dB) J1826A Fixed Optical Attenuator (3dB) J1827A Fixed Optical Attenuator (5dB) W3831AE MP2110A BERTWave Operation Manual* W3773AE BERTWave Series Remote Control Operation Manual* Z0306A Wrist Strap Z0541A USB Mouse Z0914A Ferrule Cleaner...

-

Page 42: Features

(typical value) (MP2110A-024) For sampling oscilloscope: EYE analysis in short time using high-speed sampling Compatibility of remote commands with previous Anritsu measuring instruments One or both of the following clock recovery units can be installed to the sampling oscilloscope: ... -

Page 43: Intended Use

Intended Use 1.4 Intended Use The MP2110A can be used for the following applications: Evaluating optical transceivers used in optical fiber communications Evaluating parts for digital communications Evaluating optical transceivers used in optical fiber communications Computer-based and public communications systems transmit and receive digitalized signals. - Page 44 Chapter 1 Outline The receiver sensitivity which is one of the performances in the optical transceiver is calculated by measuring the bit error rate and optical power. The following figure shows a connection example between the DUT and the measuring instruments when the DUT is the CFP4 module. TX1 to TX4 RX1 to RX4 Data and...

- Page 45 Intended Use The output waveform of the optical transceiver is evaluated using the pulse pattern generator and sampling oscilloscope. The output of optical transceiver is the wavelength multiplexed optic. Therefore, input only the optic of the wavelength to be measured using the optical demultiplexer or optical filter to MP2110A.

-

Page 46: Technical Terms

Chapter 1 Outline 1.5 Technical Terms This section explains the technical terms used in this manual. BER: Bit Error Rate The Bite Error Rate is the ratio of the total received bits and error bits. It depends on the SNR (signal to noise ratio). Standard Deviation of Noise Amplitude n Signal Amplitude s... - Page 47 Technical Terms SNR (dB) Figure 1.5-2 Relationship between SNR and BER Bit Rate The Bit Rate is the speed at which the communications interface transmits and receives data. It is expressed by the number of bits transmitted per second (bit/s or bps). 1-21...

- Page 48 Chapter 1 Outline Bathtub As an evaluation method of eye pattern waveform, there is a graph that displays the measurement result with time as the horizontal axis and bit error rate as the vertical axis. The left and right edges of the graph are the positions of the cross points of the eye pattern waveform, and have large bit error rates.

- Page 49 Technical Terms DCD: Duty Cycle Distortion The duty cycle distortion (DCD) is found from the following equation: DCD = (t – t )/Bp × 100 Where, : Time at crossing point between 50% level of Eye Amplitude and rising waveform : Time at crossing point between 50% level of Eye Amplitude and falling waveform Bp: Bit cycle...

- Page 50 Chapter 1 Outline DDJ vs Bit The amount of jitter, which is measured for each bit whose pattern changes, is displayed as a graph. The time difference between the clock and the waveform at the cross point level is measured and the result is plotted on the pattern location. When the waveform time is slower than the clock, the value is positive, and when the waveform is faster than the clock, the value is negative.

- Page 51 Technical Terms DDPWS (Data Dependent Pulse Width Shrinkage) DDPWS is the amount of pulse width shrinkage by data dependent jitter. 4… Figure 1.5-6 DDJ Measurement Method In Figure 1.5-6, the red line is the ideal symbol waveform and the blue line is the measured waveform with jitter.

- Page 52 Chapter 1 Outline Dual Dirac Estimation If the jitter elements include DJ, the histogram has multiple peaks at the waveform cross point. Dual Dirac Estimation is a method to estimate RJ and DJ using Dual Dirac function as the fitting curve of this histogram. Figure 1.5-7 Histogram of Jitter with DJ The Dual Dirac distribution is expressed as the combined formula of two normal distributions.

- Page 53 Technical Terms The Dual Dirac distribution assumes that RJ is the normal distribution and DJ is a constant value. The Jitter Analysis software displays σ and µ –µ of the Dual Dirac distribution approximated from the measured histogram to RJ (d-d) and DJ (d-d) respectively. Extinction Ratio The extinction ratio is the ratio of 1 Level and 0 Level;...

- Page 54 Chapter 1 Outline Eye Height For NRZ, eye height can be calculated by the following formula. Refer to Figure 1.5-21. Eye Height = (1 Level–3 ) – (0 Level +3 : 1 Level Standard Deviation : 0 Level Standard Deviation For PAM4, eye height varies depending on eye definition method and sample method.

- Page 55 Technical Terms Eye Levels, Eye Widths Eye Widths are the eye widths of the PAM4 waveform. They depend on how the eyes are defined. Eye Levels are the levels to measure eye widths. Level 3 Eye Width Upper Eye Level Upper Level 2 Eye Width Middle...

- Page 56 Chapter 1 Outline Eye Pattern The Eye Pattern is the pattern created by superimposing the digital waveforms sampled at the same timing. First measured waveform Second measured waveform Third measured waveform Fourth measured waveform Super- imposed waveforms Eye pattern Figure 1.5-14 Eye Pattern Drawing Method 1-30...

- Page 57 Technical Terms Eye Skews When PAM4 waveform and Sample Timing is Independent, Eye Skews are phase differences between the average value of the center of each eye (Eye Center) and the centers of Upper Eye, Middle Eye and Lower Eye. Eye Skew Middle Eye Skew Upper Level 3...

- Page 58 Chapter 1 Outline Eye Width Eye Width is equivalent to Eye Height in the horizontal direction. For NRZ, it is calculated from a histogram of the two eye pattern crossing points in the time direction. Eye Width = (t – 3 ) –...

- Page 59 Technical Terms Jitter Jitter is the variation in the time of the crossover point between the Eye Diagram rising and falling parts of the waveform. Jitter p-p (Jitter p-p): Full width of histogram in time direction Jitter RMS (Jitter RMS): Standard deviation of histogram in time direction Jitter p-p...

- Page 60 Chapter 1 Outline Table 1.5-1 Jitter Type Abbrev. Name Description Total Jitter Jitter of combined RJ and DJ Not a simple sum of RJ and DJ Random Jitter Jitter which occurs with external factors such as thermal noise. It has a characteristic to spread unlimitedly which approaches Gaussian distribution.

- Page 61 Technical Terms Levels p-p, Levels RMS, Level Skews When measuring the histogram of each level with PAM4 waveform, the peak value of its width is Levels p-p and the standard deviation is Levels RMS. If Sample Timing is Independent, Levels p-p, Levels and RMS are measured at the following positions.

- Page 62 Chapter 1 Outline Linearity It indicates the degree that the three Eye Amplitudes of the PAM4 waveform deviate from one third of the difference between Level 0 and Level 3. If the three Eye Amplitudes are equal, the linearity is 1. It is calculated with the smallest eye amplitude out of the three eye amplitudes.

- Page 63 Technical Terms One Level At Eye pattern measurement, the maximum level at the center 20% of the bit interval is the average value of the high histogram. 100 % 20 % 1 level 3 Eye height Crossing amplitude point level 3...

- Page 64 Chapter 1 Outline Outer OMA It is the optical modulation amplitude of PAM 4 waveform, and it is the difference between Level 3 and Level 0. Overshoot It is the ratio of the maximum power to Level 3 in the PAM4 waveform and is calculated by the following formula: Overshoot = Pmax –Level 3 ...

- Page 65 Technical Terms RNzero: Electrical random noise power measured at Level 0 OMA: For NRZ signal, OMA, and for PAM4 signal, Outer OMA. Bandwidth of the filter used Rise/Fall Time The Rise Time is time taken for the signal level to change to the next level.

- Page 66 Chapter 1 Outline RMS (root mean square) This is the DC voltage consuming the equal power the same as the consumed power when impressing AC voltage on a resistance. In Voltage, RMS is DC voltage consuming the equal power when AC voltage is impressing on a resistance.

- Page 67 Technical Terms Sampling Oscilloscope The sampling oscilloscope is a function for monitoring the waveform of the input signal. It requires a clock input sampling and the waveform is drawn out of the clock timing. For a periodic signal like PRBS, the waveform data is obtained by slightly varying the sampling timing.

- Page 68 Chapter 1 Outline TDEC (Transmitter and Dispersion Eye Closure) TDEC is the measured value of the eye opening of the NRZ signal and is calculated by the following formula. For details, refer to 95.8.5.2 “TDEC measurement method” of the IEEE 802.3.

- Page 69 Technical Terms TDECQ (Transmitter and Dispersion Eye Closure for PAM4) TDECQ is the measured value of the eye opening of the PAM4 signal and is calculated by the following formula. Outer TDECQ = (dB) Qt: 3.414 where SER (Symbol Error Rate) = 4.8 × 10 (as specified –4 in the IEEE 802.3cd)

- Page 70 Chapter 1 Outline Pmin: Minimum power measured in the waveform VECP (Vertical Eye Closure Penalty) VECP is the ratio of eye amplitude to eye opening and is calculated by the following formula. log( VECP = (dB) : Optical Modulation Amplitude ...

-

Page 71: Abbreviations

Abbreviations 1.6 Abbreviations The abbreviations used in this manual are listed in Table 1.6-1. Table 1.6-1 Abbreviation Abbreviation Description 100GbE 100 Giga bit Ethernet 400GbE 400 Giga bit Ethernet Application Attenuator Average Bit Error Rate BERT Bit Error Rate Tester BERTS Bit Error Rate Test Set Binary... - Page 72 Chapter 1 Outline Table 1.6-1 Abbreviation (Cont’d) Abbreviation Description Ground GPIB General Purpose Interface Bus International Electrotechnical Commission Input Insertion Internal Inter Symbol Interference International Telecommunication Union Local Area Network Maximum MDIO Management Data Input/Output Multi-mode fiber Multiplexer Not Applied NECL Negative Emitter Coupled Logic Negative...

- Page 73 Abbreviations Table 1.6-1 Abbreviation (Cont’d) Abbreviation Description Signal to Noise Ratio Sampling Scope SSPRQ Short Stress Pattern Random Quaternary Synchronous Transfer Mode SYNC Synchronize, Synchronization TDEC Transmitter and Dispersion Eye Closure TDECQ Transmitter and Dispersion Eye Closure for PAM4 Total Jitter Trig.

- Page 74 Chapter 1 Outline 1-48.

-

Page 75: Chapter 2 Before Use

Chapter 2 Before Use This chapter explains the following items: • Procedures from unpacking through turning power-on • Panel name and operation • Control panel and peripheral devices settings • Damage prevention measures Unpacking and Installation .......... 2-2 2.1.1 Unpacking ............2-2 2.1.2 Installation............ -

Page 76: Unpacking And Installation

2.1 Unpacking and Installation 2.1.1 Unpacking At unpacking, check that all items are included. Contact an Anritsu Service and Sales office if any parts are missing or damaged. Keep the original packaging materials. They are required when transporting the BERTWave in future. - Page 77 Unpacking and Installation CAUTION • If the MP2110A is not installed in a “good” direction as above, a small shock may turn it over and harm the user. • Do not stack three or more MP2110As on top of each other when using them.

- Page 78 Chapter 2 Before Use CAUTION Although the MP2110A operates at an ambient temperature of 5 to 40°C, avoid using it in locations, such as the following, since it may cause failure. • In direct sunlight for extended periods • Outdoors •...

-

Page 79: Part Names

Part Names 2.2 Part Names 2.2.1 Front Panel Remote Scope Standby Connectors Functional BERT Functional Ground Terminal Power Switch Ground Terminal Figure 2.2.1-1 Front Panel (Scope+BERT) Remote Scope Standby Connectors Functional Functional Ground Terminal Power Switch Ground Terminal Figure 2.2.1-2 Front Panel (Scope+CRU) - Page 80 Chapter 2 Before Use Table 2.2.1-1 Front Panel Description Name Description Scope Panel of the sampling oscilloscope If no scope option is installed, this slot is filled with a blank panel. BERT Panel of the bit error rate tester If neither BERT option nor MP2110A-055 is installed, this slot is filled with a blank panel.

- Page 81 Part Names BERT Panel Error Output Clk Out Ext Clk In BERT Ch 1 Ch 2 Ch 3 Ch 4 Ext Clk In Clk Out Output 1.6Vp-p Max Data Out Data Out Data Out Data Out Data Out Data Out Data Out Data Out Error...

- Page 82 Chapter 2 Before Use Scope Panel Ch B In Ch A In Scope Trigger Clk In ±2V Max 2Vp-p Max ±2V Max Status Fail Ch A In Trigger Clk In Ch B In Fail Status Figure 2.2.1-4 Scope Panel Names (MP2110A-021) Ch A In Scope Trigger Clk In...

- Page 83 Part Names The following label is on the panel of MP2110A-030, MP2110A-032, MP2110A-033, MP2110A-035, MP2110A-036, and MP2110A-039. Baseband Flat Option Installed The following tables describe the panel. Table 2.2.1-4 Lamp List Name Description Status Lights when MP2110A can receive remote commands upon successful start.

- Page 84 Chapter 2 Before Use Table 2.2.1-5 Connector List Connector Name Description Maximum Input Level Trigger Clk In For trigger clock input to 2 Vp-p the sampling oscilloscope. Ch A In* Data input Coaxial connector: ±2 V SMF: 860 to 1650 nm SMF optical connector: +8 dBm peak MMF: 800 to 860 nm...

- Page 85 Part Names CRU Panel Data In Recovered Clock Out Data Out Data Out Data In Optical Status Fail +6.5dBm Peak Max Fail Status Figure 2.2.1-9 CRU Panel Names (MP2110A-055) The following tables describe the panel. Table 2.2.1-6 Lamp List Name Description Status Lights when MP2110A can receive remote commands upon...

-

Page 86: Rear Panel

Chapter 2 Before Use 2.2.2 Rear Panel Serial Number, Option Number Label GPIB Connector Functional Inlet Ground Terminal HDMI USB3.0 Ethernet Mic Input Line Output Figure 2.2.2-1 Rear Panel The following table describes the connectors. Table 2.2.2-1 Connector List Name Description GPIB For connecting to a PC to control MP2110A remotely. -

Page 87: Power Connection

Power Connection 2.3 Power Connection 2.3.1 Power Requirements For normal operation of the MP2110A, use the power voltage range described below. Table 2.3.1-1 Power Requirements Power source Voltage range Frequency 100 Vac system 100 to 120 V 50 to 60 Hz 200 Vac system 200 to 240 V 50 to 60 Hz... -

Page 88: Connecting Power Cord

Chapter 2 Before Use 2.3.2 Connecting Power Cord Insert the power plug into an outlet, and connect the other end to the power inlet on the rear panel. To ensure that the MP2110A is properly grounded, always use the supplied 3-pin power cord. WARNING Always connect the MP2110A to a properly grounded outlet. -

Page 89: Connecting Peripheral Devices

Connecting Peripheral Devices 2.4 Connecting Peripheral Devices USB devices Connect a mouse, keyboard, storage and other USB devices to the USB connectors on the front or rear panel. External Monitor Connect an external monitor to the DP or HDMI connector on the rear-side panel. -

Page 90: Connecting Remote Control Devices

Chapter 2 Before Use 2.5 Connecting Remote Control Devices Refer to 4.3.10, “Remote Control” for details of how to set the remote control interface. Ethernet Connect an Ethernet cable that is CAT 5 cable or newer to the Ethernet connector on the rear panel. GPIB Connect the cable to the rear-panel GPIB connector. - Page 91 Connecting Remote Control Devices Connect cables without forming loops. (a) Daisy Chain (b) Star (c) Loop Figure 2.5-2 GPIB Cable Connection 2 2-17...

-

Page 92: Cautions On Handling Optical Fiber Cables

Chapter 2 Before Use 2.6 Cautions on Handling Optical Fiber Cables Optical fiber cables may degrade in performance or be damaged if handled improperly. Note the following points when handling them. CAUTION Do not pull the cable when removing the connector. - Page 93 Cautions on Handling Optical Fiber Cables CAUTION Do not excessively pull on or twist an optical fiber cable. Also, do not hang anything by using a cable. Doing so may break the optical fiber inside the cable. CAUTION Be careful not to hit the end of an optical connector against anything hard such as the floor or a desk by dropping the optical fiber cable.

-

Page 94: Connecting Coaxial Cable

Chapter 2 Before Use 2.7 Connecting Coaxial Cable Connect the coaxial cable to the MP2110A coaxial connector. Refer to 2.10 “Precautions for Preventing Damage”. 2.7.1 Notes on Coaxial Cable Connection WARNING When signals are input to the MP2110A, avoid excessive voltage beyond the rating. -

Page 95: How To Discharge The Electrostatic Charges Of The Coaxial Cable

Connecting Coaxial Cable 2.7.2 How to Discharge the Electrostatic Charges of the Coaxial Cable There is a risk of damaging MP2110A if the coaxial cable you connect to MP2110A is charged electrostatically. To prevent MP2110A from being damaged by ESD, discharge the electrostatic charges of the coaxial cable by using the ESD Discharger, which is an optional accessary of MP2110A, before cabling the connectors. -

Page 96: Turning Power On/Off

Chapter 2 Before Use 2.8 Turning Power On/Off 2.8.1 Power-on Before turning power on, connect an external monitor, a keyboard and a mouse to MP2110A. Refer to 2.4 “Connecting Peripheral Devices”. Turn on the external monitor. Connect the power cord plug, referring to 2.3 “Power Connection”. The MP2110A enters the standby state and the Standby lights orange. -

Page 97: Power-Off

Turning Power On/Off 2.8.2 Power-off Click System Menu in the application window. Click Exit. Click Yes. Press the Power switch. The Power switch blinks in green. After the power-off process has completed, the power switch lamp goes off, and the Standby lights orange. -

Page 98: Setting Control Panel

Windows settings are changed. Read the general notes in this section carefully when changes to the Windows settings are required. CAUTION Anritsu guarantees the MP2110A to work properly only when the factory settings for Windows have not been changed. -

Page 99: Setting Control Panel

Setting Control Panel 2.9.2 Setting Control Panel The system time, external display settings and Click panel settings are set at the Windows Control Panel. Do not change any settings other than those listed in Table 2.9.2-1. Table 2.9.2-1 Description of Control Panel Icon Description Date and Time... -

Page 100: Setting External Monitor

Chapter 2 Before Use 2.9.3 Setting External Monitor The external monitor resolution is changed using the following methods. MP2110A uses Windows Embedded Standard 7 (WES7) 64 bit version or Windows 10 IoT Enterprise 2019 LTSC (Win10). The setting method differs depending on the operating system. For WES7: Connect the external monitor to the monitor connector on the rear panel of the MP2110A. - Page 101 Setting Control Panel Click OK. The dialog box confirming changes of the desktop appears. Click Keep changes. 10. Click on the task bar. 11. When the external monitor resolution is set to 1280 × 800, click System Menu - Dock/Undock to fix the application window at top left of the screen (refer to 4.3.9 “Dock/Undock”).

- Page 102 Chapter 2 Before Use For Win10: Connect the external monitor to the monitor connector on the rear panel of the MP2110A. Set the MP2110A and monitor power to On. Click System Menu. Click Minimize. Right click on desk top. Click Display Settings. Change the external monitor resolution.

- Page 103 Setting Control Panel The dialog box confirming changes of the desktop appears. Click Keep changes. Click on the task bar. 10. When the external monitor resolution is set to 1280 × 800, click System Menu - Dock/Undock to fix the application window at top left of the screen (refer to 4.3.9 “Dock/Undock”).

-

Page 104: Precautions For Preventing Damage

Chapter 2 Before Use 2.10 Precautions for Preventing Damage CAUTION • Always use the supplied 3-pin power cord to ground both the MP2110A and DUT (included in test circuit). After confirming that both the MP2110A and DUT are grounded, use coaxial cables to connect them. NEVER connect the MP2110A and DUT without grounding, otherwise electrostatic discharge may damage the MP2110A. - Page 105 2.10 Precautions for Preventing Damage CAUTION Do not touch the core conductor of the coaxial cable connected to the input connector or bring it into contact with metal. Doing so may damage the input circuit of the MP2110A. CAUTION Do not touch the core conductor to the metal when connecting the coaxial cable to the connector.

-

Page 106: Precautions On Electrostatic Discharge And Electrical Overstress

Chapter 2 Before Use 2.10.1 Precautions on Electrostatic Discharge and Electrical Overstress CAUTION • When signals are input to the MP2110A, avoid excessive voltage beyond the rating. Otherwise, the circuit may be damaged. • Never feed any current or input signals to the output connector. - Page 107 2.10 Precautions for Preventing Damage CAUTION • Always use 3-pin power cords when connecting external devices, including experimental circuits, to AC outlets. Connect the ground wires of external devices and MP2110A to a common ground. • Turn on the external devices, including experimental circuits, before connecting them to the MP2110A.

- Page 108 Chapter 2 Before Use Follow the procedure below to check for electrical overstress to the MP2110A before connecting DUT (Device Under Test). Checking the ground connection using a tester Connect DUT and the ground terminal of the MP2110A with a ground wire.

- Page 109 2.10 Precautions for Preventing Damage Checking the output waveform with an oscilloscope Connect the DUT and the oscilloscope using a cable with an impedance of 50 Ω. Set the input impedance of the oscilloscope to 50 Ω. Observe the waveform with the oscilloscope, and perform the following operations to check the observed waveform for surge voltage exceeding the rated voltage*.

-

Page 110: Precautions When Using Bias-T

Chapter 2 Before Use 2.10.2 Precautions When Using Bias-T When connecting an external device such as a Bias-T to the output connectors of the MP2110A, if the output signal includes any DC voltage, variations in the output of the DC power supply or load may change the level of the output signal, risking damage to the internal circuits. - Page 111 2.10 Precautions for Preventing Damage Measurement Preparation 2: Set the MP2110A output to OFF. Set the DC power supply output to OFF. Disconnect the MP2110A and all equipment, or change the DUT connections. Since even unforeseen fluctuations in DC voltage and load (open or short circuits at the MP2110A output side and changes caused by using a high-frequency probe, etc.) can damage the DUT and the MP2110A, we recommend connecting a 50 Ω...

-

Page 112: Windows Security Measures

CAUTION If MP2110A is connected to an external network like the Internet, there may be a risk of causing unexpected problems suffering unexpected losses. Anritsu Corporation is not responsible for any losses caused by connecting it to a network. 2-38... -

Page 113: Activating Firewall

2.11 Windows Security Measures 2.11.1 Activating Firewall It is recommended to turn On the Windows firewall on MP2110A. For WES7: Windows firewall On/Off setting (WES7): Click Start → Control Panel from the Windows menu bar hidden in the lower part of the screen. Click System and Security →Windows Firewall to show Windows Firewall window. - Page 114 Chapter 2 Before Use Customize Settings window will be shown where Windows firewall On/Off settings can be changed. Use MP2110A with the following checkboxes Off (unchecked). ● Block all incoming connections, including those in the list of allowed programs ● Notify me when Windows Firewall blocks a new program Figure 2.11.1-2 Customize Settings Window 2-40...

- Page 115 2.11 Windows Security Measures Confirmation and setting of allowed programs through Windows firewall (WES7): Even if Windows firewall is On, in order for this instrument to operate properly, it is necessary to set as allowed programs those that enable external communication from MP2110A. Note: Depending on when MP2110A was released, factory default setting for allowed programs might not be set beforehand.

- Page 116 Chapter 2 Before Use Allowed Programs window will be shown where programs allowed through Windows firewall can be confirmed. Confirm if MX210000A is found and set to On (checked) under Allowed programs and features. When no such information is displayed, it is necessary to add MX210000A.

- Page 117 2.11 Windows Security Measures Procedure to add MX210000A when it is not registered (WES7): Use the mouse to click Allow another program… found in Allowed Programs window. Figure 2.11.1-5 Allowed Programs Window In Add a Program window, select MX210000A, and click Add. Figure 2.11.1-6 Add a Program Window 2-43...

- Page 118 Chapter 2 Before Use MX210000A is added to Allowed programs and features. Confirm if MX210000A is found and set to On (checked). Figure 2.11.1-7 Allowed Programs Window 2-44...

- Page 119 2.11 Windows Security Measures For Win10 Windows firewall On/Off setting (Win10) Click Start ( ) → Windows system → Control Panel from the Windows menu bar hidden in the lower part of the screen. With View by: Category, click System and Security → Windows Defender Firewall to show Windows Defender Firewall window.

- Page 120 Chapter 2 Before Use Confirmation and setting of allowed programs through Windows firewall (Win10) Even if Windows firewall is On, in order for this instrument to operate properly, it is necessary to set as allowed programs those that enable external communication from MP2110A. Click Allow an app or feature through Windows Defender Firewall found in left side of Windows Defender Firewall window.

- Page 121 2.11 Windows Security Measures Procedure to add MX210000A Main Application when it is not registered (Win10) Use the mouse to click Allow another apps… found in Allowed apps window. Figure 2.11.1-12 Allowed apps Window Add an app window is shown. Click Browse…. Figure 2.11.1-13 Add an app Window 2-47...

- Page 122 Chapter 2 Before Use Browse window of Add an app is shown. Select C:\Program Files\Anritsu\MP2100A\MX210000A\MainApp.exe, and click Open. Figure 2.11.1-14 Browse Window of Add an app In Add an app window, select MX210000A Main Application, and click Add. Figure 2.11.1-15 Add an app Window...

- Page 123 2.11 Windows Security Measures MX210000A Main Application is added to Allowed apps and features. Confirm if MX210000A Main Application is found and set to On (checked). Figure 2.11.1-16 Allowed apps Window 2-49...

-

Page 124: Installing Windows Important Update Programs (Windows Update)

Chapter 2 Before Use 2.11.2 Installing Windows Important Update Programs (Windows Update) It is necessary to regularly check for important Windows update programs and keep them up-to-date. However, the performance of MP2110A could decrease while downloading and installing Windows updates. Turn off automatic updates in Windows. Instead, it is recommended to manually check for, download, and install new updates on a periodic basis, avoiding the operating hours of MP2110A. - Page 125 2.11 Windows Security Measures Select Never check for updates (not recommended) in Important updates, then click OK. Figure 2.11.2-2 Change settings Window To check for newly available update programs (manual update), click Check for updates in Windows Update window. Figure 2.11.2-3 Windows Update Window (manual update) When a new update program is found, download and install following the displayed instructions.

- Page 126 Chapter 2 Before Use For Windows 10: Click Start ( )→ Settings ( ) from the Windows menu bar hidden in the lower part of the screen. Click Update and Security to show Windows Update window. To turn off automatic updates, select Windows Update found in left side of Windows Update window, and then click Advanced options.

- Page 127 2.11 Windows Security Measures To check for newly available update programs (manual update), click Check for updates in Windows Update window. Figure 2.11.2-6 Windows Update Window (manual update) When a new update program is found, download and install following the displayed instructions. 2-53...

-

Page 128: Using Antivirus Software

Chapter 2 Before Use 2.11.3 Using Antivirus Software It is recommended to install antivirus software on MP2110A. However, if the antivirus software updates virus definition data automatically or runs full scan in the background, the performance of MP2110A could decrease. Do not allow the software to execute them. Instead, it is recommended to manually run them on a periodic basis, avoiding the operating hours of MP2110A. -

Page 129: Chapter 3 Measurement Examples

Chapter 3 Measurement Examples This chapter explains examples of how to connect the MP2110A and the DUT and their measurement procedures. When changing the optical level input to the DUT such as the receiver sensibility measurement, connect other measurement instruments such as optical attenuator. -

Page 130: Measuring Bit Error Rate

Chapter 3 Measurement Examples 3.1 Measuring Bit Error Rate When the DUT input/output signal is electrical: Figure 3.1-1 Making Connections Using Electrical Signal Connect the DUT input connectors to PPG1 Data Out and Data Out connectors using the coaxial cables. If the DUT has only one input connector, connect it to the Data Out connector of PPG1. - Page 131 Measuring Bit Error Rate In the application window, click PPG/ED Ch1. Set Bit Rate, PPG Amplitude, ED Input Condition and Test Pattern. Refer to Chapter 5, “How to Operate BERT”, for details of the operation method. Click the PPG Data XData button and set the display to ON. Check the following items.

-

Page 132: Measuring Waveform

Chapter 3 Measurement Examples 3.2 Measuring Waveform When measuring the DUT with electrical signal inputs and outputs: Input the output signal of the built-in PPG to the DUT, and then measure the DUT output using the sampling oscilloscope. Figure 3.2-1 When Measuring DUT With Electrical Signal Inputs and Outputs (MP2110A-012, 021) Connect the DUT input connectors to PPG1 Data Out and Data Out using coaxial cables. - Page 133 Measuring Waveform Figure 3.2-2 User Interfaces Used For Operating PPG (Numbers Shown Correspond to Step Numbers.) In the application window, click PPG/ED Ch1. Set Clk Out, Bit Rate, PPG Amplitude and Test Pattern. Refer to Chapter 5, “How to Operate BERT” for details of the operation method.

- Page 134 Chapter 3 Measurement Examples Click Rate and set Tracking. Refer to Chapter 6, “How to Operate Sampling Scope” for details of the operation method. 10. Click Ch A and Ch B. 11. Click the Control Ch button and set the display to All. 12.

- Page 135 Measuring Waveform When the DUT is an optical transceiver: When the MP2110A-022, 023, 025, 026, 030, 032, 033, 035, 036, 039, 040, 042, 043, 045, 046 or 049 is selected, the output waveform of the optical transceiver can be measured using the O/E. Input the output signal of the built-in PPG to the DUT, and then connect the DUT optical output to the SMF or MMF.

- Page 136 Chapter 3 Measurement Examples Figure 3.2-5 User Interfaces Used For Operating PPG (Numbers Shown Correspond to Step Numbers.) In the application window, click PPG/ED Ch1. Set Clk Out, Bit Rate, PPG Amplitude and Test Pattern. Refer to Chapter 5, “How to Operate BERT” for details of the operation method.

- Page 137 Measuring Waveform 10 8 Figure 3.2-6 User Interfaces Used For Operating Scope (Numbers Shown Correspond to Step Numbers.) Click Scope. Refer to Chapter 6, “How to Operate Sampling Scope”, for details of the operation method. Click Time. Click Rate and set Tracking. 10.

-

Page 138: Measuring Multichannel Optical Module Bit Error Rate3-10

Chapter 3 Measurement Examples 3.3 Measuring Multichannel Optical Module Bit Error Rate This section explains the CFP4 module measurement method as an example of multichannel optical module. The CFP4 module contains four pairs of transmitters and receivers. With the MP2110A-014, the CFP4 module bit error rate can be measured for four channels simultaneously. - Page 139 Measuring Multichannel Optical Module Bit Error Rate ������� ������� TX1 to TX4 RX1 to RX4 Data and Data Data and Data Reference Clock Optical Fiber Optical Coupler or Optical Switch Optical Power Programmable Figure 3.3-1 Simultaneously Measuring Bit Error Rate for 4 Channels (MP2110A-014) 3-11...

- Page 140 Chapter 3 Measurement Examples Connect the PPG1-PPG4 Data Out connectors and Input connectors on the CFP4 for transmission using coaxial cables. Connect the PPG1-PPG4 Data Out connectors and Input connectors on the CFP4 for transmission using coaxial cables. To use the optional Reference Clock, connect the Reference Clock connector on the CFP4 for transmission and the Sync Out connector using a coaxial cable.

- Page 141 Measuring Multichannel Optical Module Bit Error Rate Figure 3.3-2 PPG/ED Settings 10. In the application window, click PPG/ED Ch1. 11. Set Bit Rate, PPG Amplitude, ED Input Condition and Test Pattern. Refer to Chapter 5, “How to Operate BERT” for details of the operation method.

- Page 142 Chapter 3 Measurement Examples 15. Change the color of the characters on the button to green by clicking on at All Outputs. Check the following items. The Output lamps 1 to 4 on the BERT panel are lit. (Refer to •...

-

Page 143: Chapter 4 Screen Operation

Chapter 4 Screen Operation This chapter explains the names of screen elements and the operating methods common among the MP2110A. Window Configuration ..........4-2 Data Input Method ............4-5 Setting System Menu ..........4-8 4.3.1 Save ............... 4-9 4.3.2 Open ............. 4-10 4.3.3 Screen Copy .......... -

Page 144: Window Configuration

Chapter 4 Screen Operation 4.1 Window Configuration Figure 4.1-1 shows the names of elements in the application window and their layout. Measurement All Measurements All Channels Status Function Menu Display Area Stop Indicator Output off Date and All Channels System Channel All Channels Time... - Page 145 Window Configuration Table 4.1-1 Application Screen Elements Name Description All BER Results Displays the BER measurement results for multiple channels. All Measurements Starts and stops up to four channels of error rate measurement (MP2110A-011, 012, 014) and up to four channels of waveform data (MP2110A-021 to 049) sampling at the same time.

- Page 146 Chapter 4 Screen Operation The buttons available on the function menu will vary depending on the installed options and software. The following table shows the relation between available buttons and installed options. Table 4.1-2 Buttons Displayed on Function Menu Option Number MP2110A-021, 022, Function Menu 023, 025, 026, 030,...

-

Page 147: Data Input Method

Data Input Method 4.2 Data Input Method The measurement setting item selection, numeric data, and character data are input from the panel displayed on the screen. The displayed panel varies depending on the input data types. Arrow Key Entry Panel Click the numeric data area when entering the numeric data of the bit rate or power voltage. - Page 148 Chapter 4 Screen Operation Numeric value entry panel Click the button for switching the display of the numeric value entry/ arrow key entry panel as shown in Figure 4.2-1, and then the numeric value entry panel as shown in Figure 4.2-2 is displayed. The key type, unit and input range displayed on the panel vary depending on the data.

- Page 149 Data Input Method Software Keyboard When entering character string data such as file name, click Screen Keyboard. In the Keyboard screen (Figure 4.2-3), click keys to enter an alphanumeric string. If you click Shift or Caps once, all keys are locked. To unlock them, click Shift or Caps again.

-

Page 150: Setting System Menu

Chapter 4 Screen Operation 4.3 Setting System Menu The following items can be set and confirmed at the system menu. • Saving measurement conditions and measurement results (Save) • Loading measurement conditions (Open) • Saving window image (Screen Copy) • Initializing device settings (Initialize) •... -

Page 151: Save

In the Keyboard screen, edit the file name. To save to a file, click OK. To cancel saving procedure, click the Close button. Measurement condition files are saved in the following folder: C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Setting Measurement result files are saved in the following folder: C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Result\CSV C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Result\TXT CSV files can be load in spreadsheet software. -

Page 152: Open

Chapter 4 Screen Operation 4.3.2 Open Loading measurement conditions from file Click Open to display the Open panel. Select the target module form the following: PPG/ED Ch 1, PPG/ED Ch 2, PPG/ED Ch 3, PPG/ED Ch 4, Scope, All Setups The displayed module varies with options. -

Page 153: Screen Copy

When clicking Default Name/Root, the folder and file names are set to the default values. The default folder is as follows: C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Screen Copy The default file name is the date and time. For example, the name of the file saved at 12:05:55.523 on 17 January... -

Page 154: Initialize

Chapter 4 Screen Operation 4.3.4 Initialize Initializing measurement conditions Click Initialize, and you are asked if you want to initialize all settings. To initialize the measurement conditions, click OK. To cancel the initialization, click Cancel. 4.3.5 Panel Lock Panel locking Preventing screen operations at other than System Menu is called “panel locking”. -

Page 155: Before Use

Setting System Menu 4.3.7 Before Use Playing back the video of countermeasure against static electricity Click Before Use. Other window is displayed and the video of countermeasure against static electricity is played back in the window. The playback time is about 1 minute 40 seconds. Figure 4.3.7-1 Display Window for Video of Countermeasure Against Static Electricity 4-13... -

Page 156: Minimize

Chapter 4 Screen Operation 4.3.8 Minimize Minimizing the screen display Click Minimize to display the desk top. MX210000A is displayed on the task bar. To display the screen, click MX210000A on the task bar. 4.3.9 Dock/Undock Changing the window display method Click Dock/Undock. -

Page 157: Remote Control

Setting System Menu 4.3.10 Remote Control Clicking Remote Control displays the following dialog box. Figure 4.3.10-1 Remote Control Dialog Box To set GPIB Click the GPIB Address text box. A dialog box for inputting the address is displayed. Enter the GPIB address in the range of 0 to 30. To complete the setting, click OK. - Page 158 Chapter 4 Screen Operation Click Change Network Connections to change the IP address, subnet mask, and gateway address of the MP2110A. The Windows Network Connections window is displayed. Right-click the Local Area Connection (Left) or Local Area Connection (Right) icon, and click Properties. Click Internet Protocol Version 4 (TCP/IPv4), and click Properties.

-

Page 159: System Information

Setting System Menu 4.3.11 System Information Displaying the system information Click System Information. The System Information dialog box appears. Software Version Figure 4.3.11-1 System Information Dialog Box Click Save To Clipboard to copy the system information to the Windows clipboard. Click Save To File to open the Save dialog box. -

Page 160: Exit

Click Exit. You will see the dialog box asking if you want to terminate the application. To terminate the application, click Yes. To cancel the application termination, click No. To restart the application: • Double-click the MX210000A icon. • On the Start menu, point to All Programs, Anritsu, and then click MX210000A. 4-18... -

Page 161: Multi-Channel Signal Output

Multi-channel Signal Output 4.4 Multi-channel Signal Output The MP2110A can set PPG channels 1 to 4 to On/Off at the same time. To output signal from PPG: Click on at All Outputs shown in Figure 4.4-1. The letters of on turn green and then the Output status indicator turns green. -

Page 162: Simultaneous Measurement Start And Stop At Multi-Channels

Chapter 4 Screen Operation 4.5 Simultaneous Measurement Start and Stop at Multi-channels The MP2110A can measure error rates for up to four channels and sample waveform data for up to four channels simultaneously. To start simultaneous measurement, click the key shown in Figure 4.5-1. -

Page 163: Linking Measurement Settings For Multiple Channels

Linking Measurement Settings for Multiple Channels 4.6 Linking Measurement Settings for Multiple Channels With the MP2110A-014, Ch Tracking is displayed in the application screen. To apply the PPG and ED settings for Ch1 to other channels, click on. In this state, altering settings for Ch1 also alters the settings for other channels. -

Page 164: Displaying Ber Measurement Results For Multiple Channels

Chapter 4 Screen Operation 4.7 Displaying BER Measurement Results for Multiple Channels With the MP2110A-014, All BER Results is displayed in the application screen. To view BER measurement results for all channels, click Open. Figure 4.7-1 All BER Results Figure 4.7-2 All BER Results Display Table 4.7-1 All BER Measurements Buttons Name Description... -

Page 165: Displaying Date/Time And Status

Displaying Date/Time and Status 4.8 Displaying Date/Time and Status To display date and time Date and time are displayed on the upper right side of the screen. Date and time can be changed in the Windows Control Panel. To display status The following three kinds of indicators indicate the status. - Page 166 Chapter 4 Screen Operation 4-24.

-

Page 167: Chapter 5 How To Operate Bert

Chapter 5 How to Operate BERT This chapter explains the BERT module setting items and how to measure the bit error. Procedure for Generating Pulse Signal ......5-2 PPG/ED Panel .............. 5-3 5.2.1 Setting Reference Clock ........5-7 5.2.2 Setting Bit Rate ..........5-8 5.2.3 Setting Patterns .......... -

Page 168: Procedure For Generating Pulse Signal

Chapter 5 How to Operate BERT 5.1 Procedure for Generating Pulse Signal The basic procedure is as shown in the following figure. Starting Set the pattern. Select a reference clock. Set positive logic or negative logic. Is the external clock used? Input the clock to Ext Is the synchronous Clk In connector. -

Page 169: Ppg/Ed Panel

PPG/ED Panel 5.2 PPG/ED Panel Clicking PPG/ED Ch1 of the function key displays the following panel. The elements that are set as common in the channels other than Ch 1 are displayed by the light blue characters. Figure 5.2-1 PPG/ED Settings Panel Figure 5.2-2 shows the bit rate display when setting Ext Clk In at Reference CLK. - Page 170 Chapter 5 How to Operate BERT When Setup/Result is clicked, the panel display is changed to the panel shown in Figure 5.2-3. And when Setup/Result is clicked again, the panel display is changed to the panel shown in Figure 5.2-1. Figure 5.2-3 PPG/ED Results Panel (In case of MP2110A-014)

- Page 171 PPG/ED Panel The following table describes the panel. Table 5.2-1 Setting Items of PPG/ED Item Description Setup/Result Switches the PPG/ED panel display. PPG Data/XData Sets the PPG data signal output On/Off. XData means on the front panel. Data The right side of the button is lit in green while the data is outputting to the connector.

- Page 172 Chapter 5 How to Operate BERT Table 5.2-1 Setting Items of PPG/ED (Cont’d) Item Description Test Pattern* Selects the test pattern by clicking the button. The polarity of test pattern can be changed by clicking POS or NEG. The polarity when the test pattern is “1” is shown below: POS: The voltage of Data connector is higher than the voltage of connector.

-

Page 173: Setting Reference Clock

PPG/ED Panel 5.2.1 Setting Reference Clock BERT uses the reference clock to generate the data and detect an error. The reference clock can be selected from the following supply sources: Internal clock generated inside the MP2110A External clock input from the Ext Clk In connector The internal clock accuracy is ±10 ppm after power is applied for 1 hour. -

Page 174: Setting Bit Rate

Chapter 5 How to Operate BERT 5.2.2 Setting Bit Rate Set the bit rate when Reference CLK has been set to Internal. The bit rate is set as common in PPG/ED Ch 1 to Ch 4. For example, when the bit rate is changed in the PPG/ED Ch1 panel, the bit rates of PPG/ED Ch2 to PPG/ED Ch4 are also changed. - Page 175 PPG/ED Panel Setting Amplitude Click the PPG Amplitude text box and set the amplitude voltage. When the attenuators are inserted between the Data Out connector and Data Out connector of MP2110A and the DUTs, click the Ext ATT text box and input the attenuation. The amplitude voltage after passing through the attenuator is displayed.

-

Page 176: Setting Patterns

Chapter 5 How to Operate BERT 5.2.3 Setting Patterns The following three test patterns can be selected. PRBS 1/2 Clock Pattern 1/16 Clock Pattern PRBS PRBS is the pattern generated at the hardware. The generated pattern length, maximum length of contiguous 1s, and maximum length of contiguous 0s differ depending on the hardware configuration. - Page 177 PPG/ED Panel Pattern Maximum Maximum Pattern PRBS Generation number of number of Length Polynomial contiguous 1s contiguous 0 2^7–1 2^9–1 2^15–1 32767 2^23–1 8388607 2^31–1 214748647 The ratio of 1s to the PRBS pattern length is 50%. 1/2 Clock Pattern “1/2 Clock Pattern”...

- Page 178 Chapter 5 How to Operate BERT Pattern Logic There are two types of logic; Positive Logic (POS) and Negative Logic (NEG). With positive logic, the voltage at the Data connector goes High when the data is “1”. With negative logic, the voltage at the Data connector goes Low when the data is “1”.

-

Page 179: Setting Output Waveform

PPG/ED Panel 5.2.4 Setting Output Waveform The PPG Data connector and Data connector are AC coupling. When it is necessary to impose DC voltage on an output waveform, connect a bias-T. CAUTION The impedance of the Data Out and Data Out connectors is 50 Ω. -

Page 180: Setting Sync Out

Chapter 5 How to Operate BERT 5.2.5 Setting Sync Out Set the signal type output from the front-panel Sync Out connector. Sync Out connector outputs a clock synchronized to the data generated by the PPG. The Sync Out Connector is a DC coupling. To monitor the waveform pattern of the pulse pattern generator, set Pattern Sync at Sync Out and connect the Sync Out connector and the Trigger Clk In connector of the sampling oscilloscope using a coaxial cable. - Page 181 PPG/ED Panel The Sync Output amplitude cannot be set. The time interval outputting the pulse varies depending on the pattern length and bit rate when Sync Output is Pattern Sync . Select the pattern for the measurement referring to Table 5.2.5-1. Table 5.2.5-1 Cycle of Sync Output (Pattern Sync) Bit Rate (kbit/s) Pattern Name...

-

Page 182: Setting Clk Out

Chapter 5 How to Operate BERT 5.2.6 Setting Clk Out Set a signal output from the Clk Out connector on the front panel. Clk Out is a function to output the clock synchronized to the data generated from the pulse pattern generator to the Clk Out connector on the front panel. -

Page 183: Inserting Bit Error

PPG/ED Panel Figure 5.2.6-2 Connection Example When Setting Ch3/4 at Clk Out 5.2.7 Inserting Bit Error Insert a bit error when confirming whether to detect the bit error at the ED. The number of bit errors to be inserted at one time is determined according to the bit rate. -

Page 184: Setting Error Detection Method

Chapter 5 How to Operate BERT 5.2.8 Setting Error Detection Method Set the conditions for detecting a bit error. Signal input connectors The block diagram for Data In and Data In connectors on BERT panel is as shown below. Data In –... - Page 185 PPG/ED Panel Make a signal input connector selection, depending on the settings for ED Input Condition. Differential 50 Ohm: Signal input connector for both Data In and Data In connectors. The differential voltage of each signal input to two connectors is the input voltage. Electrical Single-Ended Data: Signal input connector for Data In connector Electrical Single-Ended XData:...

- Page 186 Chapter 5 How to Operate BERT Threshold Level Voltage level for evaluating “1” and “0”. The input connectors are AC coupled, so set a voltage corresponding to the signal waveform excluding the DC components. The waveform excepting the waveform input to the connector and the DC component when inputting the 1.2V LVCMOS signal to the Data In connector and Data In connector is shown below.

- Page 187 PPG/ED Panel Voltage (V) Input waveform to the Data In Time connector Voltage (V) Input waveform to the Time connector POS 0 NEG 1 Figure 5.2.8-3 Values Defined as Input Waveform Pattern The ED compares the received bit string and the internally generated bit stream bit-by-bit and evaluates it differences as it errors.

-

Page 188: Setting Ed Measurement Condition

Chapter 5 How to Operate BERT 5.2.9 Setting ED Measurement Condition To set how to measure bit error: Set Gating Cycle at Gating. Single: Performs measurement until the time set at the measurement period is exceeded. Repeat: Performs measurement until ER Result button display becomes Stop. - Page 189 PPG/ED Panel Measurement method The ED Result display can be refreshed either in real time (approx. 0.1 s intervals) or when the progress bar reaches 100%. The display method is set at Current of Gating. On: Updates measurement results in real time. Off: Updates measurement results when progress reaches 100% for either Single or Repeat Gating Cycle.

- Page 190 Chapter 5 How to Operate BERT When SYNC Loss is displayed in red Pattern synchronization has not been obtained; check the following: The Test Pattern generated by the DUT matches the Test Pattern for the error detector. The Logic POS and NEG settings are correct. ...

-

Page 191: Measurement Result

PPG/ED Panel 5.2.10 Measurement Result The following measurement result is displayed in the ED Result. Start Time: Time when bit error measurement started Elapsed Time: Time elapsed from start of bit error rate measurement When Gating Cycle is Single or Repeat, when time exceeds the Time setting at Gating, the time is reset back to 0. -

Page 192: Saving Measurement Results

The measurement result of the saved bit error is as follows: Bit Error Measurement Result CC (Clock Count) EC (Error Count) ER (Error Rate) Frequency Start Time Stop Time Test Pattern Anritsu;MP2110A ;01.00;TXT---------------------------------- Pattern PRBS2^9–1 Option 12,21,24,93 Start 2017/03/27 15:46:16 2017/03/27 15:46:26 | Total --------+----------------------------------------------------------------------- | 0.0000E-11... - Page 193 Input the file name. When changing the file name, click OK, and when canceling the procedure, click Cancel and go back to the step 4. The measurement result file is saved in the following folder. C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Result\CSV C:\Users\Public\Documents\Anritsu\MX210000A\UserData\Result\TXT 5-27...

-

Page 194: Setting Restrictions

Chapter 5 How to Operate BERT 5.3 Setting Restrictions The setting items of the PPG have the following restrictions. When Test Pattern is not PRBS (Test Pattern is 1/2 Clock or 1/16 Clock) in MP2110A, the Pattern Sync is disabled due to the hardware restrictions. The setting item can be selected, but “PPG 1/8 Clock”... -

Page 195: Chapter 6 How To Operate Sampling Scope

Chapter 6 How to Operate Sampling Scope This chapter explains the Sampling Scope setting items and how to measure the waveform. Note: This chapter explains how to operate MP2110A with the software version 7.01.00 or later. Measurement Procedure ..........6-2 Explanation of Windows .......... -

Page 196: Measurement Procedure

Chapter 6 How to Operate Sampling Scope Measurement Procedure The following figure shows the basic measurement procedure. Start Calibration required? Eye mode? Perform calibration. Set pattern length. Input the signal to be Track the clock measured to the connector rate to BERT? (Ch A, Ch B, A, B, C or D) of the Scope panel. -

Page 197: Explanation Of Windows

Explanation of Windows Explanation of Windows 6.2.1 Result Window In the function menu, click Scope, and then the Scope result window is displayed. Opens the Setup Dialog Box. Opens the Measure Dialog Box. Opens the Amplitude, O/E Dialog Box. Opens the Time, CRU Dialog Box. Trace switch buttons Control Ch Sampling start/stop... - Page 198 Chapter 6 How to Operate Sampling Scope MP2110A-021 Dual Electrical Scope does not display Amplitude O/E but Amplitude. When MP2110A-054 Clock Recovery (Electrical/Optical) and MP2110A-055 26G/53Gbaud Clock Recovery (SM Optical) are not installed, not Time/CRU but Time is displayed. When Channel Math in Amplitude O/E dialog box is On, Scale/Offset cannot be operated.

- Page 199 Explanation of Windows Control Ch Toggles the channel(s) to be controlled by Sampling, Auto Scale and Clear Display. All channels Single Active channel only When Control Ch is set to Single, the buttons effective only for the active channel are indicated by the same color as the active channel. Color of the active channel is displayed.

- Page 200 Chapter 6 How to Operate Sampling Scope When Control Ch is set to Single, the buttons in the following dialog boxes and effective only for the active channel are also indicated by the same color as the active channel. Setup Dialog Box ...

- Page 201 Explanation of Windows Channel A Top level On-screen warning Channel B Top level Channel A Channel B Level scale Level scale Channel B Channel A Optical Optical connector type connector type Channel A Channel B Level offset Level offset Channel B Channel A GND level GND level...

- Page 202 Chapter 6 How to Operate Sampling Scope Note: The arrows that indicate the GND levels appear differently according to the options installed. ■ With MP2110A-021, 022, 023, 025, 026, 040, 042, 043, 045, 046 or 049, the GND levels are indicated by thick lines. Ch A: Ch B: Ch C:...

- Page 203 Explanation of Windows Figure 6.2.1-7 Quick Menu Graph display mode setting There are three graph display modes. Overlap: Overlaps traces of multiple channels. Single: Displays only the trace of the active channel. Tile: Displays four trace graphs in tile view. Single Overlap Tile...

- Page 204 Chapter 6 How to Operate Sampling Scope The graph size changes depending on the number of measurement results displayed on Result Window. Waveform display area Measurement result display area Figure 6.2.1-9 Result Window (Number of measurement items is from five to eight) Waveform display area...

- Page 205 Explanation of Windows When the number of measurement items is nine or more, Zoom display icon ( ) is shown. Clicking this icon displays Scope Result dialog box and the waveform is displayed larger. Figure 6.2.1-11 Enlarging Display of Result Window (Number of measurement items is nine or more) Click Screen Copy in the Scope Result dialog box to save the images of the Result window and Scope Result dialog box to a file.

- Page 206 Chapter 6 How to Operate Sampling Scope When clicking a measurement item, the letter turns blue, and the measurement area is displayed with a yellow dotted line in the window. When clicking the measurement item again, the display of the measurement area disappears.

- Page 207 Explanation of Windows Status Display The following statuses of the sampling scope are displayed. Table 6.2.1-1 Status Display Items Item Color Description Orange The correction value of O/E is not appropriate. Calibrate the O/E module according to 6.3.2, “Adjusting Dark Current”. Yellow There is a difference of ±...

-

Page 208: Displaying Measured Jitter

Chapter 6 How to Operate Sampling Scope 6.2.2 Displaying Measured Jitter When MP2110A-096 is installed, Graph is displayed in the Result window. Click Graph to display the Graph selection buttons. Note: Graph cannot be operated when Sampling Mode is set to Pulse or Coherent Eye. - Page 209 Explanation of Windows Figure 6.2.2-2 Example of How Corrected Measurement Results are Displayed Displaying Graphs When Graph in the Result window is clicked, Graph selection buttons appear and the graph to display can be selected. When Sampling Mode is Eye, the active channel is displayed on the button.

- Page 210 Chapter 6 How to Operate Sampling Scope Figure 6.2.2-4 Switching Graph Display 6-16...

- Page 211 Explanation of Windows 6.2.2.1 Display of Eye Measurement TJ Histogram When clicking TJ Histogram, a graph selection button, the histogram of the active channel is displayed. Figure 6.2.2.1-1 TJ Histogram Table 6.2.2.1-1 TJ Histogram Item Name Description Estimate RJ/DJ Appears when Sampling Mode is set to Histogram Eye.

- Page 212 Chapter 6 How to Operate Sampling Scope Bathtub When clicking Bathtub on the Graph selection buttons, a bathtub curve for the active channel is displayed. Figure 6.2.2.1-2 Bathtub Table 6.2.2.1-2 Bathtub Item Name Description TJ Measurement Sets the BER to measure the TJ and eye opening.

- Page 213 Explanation of Windows 6.2.2.2 Graphs of Jitter Analysis (Advanced Jitter) For jitter analysis (Advanced Jitter), except for the DDJ Histogram graph, the type of measurement edge (All, Fall or Rise) is displayed in the graph name. The measurement edge type is set on the Algorithm tab of the Jitter Measure dialog box.

- Page 214 Chapter 6 How to Operate Sampling Scope Bathtub When clicking Bathtub on the Graph selection buttons, the following graph is displayed. Figure 6.2.2.2-2 Bathtub Table 6.2.2.2-2 Bathtub Item Name Description TJ Measurement Sets the BER to measure the TJ and eye opening.

- Page 215 Explanation of Windows RJ/PJ Histogram Clicking RJ/PJ Histogram on the Graph selection buttons, a histogram that is the sum of RJ and PJ is displayed. When Estimate RJ / PJ Histogram is set to ON, histogram of RJ approximated by dual Dirac function is displayed in yellow and amplitude of PJ is displayed in red line.

- Page 216 Chapter 6 How to Operate Sampling Scope Composite Histogram Click Composite Histogram on the Graph selection buttons, TJ, RJ/PJ, and DDJ histograms are displayed. Figure 6.2.2.2-4 Composite Histogram Table 6.2.2.2-4 Composite Histogram Item Name Description TJ Samples The number of samples for the histogram RJ/PJ Samples DDJ Samples 6-22...

- Page 217 Explanation of Windows DDJ Histogram Click DDJ Histogram on the Graph selection buttons, the histogram of DDJ is displayed by edge. Figure 6.2.2.2-5 DDJ Histogram Table 6.2.2.2-5 DDJ Histogram Item Name Description All Edges When the button display is ON, the histogram is displayed.

- Page 218 Chapter 6 How to Operate Sampling Scope PJ vs Frequency When clicking PJ vs Frequency on the Graph selection buttons, spectrum of jitter is displayed. PJ Frequency Figure 6.2.2.2-6 PJ vs Frequency Table 6.2.2.2-6 PJ vs Frequency Item Name Description PJ Calculate Calculates the jitter peak spectrum frequency.

- Page 219 Explanation of Windows DDJ vs Bit When clicking DDJ vs Bit on the Graph selection buttons, Pattern, and DDJ graph are displayed. Notes: If PDJ measurement is ON, DDJ vs Bit changes to PDJ vs Bit. When the display range on the horizontal axis is 193 bits or more, the pattern graph (white line) is not displayed.

-

Page 220: Setup Dialog Box

Chapter 6 How to Operate Sampling Scope 6.2.3 Setup Dialog Box Click Setup shown in Figure 6.2.1-1, to display the Setup dialog box shown in Figure 6.2.3-1. Active channel switch Figure 6.2.3-1 Setup Dialog Box (General, Utilities tab) 6-26... - Page 221 Explanation of Windows Table 6.2.3-1 Items of Setup Dialog Box (General tab) Item Description Signal Type When MP2110A-095 is installed, select the type of signal (NRZ or PAM4). To measure jitter, select NRZ. Sampling Mode* Select sampling mode from Eye, Pulse, Coherent Eye, Advanced Jitter.

- Page 222 Chapter 6 How to Operate Sampling Scope Table 6.2.3-2 Items of Setup Dialog Box (Utilities tab) Item Description Waveform Selects the color of waveform from Color Grade or Gray Scale. It does not apply to jitter graphs. When Gray Scale is selected, click Color Select, and you can set the waveform color.

- Page 223 Explanation of Windows Active channel switch Figure 6.2.3-2 Setup Dialog Box (Save tab) 6-29...

- Page 224 This function is available when Sampling Mode is Coherent Eye and Test Pattern is other than Variable. The text file is saved to the following folder. C:\Users\Public\Documents\Anritsu\MX210000A \UserData\Result\TXT Samples / UI Sets the number of times that the amplitude is measured per UI by Pattern Capture (number of samples).

- Page 225 Explanation of Windows Table 6.2.3-4 Sampling Mode Setting and Graph Sampling Mode Advanced Jitter Graph to Bathtub (CHA) Bathtub display TJ Histogram (CHA) DDJ Histogram Bathtub (CHB) Composite Histogram TJ Histogram (CHB) DDJ vs Bit Bathtub (CHC) PJ vs Frequency TJ Histogram (CHC) RJ/PJ Histogram Bathtub (CHD)

-

Page 226: Measure Dialog Box

Chapter 6 How to Operate Sampling Scope 6.2.4 Measure Dialog Box When clicking Measure in the Figure 6.2.1-1 “Result Window”, the Measure dialog box shown in Figure 6.2.4-1 is displayed. If both Signal Type of Ch A and Ch B are set to PAM4 in the Setup dialog box, Mask Test tab cannot be operated. - Page 227 Explanation of Windows Advanced Jitter Figure 6.2.4-2 Measure Dialog Box - Amplitude/Time Tab (Jitter) 6-33...

- Page 228 Chapter 6 How to Operate Sampling Scope Table 6.2.4-1 Items of Amplitude/Time Tab Item Description Display On: Displays the Amplitude/Time measurement results in the Result window. Off: Does not display the Amplitude/Time measurement results in the Result window. Item Selection Select measurement items.

- Page 229 Explanation of Windows Clicking NRZ at Measure Setup displays the Setup (NRZ Amplitude/Time) dialog box. Figure 6.2.4-3 Setup (NRZ Amplitude/Time) Dialog Box Table 6.2.4-2 Items of Setup (NRZ Amplitude/Time) Dialog Box Item Description Rise/Fall Time Sets the position to measure Rise Time and Fall Time. Rise/Fall Time When setting to On, the Rise Time and Fall Time are corrected.

- Page 230 Chapter 6 How to Operate Sampling Scope Clicking PAM4 at Measure Setup displays the Setup (PAM4 Amplitude/Time) dialog box. Figure 6.2.4-4 Setup (PAM4 Amplitude/Time) Dialog Box The TDECQ equalizer is set on the Measure Dialog Box – Equalizer Tab shown in Figure 6.2.4-9. When you see the following message, check the settings on the General tab of the Setup dialog box.

- Page 231 Explanation of Windows Table 6.2.4-3 Items of Setup (PAM4 Amplitude/Time) Dialog Box Item Description Configuration Sampling Timing Set the reference position of the upper eye and the lower eye. Track to Middle Eye Timing: Adjust to the center eye position. Refer to Figure 1.5-11. Independent Timing: The reference positions of the three eyes can be set separately.

- Page 232 Chapter 6 How to Operate Sampling Scope *1: This is displayed when the installed scope is other than MP2110A-021. *2: The settings are valid when all of the following conditions are met: Item Selection is Item Type: PAM4. Sampling Mode is Coherent Eye Test Patterns other than Variable The following figure shows the positions of Pmax and Pmin when Peak Power Hit Ratio is set to 1%.

- Page 233 Explanation of Windows Jitter Measure Dialog Box Clicking Jitter at Measure Setup displays the Jitter Measure dialog box. If Sampling in the Setup dialog box is Advanced Jitter, the Algorithm tab and Advanced tab are displayed in the Jitter Measure dialog box. Figure 6.2.4-7 Jitter Measure Dialog Box - Algorithm Tab Table 6.2.4-4 Items of Jitter Measure Dialog Box - Algorithm Tab Item...

- Page 234 Chapter 6 How to Operate Sampling Scope Table 6.2.4-5 Settable Standards for PDJ measurement and Filter Sets (Unit Hz) PDJ Filter Standard HP1' STM-0 – 20 k – 12 k 400 k – STM-1 – 65 k – 12 k 1.3 M STM-4 –...

- Page 235 Explanation of Windows When Sampling Mode of the Setup dialog box is Advanced Jitter, the Advanced tab is displayed in the Jitter Measure dialog box. When Sampling Mode of the Setup dialog box is Eye, the settings on the Advanced tab can be configured for each channel. Advanced Jitter Figure 6.2.4-8 Jitter Measure Dialog Box - Advanced Tab 6-41...

- Page 236 Chapter 6 How to Operate Sampling Scope Table 6.2.4-7 Items of Jitter Measure Dialog Box - Advanced Tab Item Description TJ Measurement Sets the bit error rate to measure the eye opening in the Bathtub graph. Fixed RJ Set Off to display the graph using RJ calculated from the measured waveform.

- Page 237 Explanation of Windows Figure 6.2.4-9 Measure Dialog Box – Equalizer Tab 6-43...

- Page 238 Chapter 6 How to Operate Sampling Scope Table 6.2.4-8 Items of Equalizer Tab* Item Description Display Equalizer Off: Displays waveforms not applying Reference Equalizer. Waveform On: Displays waveforms applying Reference Equalizer. Equalizer Type Sets the equalizer type to automatically calculate the Tap for Reference Equalizer.

- Page 239 Explanation of Windows Figure 6.2.4-10 Measure Dialog Box - Mask Test Tab 6-45...