Table of Contents

Advertisement

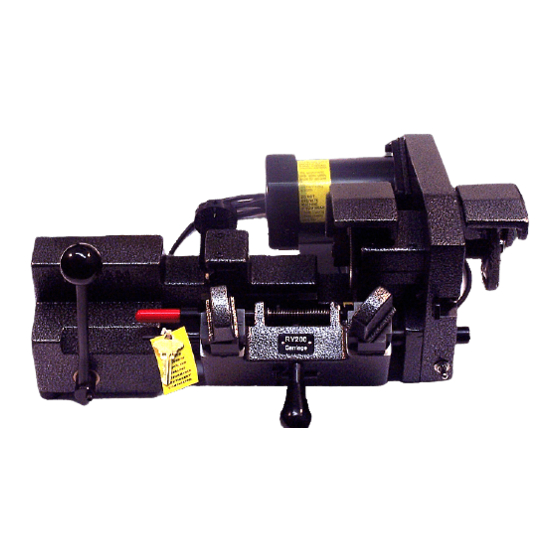

Model RY200

OPERATOR'S MANUAL

Rytan Model RY200 Semi-Automatic Key Duplicating Machine with 4-Way Jaws

NEW CUTTER AND STYLUS CUTS GM AND KWIKSET TITAN KEYS

Rytan Products are Designed and Manufactured in the U.S.A.

READ AND UNDERSTAND THIS OPERATOR'S MANUAL AND BECOME

FAMILIAR WITH YOUR NEW MACHINE BEFORE YOU START CUTTING KEYS.

RYTAN, INC. - 1648 W. 134th St. - Gardena, CA. 90249 (310) 328-6553 - fax (310) 212-6002

RYTAN, INC. RESERVES THE RIGHT TO MAKE CHANGES WITHOUT NOTICE. PRICES MAY VARY FROM YOUR DISTRIBUTOR.

for Cylinder Keys and Automotive Keys

CLAMPS MORE KEYS

BUILT IN MICRO-ADJUST STYLUS

MA380 ADJUSTABLE STYLUS

.0005"Accurate

(1/2 thousanth!)

Included!

RY20005 Complete

Carriage Assembly

Included!

RY39 Auxillary Lamp Kit

ADDITIONAL COST

RY114 Key Gauge Protector

Included!

NEW 4-WAY JAWS

CLAMPS MORE KEYS

3-WAY

2-WAY

I N C O R P O R A T E D

NOW YOU CAN CUT KEYS LIKE GM AND KWIKSET

TITAN FIRST CUT WITH ONE SIDE STRAIGHT,

LIKE THE FACTORY!

NEW CUTTER RY20030

and RY20028 STYLUS

CUT MORE KEYS

ADD $135.00

RY101 Wire Brush Kit

Included!

Advertisement

Table of Contents

Summary of Contents for Rytan RY200

- Page 1 FAMILIAR WITH YOUR NEW MACHINE BEFORE YOU START CUTTING KEYS. RYTAN, INC. - 1648 W. 134th St. - Gardena, CA. 90249 (310) 328-6553 - fax (310) 212-6002 RYTAN, INC. RESERVES THE RIGHT TO MAKE CHANGES WITHOUT NOTICE. PRICES MAY VARY FROM YOUR DISTRIBUTOR.

-

Page 2: Table Of Contents

TABLE OF CONTENTS INTRODUCTION GETTING STARTED SAFETY RULES MOUNTING THE MACHINE CUTTING STANDARD KEYS CUTTING DEEP CUTS VISE JAWS TOP SHOULDER GAUGING CLAMPING KEYS BEST and TIP GAUGING RELEASING THE CARRIAGE CUTTER SHAFT LOCK REMOVING/REPLACING CUTTER DEPTH ADJUSTMENT SPACE ADJUSTMENT KEY GAUGE ADJUSTMENT CARRIAGE OVER TRAVEL ADJ. -

Page 3: Mounting The Machine

Secure keys properly in vises. Don’t hold key head for support when cutting. If it doesn’t clamp properly, don’t try to cut it! Maintain a sharp cutter wheel. A dull cutter wheel is not only inefficient but dangerous. A dull cutter wheel can produce excessive cutting force on a key blank and exceed the machine’s vise jaws clamping force to a point where the key blank could be ripped out of the machine. -

Page 4: Cutting Standard Keys

Always cut keys from Bow-to-Tip. NEVER MAKE YOUR FIRST CUT FROM TIP-TO-BOW. The RY200 is specifically designed to cut most cylinder keys and U.S. and Foreign automotive keys by operating the machine’s “stick-shift” lever SMOOTHLY from Right-to-Left. The key will be cut properly starting at the Bow and ending at the tip of the key. -

Page 5: Vise Jaws

Suggestion: Keep a small magnet near your key machine to identify steel keys. Before cutting a steel key try filing a small groove where one of the deeper cuts will be made – if the key won’t file easily it won’t cut any better in your key machine and will most likely ruin your cutter! VISE JAWS Choosing the correct vise jaw. -

Page 6: Top Shoulder Gauging

VISE JAW REPLACEMENT Vise jaws (cartridges) are replaced in pairs as an assembly, a matched set consisting of (one top jaw and one bottom jaw), you will need two sets for your key machine. You will disassemble and re-install the old plungers, springs, and screws. Or you can buy a complete set with the plunger, top jaw, bottom jaw, screws and springs. -

Page 7: Clamping Keys

CLAMPING KEYS Open the vise jaws only wide enough to slide the key in. With the key all the way into the “throat” of the vise jaws - put your index finger against the key blade and with moderate force against the key in to the vise jaw, gently slide the key left and right a few times (about 1/8”... -

Page 8: Releasing The Carriage

Always remember to flip DOWN your key gauges before cutting a key. Failure to do so will prevent the key from being cut. Fig. 10 BEST AND FALCON (BEHIND THE TIP) KEY GAUGING These keys must be gauged from a “tip” location that is behind the actual tip of the key. Position the key in the vise so that the “tip”... -

Page 9: Cutter Shaft Lock

SWITCH “ON” YOUR MACHINE The power switch is located at the lower right, front of the machine. See figure 12. New Cutter will cut straight on left side Adjustable Stylus NEW 4-WAY VISES CLAMPS MORE KEYS 3-WAY 2-WAY PRESS DOWN 1. -

Page 10: Removing/Replacing Cutter

Press DOWN firmly on the cutter shaft lock. While holding the lever down - rotate the cutter by hand until the cutter shaft lock “clicks” in to position. When turning the cutter by hand there is only ONE locking position to be found. Once the cutter shaft lock is fully depressed - Hold it There. You may now proceed with removing the cutter shaft lock nut and the cutter. - Page 11 Remember to LOCK the cutter before removing the cutter wheel. Use a 1” open-end or hex wrench to remove the Left-Hand Nut. See Fig. 13. REPLACING THE CUTTER Before your replace the cutter - clean off any cuttings from the cutter shaft with a clean rag. Apply a small amount of grease to the cutter shaft face, shank, and threads before installing the cutter wheel and Left-Hand Nut.

-

Page 12: Depth Adjustment

New Cutter will cut straight on left side Adjustable Stylus of key cut (.0005”) one-half thousanth INCH NEW 4-WAY VISES CLAMPS MORE KEYS Cutter 3-WAY Shaft LOCK 2-WAY Power Switch UP - ON Down - off Fig. 15 DEPTH ADJUSTMENT Depth is adjusted at the back end of the stylus. -

Page 13: Key Gauge Adjustment

screws to keep the cutter shaft assembly in place so you can’t move it with your hand – but you can move it with gentle-to-moderate tapping with your small plastic mallet. Turn the cutter BACKWARDS with your hand and observe which way you must move the cutter. Use your small plastic mallet to “nudge”... -

Page 14: Maintenance

There are no special tools, fixtures or alignment jigs required to install the parts used in this key machine. Because Rytan manufactures the machines in-house you are assured a supply of new replacement parts and updates for as long as YOU want us to make the machines. -

Page 15: Troubleshooting

What key machine operators often forget is if the depth adjustment is off by as little as 1-1/2 thousandths of an inch (.0015”) they will accumulate generations. In as little as five generations the key probably won’t work in the lock. - Page 16 We’ve seen Schlage C key blanks with variations of up to 15 thousandths of an inch (.015”) between top and bottom shoulder positions – between keys taken from the same box. It happens more often than you think. The solution? Don’t bottom shoulder gauge your keys anymore. Cutter Stalls Out There are six possible causes for this problem.

- Page 17 there’s movement in the bearings you need to replace the cutter shaft assembly. If there is no movement it may be the other bearing next to the drive pulley—you will have to remove the drive belt to be able to check it out. Another possibility is the way some of the ball bearing cages are made inside the bearings—these ball cages have an assembly opening created at the bearing factory.

- Page 18 Replace the cutter wheel when deburring the key seems to take longer than normal. Replace the cutter wheel when you find yourself “assisting” or “force-feeding” the carriage more often,especially in deep cuts. NOTE: Rytan’s key machine cutter can be resharpened. Call us for details.

- Page 19 Remove the left-hand nut and cutter wheel. Remove the access plate and wire brush if installed on your RY200 and loosen the four motor mounting screws to loosen the drive belt. Loosen the two #10-32 socket head cap screws located on the top front edge of the cutter head –...

- Page 20 Reinstall the “stick-shift” and drive shaft assembly and reattach the two piece drive shaft linkage and you’re almost done. Turn the machine back onto its feet and observe the carriage spring attached to the ¼” diameter grooved pin driven into the carriage shaft. Take your small hammer and a steel rod or drift and drive the pin back into the carriage shaft.

-

Page 21: Customer Information

Rytan, Inc. provides the following information on warranty and service for the RY200 key duplicating machine: Warranty Registration The Warranty Registration Form must be filled out and mailed to Rytan, Inc. within TEN days of date of purchase. Failure to do so will VOID the warranty.

Need help?

Do you have a question about the RY200 and is the answer not in the manual?

Questions and answers