Table of Contents

Advertisement

USER INSTRUCTIONS

Installation

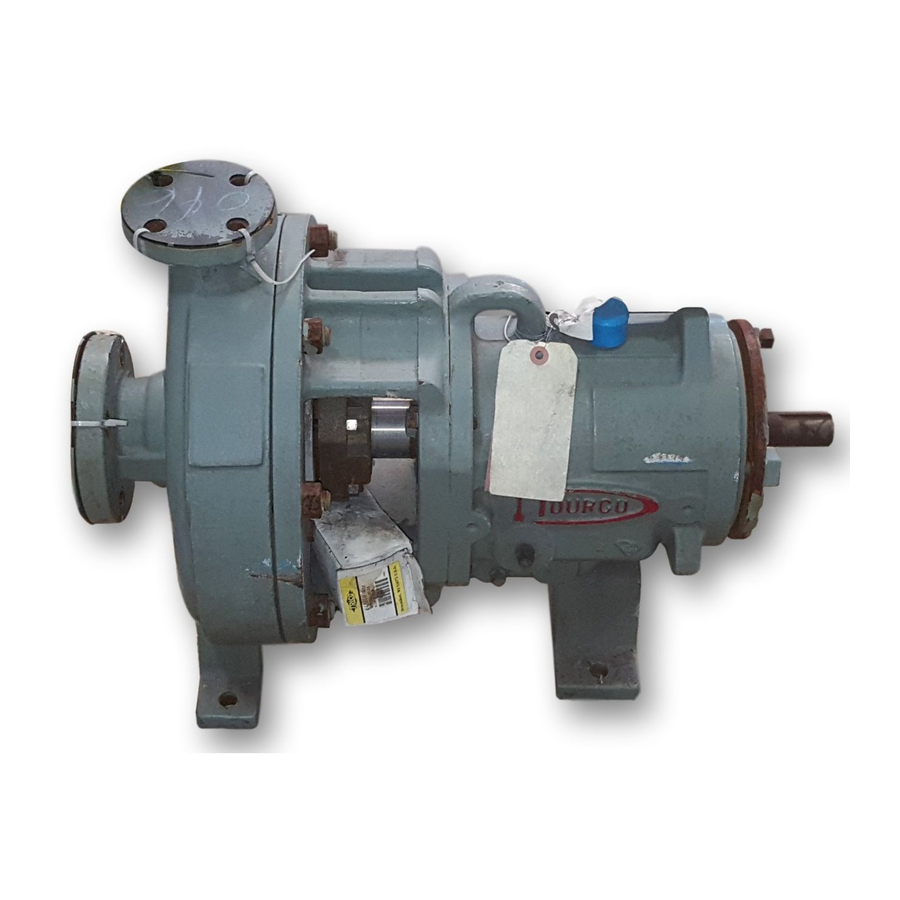

Durco Mark 3 sealed metallic pumps

Operation

Maintenance

Mark 3 Standard, In-Line, Lo-Flo, Recessed Impeller,

Unitized Self-Priming and Sealmatic pumps

PCN=71569102 08-06 (E) (incorporating P-10-502-E)

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Advertisement

Table of Contents

Summary of Contents for Flowserve Pump

-

Page 1: User Instructions

USER INSTRUCTIONS Installation Durco Mark 3 sealed metallic pumps Operation Maintenance Mark 3 Standard, In-Line, Lo-Flo, Recessed Impeller, Unitized Self-Priming and Sealmatic pumps PCN=71569102 08-06 (E) (incorporating P-10-502-E) These instructions must be read prior to installing, operating, using and maintaining this equipment. -

Page 2: Table Of Contents

8.4 Mark 3 Lo-Flo, Group 2... 61 8.5 Mark 3 Unitized Self Priming pump, Group 2 ... 62 8.6 Mark 3 Recessed Impeller pump, Group 2 ... 62 8.7 Mark 3 In-Line pump, Group 1 ... 63 8.8 Mark 3 In-Line pump, Group 2 ... 64 8.9 Mark 3 C-Face Adapter,... -

Page 3: Introduction And Safety

Information in these User Instructions is believed to be reliable. In spite of all the efforts of Flowserve Pump Division to provide sound and all necessary information the content of this manual may appear insufficient and is not guaranteed by Flowserve as to its completeness or accuracy. -

Page 4: Safety

THE PUMP IS OPERATIONAL THERMAL SHOCK Rapid changes in the temperature of the liquid within the pump can cause thermal shock, which can result in damage or breakage of components and should be avoided. NEVER APPLY HEAT TO REMOVE IMPELLER Trapped lubricant or vapor could cause an explosion. - Page 5 PREVENT EXCESSIVE EXTERNAL PIPE LOAD Do not use pump as a support for piping. Do not mount expansion joints, unless allowed by Flowserve in writing, so that their force, due to internal pressure, acts on the pump flange.

-

Page 6: Mark 3 User Instructions English 71569102

Where there is any risk of the pump being run against a closed valve generating high liquid and casing external surface temperature, it is recommended that users fit an external surface temperature protection device. -

Page 7: Name Plate And Safety Labels

Avoid entrapment of liquid in the pump and associated piping due to closing of suction and discharge valves, which could cause dangerous excessive pressures to occur if there is heat input to the liquid. -

Page 8: Noise Level

Note that a motor driven by an inverter may show an increased noise at some speeds. If a pump unit only has been purchased for fitting with your own driver then the “pump only”... -

Page 9: Transport And Storage

Make sure the completion of the choker hitch on the discharge nozzle is toward the coupling end of the pump shaft as shown in figure 2-1. The sling lengths should be adjusted to balance the load before attaching the lifting hook. -

Page 10: Storage

2-1. 2.3.2.2 In-Line assemblies If the pump is to be lifted as a complete assembly, the motor lifting lugs must be used to ensure that the assembly does not flip over. Check with motor supplier for lifting lug capacities. -

Page 11: Recycling And End Of Product Life

• Pump design variation A = This pump has been redesigned from an earlier H = This pump is designed for a higher flow capacity HH = This pump is designed for a higher head than • Actual impeller size “12.5”... -

Page 12: Design Of Major Parts

(BEP). Figure 3-7 identifies the MCF for all Mark 3 pump models with the exception of the Lo-Flo pump line; there is no MCF associated with this product line. 3.4.5 Minimum suction pipe submergence The minimum submergence is shown in figure 3-8 and 3-9 for Unitized self-priming pumps. - Page 13 Figure 3-2: Alloy cross-reference chart Flowserve Designation material code E3020 Ductile iron E3033 High chrome iron E4027 High chrome iron E4028 High chrome iron C3009 Carbon steel C3062 Durco CF8 C3069 Durco CF3 C3063 Durco CF8M C3067 Durco CF3M C3107 Durcomet 100 C4028 Durimet 20...

- Page 14 Figure 3-3: Class 150 flanges Temp ºC ( ºF) 19.0 – – (-100) (275) 17.2 19.7 19.0 (-20) (250) (285) (275) 17.2 19.7 19.0 (250) (285) (275) 17.2 19.7 19.0 (100) (250) (285) (275) 16.2 17.9 15.9 (200) (235) (260) (230) 14.8 15.9...

- Page 15 Figure 3-4B: Group 2 - 13 in. Lo-Flo pumps with Class 300 flanges Temp ºC ( ºF) 31.0 – – (450) (-100) 31.0 31.0 31.0 (450) (450) (450) (-20) 31.0 31.0 31.0 (450) (450) (450) 31.0 31.0 31.0 (450) (450) (450) (100) 29.1...

- Page 16 Figure 3-5a: Suction pressure limits 1 750 r/min 27.5 22.5 17.5 12.5 Figure 3-5b: Suction pressure limits 3 500 r/min 27.5 22.5 17.5 12.5 Page 16 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 Specific Gravity Specific Gravity flowserve.com...

-

Page 17: Suction Pressure Reference Numbers

Open impeller pumps including the Lo-Flo and Recessed Impeller products are limited in suction pressure only by the Pressure-Temperature ratings. Sealmatic pump suction pressure is limited by the repeller. Page 17 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06... -

Page 18: Installation

4.2 Part assemblies The supply of motors and baseplates are optional. As a result, it is the responsibility of the installer to ensure that the motor is assembled to the pump and aligned as detailed in section 4.5 and 4.8. 4.3 Foundation 4.3.1 Protection of openings and threads... - Page 19 4-1. 3. The baseplate must be designed to allow the user to final field align the pump and driver to within their own particular standards and to compensate for any pump or driver movement that occurred during handling.

-

Page 20: Grouting

After the base is level, it is locked in place by locking the stilt adjusters. c) Next the initial pump alignment must be checked. The vertical height adjustment provided by the stilts allows the possibility of slightly twisting the baseplate. -

Page 21: Initial Alignment

Check initial alignment. If the pump and motor were removed from the baseplate proceed with step j) first, then the pump and motor should be reinstalled onto the baseplate using Flowserve’s factory preliminary alignment procedure as described in section 4.5, and then continue with the following. -

Page 22: Piping

All four motor feet are tightened down. The pump and motor shafts are then aligned horizontally, both parallel and angular, by moving the pump to the fixed motor. The pump feet are tightened down. k) Both horizontal and vertical alignment is again final checked as is the coupling spacer gap. - Page 23 Avoid the use of throttling valves and strainers in the suction line. Start up strainers must be removed shortly before start up. When the pump is installed below the source of supply, a valve should be installed in the suction line to isolate the pump and permit pump inspection and maintenance.

- Page 24 Compare the “adjusted Figure 4-16 loads” to the values shown in figure 4-15. The lower of these two values should be used as the adjusted figure 4- 15 values. (The HI standard also asks that figure 4- 15 loads be reduced if figure 4-17 or 4-18 values are lower.

- Page 25 0.95 0.75 0.95 Equations ≤ ≤ ≤ ≤ Figure ≤ ≤ Adjusted ≤ ≤ Adjusted ≤ Adjusted Adjusted Remarks Maximum individual 4-15 loading Nozzle stress, bolt stress, pump 4-16 slippage y-axis 4-17 movement z-axis 4-18 movement Combined axis movement flowserve.com...

- Page 26 Figure 4-15: Maximum individual loading Pump size Forces N (lbf) 4 670 3 336 1K 1.5x1-LF4 (1 050) (750) 4 670 3 336 1K 1.5x1-6 (1 050) (750) 4 670 5 516 1K 3x1.5-6 (1 050) (1 240) 4 670...

- Page 27 Figure 4-16: Maximum combined loading Pump size Forces N (lbf) 8 985 3 336 1K 1.5x1-LF4 (2 020) (750) 8 985 3 336 1K 1.5x1-6 (2 020) (750) 8 985 5 516 1K 3x1.5-6 (2 020) (1 240) 8 985...

- Page 28 4.6.4.2a Pump mounting Review Pump mounting, section 4.3. The pump may be mounted such that it is free to move with the piping. The pump may be supported by the piping, so that it is free to move in all directions.

- Page 29 Page 29 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 4.6.4.2c Pump stand limitations In cases where the pump is rigidly mounted by the pump stand, both the casing limitations and the pump stand limitations must be satisfied. Due to the limited load capacity of the pump stands, it may be necessary to restrain the piping to prevent loads.

-

Page 30: Mechanical Seal

4.6.6 Auxiliary piping 4.6.6.1 Mechanical seal When the pump is intended to be equipped with a mechanical seal, it is Flowserve standard practice to install the mechanical seal in the pump prior to shipment. Specific order requirements may specify that the seal be shipped separately, or none be supplied. -

Page 31: Electrical Connections

4.6.6.4 Piping connection - bearing housing cooling system Make connections as shown below. Liquid at less than 32 C (90 F) should be supplied at a regulated flow rate of at least 0.06 l/s (1 US gpm). 4.6.6.5 Piping connection - support leg cooling for centerline mounting option If the casing is centerline mounted, and the process temperature is over 178 C (350 F), then the casing... -

Page 32: Final Shaft Alignment Check

0.05 mm (0.002 in.) parallel, and 0.0005 mm/mm (0.0005 in./in.) angular misalignment. (See section 6.8.4.7.) g) Operate the pump for at least an hour or until it reaches final operating temperature. Shut the pump down and recheck alignment while the pump is hot. -

Page 33: Commissioning, Startup, Operation And Shutdown

If there are any circumstances in which the system can allow the pump to run dry, or start up empty, a power monitor should be fitted to stop the pump or prevent it from being started. This is particularly relevant if the pump is handling a flammable liquid. - Page 34 Synthetic Some synthetic lubricants require Viton O-rings. EXXON POLYREX EM (or compatible) – horizontal Polyurea with mineral oil Grease EXXON Unirex N3 (or compatible) – In-Line Lithium Complex with mineral oil Figure 5-4: Oil viscosity grades Maximum oil ISO viscosity...

- Page 35 (polyurea) and oil (mineral) should be used. In the case of the In-Line pump the bearings are packed with Exxon Unirex N3 grease. For relubrication, a grease with the same type base (lithium) and oil (mineral) should be used.

-

Page 36: Impeller Clearance

Flowserve coupling guards are safety devices intended to protect workers from inherent dangers of the rotating pump shaft, motor shaft and coupling. It is intended to prevent entry of hands, fingers or other body parts into a point of hazard by reaching through, over, under or around the guard. -

Page 37: Priming And Auxiliary Supplies

The Mark 3 standard, Sealmatic, Recessed Impeller, Lo-Flo, and In-Line centrifugal pump will not move liquid unless the pump is primed. A pump is said to be “primed” when the casing and the suction piping are completely filled with liquid. Open discharge valves a slight amount. -

Page 38: Starting The Pump

For example, vibration may exceed the limit set by the ASME standard. The size of the pump, the energy absorbed, and the liquid pumped are some of the considerations in determining the minimum continuous flow (MCF). -

Page 39: Stopping And Shutdown

It is used to determine the likelihood that a fluid will vaporize in the pump. It is critical because a centrifugal pump is designed to pump a liquid, not a vapor. -

Page 40: Maintenance Schedule

However, it is also important to periodically repeat the Pre start-up checks listed in section 5.1. These checks will help extend pump life as well as the length of time between major overhauls. 6.1.2 Need for maintenance records... -

Page 41: Recommended Spares And Consumable Items

Part name – see section 8 Part item number – see section 8 Material of construction (alloy) Number of parts required The pump size and serial number can be found on the nameplate located on the bearing housing. (See figure 3-1.) 6.3 Recommended spares and... -

Page 42: Setting Impeller Clearance And Impeller Replacement

3 mm (0.125 in.) from the casing cutwater. If this close clearance is not maintained the pump may not prime. Do not adjust the impeller clearance with the seal set. Doing so may result in seal leakage and/or damage. - Page 43 [6570.3] in incremental steps up to the final torque value to lock the bearing carrier in place. Example: If a pump was to be placed in a service with an operating temperature of 100 C (212 F) the impeller setting would be 0.53 mm (0.021 in.) off the rear cover plate.

-

Page 44: Disassembly

For this reason, the following practice is recommended. Before the pump is taken out of service, adjust the impeller until it touches the casing and then rotate the bearing carrier until the desired impeller clearance is obtained. - Page 45 If packing [4130] is used, remove it and the seal cage [lantern ring, 4134]. Remove the gland [4120]. s) If the pump has a hook type sleeve [2400] it can now be removed. Unit now appears as shown in figure 6-12.

- Page 46 Mark 3 design On Group 1 and 2 pumps the bearing carrier is turned by using a strap wrench, with the strap located around the outside diameter of the carrier face. On Group 3 pumps, the bearing carrier is turned by using a spanner wrench to engage the cogs on the outside diameter of the bearing carrier.

-

Page 47: Examination Of Parts

6.8.4.3 Impeller balancing Shaft whip is deflection where the centerline of the impeller is moving around the true axis of the pump. It is not caused by hydraulic force but rather by an imbalance with the rotating element. Shaft whip is... -

Page 48: Power End

0.13 (0.005) Shaft run-out is the amount the shaft is “out of true” when rotated in the pump. It is measured by attaching a dial indicator to a stationary part of the pump so that its 0.05 (0.002) 0.05 (0.002) - Page 49 6.8.4.7 Installed pump Complete pump installed. Shaft movement caused by pipe strain Pipe strain is any force put on the pump casing by the piping. Pipe strain should be measured as shown below. Install the indicators as shown before attaching the piping to the pump. The suction and...

-

Page 50: Assembly Of Pump And Seal

Modern vibration analysis equipment not only detects if a vibration problem exists, but can also suggest the cause of the problem. On a centrifugal pump, these causes can include the following: unbalance, misalignment, defective bearings, resonance, hydraulic forces, cavitation and recirculation. - Page 51 a) Install the inboard bearing [3011] on the shaft [2100]. Mark 3A and ANSI 3A design The inboard bearing must be positioned against the shoulder as shown in figure 6-22. Mark 3 design On Group 1 and Group 2 shafts, the inboard bearing must be located as shown in figure 6-24.

- Page 52 The locknut should then be retightened repeatedly during the time the bearing is cooling. Once cool the locknut should be removed. Figure 6-26 Pump Press force N (lbf) Group 1 5 780 (1 300)

- Page 53 Orient the bearing housing adapter with the two holes for capscrews [6570.5] on a horizontal line. g) If the pump has lip seals, install the deflector [2540]. h) If the pump is equipped with a hook type sleeve [2400], slip it into place over the impeller end of the shaft [2100].

- Page 54 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 installation of each ring, have an assistant turn the pump shaft in one direction. This movement of the shaft will tend to draw the rings into the stuffing box. d) A split gland [4120] is an assembly of two matched gland halves that are bolted together.

- Page 55 Once the pump is flooded, check the seal to ensure it is not leaking. If the seal leaks, repeat step j) above, applying only enough pressure to the drive collar to stop the leak.

- Page 56 Install a new rear cover gasket [4590.1] between the rear cover plate [1220] and the casing [1100]. b) Use studs [6572.1] and nuts [6580.1] to complete the rebuild of your Flowserve Mark 3 pump. Page 56 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06...

-

Page 57: Faults; Causes And Remedies

POSSIBLE REMEDIES Recalculate NPSH available. It must be greater than the NPSH required by pump at desired flow. If not, redesign suction piping, holding number of elbows and number of planes to a minimum to avoid adverse flow rotation as it approaches the impeller. - Page 58 Pump not reaching design flow rate Pump not reaching design head (TDH) No discharge or flow with pump running Pump operates for short period, then loses prime Excessive noise from wet end Excessive noise from power end PROBABLE CAUSES Brinelling of bearing identified by...

-

Page 59: Parts List And Drawings

8 PARTS LIST AND DRAWINGS 8.1 Standard Mark 3 pump, Group 1 Optional duplex arrangement Item Description 1100 Casing 1220 Cover 1340 Adapter - bearing housing 2100 Shaft 2200 Impeller 2400 Sleeve, optional 2530.1 Retaining ring - bearing 2530.2 Retaining ring - clamp type... -

Page 60: Standard Mark 3 Pump, Group 2 And Group 3

8.2 Standard Mark 3 pump, Group 2 and Group 3 Group 2 Optional duplex bearing arrangement Group 3 Standard bearing clamp arrangement Item Description 1100 Casing 1220 Cover 1340 Adapter - bearing housing 2100 Shaft 2200 Impeller 2400 Sleeve, optional 2530.1... -

Page 61: Mark 3 Sealmatic Pump, Group 2

8.3 Mark 3 Sealmatic pump, Group 2 8.4 Mark 3 Lo-Flo, Group 2 Page 61 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 Item 1100 1220 1220.1 2200 2200.1 4120 4200 4590.1 4590.2 4590.9 4610.10 4610.11 6570.13 6572.2 6580.2 Notes: See figure 6-30, GP3 Sealmatic wet end. -

Page 62: Mark 3 Unitized Self Priming Pump, Group 2

8.5 Mark 3 Unitized Self Priming pump, Group 2 8.6 Mark 3 Recessed Impeller pump, Group 2 Page 62 of 68 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 Item 1100 2200 4590.1 4590.2 6572.1 6580.1 Description Casing Impeller Gasket – cover... -

Page 63: Mark 3 In-Line Pump, Group 1

8.7 Mark 3 In-Line pump, Group 1 Item Description 1100 Casing 1220 Cover 2100 Shaft 2200 Impeller 2400 Sleeve, optional 2530.1 Retaining ring - bearing 2530.2 Retaining ring - clamp type 2540 Deflector - inboard optional 3011 Ball bearing - inboard... -

Page 64: Mark 3 In-Line Pump, Group 2

8.8 Mark 3 In-Line pump, Group 2 Item Description 1100 Casing 1220 Cover 1340 Adapter - bearing housing 2100 Shaft 2200 Impeller 2400 Sleeve, optional 2530.1 Retaining ring - bearing 2530.2 Retaining ring - clamp type 2540 Deflector - inboard optional... -

Page 65: Mark 3 C-Face Adapter, Group 1 And Group 2

8.9 Mark 3 C-Face Adapter, Group 1 and Group 2 Item Description 3134 Support foot 3160 Motor pedestal – C-Face 3200 Bearing housing 6570.15 Screw – bearing housing 6570.16 Screw – coupling guard 8.10 General arrangement drawing The typical general arrangement drawing and any specific drawings required by the contract will be sent to the Purchaser separately unless the contract specifically calls for these to be included into the User... -

Page 66: Certification

User Instructions. 10.2 Change notes If any changes, agreed with Flowserve Pump Division, are made to the product after it is supplied, a record of the details should be maintained with these User Instructions. - Page 67 MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06 Notes: Page 67 of 68 flowserve.com...

- Page 68 Your Flowserve factory contacts: Flowserve Pump Division 3900 Cook Boulevard Chesapeake, VA 23323-1626 USA Telephone +1 757 485 8000 Fax +1 757 485 8149 Flowserve Pumps Limited PO Box 17, Newark, Notts NG24 3EN United Kingdom Telephone (24 hours) +44 (0)1636 494 600 Sales &...

Need help?

Do you have a question about the Pump and is the answer not in the manual?

Questions and answers