Table of Contents

Advertisement

Installation/Operating Manual

2017.01

Pump Type:

Pump Serial Number:

Date:

Purchaser:

Purchaser's Order Number:

GIW / KSB Work Order Number:

Shipped To:

Include the pump's serial number when ordering replacement parts

This is a standard maintenance manual provided for your convenience

This manual may include additional documentation not applicable to your specific pump

GIW INDUSTRIES, INC.

5000 Wrightsboro Road

Grovetown, GA 30813 USA

FAX

www.giwindustries.com

+1 (888) 832-4449

+1 (706) 855-5151

KSB AG

Johann-Klein-Str. 9

D-67227 Frankenthal, Germany

+49 6233 86-0

FAX

+49 6233 86-3289

www.ksb.com

MDX

[en-US]

.

Advertisement

Table of Contents

Summary of Contents for KSB GIW MDX

- Page 1 Pump Serial Number: Date: Purchaser: Purchaser’s Order Number: GIW / KSB Work Order Number: Shipped To: Include the pump’s serial number when ordering replacement parts This is a standard maintenance manual provided for your convenience This manual may include additional documentation not applicable to your specific pump GIW INDUSTRIES, INC.

- Page 2 All rights reserved. Contents provided herein must neither be distributed, copied, reproduced, edited or processed for any other purpose, nor otherwise transmitted, published or made available to a third party without KSB´s express written consent. Subject to technical modification without prior notice.

-

Page 3: Table Of Contents

MDX [en-US] Contents Section Page Section Page General Maintenance Supervision of Operation Drainage / Disposal Safety Lubrication and Lubricant Change Safety Markings 7.3.1 Underwater Operation ... - Page 4 MDX [en-US] Index Section Page Section Page Packing Accessories Alignment Parts Life Assembly Safety Personnel Assembly, Mechanical End Piping System Design Assembly, Wet End Piping, Allowable Forces and Moments Auxiliary Connections Piping, Cleaning Baseplate Piping, Connecting Bearing Assembly Mounting Power Supply Bearing Housing Assembly Priming the Pump Bearing Installation...

-

Page 5: General

Consult your pump/unit drawings and Bill of Materials for details. If you need any additional information or instructions exceeding the scope of this manual or in case of damage, please contact your GIW / KSB representative. -

Page 6: Safety

MDX [en-US] Safety These operating instructions contain fundamental information that must be complied with during installation, operation and maintenance. Therefore this operating manual must be read and understood both by the installing personnel and the responsible trained personnel / operators prior to installation and commissioning, and it must always be kept close to the operating location of the machine / unit for easy access. -

Page 7: Non-Compliance With Safety Instructions

For sectional drawings and bills of material relating to your specific pump and equipment, locate an official copy of the documentation provided by GIW / KSB. This may be shipped separately from the pump and will include drawings and bills of material as attachments to this basic manual. - Page 8 MDX [en-US] Avoid the use of mounting aids as much as possible. Should a mounting aid be required, use a commercially available contact adhesive. The adhesive should only be applied at selected points (three to four spots) and in thin layers. Do not use cyanoacryiate adhesives (quick-setting adhesives).

-

Page 9: Transport And Storage

Storage Requirements 3.2.1 Storage of New Pumps - Pumps under Warranty Consult your sales contract documents and/or your GIW / KSB representative for detailed instructions. Note that failure to follow proper storage procedures will void your warranty. 3.2.2 Pump Storage CAUTION ... - Page 10 MDX [en-US] Storage Upon Receipt and up to 3 Months: Pump should stored indoors and out of the weather until ready for installation. In construction environments where indoor storage is not available, store the pump on blocks or pallets, build a frame around it and cover with tarpaulin.

-

Page 11: Pump Parts Storage

MDX [en-US] 3.2.3 Pump Parts Storage CAUTION For proper storage ensure: All machined surfaces must be coated with rust protector Grease and plug all drilled and threaded holes Check monthly for paint breakdown on casting Check monthly for visible sign of rust on machine surface ... -

Page 12: Removal From Storage

MDX [en-US] 3.2.4 Removal from Storage Remove rust from machined surfaces using a wire brush. Remove rust inhibitor from all machined surfaces prior to installation/assembly. Check the painted surfaces for any signs of corrosion or breaks in the coatings and touch-up as needed. ... -

Page 13: Recommended Lifting

MDX [en-US] Recommended Lifting WARNING Actual safe lifting method will vary with pump configuration and type of lifting equipment Alternate Transport of the pump... -

Page 14: Description

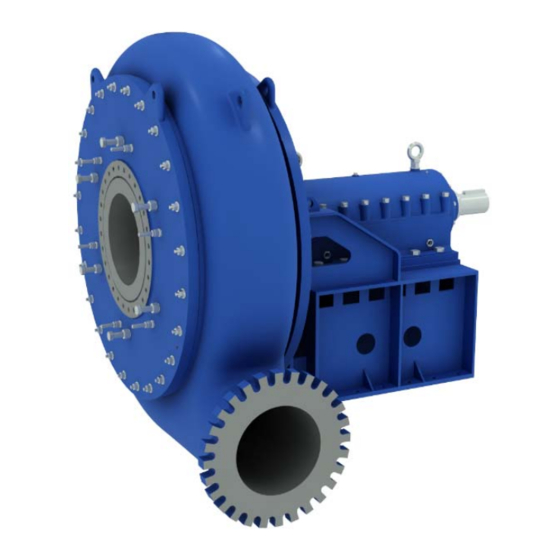

Imperial or Metric size. Crossover between Imperial and Metric tools or spare parts is generally not recommended. Contact your GIW / KSB representative for specific problems or questions. The MDX is a centrifugal pump for handling highly abrasive slurries for mill circuit applications. Applications include SAG (Semi- Autogenous Grinding) and ball mill discharge;... -

Page 15: Accessories

MDX [en-US] Accessories Couplings, pulleys, belts, motor mounts and/or base plates may be provided. Refer to the bill-of-materials, data sheets and/or drawings for further information. Dimensions and Weights Dimensions and weights are listed on the pump installation plan. -

Page 16: Forces And Moments At Nozzles

HI/ANSI 9.6.2-2008 table 9.6.2.1.4a and API 610-2004, Table 4. Higher allowable loads may be possible depending on individual pump configuration and operating conditions. Contact your GIW / KSB Application Engineer for more information. NOTE: Discharge branch coordinate system always moves with the branch angle. -

Page 17: Installation At Site

MDX [en-US] Installation at Site Safety Regulations WARNING Electrical equipment operated in hazardous locations must comply with the applicable explosion protection regulations. This is indicated on the motor rating plate. If the equipment is installed in hazardous locations, the applicable local explosion protection regulations and the regulations of the test certificate supplied with the equipment and issued by the responsible approval authorities must be observed and complied with. -

Page 18: Place Of Installation

MDX [en-US] CAUTION All components must be level during system operation unless special provisions for bearing lubrication and oil sealing have been made. After attaching the unit to the foundation and connecting the piping, the pump and drive train must be thoroughly checked and, if necessary, realigned. ... -

Page 19: Connecting The Piping

MDX [en-US] Connecting the Piping WARNING Danger of life when toxic or hot media are handled. CAUTION Never use the pump itself as an anchorage point for the piping. Permissible forces and moments must not be exceeded (see to section 4.7). Refer to your drawing for spool piece recommendation to ease maintenance. -

Page 20: Commissioning / Operation

If the pump has been in long term storage (more than 3 months), ensure proper storage procedures were followed, including instructions for removing the pumps from storage (see contract documents and/or contact your GIW / KSB representative). Failure to follow proper storage procedures will void your warranty. See Section 3.2 "Storage Requirements". -

Page 21: Shaft Seal Commissioning

Stuffing Box Commissioning Prior to commissioning, the gland packing supplied with the pump must be adjusted. Preformed packing rings sets from GIW / KSB are recommended. For alternate brands, refer to packing manufacturer’s instructions regarding installation and use. ... -

Page 22: Cleaning The Plant Piping

MDX [en-US] If a Variable Frequency Drive (VFD) or other controller is used, it is recommended to permanently disable REVERSE and BRAKE function during controller set up. 6.1.4 Cleaning the Plant Piping WARNING Cleaning operations for flushing and pickling service must be matched to the casing and seal materials used. Any chemicals or high temperatures used must be compatible with all pump parts. -

Page 23: Shutdown

Failure to do so may result in power overload, excessive vibration, overheating, and/or excessive corrosion or wear. If a data sheet is not available, contact your GIW / KSB representative. CAUTION Any make up water or outside water supply for the system must be installed so that the GIW pump will never be exposed to a pressure in excess of its maximum allowable operating pressure. -

Page 24: Density Of The Medium Handled

Failure to operate the seals within the above parameters may result in premature seal failure or oil leakage through the Duo- Cone seals. Any change in the operating conditions should be discussed with your GIW / KSB representative to establish if the... -

Page 25: Maintenance

MDX [en-US] Maintenance WARNING Refer to Section 2.9 "Assembly & Disassembly Safety" prior to working on the pump. Supervision of Operation WARNING Operational procedures which may cause system water hammer must be avoided. Sudden and catastrophic failure of pump casing and plates may result. ... -

Page 26: Procedures For Maximum Parts Life

The wear of slurry pump parts is influenced by many factors and the following procedures are designed to help you get the most out of your wet end wear parts. If problems occur, contact your GIW / KSB representative for a review of your application. - Page 27 In the event problems are encountered, contact your GIW / KSB representative. The pump serial number, in addition to the following, should be furnished to assist in evaluation of the problem: Pump serial number (from the nameplate on the pedestal or bearing housing), customer location, and the approximate startup date.

-

Page 28: Mechanical End

GIW REGEN Service Centers remanufacture bearing assemblies and refurbish pumps. GIW will rebuild your assembly and return it to its original specifications using genuine OEM replacement parts. Contact your GIW / KSB Sales Representative for details. WARNING Refer to Section 2.9 "Assembly & Disassembly Safety" prior to working on the pump. -

Page 29: Mechanical End Assembly

MDX [en-US] In Limited End Float (LEF) bearing assemblies the drive end radial bearing will be a single row taper roller bearing. These bearings are hot when installed and are press fitted to the shaft. It is difficult to remove them from the shaft undamaged, and they should be removed only if a bearing needs to be replaced. -

Page 30: Closing The Housing

MDX [en-US] The drive end radial bearing next to the thrust bearing should be mounted with its inner race in direct contact with the split ring (or split thrust collar). If it is a taper lock type, first position it on the shaft while loosely mounted on its adapter. The locknut should then be tightened until the internal bearing clearance as determined with a feeler gauge is equal to the actual un-mounted clearance minus the required decrease as specified in the chart above. -

Page 31: Installing End Covers And Seals

MDX [en-US] End Cover End Cover Fasteners Upper Housing Oil Fill Port Upper Housing Fasteners Lower Housing Adjustment Screw 8.3.3 Installing End Covers and Seals CAUTION Flinger and labyrinth seal clearances must be verified. Failure to do so may result in damage to the seals, overheating, and bearing damage. - Page 32 MDX [en-US] Mount the bearing housing adjustment nut with adjusting screw onto the bottom of the housing. When placing the bearing assembly onto the pedestal, ensure that the slotted tab on the pedestal fits into the slot of the adjusting screw. ...

- Page 33 MDX [en-US] Torque Requirements – Bearing Assembly Clamp Bolts ENGLISH FASTENERS – Grade 8 Anti-Sieze Lubricated / Oiled Size ft-lbs ft-lbs 3/4 “ 1” 1 1/8” 1085 1300 1 1/4” 1150 1560 1360 1840 1 1/2” 1900 2575 2660 3600 1 3/4”...

-

Page 34: Shaft Seal

MDX [en-US] Shaft Seal Mechanical Seal CAUTION Mechanical seals require safety checks prior to start-up such as removing seal assembly fixtures, checking axial alignment, checking torques etc. Refer to the mechanical seal operating manual for all required safety checks. Mechanical seals are precision devices which require special care for their proper operation. -

Page 35: Stuffing Box Packing

The following provides an introduction to packing basics. Refer to your GIW Pump Maintenance Manual, GIW / KSB representative and/or packing supplier for further detail. The packing type must be compatible with your pumping application. This includes pressure, temperature, pH and solids content. - Page 36 MDX [en-US] Forward Flush and Throat Bushing stuffing boxes are generally pressure controlled, but flow control is an option. Seal water requirements listed in the table show potential flow with worn packing. Flow control may be achieved in different ways. A Positive Displacement pump that delivers the correct volume can be used with a safety or “pop-off”...

-

Page 37: Wet End

MDX [en-US] Wet End 10.1 Wet End Overview The pump casing is cast as a single piece and is made of a high-chrome white iron for hardness and abrasion and corrosion resistance. Custom materials are available for highly corrosive applications. All standard impellers are double shrouded multi-vane designs. -

Page 38: Impeller Removal With Release Ring Assemblies

Impeller release rings could spring suddenly and injure nearby personnel. For large highly loaded pumps in corrosive environments, an IRR (impeller release ring) tool may be more effective. To order this tool, GIW part number 2009B, contact your GIW / KSB representative. ... - Page 39 MDX [en-US] Screw the two SHCS that come with the tool into the push off holes finger tight. Tighten the tab bolts with a wrench while pushing the tabs into the IRR grooves. Tighten the SHCS that hold the tool to the IRR. ...

-

Page 40: Impeller Break-Loose Device

MDX [en-US] 10.2.4 Impeller Break-Loose Device WARNING Impeller Break-Loose Device Energy can be released during disassembly of the tightened Impeller. Break loose devices, lifting devices and Impeller release rings could spring suddenly and injure nearby personnel. Rotate the impeller until the tip of one blade is facing the pump discharge. ... -

Page 41: Mounting The Shaft Sleeve

MDX [en-US] 10.3.1 Mounting the Shaft Sleeve For Pumps with Impeller Release Ring WARNING The segmented release ring fasteners must be carefully inspected for damage or cracking and replaced if not in good condition. Bolts are made from high grade A286 stainless steel and replacement parts should be obtained from GIW to ensure quality. -

Page 42: Hub Plate (If Applicable)

MDX [en-US] For Pumps without Impeller Release Ring A light coat of anti-seize can be applied inside the shaft sleeve Do not allow anti-seize compound to come in contact with any of the axial faces of the shaft sleeve, including the impeller contacting face and the face in contact with the shaft shoulder. -

Page 43: Impeller Installation

MDX [en-US] 10.3.4 Impeller Installation Coat the shaft threads heavily with anti-seize compound. Do not coat the shaft sleeve faces which contact the impeller and the step in the shaft. Two 0.5mm (0.020 inch) aramid gaskets (400.10) are placed between the shaft sleeve and the impeller hub face to prevent galling and to ensure ease of impeller removal. - Page 44 MDX [en-US] Lay plate 16-1 onto liner making sure the rabbet fit is aligned. Install and tighten washers, gaskets and nuts (400.02, 550.02, 50-7.02, 543.02, 920.02, and 920.03/05) to studs using a cross torque technique (see sample sequence in figure below).

-

Page 45: Snap Ring Gasket

MDX [en-US] Apply general purpose lithium-based grease to the surface of the liner to be in contact with the gasket. Install Teflon lined snap ring gasket (40-2 or 40-2.01) over liner (13-19), Install gasket over greased surface of liner (13-19). ... -

Page 46: Suction Liner Adjustment

MDX [en-US] Hub Plate Snap Ring Gasket Hub Liner Pump Casing Protrustion Snap Ring Gasket Installation 10.3.7 Suction Liner Adjustment General Adjustment Instructions: To adjust the suction liner, the nuts (920.02, 920.03/05 and 920.04) must be loosened and the pushers will need to be turned to push the liner forward. -

Page 47: Setting The Nose Gap

MDX [en-US] Distance per Full Turn of Distance per Full Turn of Bolt Size Bolt Size Adjustment Bolt Adjustment Bolt ENGLISH inch METRIC inch 3/4" – 10 NC 0.100 2.54 M20 – 2.5 0.098 2.50 1" – 8 NC 0.125 3.18 M24 –... - Page 48 MDX [en-US] Minimum Nose Gap Minimum Nose Limited End Gape for Shaft Size Conventional Urethane Liners Float inch inch inch 3 - 15/16 0.07 1.78 0.012 0.30 5 - 7/16 0.09 2.29 0.012 0.30 6 - 7/16 0.09 2.29 0.012 0.30 7 - 3/16 0.09...

-

Page 49: Tooling

MDX [en-US] Tooling 11.1 Torque Requirements Torque requirements listed below and in previous sections are for lubricated bolting. All bolts must be lubricated to ease in pump assembly and disassembly. Anti seize compound is preferred, but well oiled is also acceptable. Special Torque Requirements ... -

Page 50: Spare Parts Stock

The quantities of parts kept in store will depend upon the severity of the slurry duty and the number of units operating. Maintenance practices may also favor keeping fully built sub-assemblies or complete pumps on hand in some cases. Previous experience in similar duties often provides the best experience. If in doubt, contact your GIW / KSB representative for specific recommendations. -

Page 51: Troubleshooting

Adjustment may be needed to system design and/or excessive flowrate. pump operating conditions. ■ ■ Contact your GIW / KSB representative for further advice. Pump and piping are not completely vented or Vent and / or prime. ■ ■ ■... - Page 52 Check suction line friction loss calculations. Alter ■ ■ ■ ■ design if necessary. Contact your GIW / KSB representative for further advice. Density or viscosity of the fluid pumped is higher Adjustment may be needed to system design and/or ■...

-

Page 53: Notes

MDX [en-US] Notes...

Need help?

Do you have a question about the GIW MDX and is the answer not in the manual?

Questions and answers