Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Bently Nevada 3300/50

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

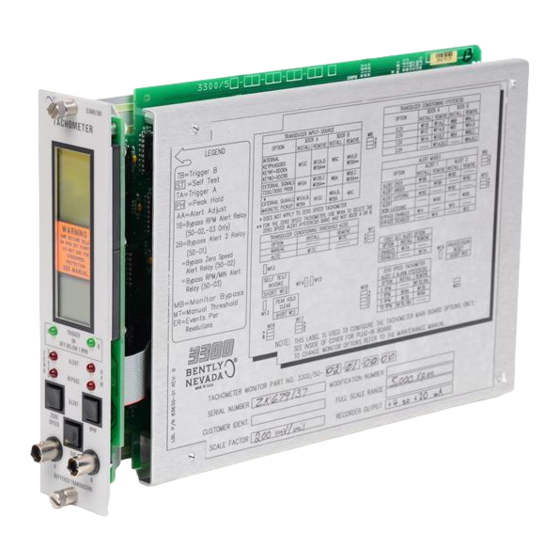

- Page 2 PART NO. 83870-01 3300/50 TACHOMETER INCLUDES DUAL SETPOINT, ZERO SPEED, AND • ROTOR ACCELERATION TACHOMETERS. OPERATION MANUAL NEVADA ra...

- Page 3 NOTICE READ THE FOLLOWING BEFORE INSTAWNG OR OPERATING EQUIPMENT Bently Nevada Corporation has attempted to identify areas of risk created by improper installation and/or operation of this product. These areas of information are noted as WARNING or CAUTION for your protection and for the safe and effective operation of this equipment. Read all instructions before installing or operating this product.

- Page 4 • Tachometer Operation NOTICE WARNING ! Bently Nevada Tachometers are not designed for use independently as, or a component of, a speed control or overspeed protection system. Bently Nevada Tachometers d o not provide protective redundancy and the response speed needed for reliable operation a s a speed control o r overspeed protection system.

- Page 5 83870-01 • Tachometer Operation • Blank Page •...

- Page 6 3300/50 Tachometer Maintenance, 83871-01 • Dynamic Data Manager System, 46390-01 Keyphasore is a registered trademark of Bently Nevada Corporation Proximitor® is a registered trademark of Bently Nevada Corporation Document No. 83870-01 First Printing: March 1989 Revision NC: March 1989 Copyright© 1 9 8 9 Bently Nevada Corporation...

- Page 7 83870-01 Tachometer Operation Blank Page...

-

Page 8: Table Of Contents

83870-01 • Tachometer Operation CONTENTS SECTION TITLE SYSTEM OVERVIEW DUAL SETPOINT TACHOMETER ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER MONITOR OPTIONS PROGRAMMABLE OPTIONS MONITOR FUNCTIONS BYPASS DUAL SETPOINT TACHOMETER • ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER ALERT DUAL SETPOINT TACHOMETER ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER READ GAP VOLTAGE READ SETPOINTS... - Page 9 83870-01 • Tachometer Operation • Blank Page • v i i i...

-

Page 10: Dual Setpoint Tachometer

83870-01 • Tachometer Operation DUAL SETPOINT TACHOMETER SYSTEM 5 I GNAL I N P U T RELAY MODULE LOCATION 3 ) 0 0 , 5 0 41.-Nr4r• #'1 • " 4 " • " • ' , 0 - 1 1 " • Irle"• • - • - 4 ' • TACHOMETER 1 . -

Page 11: Zero Speed Tachometer

S I G N A L I N P U T R E L A Y MODULE L O C A T I O N 3300/50 TACHOMETER I I M M M M M M I N I M I .3 6 0 0... - Page 12 • Tachometer Operation 83870-01 1 3 I ROTOR ACCELERATION TACHOMETER SYSTEM I S I G N A L I N P U T R E L A Y MODULE L O C A T I O N E i ) 3 3 0 0 / S 0 TACHOMETER .....

-

Page 13: Monitor Options

MONITOR OPTIONS TACHOMETER PART NUMBER TACHOMETER TYPE A L E R T RELAYS A G E N C Y APPROVAL B A R R I E R S 3300/50 01 = DUAL SETPOINT = NONE = NOT REOD = NOT REQ'D... -

Page 14: Programmable Options

+1 TO + 5 Vdc 0 TO -10 Vdc * OPTIONS SHIPPED FROM BENTLY NEVADA NOTE 1: MAGNETIC PICKUPS ARE NOT ALLOWED FOR ZERO SPEED APPUCATIONS. NOTE 2: ALL VERSIONS OF THE TACHOMETER DRIVE ONLY THE RACK FIRST OUT ALERT BUS. -

Page 15: Monitor Functions

83870-01 Tachometer Operation MONITOR FUNCTIONS ROTOR SPEED MONITORING - The Tachometer function provides continuous monitoring of shaft rotative speed. The Tachometer accepts input from either a proximity probe or magnetic pickup (not recommended). The Tachometer measures the time between Keyphasor pulses and calculates the rotor speed in revolutions per minute (RPM). - Page 16 • Tachometer Operation 83870-01 MONITOR FUNCTIONS (CONT) ALERT - Pressing one o f the Alert switches on the front panel o f the monitor causes the corresponding Alert setpoint to be displayed on the front panel. When the particular Alert setpoint conditions have been met, the Alert LEDs will illuminate and the Alert relay contacts are activated.

- Page 17 Tachometer Operation 83870-01 • MONITOR FUNCTIONS (CONT) SELF TEST - The monitor has three categories of self test: power-up, cyclic, and user-invoked. A power-up self test, consisting of a series of basic monitor OK tests, is performed automatically each time the monitor is turned on. A cyclic self test is performed automatically while the monitor is operating.

- Page 18 83870-01 • Tachometer Operation 00 MOT IISE FOR 00 MOT L 4 ! FOi CNERSPEK ovenspeeD OVERSPIEE0 PROTECT iCPi PROTECT ION PROTECT ION SEE MANUAL SEE MANUAL SEE MANUAL - 600 RPM/MIN 0 T R I G G E R [ T o TRIGGERX A •...

-

Page 19: Bypass 8 Dual Setpoint Tachometer

Tachometer Operation 83870-01 • 8 I BYPASS (DUAL SETPOINT TACHOMETER) 3 3 0 0 / 5 0 3 3 0 0 / 5 0 TACHOMETER TACHOMETER 3600 WARNING WARNING ONE SECOND D E L AY ONE SECOND D E L AY ON RPM S E T P O I N T S ON RPM S E T P O I N T S DO N O T U S E F O R... - Page 20 83870-01 • Tachometer Operation 9 I BYPASS (ZERO SPEED TACHOMETER) 3 3 0 0 / 5 0 3 3 0 0 / 5 0 3 3 0 0 / 5 0 TACHOMETER TACHOMETER TACHOMETER 3600 3600 ZERO SPEED ZERO SPEED ZERO SPEED ENABLED ENABLED...

- Page 21 83870-01 1 1 1 1 1 Tachometer Operation 10 I BYPASS (ROTOR ACCEL. TACHOMETER) 3 3 0 0 / 5 0 3 3 0 0 / 5 0 3 3 0 0 / 5 0 T A C H O M E T E R T A C H O M E T E R T A C H O M E T E R 3600...

- Page 22 83870-01 Tachometer Operation ALERT (DUAL SETPOINT TACHOMETER) D.,------- .----,------isf. OVERSPEE0 PROTECT 1 w SEE MANUAL A 0 Tc:',.?.?cER, 4 • A L E R T P 1 p A L E R T I BYPASS LED DISPLAY RELA Y DRIVE CONDITION •...

-

Page 23: Alert

• Tachometer Operation 33870-01 ALERT (ZERO SPEED TACHOMETER) DO N O T U S E F O R O12P3PtEr., P R o r e C T IOM SEE MANUAL TRIGGER OFF B E L 01/ t R P M ALERT •... - Page 24 • Tachometer Operation 83870-01 ALERT (ROTOR ACCEL. TACHOMETER) 00 PDT USE FOii ommomm mmnmr SEE MANUAL 6 0 0 RPM/MIN 0 TRIGGER I R G E R o r c SEI.Ou I RPM • R M O ALERT Pi I M N o BYPASS •...

- Page 25 Tachometer Operation 83870-01 • I 1 4 R E A D GAP VOLTAGE PRESS GAP SWITCH AND READ GAP VOLTAGE FOR BOTH TRANSDUCER A AND TRANSDUCER B. 3300/E0 TACHOMETER -12.3 XDCR A VOLTS WARNING ONE SECOND DELAY ON RPM SET POINTS DO NOT USE FOR OVERSPEED PROTECTION...

-

Page 26: Read Setpoints

• Tachometer Operation 83870-01 READ SETPOINTS (DUAL SETPOINT TACH.) PRESS THE ALERT 1 SWITCH AND READ PRESS THE ALERT 2 SWITCH AND READ THE ALERT 1 SETPOINT ON THE FRONT THE ALERT 2 SETPOINT ON THE FRONT PANEL DISPLAY. U P ARROW INDICATES PANEL DISPLAY. - Page 27 INDICATES OVER SPEED SETPOINT. DOWN UNDER SETPOINT. ( Z E R O S P E E D I S ARROW INDICATES U N D E R S P E E D ALWAYS AN UNDER SETPOINT.) SETPOINT. 3300/50 3300/30 TACHOMETER TACHOMETER 3700...

- Page 28 83870-01 • Tachometer Operation READ SETPOINTS (ROTOR ACCEL. TACH.) PRESS THE RPM/MIN ALERT SWITCH AND PRESS THE RPM ALERT SWITCH AND READ THE RPM/MIN ALERT SETPOINT ON READ THE RPM ALERT SETPOINT ON THE THE FRONT PANEL DISPLAY. UP ARROW FRONT PANEL DISPLAY.

-

Page 29: Read Peak Hold

Tachometer Operation 83870-01 READ PEAK HOLD • PRESS BOTH ALERT SWITCHES SIMULTANEOUSLY AND READ THE PEAK HOLD VALUE. 3300/50 TACHOMETER 1 1 1 1 1 1 1 1 1 1 1 1 7 3603 WARNING ONE SECOND D E L AY... -

Page 30: Reset Peak Hold

83870-01 Tachometer Operation RESET PEAK HOLD RESET THE VALUE STORED IN PEAK HOLD MEMORY BY SHORTING ACROSS PEAK HOLD (PH) PINS. 7300/50 TACHOMETER ..3600 • WARNING CP4 SECOND CIELpr ON W V SET POINTS 00 NOT I.41 7Cf1 CPETISPEE5 PROTECT I CPI... -

Page 31: Enable (Zero Speed Tachometer)

Tachometer Operation 8387001 • ENABLE (ZERO SPEED TACHOMETER) WHEN T H E EXTERNAL Z E R O SPEED WHEN T H E EXTERNAL Z E R O SPEED ENABLE CONTACTS A R E OPEN, T H E ENABLE CONTACTS ARE CLOSED, THE ENABLE INDICATOR WILL EXTINGUISH AND ENABLE INDICATOR WILL SHOW AND THE THE ZERO SPEED BYPASS LED WILL... -

Page 32: Self Test

• Tachometer Operation 83870-01 SELF TEST THE MONITOR HAS THREE LEVELS OF SELF TESTS: POWER-UP TEST: PERFORMED ONLY WHEN THE MONITOR IS TURNED ON. CYCUC TEST: PERFORMED CONTINUOUSLY. USER-INVOKED TEST: PERFORMED ONLY WHEN INITIATED BY USER. 3 3 0 0 / 7 0 TACHOMETER IF ERRORS ARE DETECTED DURING CYCUC SELF TESTS: E r r o r... - Page 33 Tachometer Operation 83870-01 • SELF TEST (CONT) INITIATE USER-INVOKED TEST BY SHORTING ACROSS TWO SELF TEST (ST) PINS. CAUTION MACHINE PROTECTION WILL BE LOST FOR DURATION OF TEST.

- Page 34 83870-01 • Tachometer Operation SELF TEST (CONT) AT THE COMPLETION OF USER-INVOKED SELF TEST, THE MONITOR WILL RECALL STORED ERROR CODES, IF ANY. THESE ERROR CODES MUST BE READ AND CLEARED WITH USER INTERACTION TO ALLOW MONITORING TO CONTINUE. TACHOMETER E r r o r READ CODES ON UST;...

- Page 35 Tachometer Operation 83870-01 I 21 I SELF TEST (CONY) ERROR CODE DESCRIPTION ROM CHECKSUM HAS FAILED. * EEPROM FAILURE NO. 1. * * E r r o r E E P R O M FAILURE NO. 2. * * * ADJUST SETPOINTS + 7 .

- Page 36 83870-01 • Tachometer Operation I 2 2 I P AGE ALERT ALERT BYPASS ALERT RELAYS BUFFERED OUTPUTS CYCLIC TEST ERROR CODE FIRST OUT 14, 15 FIRST OUT ALERT MONITOR BYPASS MONITOR OK OKRELAY ... . .

- Page 38 • PART NO. 83871-01 3300/50 TACHOMETER INCLUDES DUAL SETPOINT, ZERO SPEED, AND • ROTOR ACCELERATION TACHOMETERS. MAINTENANCE MANUAL BENTLY r \ NEVADA • •...

- Page 39 NOTICE READ THE FOLLOWING BEFORE INSTALUNG OR OPERATING EQUIPMENT Bently Nevada Corporation has attempted to identify areas of risk created by improper installation and/or operation of this product. These areas of information are noted as WARNING or CAUTION for your protection and for the safe and effective operation of this equipment. Read all instructions before installing or operating this product.

- Page 40 Tachometer Maintenance 83871-01 NOTICE WARNING ! Bently Nevada Tachometers are not designed for use independently as, or a component of, a speed control or overspeed protection system. Bently Nevada Tachometers do not provide protective redundancy and the response speed needed for reliable •...

- Page 41 Tachometer Maintenance Blank Page...

- Page 42 3300/50 Tachometer Operation, 83870-01 • Dynamic Data Manager System, 46390-01 Keyphasor® is a registered trademark of Bently Nevada Corporation Proximitore is a registered trademark of Bently Nevada Corporation Document No. 83871-01 First Printing: March 1989 Revision NC: March 1989 Copyright() 1 9 8 9 Bently Nevada Corporation...

- Page 43 Tachometer Maintenance Blank Page...

- Page 44 83871-01 • Tachometer Maintenance CONTENTS TITLE SECTION SYSTEM OVERVIEW DUAL SETPOINT TACHOMETER ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER FRONT PANEL FEATURES DUAL SETPOINT TACHOMETER ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER MONITOR REMOVAL MONITOR DISASSEMBLY SIGNAL INPUT RELAY MODULE • 10 ..MONITOR OPTIONS MONITOR FULL SCALE RANGE ADJUSTMENT EVENTS PER REVOLUTION ADJUSTMENT THRESHOLD AND HYSTERESIS ADJUSTMENTS...

-

Page 45: Index

Tachometer Maintenance 83871-01 • CONTENTS PAGE SECTION TITLE TEST ALERTS ..DUAL SETPOINT TACHOMETER ... . . ZERO SPEED TACHOMETER ROTOR ACCELERATION TACHOMETER 26 ..TEST TRIGGER OKs S E L F TEST FIELD WIRING DIAGRAMS DUAL SETPOINT TACHOMETER... -

Page 46: Dual Setpoint Tachometer

83871-01 f b T a c h o m e t e r Maintenance DUAL SETPOINT TACHOMETER SYSTEM SIGNAL INPUT RELAY e 2 2 0 0 , 1 0 MODULE LOCATION 1 4 4 1 . ••• 01/.4-4444.44.i TACHOMETER ..4'44 i•e-44.6.6.6. -

Page 47: Zero Speed Tachometer

Tachometer Maintenance 83871-01 ZERO SPEED TACHOMETER SYSTEM S I GNAL I NPUT R E L AY MODULE LOCATION 3 3 0 0 / 3 0 01,4j4S4v-4 4 r . • ' • '4r " V * / v . •••-4 • • 0 411.•... -

Page 48: Rotor Acceleration Tachometer

83871-01 • Tachometer Maintenance 3 I ROTOR ACCELERATION TACHOMETER SYSTEM I SIGNAL I N P U T RELAY MODULE LOCATION e 3 3 0 0 / 5 0 TACHOMETER 3 6 0 0 WARNING 3300 RACK MI MGM Dam MIWWWftmn 00 N O T I l l F O R MMMO M M U M... -

Page 49: Front Panel Features 4 Dual Setpoint Tachometer

• Tachometer Maintenance 83871-01 1..4j FRONT PANEL (DUAL SETPOINT TACHOMETER) 3 3 0 0 / 5 0 TOP D I S P L AY I N D I C AT E S ROTOR SPEED I N RPM T A C H O M E T E R 3 6 0 0 WARNING ONE SECCND DELAY... -

Page 50: Zero Speed Tachometer

( Z E R O S P E E D T A C H O M E T E R ) 3300/50 TOP D I S P L AY I N D I C AT E S ROTOR SPEED I N RPM... - Page 51 Tachometer Maintenance 83871-01 FRONT PANEL (ROTOR ACCEL. TACHOMETER) • 3300/50 TOP D I S P L AY I N D I C AT E S TACHOMETER ROTOR SPEED I N RPM Nimummimmilmr 3 6 0 0 WARNING ONE SECOND DELAY...

-

Page 52: Monitor Removal

• 83871-01 Tachometer Maintenance Monitor Removal CAUTION The machine i s not protected when the monitor is removed from the rack. 1. Loosen two screws. 2. Pull monitor from rack. • • .."-. 10001.8, I M I N I M M I N I I I I 0 •... -

Page 53: Monitor Disassembly

Tachometer Maintenance 83871-01 Monitor Disassembly MAIN C I R C U I T BOARD / / / STANDOFF ( 4 PLACES Side Cover Removal Squeeze t h e retaining tips o n each standoff, a n d remove the side cover from the monitor. - Page 54 • 83871-01 Tachometer Maintenance Monitor Disassembly [Cont] Front Panel Removal WASHER RETAINING SPRING SCREW SLIDING STANDOFF RIBBON CABLE •...

-

Page 55: Signal Input Relay Module

Tachometer Maintenance 83871-01 Signal Input Relay Module /!\ WARNING High Voltage present Could cause shock, bums or death. Do Not touch exposed wires or terminals. • The Signal Input Relay Module is on the back o f t h e r a c k . F o r r e l a y configuration, see Installation Manual. -

Page 56: Monitor Options

Monitor Options TACHOMETER PART NUMBER TACHOMETER 'TYPE A L E R T RELAYS A G E N C Y APPROVAL B A R R I E R S 3300/50 01 = DUAL SETPOINT = NONE = NOT REQ'D = NOT REQ'D... - Page 57 83871-01 i l l Tachometer Maintenance Monitor Options (Cont) Main Board Option Settings All monitor options, except for the Recorder options, are located on the Tachometer Main Board. Table 1 shows these options and their jumper positions. Table 1 Option Settings on the Main Board Jumper Remove Option...

-

Page 58: Dual Setpoint Tachometer

83871-01 Tachometer Maintenance Monitor Options (Cont) Table 1 Option Settings on the Main Board (Continued) Jumper Remove Option Install Alert Modes: Alert 1 ( S e e Table 2) * Over Alert W1 8B W1 8B Under Alert W1 8C * Latching Alert W1 8C Nonlatching Alert... - Page 59 Tachometer Maintenance 83871-01 110 i Monitor Options (Cont) Jumper Locations on the Recorder Piggy Board Table 3 Option Settings on the Recorder Piggy Board Jumper Recorder Option Remove Install +4 to +20 mA W1 B,C,D W2B, D,E W3A,C W1A,E W2A,C,F,G W3B,D W4A,C,F,G W5A,E W 6 W 7 W4B,D,E W5B,C,D +1 to + 5 Vdc...

- Page 60 83871-01 • Tachometer Maintenance Monitor Full Scale Range Adjustment NOTE: Information in [brackets] applies to the Rotor Acceleration (RPM/MIN) Tachometer only. The Tachometer RPM [and RPM/MIN] Full Scale Range Adjustment allows the RPM [and RPM/MIN] Recorder outputs to be properly scaled to the expected operating range of the shaft being monitored. The Tachometer is shipped with a Full Scale Range of 5000 RPM [500 RPM/MIN].

- Page 61 Tachometer Maintenance 83871-01 1 1 I Monitor Full Scale Range Adjustment (Cont) TACHOMETER 5000 4. Install Monitor in Rack. The RPM [and RPM/MIN] display will s h o w t h e a r•-) current R P M [ a n d WARNING 2 8 (..,4 l i e I M O...

- Page 62 • Tachometer Maintenance 83871-01 Monitor Full Scale Range Adjustment (Cont) SYSTEM M O N I TO R TACHOMETE (8.] T o adjust t h e 5000 RPM/MIN F u l l S c a l e Range, press and hold the left Alert switch on the front panel.

- Page 63 83871-01 • Tachometer Maintenance Events Per Revolution Adjustment The Events Per Revolution Adjustment allows the Tachometer to observe a rotating shaft at other than one Event per Revolution, This is the case when observing a multi-tooth gear or when observing a shaft driven at some ratio of the actual rotor speed.

- Page 64 83871-01 • Tachometer Maintenance Events Per Revolution Adjustment (Cont) ' 3 e TAcm:mETER EVENTS P E R R E V O L U T I O N Example 3: NUMERATORO In this example, both probes are observing an wARNiN3 eleven tooth gear being driven from a 2 4 w.

- Page 65 T achometer Maintenance 83871-01 • 112 I Events Per Revolution Adjustment (Cont) Example 5: In t h i s example, b o t h probes a r e T ACHOMETER EVENTS P E R R E V O L U T I O N observing an eighteen tooth gear on the NUMERATOR 1 5 7...

- Page 66 83871-01 Tachometer Maintenance 112 1 Events Per Revolution Adjustment (Cont) Events per Revolution Adjustment Procedure: CAUTION Machine Protection Will be lost during the Events per Revolution Adjust Procedure. 1. Remove Monitor (Section 7) 2. Remove Monitor side cover (Section 8) 0 0 F S A D J 0 0 E / R B 0 0 E / R A...

- Page 67 83871-01 • Tachometer Maintenance Events Per Revolution Adjustment (Cont) e— SYSTEM MONITOR 6. T o adjust t h e E / R numerator, press and hold the right Alert switch on the front p a n e l . T h e E / R numerator w i l l r e m a i n flashing.

- Page 68 83871-01 • Tachometer Maintenance 12 I Events Per Revolution Adjustment (Cont) '3 E ) T ACHOMETER 10r When t h e correct Events p e r Revolution numerator and denominator have been selected, reset Switch 6 WARNING (ER) to the OFF position. This will lock •Droes i d •...

- Page 69 Tachometer Maintenance 83871-.01 Threshold and Hysteresis Adjustments • The Tachometer, has both Manual and Automatic Threshold modes. The Threshold mode is selected using option jumper W17C. The Dual Setpoint and Rotor Accel Tachometers are shipped in the Auto Threshold mode. The Zero Speed Tachometer is shipped in the Manual Threshold mode. The events per revolution into the monitor will determine the minimum RPM which can be used with Auto Threshold.

- Page 70 • Tachometer Maintenance 83871-01 113 I Threshold and Hysteresis Adjustments (Cont) e.— 3. When adjusting t h e Transducer A Manual TRIGGER B Threshold, connect an oscilloscope to the TRIGGER TACMCMUER TEST P O I N T A Test Point (TA) located behind the front panel. When adjusting the Transducer B Manual Threshold, 1:0C connect the oscilloscope to the TRIGGER B Test...

- Page 71 83871-01 • Tachometer Maintenance Threshold and Hysteresis Adjustments (Cont) 8. Adjust Threshold A UP until the TRIGGER OK A LED extinguishes and the oscilloscope shows no square wave. Note the Threshold A value at which this occurs. 9. Adjust Threshold A DOWN until the TRIGGER OK A LED comes back on, and the oscilloscope shows the TRIGGER A square wave.

- Page 72 • 83871-01 Tachometer Maintenance Threshold and Hysteresis Adjustments (Cont) 18. Close the monitor front panel. Hysteresis Adjustment: The Tachometer is shipped with a Hysteresis of 0.5 Volts. This should work well in most installations. However, if the above Manual Threshold Adjust Procedure cannot be completed successfully, or the Auto Threshold does not function in a certain application, then the Hysteresis may require adjustment.

- Page 73 • 83871-01 Tachometer Maintenance Adjust Alert Setpoints (Dual Setpoint Tach) A c H o m E T E R jaw 3 6 0 0 1. Open and slide over the AA — front panel. 2. S e t Switch 1 , Alert I 1 I Adjust (AA) t o t h e O N S E E .

- Page 74 • Tachometer Maintenance 83871-01 Adjust Alert Setpoints (Dual Setpoint Tach.) (Cont.) 5. Press and hold the RPM SYSTEM MONITOR Alert 2 switch (left), t o adjust the RPM Alert 2 setpoint. The current RPM Alert 2 setpoint n o w flashes on the display.

- Page 75 83871-01 Tachometer Maintenance 115 I Adjust Alert Setpoints (Zero Speed Tach.) 1, Open and slide over the front panel. 2. S e t Switch 1 , Alert Adjust (AA) t o t h e O N position. The RPM display flashes t o indicate Alert Adjust Mode.

- Page 76 4110 Tachoineter Maintenance 83871-01 L11.1 Adjust Alert Setpoints (Zero Speed Tach.) (Cont.) SYSTEM MONITOR T A C H O M E T E R 5, Press and hold the Zero Speed Alert switch (left), to adjust the Zero Speed Alert ZERO SPEED setpoint.

- Page 77 83871-01 Tachometer Maintenance 116 I Adjust Alert Setpoints (Rotor Accel Tach) TACtiOWTER 3600 1. Open and slide over the front panel. le t•-•)En W A R N I N G Oa •••••• •Dai. 2. S e t Switch 1 , A l e r t M B - 401mM NEMOINN...

- Page 78 83871-01 i l Ta c h o m e t e r Maintenance 116 I Adjust Alert Setpoints (Rotor Accel Tach) (Cont) 1 e — SYSTEM MONITOR 5. Press a n d hold t h e RPM/MIN Alert switch (left), to adjust the RPM/MIN Alert setpoint.

- Page 79 • Tachometer Maintenance 83871-01 Bypass (Dual Setpoint Tach.) CAUTION Machine Protection will be lost while Bypass is Set the 2B (Bypass Alert 2 Relay) Switch to the ON position to bypass the Alert 2 relay. The Bypass LED will turn on. The monitor will otherwise function normally. The RPM Alert 1 relay cannot be Bypassed.

- Page 80 83871-01 Tachometer Maintenance 118 I Bypass (Zero Speed Tach.) CAUTION Machine Protection will be lost while Bypass is Set the 1B (Bypass RPM Alert Relay) Switch to the ON position to bypass the RPM Alert relay. The RPM Bypass LED will turn on. The monitor will otherwise function normally. Set the 2B (Bypass Zero Speed Alert Relay) Switch to the ON position to bypass the Zero Speed Alert relay.

- Page 81 Tachometer Maintenance 83871-01 Bypass (Rotor Accel Tach.) • CAUTION Machine Protection will be lost while Bypass is Set the 1B (Bypass RPM Alert Relay) Switch to the ON position to bypass the RPM Alert relay. The RPM Bypass LED will turn on. The monitor will otherwise function normally. Set the 2B (Bypass.

- Page 82 • Tachometer Maintenance 83871-01 Monitor Bypass (Dual Setpoint Tach.) CAUTION Machine Protection will be lost while Monitor Bypass is on. Set the MB (Monitor Bypass) Switch to the ON position. The Bypass LED will turn on, the Trigger OK LEDs will turn off, and the RPM display will go to zero. 3 3 0 0 / 5 0 TACHOMETER l i m m e m o w...

-

Page 83: Zero Speed Tachometer

• 83871-01 Tachometer Maintenance 21 I Monitor Bypass (Zero Speed Tach.) CAUTION Machine Protection will be lost while Monitor Bypass is on_ Set the MB (Monitor Bypass) Switch to the ON position, The Bypass LEDs will turn on, the Trigger OK LEDs will turn off, and the RPM display will go to zero. - Page 84 Tachometer Maintenance 83871-01 122 M o n i t o r Bypass (Rotor Accel Tach.) CAUTION Machine Protection will be lost while Monitor Bypass is on. Set the MB (Monitor Bypass) Switch to the ON position. The Bypass LEDs will turn on, the Trigger OK LEDs will turn off, and the RPM and RPM/MIN displays will go to zero.

- Page 85 83871-01 I l l Tachometer Maintenance 23 I Test Alerts (Dual Setpoint Tach.) n c n CAUTION Tests will exceed Alert set PROXIMITOR point levels causing Alerts to activate. This could result in r e l a y contact s t a t e change.

- Page 86 83871-01 • Tachometer Maintenance 23 I Test Alerts (Dual Setpoint Tach.) (Cont.) 6. Adjust the function generator frequency until the Tachometer displays a n RPM reading above the ALERT 1 over speed setpoint or below the ALERT 1 under speed setpoint. 7.

- Page 87 83871.01 • Tachometer Maintenance 124 I Test Alerts (Zero Speed Tach.) CAUTION M O M Tests will exceed Alert set PROX I M I TOR A point levels causing Alerts to activate. This could result in r e l a y contact s t a t e change.

- Page 88 83871-01 Tachometer Maintenance 1 2 4 1 Test Alerts (Zero Speed Tach.) (Cont.) 6. Adjust t h e function generator frequency until t h e Tachometer displays an RPM reading above the RPM Alert over speed setpoint or below the RPM Alert under speed set TA C H O M E T E R 3700 point.

- Page 89 Tachometer Maintenance 83871-01 i l l Test Alerts (Rotor Accel Tach.) CAUTION ammo' M I L Tests w i l l exceed Alert PROX M I TOR A setpoint l e v e l s causing Alerts to activate. This could result in relay contact state Cm—...

- Page 90 83871-01 Tachometer Maintenance Test Alerts (Rotor Accel Tach.) (Cont.) 6. Adjust the function generator frequency until the Tachometer displays an RPM reading above the RPM Alert over speed setpoint or below the RPM Alert under speed setpoint. 7. Verify that the RPM Alert LED turns on (Flashing if the first out option is selected), and that the RPM Alert relay has changed state.(The Relay will not change state if the Alert 1 Relay has been Bypassed.

-

Page 91: 26 I Test Trigger Oks

83871-01 Tachometer Maintenance 26 I Test Trigger OKs CAUTION Machine Protection could be lost during t h e Test PROXIMITOR A Trigger OKs Procedure. A\WARNING KEYPHASOR O R GEAR PROXIMITOR B High Voltage present could c a u s e s h o c k , bums or death. - Page 92 • 83871-01 Tachometer Maintenance 126 I Test Trigger OKs (Cont.) TACHOMETER 3600 TRANSDUCER A WIRING J"r . G D SEE MANUAL I®I TRANSDUCER B WIRING A • .77.1', 1 ' . 1 0 SIGNAL I N P U T RELAY MODULE 1.

-

Page 93: E L F Test

83871-01 Tachometer Maintenance 27 I S E L F TEST THE MONITOR HAS THREE LEVELS OF SELF TESTS: POWER-UP TEST: PERFORMED ONLY WHEN THE MONITOR IS TURNED ON. CYCLIC TEST: PERFORMED CONTINUOUSLY. USER-INVOKED TEST: PERFORMED ONLY WHEN INITIATED BY USER. 1 3 0 0 / 5 0 TACHOMETER IF ERRORS ARE DETECTED DURING CYCLIC SELF TESTS:... - Page 94 • 83871-01 Tachometer Maintenance SELF TEST (CONT) INMATE USER-INVOKED TEST BY SHORTING ACROSS TWO SELF TEST (ST) PINS. CAUTION MACHINE PROTECTION WILL BE LOST FOR DURATION OF TEST.

- Page 95 • Tachometer Maintenance 83871-01 SELF TEST (CONT) AT THE COMPLETION OF USER-INVOICED SELF TEST, THE MONITOR WILL RECALL STORED ERROR CODES, IF ANY. THESE ERROR CODES MUST BE READ AND CLEARED WITH USER INTERACTION TO ALLOW MONITORING TO CONTINUE. TACHOMETER E r r o r READ CODES ON UST;...

- Page 96 • 83871-01 Tachometer Maintenance I 2 7 I SELF TEST (CONT) ERROR CODE DESCRIPTION ROM CHECKSUM HAS FAILED. * EEPROM FAILURE NO. 1. * * E E P R O M FAILURE NO. 2. * * * ADJUST SETPOINTS + 7 . 5 V / -VT NODE OUT OF TOLERANCE. * * WARNING NODE OUT OF TOLERANCE.

- Page 97 Tachometer Maintenance 83871-01 • Field Wiring Diagram (Dual Setpoint Tach) moms PROXIMITOR A r / i . 0 KEYPHASOR O R GEAR PROXIMITOR S ® _____ R P M I R E C O R D E R OUTPUT * A . ALERT 2 ALERT 1 RELAY...

-

Page 98: Field Wiring Diagrams

• Tachometer Maintenance 83871-01 128 I Field Wiring Diagram (Dual Setpoint Tach) (Cont) I 1. Wiring Recommendations: a. Signal Module to Proximitor, 18 to 22 AWG solid or stranded 3 - wire shielded with insulating sheath. 1000 feet (305 metres) maximum. b. - Page 99 83871-01 Tachometer Maintenance Field Wiring Diagram (Zero Speed Tach) PROX I M I TOR A KEIPHASOR O R G E A R PROX I M I TOR B — RECORDER OUTPUT TO EXTERNAL ZERO SPEED ENABLE CONTACTS USER SUPPLIED) ZERO SPEED ALERT ALERT RELAY...

- Page 100 • Tachometer Maintenance 83871-01 129 I Field Wiring Diagram (Zero Speed Tach) (Cont) I 1. Wiring Recommendations: a. Signal Module to Proximitor, 18 to 22 AWG solid or stranded 3 - wire shielded with insulating sheath. 1000 feet (305 metres) maximum. b.

- Page 101 • 83871-01 Tachometer Maintenance Field Wiring Diagram (Rotor Accel Tach) PROBE A PROXIMITOR A PROBE B 4 KEYPHASOR OR GEAR PROXIMITOR B • RPM/MINUTE RECORDER RECORDER L L OUTPUT OUTPUT j \ P RPM/MINUTE ALERT ALERT RELAY RELAY CONTACTS CONTACTS SIGNAL I N P U T RELAY MODULE •...

- Page 102 • 83871-01 Tachometer Maintenance 130 I Field Wiring Diagram (Rotor Accel Tach) (Cont) 1. Wiring Recommendations: a. Signal Module to Proximitor, 18 to 22 AWG solid or stranded 3 - wire shielded with insulating sheath. 1000 feet (305 metres) maximum. b.

-

Page 103: 131 I Recommended Spare Parts

If the monitor has been modified, specify the modification number on the parts order. User must set programmable options (Reference section 10 of this manual). If in doubt about the part number, call your Bently Nevada Corporation representative before ordering. TACHOMETER... -

Page 104: Specifications

• 83871-01 Tachometer Maintenance 132 I Specifications INPUTS Signal Inputs: R e d u n d a n t inputs. Any two of the following: Proximity Probes. 0 to -24 or 0 to -18 Volt. Magnetic Pickups. (Not allowed for Zero Speed Application) 3300 System (Rack) Keyphasors. - Page 105 Tachometer Maintenance 83871-01 Specifications (Cont) ZERO SPEED ALERT (Zero Speed Tach Only) Setpoint: Adjustable from 1 to 100 RPM Requirements: External Zero Speed Enable contacts (user-supplied) must be closed. Three valid inputs below the Zero Speed setpoint, or one minute (maximum) without an input trigger. Both transducers must meet all OK detection requirements as the rotor speed approaches the Zero Speed setpoint.

- Page 106 • Tachometer Maintenance 83871-01 Specifications (Cont) CONTROLS Front Panel: Front panel switches (3) for reading the ALERT setpoints, PEAK HOLD value, and probe gap voltage. Internal: Switches on circuit board for setpoint adjustment, Relay Bypass, Monitor Bypass, and monitor set-up. External: External remote controls: Reset, Inhibit, setpoint, full scale and hysteresis adjust (t and I).

- Page 107 Tachometer Maintenance 63871-01 • Index PACE ALERT ......... . . 29, 30, 31, 32, 33 ALERT BYPASS .

-

Page 108: Schematics And Technical Drawings

83871-01 Tachometer Maintenance Appendix SCHEMATICS AND TECHNICAL DRAWINGS •... - Page 109 • • •...

- Page 110 2 0 / 0 0 0 0 0 / 0 0 0 4 0 0 0 0 / 0 W O U C C M O C I O W 4 0 ..0. . 0 T0000. 00..0. 0 0 O O ou0.000.00..

- Page 111 • • • 3 3 0 0 / 5 0 SP ARE COMPONENTS VOL T AGE CHART C O M M SHIT 201E R E F DESIS PIN No. U 3 0 01,24,25,27,28,36, +7.5 FI 2 3 1 1-5 R P 1 FP10 +7.5 02,5...

- Page 112 f l a l p ' 1 1 . 1 1 1 6 0 V i l i w i r e W. 1 • 5 5 III iv a T o s a i i s e s a 5 — W W W W L 5 - gi•...

- Page 113 1111111811 g — I H R I S H O L D L . I . E L A D J u S 1 C l i t C u l i p y • :*11 6 a l ' I L . t Sil M I ! ;...

- Page 114 • A t It 4 - 4 — 0 5 . I I 4 4 4 [ 4 4 4 3 3 0 0 / 5 0 TACHOMETER PWA A N D SCHEMATIC DRAWINGS S H E E T 5 O F 9...

- Page 115 S W Vtilgo s e t s % 9 . 9 • 2 1 S t . , S t P I ; — c 9 -4k # 3300/50 T ACHOMETER PW A AND SCHEMA TIC DRA WINGS SHEET 6 OF 9...

- Page 116 • .Z.V.7.4 • 4 . 4 4 3 3 0 0 / 5 0 TACHOMETER PWA A N D SCHEMATIC DRAWINGS S H E E T 7 O F 9...

- Page 117 • 7 1 ' i 0 . 1 1 3 - - u - f l i ; 1 1 y y —0 sszi i y j i sass 31 Oil t q c E 2 2 2 1 1 e 1 6 1 5 1 'rz 1085s 104 gp.

- Page 118 • f i R C K P L I I N E 1 2 5 • 7 , - • k A a ! A $ 2 . 3 t ` . 1 F. , 3 3 0 0 / 5 0 TACHOMETER PWA A N D SCHEMATIC DRAWINGS S H E E T 9 O F 9...

- Page 119 W 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C) t i T 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 3 1 0 2 1...

- Page 120 • • • S i g n a l I n p u t / R e l a y M o d u l e ( E p o x y ) S c h e m a t i c Page ( 1 o f 2 )

- Page 121 • R mogp t i l t P A M M A R I ! ! ! ! I I P A l m s a l u i s g s a l i v c w s e s s s mm,:ig: 41.1.

- Page 122 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the 3300/50 and is the answer not in the manual?

Questions and answers