Summary of Contents for SMC Networks PF3A703H-L

- Page 1 No.PF※※-OMX0002 PRODUCT NAME Digital Flow Switch compatible) MODEL/ Series/ Product Number PF3A703H-L PF3A706H-L PF3A712H-L...

-

Page 2: Table Of Contents

Table of Contents Safety Instructions Model Indication and How to Order Names and Functions of Individual Parts Definition and terminology Mounting and Installation Installation Piping method Wiring Outline of Settings [Measurement mode] Change of Set Value [3 step setting mode] Default setting Change of Set Flow and Hysteresis [Simple setting mode] Change the Function Settings [Function selection mode]... - Page 3 Other Settings Maintenance Forgotten the Security Code IO-Link Specifications Outline of IO-Link functions Communication specifications Process data IO-Link parameter setting Troubleshooting Error display Specifications Characteristics data Dimensions No.PF※※-OMX0002...

-

Page 4: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger". They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) and other safety regulations. - Page 5 Safety Instructions Caution 1.The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

- Page 6 ■Operator ♦This Operation Manual is intended for those who have knowledge of machinery using pneumatic equipment, and have sufficient knowledge of assembly, operation and maintenance of such equipment. Only those persons are allowed to perform assembly, operation and maintenance. ♦Read and understand this Operation Manual carefully before assembling, operating or providing maintenance to the product.

- Page 7 Caution ■Do not touch the terminals and connectors while the power is on. Otherwise electric shock, malfunction and damage to the product can result. ■After maintenance is complete, perform appropriate functional inspections and leak test. Stop operation if the equipment does not function properly or there is leakage of fluid. When leakage occurs from parts other than the piping, the product itself may be damaged.

- Page 8 ●Product handling Mounting •Tighten to the specified tightening torque. If the tightening torque is exceeded, the product can be damaged. Insufficient torque can cause displacement of the product from its proper position and the looseness of the mounting screws. •If a commercially available switching power supply is used, be sure to ground the frame ground (FG) terminal.

- Page 9 Wiring (Including connecting/ disconnecting of the connectors) •Do not pull hard on the lead wire. Especially never lift the product equipped with fitting and piping by holding the lead wires. Damage to the connector, circuit board, cover or internal components may result, causing failure or malfunction. •Avoid repeatedly bending, stretching or applying a heavy object or force to the lead wire.

- Page 10 Operating environment •Do not use the product in an environment where the product is constantly exposed to water splashes. Otherwise failure or malfunction can result. Take measures such as using a cover. •Do not use the product in an environment where corrosive gases or fluids can be splashed. Otherwise damage to the internal parts can result, causing malfunction.

- Page 11 Adjustment and Operation •Connect the load before turning the power supply on. •Do not short-circuit the load. Although error is displayed when the product load has a short circuit, generated over current may lead to the damage of the product. •Do not press the setting buttons with a sharp pointed object.

-

Page 12: Model Indication And How To Order

Model Indication and How to Order Accessories/Part numbers If an accessory is required, order using the following part number. Product number Description Note ZS-37-A Lead wire with M12 connector Length: 3 m ZS-49-A Lead wire with M12 connector Length: 3 m, M12 (female) - M12 (male) -11- No.PF※※-OMX0002... -

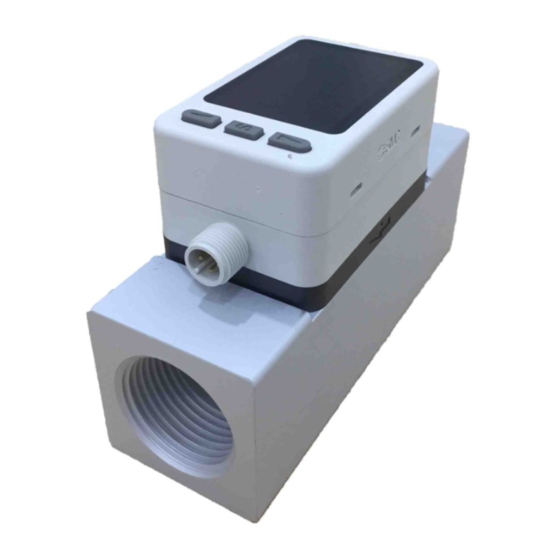

Page 13: Names And Functions Of Individual Parts

Names and Functions of Individual Parts Body Connector pin numbers (on the product) DC(+) FUNC DC(-) OUT (C/Q) Element Description Display See below Connector M12 4-pin connector for electrical connections. Lead wire with Lead wire for power supply and outputs. M12 connector Piping port For piping connections. - Page 14 ●IO-Link indicator light operation and display IO-Link status Communication 1 indicator light Status Sub screen display Content with master Normal communication status Operate (Reading of measurement value) Correct Start up When communication starts up. Preoperate IO-Link Version of master and mode Version does IO-Link does not match...

-

Page 15: Definition And Terminology

■Definition and terminology Term Definition The total amount of fluid that has passed through the device. If an Accumulated flow instantaneous flow of 100 L/min lasts for 5 minutes, the accumulated flow will be 5 x 100 = 500 L. Accumulated flow external A function to reset the accumulated value to "0"... - Page 16 Terminology Definition Function that prevents changes to the settings of the flow switch (disables Key-lock function button operation). The flow which is converted into the volume at 0 C and 101.3 kPa (absolute Normal condition pressure). <nor> indicates that the product is in normal condition. Operating pressure range The pressure range in which the product can be used.

-

Page 17: Mounting And Installation

Mounting and Installation Mounting •Never mount the product in a place that will be used as a mechanical during piping. •Attach the piping so that the fluid flows in the direction indicated by the arrow on the body. •Never mount the product upside down. •The monitor with integrated display can be rotated. -

Page 18: Installation

■Installation Direct mounting •Install the product with 4 screws suitable for the product number according to the required tightening torque. Product number Suitable screws Tightening torque Thread depth 1.5 Nm±10% PF3A703H Equivalent to M4 3 Nm±10% PF3A706H Equivalent to M5 5.2 Nm±10%... -

Page 19: Piping Method

■Piping •Do not connect equipment or piping which may generate a fluctuation in flow or drift at the IN side of the product. When installing a regulator at the IN side of the product, make sure that hunting is not generated. •The piping on the IN side must have a straight section of piping whose length is 8 times the piping diameter or more. -

Page 20: Wiring

■Wiring Connection •Connections should only be made with the power supply turned off. •Use a separate route for the product wiring and any power or high voltage wiring. If wires and cables are routed together with power or high voltage cables, malfunction may result due to noise. •If a commercially available switching power supply is used, be sure to ground the frame ground (FG) terminal. - Page 21 Internal circuit and wiring examples NPN output type PF3A7##H-##-L#-## Maximum applied voltage: 28 V Maximum load current: 80 mA Internal voltage drop 1.5 V max. NPN output type PF3A7##H-##-L#-## Maximum load current: 80 mA Internal voltage drop 1.5 V max. : The output type (NPN or PNP) can be set using [F 0].

- Page 22 NPN + Analogue output type PF3A7##H-##-L3/L4#-## Maximum applied voltage: 28 V Maximum load current: 80 mA Internal voltage drop 1.5 V max. L3: Analogue output: 1 to 5 V or 0 to 10 V Output impedance: 1 kΩ L4: Analogue output: 4 to 20 mA Max.

- Page 23 NPN + External input type PF3A7##H-##-L3/L4#-## Maximum applied voltage: 28 V Maximum load current: 80 mA Internal voltage drop 1.5 V max. External input: applied voltage of 0.4 V max. (reed or solid state input) for 30 ms or longer PNP + External input type PF3A7##H-##-L3/L4#-## Maximum load current: 80 mA...

- Page 24 Used as IO-Link device PF3A7##H-##-L#-## PF3A7##H-##-L3/L4#-## : Numbers in the figures show the connector pin layout. -23- No.PF※※-OMX0002...

- Page 25 Example of wiring for accumulated pulse output NPN output type PF3A7##H-##-L/L3/L4#-## PNP output type PF3A7##H-##-L/L3/L4#-## -24- No.PF※※-OMX0002...

-

Page 26: Outline Of Settings [Measurement Mode]

Outline of Settings [Measurement mode] Power is supplied. The output will not operate for 3 seconds after supplying power. The identification code of the product is displayed. [Measurement mode] Measurement mode is the condition where the flow is detected and displayed, and the switch function is operating. -

Page 27: Change Of Set Value [3 Step Setting Mode]

Change of Set Value [3 step setting mode] 3 step setting mode In the 3 step setting mode, the set value selected in the sub display and the hysteresis can be changed in just 3 steps. Use this mode if the product is to be used straight away, after changing only the set values. The current flow value is displayed on the main display ■Default setting When the flow exceeds the set value [P_1], the switch will be turned ON. - Page 28 <Operation> [Hysteresis mode] In the 3 step setting mode, the set value (P_1 or n_1) and hysteresis (H_1) can be changed. Set the items on the sub display (set value and hysteresis) using the ▲ or ▼ buttons. When changing the set value, follow the operation below. The hysteresis setting can be changed in the same way.

- Page 29 [Window comparator mode] The Flow switch turns on within a set flow range (from P1L to P1H). Set P1L, the lower limit of the switch operation, and P1H, the upper limit of the switch operation and WH1 (hysteresis) following the instructions given above.

-

Page 30: Change Of Set Flow And Hysteresis [Simple Setting Mode]

Change of Set Flow and Hysteresis [Simple setting mode] ■Simple setting mode In the simple setting mode, the set value, hysteresis and delay time can be changed while checking the current flow value (main display). <Operation> [Hysteresis mode] (1) Press the S button for 1 second or longer (but less than 3 seconds) in measurement mode. [SEt] is displayed on the main display. - Page 31 [Window comparator mode] Set P1L, the lower limit of the switch operation, and P1H, the upper limit of the switch operation, and WH1 (hysteresis) following the instructions given above. (refer to setting method on page 29) (When reversed output is selected, the main screen displays n1L and n1H.) [Accumulated output mode] Set each P1 (set value), referring to the Setting method on page 29.

-

Page 32: Change The Function Settings [Function Selection Mode]

Change the Function Settings [Function selection mode] ■Function selection mode In this mode, each function setting can be changed separately. In measurement mode, press the S button for 3 seconds or longer to display [F 0]. Press the ▲ or ▼ button to select the function to be changed. Press the S button for 2 seconds or longer to return to measurement mode. -

Page 33: Default Setting

■Default setting Function (Main display) Default Settings Applicable (Right sub display) Page (Main display) (Left sub display) [rEF ] Select display units [ Std] Standard condition 1 [F 0] [Unit] Units selection function L] L/min Page [NorP] Select NPN/PNP [ PnP] PNP output [oUt1] Select output mode [ HYS] Hysteresis mode [1ot ] Select switch mode... -

Page 34: F0 Reference Condition/Units Selection Function/Switch Output Function

■[F 0] Reference condition/Units selection function/Switch output function Reference condition Standard condition or normal condition can be selected. Standard condition and normal condition are defined as follows: •Standard condition: Displayed flow rate which is converted to volume at 20°C, 101.3 kPa (absolute pressure). •Normal condition: Displayed flow rate which is converted to volume at 0°C, 101.3 kPa (absolute pressure). - Page 35 Flow specification when [Ft] is selected by the units selection function Models PF3A703H PF3A706H PF3A712H Rated flow range 1.1 to 105.9 cfm 2.2 to 211.8 cfm 4.5 to 424 cfm Instantaneous flow 1.1 to 111.2 cfm 2.2 to 222.4 cfm 4.5 to 445.0 cfm Setting flow range...

-

Page 36: F1 Setting Of Out1

■[F 1] Setting of OUT1 Set the output mode of OUT1. ●Switch output modes Select the output mode required from the table below. Normal output Reversed output Hysteresis mode Window comparator mode Accumulated output mode (Increment) Accumulated output mode (Decrement) Accumulated pulse output mode... - Page 37 ●Flow setting chart Refer to the list of switch output modes for the setting procedure. Mark the procedure path with a pen or a marker. Enter the items you selected, following the procedure below. -36- No.PF※※-OMX0002...

- Page 38 Follow the setting flow chart. <Operation> Display [F_1] by pressing ▲ or ▼ button in function selection mode. Press the S button. Move on to select output mode. Select output mode Press the ▲ or ▼ button to select the output mode. Move on to select normal output/ Press the S button to set.

- Page 39 Select display colour Press the ▲ or ▼ button to select the display colour. Press the S button to set. Return to function selection mode. [F 1] Setting of OUT1 completed : Selected item becomes valid after pressing S button. : After enabling the setting by pressing S button, it is possible to return to the measurement mode by keeping pressing S button.

- Page 40 a. When hysteresis mode is selected Input of set value Set the flow based on the setting method on page 35. The snap shot function can be used. (Refer to page 66) Press the S button to set. Move on to setting of hysteresis. Setting of Hysteresis Set the flow based on the setting method on page 35.

- Page 41 b. When window comparator output mode is selected Input of set value (Lower limit value) Set the flow based on the setting method on page 35. The snap shot function can be used. (Refer to page 66) Press the S button to set. Move on to input of set value (upper limit value).

- Page 42 c. When Accumulated output mode is selected Select accumulated output increment (addition)/ decrement (subtraction) Press the ▲ or ▼ button to select the accumulated increment/decrement. Press the S button to set. Move on to input the set value. Input of set value Set the flow based on the setting method on page 35.

- Page 43 ●Setting range of the accumulated flow output The accumulated output setting range is displayed by the set value of the 4 digits and the units. Set the value by key operation in the sub display. The upper 4 digits of the value is displayed by shifting of the digit.

- Page 44 d. When accumulated pulse output mode is selected Select accumulated pulse output Press the ▲ or ▼ button to select accumulated pulse output. s Press the S button to set. Move on to select display colour. Select display colour (Refer to select display colour of page 38.) : When the accumulated pulse output mode is selected, the output operation indicator LED will turn off.

-

Page 45: F3 Select Digital Filter

■[F 3] Select digital filter The digital filter of the switch output and analogue output can be selected. Output chattering can be prevented by setting the digital filter. <Operation> Display [F_3] by pressing ▲ or ▼ button in function selection mode. Press the S button. -

Page 46: F5 Func Setting

■[F 5] FUNC setting Analogue output or external input can be selected. •When analogue output is selected 1 to 5 V or 0 to 10 V can be selected when the analogue voltage output type is used. The flow value corresponding to 5 V (10 V) or 20 mA can be selected with the analogue output free range function. - Page 47 <Operation> Display [F_5] by pressing ▲ or ▼ button in function selection mode. Press the S button. Move on to select FUNC. Select FUNC Press the ▲ or ▼ button to select the FUNC setting. [AoUt] Analogue output is selected [in] External input is selected When the model includes the analogue...

- Page 48 Select analogue output free range function Press the ▲ or ▼ button to select analogue output free setting function. [on] Free range function [oFF] Free range function ON is selected OFF is selected. Press the S button to set Press the S button to return value input.

-

Page 49: F10 Sub Display Setting (Line Name Setting)

■[F10] Sub display setting (Line name setting) Add the displayed item to the sub display. •Default setting: Accumulated value, OUT setting, peak value, and bottom value are displayed. •Addition of line name: Line name can be added to the default display. A line name can be input. - Page 50 ●Characters for entering the line name Maximum number of digits for entering the line name is 9 digits. However, the number of allowable characters is dependent on the number of the digit. Characters Number of digits 11 seg 7 seg 7 seg 7 seg 7 seg...

-

Page 51: F13 Setting For Reverse Display Mode

■[F13] Setting for reverse display mode This function is used to rotate display upside down. It is used to correct the display when it is upside down due to installation of the product. When the reverse display function is ON, the function of the ▲ and ▼ buttons are reversed. <Operation>... -

Page 52: F14 Zero Cut-Off Setting

■[F14] Zero cut-off setting When the flow is close to 0 L/min., the product rounds the value and zero will be displayed. Flow value will be displayed even when the flow rate is 0 L/min. when the pressure is high or depending on the installation orientation. - Page 53 ●Settable flow range when [L] is selected by the units selection function Displayable flow range Zero cut-off Zero cut-off set value range PF3A703H PF3A706H PF3A712H 0%F.S. 0 to 3150 L/min 0 to 6300 L/min 0 to 12600 L/min 30 to 3150 L/min 60 to 6300 L/min 120 to 12600 L/min 0 to 1%F.S.

- Page 54 ●Flow specification when [Ft] is selected by the units selection function. Set point range Zero cut-off Zero cut-off set value range PF3A703H PF3A706H PF3A712H 0 to 111.2 cfm 0 to 222.4 cfm 0 to 445.0 cfm 0%F.S. 1.1 to 111.2 cfm 2.2 to 222.4 cfm 4.5 to 445.0 cfm (Displays 0 when the...

- Page 55 ●When the set value and hysteresis of the switch output (OUT1/2) is set within the zero-cut range. The operating point of the switch output will be changed, depending on the zero-cut setting value. However, please note that the set value and hysteresis of the switch output will not be changed. To maintain the on-off point, set the value and hysteresis without the zero cut-off range.

-

Page 56: F30 Setting Of Accumulated Value Holding Time

■[F30] Setting of accumulated value hold In the default setting, the accumulated flow value is not held when the power supply is turned off. This function enables the accumulated flow value to be stored in permanent memory every 2 or 5 minutes. : When using the accumulated value hold function, calculate the product life from the operating conditions, and use the product within its life. -

Page 57: F80 Set Display Off Mode

■[F80] Set display OFF mode This function will turn the display OFF if no buttons are pressed for 30 seconds. However when a flow monitor (PFG3 series) is connected, the displayed value might be different, due to an error. When the flow monitor display is used, it is recommended to set this product to the display OFF mode. -

Page 58: F81 Security Code

■[F81] Security code The security code can be turned on and off and the security code can be changed when unlocked. < Operation > Display [F81] by pressing ▲ or ▼ button in function selection mode. Press the S button. Move on to Setting of security code Setting of Security code Press the▲... - Page 59 Changing of security code. New security code is displayed on the main display. Press the ▲ or ▼ button to change the value. Press the S button to move on to input the next digit. After entry, the changed security code will flash by pressing the S button for 1 second or longer.

-

Page 60: F90 Setting Of All Functions

■[F90] Setting of all functions Each time the S button is pressed, the function steps in the order shown in the following table. <Operation> Display [F90] by pressing ▲ or ▼ button in function selection mode. Press the S button. Move on to the suction signal input check. - Page 61 Order of function settings Order Function Applicable model Reference condition All models [F 0] Unit selection function Model with units selection function Select NPN/PNP All models OUT1 output mode All models All models OUT1 switch operation (When setting mode is selected, except output off mode) All models OUT1 set value (When setting mode is selected, except accumulated pulse...

-

Page 62: F96 Check Of Input Signal

■[F96] Check of input signal When the external input is selected by the FUNC setting, the ON/OFF of the input signal can be checked. : However when analogue output is selected, the ON/OFF of the input signal cannot be checked. <Operation>... -

Page 63: F98 Setting Of Output Check

■[F98] Setting of output check The operation of the output can be checked by switching the output ON/OFF by pressing a button, without the need for a flow of fluid. < Operation > Display [F98] by pressing ▲ or ▼ button in function selection mode. Press the S button. - Page 64 Accumulated pulse output check Accumulated pulse is output for 10 times by pressing the ▲ button. Accumulated pulse is stopped by pressing the ▼ button. : When the converted pulse value is 100 L/pulse, the value is changed from 0 to 1000 by pressing the ▲ button once (total of 10 times of output).

- Page 65 PD diagnostic bit (flow) check Press the ▲ or ▼ button to select diagnostic bit (flow) check. : This function is available with IO-Link communication. : Refer to page for details of the diagnostic information. Move on to PD flow Press the SET button to set.

-

Page 66: F99 Reset To The Default Settings

■[F99] Reset to the default settings If the Flow switch settings are uncertain, the default values can be restored. <Operation> Display [F99] by pressing ▲ or ▼ button in function selection mode. Press the S button. Move on to reset to factory default settings. Rest to factory default settings. -

Page 67: Other Settings

Other Settings ●Reset operation The Accumulated Flow, Peak Value and Bottom Value can be reset. To reset the accumulated value, press the ▼ and S buttons for 1 second or longer. ●Snap shot function The current flow rate value can be stored to the switch output ON/OFF set point. When the items on the Sub display (left) are selected in either 3 step setting mode, Simple setting mode or Setting of each function mode, by pressing the ▲... - Page 68 ●Key-lock function The key lock function is used to prevent errors occurring due to unintentional changes of the set values. If S button is pressed while the keys are locked, [LoC] is displayed on the sub display (left) for approximately 1 second.

- Page 69 <Operation – Without security code input> •Locking (1) Press the S button for 5 seconds or longer in measurement mode. When [oPE] is displayed on the main display, release the button. The current setting [LoC] or [UnLoC] will be displayed on the sub display. (2) Select the key locking/ un-locking with ▲...

-

Page 70: Maintenance

Maintenance How to reset the product after a power loss or when the power has been unexpectedly removed The settings for the product are retained in memory prior to the power loss or de-energizing of the product. The output condition is also recoverable to that prior to the power loss or de-energizing. However, this may change depending on the operating environment. -

Page 71: Io-Link Specifications

IO-Link Specifications ■Outline of IO-Link functions ○Communication function This product can check the temperature measurement value, diagnostic information and switch output status using cyclic data communication via the IO-Link system. ○Product status monitoring function This function monitors the product status via the IO-Link. •Several errors (e.g. -

Page 72: Process Data

■Process data Process data is the data which is exchanged periodically between the master and device. This product process data consists of switch output status, error diagnostics, fixed output and flow measurement value. (Refer to the table below.) Bit offset Item Notes OUT1 output... - Page 73 ○Unit specification and flow measurement value (PD) Flow value PD value Flow Display/settable Display/settable Series Unit Rated flow range Rated flow range range range range Min. Max. Min. Max. 3,000 L 30 to 3000 30 to 3150 40 to 4000 40 to 4200 L/min 6,000 L...

- Page 74 ○Conversion formula of the process data and flow measurement value (1) Conversion formula from the process data to the flow measurement value: Pr = a × (PD) + b (2) Conversion formula from the flow gauge measurement value to the process data: (PD) = (Pr –...

-

Page 75: Io-Link Parameter Setting

■IO-Link parameter setting ○IODD file IODD (I/O Device Description) is a definition file which provides all properties and parameters required for establishing functions and communication of the device. IODD includes the main IODD file and a set of image files such as vendor logo, device picture and device icon. - Page 76 ●ISDU parameters Index 1 Parameters Initial value Remarks Access index (dec) 0x0002 Refer to "System command" on System command page 75. 0x000C Refer to "Device access lock Device access lock 0x0000 (12) parameter" on page 76. 0x0010 Vendor name SMC Corporation (16) 0x0011 Vendor text...

- Page 77 ●Device access lock parameter (index 12) The contents are as follows. Data type: 16 bit Record Value Contents Key lock release, DS unlock (Initial value) Key lock release, DS lock Key lock, DS unlock Key lock, DS lock [Key lock] This function prevents the user from physically changing the setting of the flow switch (button operation is not accepted).

- Page 78 ●Device detail status parameters (index 37) Detailed event contents of readable device status are as follows. Event classification Array Event content Event code Definition Value Error 0xF4 0x8D02 Internal failure of digital flow switch Error 0xF4 0x8D03 Internal failure of digital flow switch Error 0xF4 0x8D04...

- Page 79 ●Product individual parameters Data Data Index Access Initial 4 Parameter type storage Set value Remarks 1 index value 2 3 When the unit selection function is Unit 0: L/min (L) not included, 1000 0x03E8 1: cfm (ft (Selection of display unit) a read/write to an un-selectable item is rejected.

- Page 80 ●Product individual parameters (continued) Data Data Index Access Initial 4 Parameter type storage Remarks Set value 1 index value 2 3 0: HYS (Hysteresis) 1: Wind (Window comparator) oUt2 2: AC (Selection of output (Accumulated output) mode) 3: PLS 1410 0x0582 (Accumulated pulse) 4: Err (Error output) 5: oFF (Output OFF)

- Page 81 ●Product individual parameters (continued) Data Data Index Access Initial 4 Parameter type storage Remarks Set value 1 index value 2 3 0: 100 (L/pulse) 1320 0x0528 PLS1_L 1: 1000 (L/pulse) 3000/6000 L range 0: 1 (L/pulse) 1: 10 (L/pulse) 1330 0x0532 PLS1_Ft 12000 L range 0: 10 (L/pulse)

- Page 82 ●Product individual parameters (continued) Data Data Index Access Initial 4 Parameter type storage Remarks Set value 1 index value 2 3 0: oFF (Unused) (Security code 1: on (Used) Used/Not used) 2410 0x096A Setting range PinCode 0x0000 to 0x03E7 (Security code (0 to 999) setting) Line name...

- Page 83 1: "R" means Read and "W" means Write. 2: Refer to the table below for the symbol. Data type Data length Symbol Description (IO-Link standard) Bit [byte] 8[1] UIntegerT Unsigned integer 16[2] IntegerT 16[2] Signed integer 32[4] Float32T Floating point number 3: "Y"...

- Page 84 [dEF selection of display items during standard setting] Value Setting content Supplemental information HYS mode set value HYS mode hysteresis Wind mode lower side set value Wind mode upper side set value OUT1 Wind mode hysteresis Accumulated output mode Accumulated pluse output mode Err mode oFF mode When the value which does not match the OUT...

- Page 85 [Line name communication data] Value (16 hex number) 7seg 11seg Value (16 hex number) 7seg 11seg Value (16 hex number) 7seg 11seg -84- No.PF※※-OMX0002...

-

Page 86: Troubleshooting

Troubleshooting If an operation failure of the product occurs, please confirm the cause of the troubles from the following table. If a cause applicable to the troubles cannot be identified and normal operation can be recovered by replacement with a new product, this indicates that the product itself was faulty. Problems with the product may be due to the operating environment (installation etc). - Page 87 Problem Possible Error indication Investigation method Countermeasure causes (1) Check if the output current is 80 mA or greater. (1)(2) Connect the appropriate (2) Check if the connected load load. complies with the specification. (3) Use a relay with a surge Excess current Check if the load is short circuited.

- Page 88 Problem Possible Error indication Investigation method Countermeasure causes Incorrect power Check if the power supply voltage is Power supply voltage is 24 VDC supply 24 VDC ±10%. ±10%. Check the power supply wiring The display turns Check if the brown and blue wires are off.

- Page 89 Problem Possible Error indication Investigation method Countermeasure causes Effect of line pressure fluctuation Check the set flow rate (hysteresis). Check the flow rate setting. because hysteresis is too The operation is narrow. unstable. (1) Check the power supply wiring. (chattering) (1) Check and correct the wiring.

-

Page 90: Error Display

■Error display Error name Error display Description Measures Instantaneous flow Flow rate exceeding the upper limit Reset applied flow rate to a level within error of the settable flow range is applied. the settable flow range. Turn the power off and remove the The switch output load current is Over current error cause of the over current. -

Page 91: Specifications

Specifications Models PF3A703H PF3A706H PF3A712H 1 Applicable fluid Air, N Fluid Operating fluid temperature 0 to 50 Detection method Heating type sensor Rated flow range 30 to 3000 L/min 60 to 6000 L/min 120 to 12000 L/min Instantaneous 30 to 3150 L/min 60 to 6300 L/min 120 to 12600 L/min flow... - Page 92 Models PF3A703H PF3A706H PF3A712H 7 Voltage output: 1 to 5 V (0 to 10 V can also be selected Output type Current output: 4 to 20 mA Output Output impedance approx. 1 kΩ Analogue voltage 6 output Impedance Current Max. load impedance 600 Ω output 8 Response time...

- Page 93 1: The air quality class is according to JIS B 8392-1:2012 [3:6:-] and ISO8573-1:2010 [3:6:-]. 2: When using the accumulated value hold function, calculate the product life from the operating conditions, and use the product within its life. Maximum updating time of accumulated value is 1.5 million times. If the product is energized for 24 hours per day, the product life will be as follows: •Data memorized every 5 minutes --- 5 minutes x 1.5 million times = 7.5 million minutes = 14.3 years •Data memorized every 2 minutes --- 2 minutes x 1.5 million times = 3 million minutes = 5.7 years...

-

Page 94: Characteristics Data

■Characteristics data ●Flow rate/ Analogue output 2 2 0 L/min 0 L/min Voltage output Voltage output 1.04 V 0.1 V 10 V 1 1, 3 (1 to 5 V) (0 to 10 V) 1 Current output 4 mA 4.16 mA 20 mA Models Minimum value of rated flow range... - Page 95 ●Pressure loss (reference value) •PF3A703H (For 3000 L/min) •PF3A706H (For 6000 L/min) •PF3A712H (For 12000 L/min) -94- No.PF※※-OMX0002...

- Page 96 ●IN side straight pipe length and accuracy (reference value) •Do not connect equipment or piping which may generate a fluctuation in the flow or drift at the IN side of the product. When installing the regulator at the IN side of the product, make sure that hunting is not generated. •The piping on the IN side must have a straight section of piping whose length is 8 times the piping I.D.

-

Page 97: Dimensions

■Dimensions Symbol Models PF3A703H 79.1 55.3 22.5 4 x M4 x 0.7 depth 7 PF3A706H 94.1 70.3 4 x M5 x 0.8 depth 8 PF3A712H 104.1 80.3 4 x M6 x 1.0 depth 9 -96- No.PF※※-OMX0002... - Page 98 Lead wire with M12 connector (ZS-37-A) Pin number Description Colour DC(+) Brown FUNC White DC(-) Blue Black : 4-wire lead wire with M12 connector for PF3A series. Lead wire with M12 connector (ZS-49-A) M12 female M12 male Description Pin number Pin number N.C.

- Page 99 Revision history 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © 2020 SMC Corporation All Rights Reserved No.PF※※-OMX0002...

Need help?

Do you have a question about the PF3A703H-L and is the answer not in the manual?

Questions and answers