Summary of Contents for McHale W2020

- Page 1 W2020 Round Bale Wrapper Operator Instruction Manual Issue 4 McHale Ballinrobe Co. Mayo F31 K138 Ireland Tel: +353 94 9520300 I.S. EN ISO 9001:2015 Email: sales@mchale.net Website: www.mchale.net CLT00392_7.03...

- Page 2 If there is any conflict as to the accuracy or content, of any translation, the English source manual remains the authorised document. No part of this manual may be reproduced, distributed or translated, in any form or by any means, without prior written permission by McHale.

- Page 3 It is vital to replace defective parts of the machine immediately and to use only genuine McHale spare parts, as these are designed and manufactured to the same standard as the original machine. Spare parts can be obtained from your McHale dealer.

-

Page 4: Table Of Contents

McHale W2020 Round Bale Wrapper Table of contents Introduction Product information Designated use of the machine Front view General specifications Tractor requirements Optional equipment * General safety Be aware of all safety information Follow all safety instructions Store all items carefully... - Page 5 McHale W2020 Round Bale Wrapper Control box functions Control box features Remote options Automatic wrapping of bale Calibration procedure Warning messages Road traffic safety & operation Before travelling on any public roadway Field operation & machine adjustments Loading plastic film...

-

Page 6: Introduction

If you have any questions in relation to the instructions in the manual, please contact your McHale dealer. It is highly recommended that training be sought from your local McHale dealer. The operator is solely responsible for the safe use and maintenance of the machinery, in accordance with this manual. -

Page 7: Product Information

The relevant health and safety requirements that may be in force in the country of use will be strictly followed. No other equipment or accessories, other than released by McHale, are installed in the machine. The use of any other equipment or accessory is entirely at the owner/operator’s risk. -

Page 8: Front View

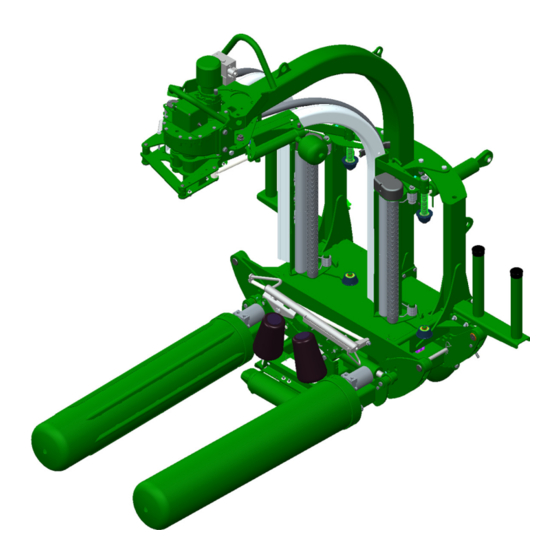

McHale W2020 Round Bale Wrapper 2.2 Front view 11 10 No. Machine function Lift arm (ribbed) Bobbins Dispenser trip arm Dispenser motor and brake unit Satellite dispenser arms (folded) Top link Dispenser Hydraulic control valve (under panel) Cut & hold... -

Page 9: General Specifications

Remote hand piece 64% gears Alternative to standard 70% film stretch (*) May not be available in all countries, check with your McHale dealer for availability in your country. Side-tip option The side-tip option is used for knocking the bale onto its side and is very useful for... -

Page 10: General Safety

& instructions explained’). The spare part codes for each decal are also listed, which are available from your McHale dealer. If safety decals are damaged or missing due to wear and tear or component replacement, ensure that they are replaced. -

Page 11: Store All Items Carefully

McHale W2020 Round Bale Wrapper As with all machinery, learn all operations and use controls by reading this manual thoroughly. Do not attempt to let anyone operate this machine without being fully instructed. 3.3 Store all items carefully Store all attachments in a secure and safe manner so as to prevent items from falling. -

Page 12: Trained Operator Criteria

McHale W2020 Round Bale Wrapper 3.7 Trained operator criteria Age related requirements General requirements The operator needs to be fully The operator must be in full trained in the use of this machine control of his/her senses and 18 + and have a valid tractor driver’s... -

Page 13: General Safety Warnings

Read and understand this operator manual before using the machine. If any of the instructions appear unclear do not hesitate to contact your McHale dealer. Only competent persons who have read and fully understood this manual are qualified to operate this machine. - Page 14 McHale W2020 Round Bale Wrapper It is the operator’s responsibility to ensure that there is no person in the ‘Danger Zone’ while operating the machine, especially during start up. Before repair or reassembly Safe lifting gear of sufficient capacity must be used for machine assembly. All ...

- Page 15 Maintenance and repair work exceeding the content of this manual should only be carried out by qualified persons or your McHale dealer. When conducting maintenance work tie long hair behind your head. Do not ...

- Page 16 Never use a machine where a malfunction exists! Contact your McHale dealer to achieve a solution. Always think ‘Safety First’! Avoid heating near pressurised fluid lines, as pressurised lines can be ...

- Page 17 McHale W2020 Round Bale Wrapper Never leave children alone in a tractor cab as they can interfere with controls and many children have been killed falling from the door or rear window of a tractor. Children under 16 years of age should never operate power-driven ...

-

Page 18: Specific Safety Warnings

Do not work on hydraulic systems unless you are qualified to do so. This work should only be carried out by qualified persons or your McHale dealer. 4.2 Noise level The European Directive 2003/10/EC directs employers and employees to ... -

Page 19: Special Safety Devices/Instructions

McHale W2020 Round Bale Wrapper A functioning fire extinguisher should always be available on the tractor. The machine is to be kept clear of oil, grease, crops, string, plastic or any other flammable material at all times. Do not continue to work with overheated parts, cables or pipes, unless you ... -

Page 20: Safety Instruction Decal Locations

McHale W2020 Round Bale Wrapper 4.5 Safety instruction decal locations... -

Page 21: Safety Warnings & Instructions Explained

Therefore it has to be ensured that all safety warnings and instructions are understood and followed. If any of the decals are damaged or missing, they are available from your McHale dealer. The relevant part numbers are shown in brackets. The decals featured on the machine are displayed with their meanings below:... - Page 22 McHale W2020 Round Bale Wrapper Lifting hook location. (CST00032) Do not dismantle. High pressure always. (CST00056) Read instruction manual before use (CST00057) Grease daily. (CST00060) Keep clear of rotating dispenser arms. (CST00083)

- Page 23 McHale W2020 Round Bale Wrapper Warning! Never operate dispenser above 30 rpm. (CST00701) Insert dispenser latch handle here. (CST00703) Diagram of plastic film path through dispenser. (CST00704) Keep hands out of trap area. (CST00705) Keep hands clear of rotating rollers.

-

Page 24: Machine Lifting Guidelines

McHale W2020 Round Bale Wrapper 4.7 Machine lifting guidelines WARNING: Machine lifting Only use chains or strapping that are rated for a minimum load of 1.0 tonne (1,000 kg) when using the lift eye location on the chassis, shown below. -

Page 25: Tractor Requirements & Preparation

3-point linkage CAT 2 Two ½” female quick-releases (feed and return) for hydraulic power supply The return line must be freeflow to tank (check with a McHale dealer for details) 12 V/ 20 A socket or battery power cable The following items are required for fitment of the wrapper to an industrial loader: Loader bracket frame and set of suitable mounting brackets. -

Page 26: Machine Set-Up & The Tractor Hydraulic System

McHale W2020 Round Bale Wrapper 5.3 Machine set-up & the tractor hydraulic system CAUTION: Hydraulic system setup It is very important to determine the correct hydraulic system on the tractor, as a wrong setup will cause serious damage to the tractor hydraulic system, or at least excessive heating of the oil. -

Page 27: Which Hydraulic System Is Used

McHale W2020 Round Bale Wrapper 5.4 Which hydraulic system is used? 1. Open-centre 2. Closed-centre 3. Load-sensing Set as open-centre Set as closed-centre / (default factory setting) load-sensing Does the tractor have a ‘Power Beyond’ & ‘Sensing Line’ connection fitted? -

Page 28: Hydraulic Spool Valve Setup

McHale W2020 Round Bale Wrapper 5.5 Hydraulic spool valve setup Procedure to select open/closed centre valve configuration. Using a 19 mm spanner, loosen locknut (1), as shown below. With a ¼’’ Allen Key, tighten or unscrew the bolt according to the following guidelines: ... -

Page 29: Connecting The Control Box

McHale W2020 Round Bale Wrapper 5.7 Connecting the control box The electronic control box must be located inside the tractor cab in the operator’s field of vision and within easy reach of the red emergency stop button. (See ‘Electronic control system’). -

Page 30: Machine And Tractor Stability

5.9 Machine and tractor stability In order to ensure the stability of the combination of W2020 and tractor, it may be necessary to add ballast to the tractor. If there is insufficient ballast the W2020-tractor combination may become unstable. - Page 31 (m) Distance from the centre of the lowest points of the three point linkage to the centre of gravity of the W2020 and bale (m) WARNING: The above calculations are a guide only Travelling over rough or sloping ground may require additional ballast...

-

Page 32: Bale & Film Requirements

McHale W2020 Round Bale Wrapper Bale & film requirements 6.1 Bale requirements The bales to be wrapped should be well shaped, dense and of suitable quality for making silage. Substandard material will not produce good quality silage regardless of how well the bale is wrapped. -

Page 33: Number Of Wrapping Arm Rotations

McHale W2020 Round Bale Wrapper 6.3 Number of wrapping arm rotations To determine the number of wrapping arm rotations required to cover a bale, carry out the following procedure: Using manual operation, from the control box, manually count the number of wrapping arm rotations to cover the bale completely with plastic film Add 0.5 to this number... -

Page 34: Electronic Control System

McHale W2020 Round Bale Wrapper Electronic control system (Software version EP348-120 onwards) Displays manual (MAN) or automatic (AUTO) mode Clock Film layers Bale counters Voltage 1 or 2 film rolls Adjust the side-tip arm Roller rotation on/off Adds 1 additional... -

Page 35: Control Box Functions

McHale W2020 Round Bale Wrapper 7.1 Control box functions Function Manual (MAN) Automatic (AUTO) Emergency stop button. Push to stop. Turn clockwise to reset. Menu button. Press once to enter the machine menu. AUTO/MAN button. Press to switch between manual and automatic modes. -

Page 36: Control Box Features

McHale W2020 Round Bale Wrapper 7.2 Control box features When the control box is first switched on it displays ‘McHale’ followed by the software version number. After a short delay, the working display appears. The working display features an image of the machine, which is surrounded by general working information. - Page 37 McHale W2020 Round Bale Wrapper Bale counters The bale sub total is displayed on the right side of the screen. The control box contains ten different bale counters (A - J) which can be reset and a grand total counter which can not be reset.

- Page 38 McHale W2020 Round Bale Wrapper 7.2.1 Menu structure...

- Page 39 McHale W2020 Round Bale Wrapper Machine settings 1 This menu allows the user to adjust settings in relation to bale wrapping. The toggle key (button C) can be used to scroll between each setting. When the arrow is beside the required setting then the + and - soft keys can be used to increase/decrease the value.

- Page 40 McHale W2020 Round Bale Wrapper Auto unload In AUTO mode with Auto unload turned on, one touch of unload bale (Button 7) brings the roller arms to a fully open position. The unload button must be pressed and held if Auto unload is set to off or when in MAN mode.

- Page 41 McHale W2020 Round Bale Wrapper Dispenser reverse option This allows the wrap-arm to be reversed at the end of wrapping. There are three options to reverse the dispensers: On (): The operator can press Button C to reverse the dispensers.

- Page 42 McHale W2020 Round Bale Wrapper Counters This menu allows the user to manage bale counters. The toggle key (button C) can be used to scroll between each counter. Press to select a new subtotal. Press ‘ESC’ to return to the main menu.

-

Page 43: Remote Options

Press button C to select the beeper/key tone volume. Use the left and right arrows to adjust the setting. Technician menu Reserved for McHale technicians. This menu is password protected as settings in it are critical to correct machine operation. - Page 44 McHale W2020 Round Bale Wrapper 7.3.1 Wired remote Select Machine settings 2 in the main menu. Scroll through the settings to remote setting. Using the + and - buttons set the remote setting to wired remote. Wrap/Pause/Resume/Rewrap Load bale Unload bale 7.3.2 Radio remote...

- Page 45 McHale W2020 Round Bale Wrapper Press the stop button on the remote. A code will be shown when the remote has been paired with the control unit. The radio remote only works machine functions when the control unit is in Auto mode. Press the red button on the rear of the remote when pressing any button, except the stop button.

-

Page 46: Automatic Wrapping Of Bale

McHale W2020 Round Bale Wrapper 7.4 Automatic wrapping of bale The following details a typical sequence for wrapping a bale: 1. Switch from MAN to AUTO by pressing button 3. 2. Press button 6 to load the bale. The rollers will load the bale onto the wrapper. -

Page 47: Calibration Procedure

McHale W2020 Round Bale Wrapper 7.5 Calibration procedure 1. From time to time the machine may need to be calibrated. This can be necessary after the software is updated or the settings have been reset to defaults. 2. Update the control unit to software version EP348- 084 or higher. - Page 48 McHale W2020 Round Bale Wrapper Safety switch If either of the safety arms are tripped a warning will be displayed and the satellite will stop. When the safety arm is released, press and hold ‘Resume’ to continue wrapping. (2115) Filter blocked If the filter is blocked a warning will be displayed.

- Page 50 W2020 Menu structure...

-

Page 51: Road Traffic Safety & Operation

McHale W2020 Round Bale Wrapper Road traffic safety & operation 8.1 Before travelling on any public roadway WARNING: Complete a full inspection before travelling on the road Ensure that a full inspection is completed every time before attempting to go on to a public roadway, always think and practice safety! The following should be inspected every time, before travelling on a public road: Ensure satellite arms have automatically returned to the home position. -

Page 52: Field Operation & Machine Adjustments

McHale W2020 Round Bale Wrapper Field operation & machine adjustments Detailed instructions on how to operate the machine are outlined in the following pages. These should be used along with learning the precise functionality of each adjustment. WARNING: Check before starting or moving the machine Before starting or moving the machine, ensure there is nobody in the vicinity, especially children, that may be out of view. -

Page 53: Preparing Machine In Field For Wrapping

McHale W2020 Round Bale Wrapper ENVIRONMENT: Recycling of the plastic film Respect the environment! Never throw away or burn the waste plastic film. Always take waste materials to a recycling centre. 9.2 Preparing machine in field for wrapping Remove trip arm catch from leading dispenser. -

Page 54: Wrapping Process

McHale W2020 Round Bale Wrapper 9.3 Wrapping process The following is the recommended method for working the wrapper on the rear three- point linkage of a tractor. It assumes the bales are well shaped for wrapping. However since it is impossible to allow for all differing conditions and terrain it may be necessary for the operator to vary this procedure. -

Page 55: Dispenser Gears

9.4 Dispenser gears The dispenser rollers are set for a standard film stretch of 70%. Optional sets of dispenser gears for 64% film stretch are available from your McHale dealer. One kit (A) is necessary for each dispenser on the machine. -

Page 56: Releasing Cut And Hold Oil Pressure

McHale W2020 Round Bale Wrapper 9.5 Releasing cut and hold oil pressure WARNING: Only competent operators should carry out this task It is very important that care is taken in carrying out the following procedure to protect both the operator and any personnel that may be nearby. -

Page 57: Dispenser Stop-Position Magnet Adjustment

McHale W2020 Round Bale Wrapper 9.6 Dispenser stop-position magnet adjustment In the unlikely event of the dispenser not finishing in the correct position such that the cut & hold cannot get a firm grip on the plastic, then it may be necessary to adjust the magnets as shown below (bale dimensions can also be a factor). -

Page 58: Bale Height Adjustment

McHale W2020 Round Bale Wrapper 9.7 Bale height adjustment In order to wrap bales of different diameters the closed width of the rollers arms can be adjusted to lower the bale centre of rotation for larger diameter bales. This means a bale up to 1.52 m (60”) can be wrapped without having to adjust the height of the... -

Page 59: Trip Arm Switch

McHale W2020 Round Bale Wrapper 9.8 Trip arm switch The trip arm switch will need to be properly adjusted if it ever needs replacement or has been moved for any reason. This may be adjusted as follows: Loosen two M4 bolts just enough to move switch. -

Page 60: Dispenser Height Adjustment

McHale W2020 Round Bale Wrapper 9.9 Dispenser height adjustment The plastic film needs to be applied around the centre of the bale to ensure optimum coverage. To adjust this the dispenser may need to be adjusted up or down as necessary. -

Page 61: How To Test Trip Arm Operation

If there is any dispenser movement while an arm is tripped there is a serious safety issue with the switch. The machine must not be operated and a McHale authorised dealer should be contacted for further assistance. WARNING: Do not operate the dispenser above 30 rpm... -

Page 62: Lift Arm Roller Adjustment

Upon releasing the rotation button, the arm rotation should stop immediately. If there is any run-on, then do not operate the machine and contact your McHale dealer for further assistance. 9.11 Lift arm roller adjustment This slack adjustment should be carried out if excessive movement is found at the motor end of the lift arm rollers. - Page 63 McHale W2020 Round Bale Wrapper 4. Use a size 38 spanner to rotate the eccentric nut. Note the location of the indication hole ‘A’. Rotating this towards the notch ‘B’ on the fixed plate reduces roller free play. 5. Both eccentric nuts each side of the box...

-

Page 64: Machine Maintenance

WARNING: Inspections in the ‘Danger Zone’ during machine operation require a second trained operator at the controls McHale recommend that nobody is ever in the ‘Danger Zone’ at any time during machine operation, but in the event of carrying out inspections... - Page 65 McHale W2020 Round Bale Wrapper Every day Grease bale lift arm hinges. Grease bale roller gears. Grease bale lift arm hydraulic cylinder ends. Grease cut and hold assembly. Check all guards and safety related components. Check for any oil leaks and damaged pipes.

- Page 66 McHale W2020 Round Bale Wrapper Every month Check oil level in brake unit. Check dispenser drive gearbox oil level. Grease dispenser top coil roller shaft. Every year Clean and lubricate all moving parts. Change oil and grease on the brake unit.

- Page 67 Carefully clean all machine sections, inside and out. Dirt and foreign objects are likely to draw moisture and cause rusting of steel components. McHale recommend that the machine be blown down with an air line, as opposed to a pressure washer, due to the dangers involved with pressure washing and to protect the overall paint work on the machine.

-

Page 68: Dispenser Gearbox Oil Level

McHale W2020 Round Bale Wrapper 10.2 Dispenser gearbox oil level WARNING: Before working on this machine Always ensure that the tractor is shut down, the hand brake applied and the ignition key removed. The oil can be topped up as follows: Check oil level in dispenser gearbox using sight glass on side of gearbox housing. -

Page 69: Dispenser Trip Arms

McHale W2020 Round Bale Wrapper 10.4 Dispenser trip arms WARNING: Always think 'Safety First'! Always ensure tractor is switched off, hand brake applied, engine stopped and ignition key removed before working on machine. Check that trip arm is free to rotate. -

Page 70: Tightening Torque Values

McHale W2020 Round Bale Wrapper 10.5 Tightening torque values It is important that the correct torques for fasteners are adhered to. Below are tables of recommended torques for these. These are to be used unless torques are otherwise specified. These values are for general use only. Check tightness of all fasteners periodically. -

Page 71: Storage

Carefully clean all machine sections, inside and out. Dirt and foreign objects are likely to draw moisture and cause rusting of steel components. McHale recommend that the machine be blown down with an air line, as opposed to a pressure washer, due to the dangers involved with pressure washing and to protect the overall paint work on the machine. -

Page 72: Troubleshooting

McHale W2020 Round Bale Wrapper Troubleshooting 12.1 Troubleshooting overview This section has been compiled by McHale service personnel in conjunction with McHale importers and dealers. It outlines some common problems which can occur and acts as a quick reference section or check list to resolve the problem. It is important to note that it outlines the common problems and to this effect it is not exhaustive. - Page 73 McHale W2020 Round Bale Wrapper 12.1.3 Dispenser rotation or ‘Dispenser Safety’ displayed Symptom Reason Solution Dispensers do not rotate No hydraulic oil flow/ Turn on oil. Ensure that return. (Check tractor ‘tank return’ line is manual for hydraulic connected ‘to tank’ and...

- Page 74 McHale W2020 Round Bale Wrapper 12.1.7 Auto start cycle will not run once pressed Symptom Reason Solution Auto start cycle will not No hydraulic oil flow/ Turn on oil. Ensure that run once pressed return. (Check tractor ‘tank return’ line is manual for hydraulic connected ‘to tank’...

-

Page 75: Certification & Warranty

The PDI (pre-delivery inspection) form that is filled out on the commissioning of every new machine, should also be used during the transfer of ownership of a McHale machine. The same check list must be completed and any areas requiring attention addressed before the re-sale of the machine should occur. - Page 76 McHale W2020 Round Bale Wrapper Declaration of Conformity DECLARATION OF CONFORMITY We hereby certify that the machinery stipulated below complies with all the relevant provisions of the EC Machinery Directive 2006/42/EC and the national laws and regulations adopting this directive.

- Page 77 ENSURE THAT THE TRACTOR IS OF THE CORRECT SPECIFICATION FOR THIS MACHINE. REFER TO THE OPERATOR INSTRUCTOR MANUAL BEFORE MAKING ANY ADJUSTMENTS! This machine must be registered on www.mchale.net by the Dealer in order to qualify for Warranty! Check that all accessories are with On electronic machines run the the Owner/Operator.

- Page 78 McHale W2020 Round Bale Wrapper McHale Limited Warranty Engineering, Ballinrobe, Co. Mayo, Ireland (hereinafter called ‘the company’) warrants to the original retail purchaser that new products sold and registered with the company, shall be, at the time of delivery, free from defects in material and workmanship, and that such equipment is covered under Limited Warranty providing the machine is used and serviced in accordance with the recommendations in the operator’s manual.

- Page 79 McHale W2020 Round Bale Wrapper The importer will be responsible for the following costs: All warranty labour charges. The warranty is dependent on the strict observance of the following: The machine has been put in service by the dealer according to our instructions.

-

Page 80: Appendix

Appendix 14.1 Unit conversion tables Length inch (in) foot (ft) yard (yd) mile (mi) 0.001 0.000001 0.03937 0.003281 0.001094 6.21e-07 0.01 0.00001 0.393701 0.032808 0.010936 0.000006 1000 0.001 39.37008 3.28084 1.093613 0.000621 1000000 100000 1000 39370.08 3280.84 1093.613 0.621371 25.4 2.54 0.0254 0.000025... - Page 81 Mass gram (g) tonne US ton Imp. ton pound (lb) ounce (oz) 0.001 0.000001 0.000001 9.84e-07 0.002205 0.035273 1000 0.001 0.001102 0.000984 2.204586 35.27337 1000000 1000 1.102293 0.984252 2204.623 35273.96 907200 907.2 0.9072 0.892913 2000 32000 1016000 1016 1.016 1.12 2240 35840 453.6...

- Page 82 9.80665 7.233003 86.79603 1.35582 0.138255 0.112985 0.011521 0.083333 Temperature conversion formulas Degree Celsius (°C) (°F - 32) x 5/9 (K - 273.15) Degree Fahrenheit (°F) (°C x 9/5) + 32 (1.8 x K) - 459.67 Kelvin (K) (°C + 273.15) (°F + 459.67) ÷...

Need help?

Do you have a question about the W2020 and is the answer not in the manual?

Questions and answers