Summary of Contents for Claydon HYBRID MOUNTED

- Page 1 OPERATORS MANUAL HYBRID MOUNTED CLAYDON YIELD-O-METER LTD BUNTERS ROAD, WICKHAMBROOK, NEWMARKET, SUFFOLK, CB8 8XY TEL: +44 (0)1440 820 327 EMAIL: info@claydondrill.com www.claydondrill.com...

- Page 2 LOCATION OF IDENTIFICATION PLATE Claydon Yeildmeter Ltd Gaines Hall, Wickhambrook Newmarket, Su olk, CB8 8YA, England +44 (0)1440 820327 www.claydondrill.com Model: Serial No: Year: Mass Min/Max: OPERATORS MANUAL - HYBRID MOUNTED...

-

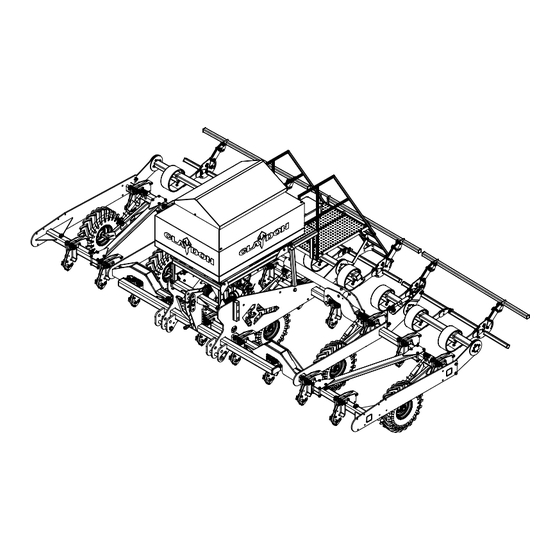

Page 3: Identification Of Machine

PLEASE ENSURE SEPARATE WARRANTY REGISTRATION CARD IS FILLED IN UPON PURCHASE OF YOUR DRILL TO VALIDATE WARRANTY CLAIMS. THIS IS LOCATED AT THE REAR OF YOUR OPERATORS MANUAL. The Claydon Hybrid Mounted range offers drills with the following specification: WEIGHT NUMBER OF HORSE POWER... - Page 4 OPERATORS MANUAL - HYBRID MOUNTED...

- Page 5 CONTENTS INTRODUCTION SAFETY DIRECTIVE PROVISIONS PRE-WORK PREPARATION IN FIELD OPERATION CARE AND MAINTENANCE DECLARATION OF CONFORMITY WARRANTY REGISTRATION OPERATORS MANUAL - HYBRID MOUNTED...

- Page 6 INTRODUCTION OPERATORS MANUAL - HYBRID MOUNTED...

- Page 7 Claydon Yield-O-Meter using the contact details given on the front cover. The Claydon Hybrid Mounted will give many years of excellent service with little maintenance due to its robust construction and its small number of moving parts. However, regular routine maintenance will give you the optimum efficiency and working machine life of your drill.

- Page 8 SAFETY Safety Sticker Location Safety stickers can be found located on your Claydon Hybrid Mounted drill at numerous locations, these stickers must be observed to ensure your safety and that the machine is operated in a safe manner. If any of the stickers become illegible or damaged, new stickers can be ordered and attached in the appropriate position.

- Page 9 Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha 12.7 10.6 12.1 16.2 13.2 14.5 19.1 15.9 16.8 22.6 11.9 18.5 19.3 25.4 14.0 21.2 21.7 28.2 15.9 22.8 24.1 29.1 17.2 24.4 DC0018 OPERATORS MANUAL - HYBRID MOUNTED...

- Page 10 Defective hydraulic hoses or incorrectly seated hydraulic couplings can trigger unpredictable machine movements and cause injury Keep clear of slewing range. There is an extreme risk of injury from slewing or folding machine parts. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 11 Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha Kg/Ha 12.7 10.6 12.1 16.2 13.2 14.5 19.1 15.9 16.8 22.6 11.9 18.5 19.3 25.4 14.0 21.2 21.7 28.2 15.9 22.8 24.1 29.1 17.2 24.4 DC0018 OPERATORS MANUAL - HYBRID MOUNTED...

- Page 12 DIRECTIVE PROVISIONS OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 13: Airborne Noise Emissions

DIRECTIVE PROVISIONS Directive Provisions This Claydon Hybrid Mounted Seed Drill conforms to Machinery Directive 2006/42/EC (see Appendix B – Declaration of Conformity at the rear of the manual). AIRBORNE NOISE EMISSIONS The A-weighted emission sound pressure level of measurements taken directly at the fan is 94dBA. - Page 14 1 x Claydon Instruction DVD 1 x Parts Catalogue 1 x Calibration Tongs 1 x Calibration Scales 1 x RDS Operation manual 1 x Fan 1” ISO with 18L male thread (Please contact your supplier if any are missing.) OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 15: Electrical Connections

PRE-WORK PREPARATION Connecting the Drill to the Tractor The Claydon Drill can be mounted onto any CATIIIN or CATIVN compatible three point linkage with the linkage pins supplied and CATIII balls (not supplied). Once the drill is attached and at the correct working depth, the top link should be set at an angle in which the convergence point between the upper and lower link arms should fall at the front axle (Figure 5). -

Page 16: Hydraulic Connections

The fan free flow return cannot be connected to the tractor ISO. Incase of difficulty knowing the correct connections available on the rear of your tractor consult your tractor operators manual or Claydon dealer immediately for assistance. Failure to connect tractor to drill correctly can result in serious damage to hydraulic components on both drill and tractor. - Page 17 When the drill is in transport, the Hydraulic valve taps (located on the hydraulic cylinders, Figure 9) should be locked off to prevent the marker arms being unfolded. Location of marker arm isolation hydraulic tap OPERATORS MANUAL - HYBRID MOUNTED...

- Page 18 ENSURE THE LADDER IS FOLDED UP WHEN THE DRILL IS WORKING OPENING THE HOPPER Open the hopper cover as shown in the photos above. ENSURE THE HOPPER COVER IS CLOSED WHEN THE DRILL IS WORKING OPERATORS MANUAL - HYBRID MOUNTED...

- Page 19 This is achieved by slackening the bolts at the stub axle shaft and allowing the whole unit to pivot round on the slotted holes. 1. Stub axle bolts (x3) 2. Marker arm tine 3. Marker arm wheel OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 20: Folding The Drill

OPERATORS MANUAL - HYBRID MOUNTED... -

Page 21: Setting The Seed Depth

Use a tape measure to ensure all three axles are the same. Once the correct depth is achieved it is possible to lock off the top links using the locking tab on the top thread on the links. OPERATORS MANUAL - HYBRID MOUNTED... - Page 22 75-100mm for Spring Beans The top hole should not be used on brand new tines; it is only to be used once the tine has begun to wear. Do not operate the front tine deeper than 150mm. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 23 This angle can be adjusted by altering the pin holes on the connecting arm. The image about displays our suggested setting. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 24 • Wet conditions - Remove pressure from ski boards • Dry conditions - Apply pressure to level boards • Ideal conditions - Zero pressure (top link becomes loose during work) 1. Level board adjuster OPERATORS MANUAL - HYBRID MOUNTED...

- Page 25 This is accomplished by removing the two bolts, sliding the point further down the tine and reinserting the bolts. This will ensure a clear mark is left behind the drill. 1. Marker point 2. Bolts to remove in order to extend point OPERATORS MANUAL - HYBRID MOUNTED...

- Page 26 The seed level sensor can be set in three positions for different seed rates: the upper for high seed rates, the middle setting for medium seed rates and the lower position is ideal for low seed rates i.e. Oilseed rape. UPPER SEED LEVEL MIDDLE SEED LEVEL LOWER SEED LEVEL OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 27: Setting The Fan Speed

There are no recommended settings it is purely user defined to achieve the best results for your requirements. An ideal guide would be to set the fan between 3500 RPM and 4000 RPM for most crops. OPERATORS MANUAL - HYBRID MOUNTED... - Page 28 Small seed setting Large seed setting Red lever (on shaft) out maximum Red lever (on shaft) in (max open- opening 25 ing 105) Deflector set for small seeds (OSR) Deflector set for large seeds (Cereals) OPERATORS MANUAL - HYBRID MOUNTED...

- Page 29 7. Seed shut off slide 1. Red gear should always remain in the closed position (high gear) 2. Lid for emptying large amounts of product and cleaning metering wheel 3. Outlet for emptying smaller amounts of product (e.g. OSR/microfertiliser) OPERATORS MANUAL - HYBRID MOUNTED...

- Page 30 This is the view of the metering unit as seen from the left rear quarter of the chassis. Remove elbow allowing access to the trap door on the bottom of the venturi box as shown in photo on the left. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 31 Note: It is important to press and hold the button for three seconds each time it is used to prevent miss starts / stop resulting in false readings OPERATORS MANUAL - HYBRID MOUNTED...

- Page 32 KGs, Grams not LBs Return to the tractor cab and displayed on the ISOCAN screen should be this page. Press the appropriate button to select the required units i.e. Gram or Kg. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 33 0.5% to Follow steps 1 - 8 a further 3 times to gain an accurate calibration setting on the drill. When finished stow scales safely away and re-attach the elbow as shown in the photo. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 34 IN FIELD OPERATION Seed Rate Calibration Chart - 3M OPERATORS MANUAL - HYBRID MOUNTED...

- Page 35 IN FIELD OPERATION Seed Rate Calibration Chart - 4M OPERATORS MANUAL - HYBRID MOUNTED...

- Page 36 IN FIELD OPERATION Seed Rate Calibration Chart - 4.8M OPERATORS MANUAL - HYBRID MOUNTED...

- Page 37 IN FIELD OPERATION Seed Rate Calibration Chart - 6M OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 38: Care And Maintenance

Lubrication should be performed by using multi-purpose grease. An overview of the greasing points for the Hybrid 3M Mounted can be seen below. 1. Marker arm wheel hubs 2. Marker arm rams 3. Wheel hubs 4. Center wheel hubs OPERATORS MANUAL - HYBRID MOUNTED... - Page 39 Lubrication should be performed by using multi-purpose grease. An overview of the greasing points for the Hybrid 4M Mounted can be seen below. 1. Wheel hubs 2. Center wheel hubs 3. Folding pivot pins 4. Rear ram OPERATORS MANUAL - HYBRID MOUNTED...

- Page 40 Lubrication should be performed by using multi-purpose grease. An overview of the greasing points for the Hybrid 4.8M Mounted can be seen below. 1. Wheel hubs 2. Center wheel hubs 3. Folding pivot pins 4. Rear ram OPERATORS MANUAL - HYBRID MOUNTED...

- Page 41 Lubrication should be performed by using multi-purpose grease. An overview of the greasing points for the Hybrid 6M Mounted can be seen below. 1. Wheel hubs 2. Center wheel hubs 3. Folding pivot pins 4. Rear ram OPERATORS MANUAL - HYBRID MOUNTED...

- Page 42 On the seeding leg, hook the removal tool (supplied) over the top of the share and push the pin down, hit the top with a hammer to remove the share. Now simply slide the new share up the speed-Loc adaptor and hit the bottom with a hammer until the locking pin pushes back out. OPERATORS MANUAL - HYBRID MOUNTED...

- Page 43 To remove and refit the seed boot undo the nut, remove the bolt and let the boot drop out of the boot holder, place new boot in holder and push bolt back into place, retighten the nut. NB. Use 9/16” spanners OPERATORS MANUAL - HYBRID MOUNTED...

-

Page 44: Winter Storage

On the seeding leg, hook the removal tool (supplied) over the top of the share and push the pin down, hit the top with a hammer to remove the share. Now simply slide the new share up the speed-Loc adaptor and hit the bottom with a hammer until the locking pin pushes back out. OPERATORS MANUAL - HYBRID MOUNTED... -

Page 45: Declaration Of Conformity

DECLARATION OF CONFORMITY OPERATORS MANUAL - HYBRID MOUNTED... - Page 46 Oliver Claydon Position: Director of Design and Production Done at Gaines Hall Wickhambrook On 21/06/2012 The technical documentation for the machinery is available from: Name: Claydon Yieldometer Ltd Address: Bunters Road Wickhambrook Newmarket, Suffolk, CB8 8XY OPERATORS MANUAL - HYBRID MOUNTED...

- Page 47 CLAYDON YIELD-O-METER LTD BUNTERS ROAD, WICKHAMBROOK, NEWMARKET, SUFFOLK, CB8 8XY TEL: +44 (0)1440 820 327 EMAIL: info@claydondrill.com www.claydondrill.com...

-

Page 48: Warranty Registration Card

WARRANTY REGISTRATION CARD In order to activate your Claydon Warranty this page must be completed and returned to: Claydon Yield-O-Meter Ltd Bunters Road, Wickhambrook, Newmarket, Suffolk, CB8 8XY Tel: +44 (0) 1440 820 327 Fax: +44 (0) 1440 820 642... - Page 50 CHECK SHEET & CONFORMATION FORM All points in this form must be completed on the commissioning of a new Claydon machine with the end user. This form along with a filled in Warranty Card (located in the instruction manual) must be, fully...

Need help?

Do you have a question about the HYBRID MOUNTED and is the answer not in the manual?

Questions and answers