Table of Contents

Advertisement

Quick Links

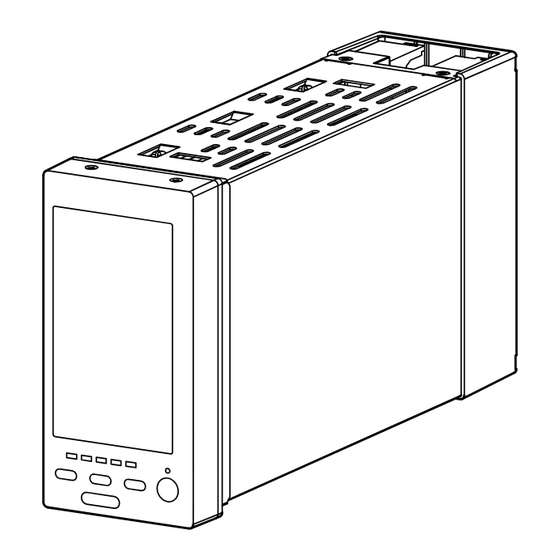

SC100/200 Series

MULTI-FUNCTION PID CONTROLLER

USERS MANUAL

Applicable

Models

SC100

SC110

SC200

SC210

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Tel: +81-6-6659-8201

Fax: +81-6-6659-8510

http://www.m-system.co.jp/

E-mail: info@m-system.co.jp

1

SC100/200 Series Users Manual EM-6337-B Rev.15

Advertisement

Table of Contents

Summary of Contents for M-system SC100

- Page 1 SC100/200 Series MULTI-FUNCTION PID CONTROLLER USERS MANUAL Applicable Models SC100 SC110 SC200 SC210 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN Tel: +81-6-6659-8201 Fax: +81-6-6659-8510 http://www.m-system.co.jp/ E-mail: info@m-system.co.jp SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 2: Table Of Contents

3.10. PERFORMANCE ....................... 17 3.11. STANDARDS & APPROVALS .................... 17 3.12. FRONT PANEL CONFIGURATION ................... 18 3.12.1. SC100/200 FRONT PANEL CONFIGURATION ............ 18 3.12.2. SC110/210 FRONT PANEL CONFIGURATION (MV output backup type) .... 19 3.13. SYSTEM CONFIGURATION EXAMPLE ................20 4. INSTALLATION ..................22 4.1. - Page 3 6.3.1.16. ALARM BLINKING ..................60 6.3.1.17. BARGRAPH COLOR ..................60 6.3.1.18. DIGITAL DISPLAY COLOR ................60 6.3.1.19. TREND RECORDING ...................60 6.3.1.20. STORING INTERVAL ..................60 6.3.1.21. TREND CHANNEL ..................60 6.3.1.22. TREND GRAPH COLOR ................60 6.3.1.23. SELECTED LOOP COLOR ................60 SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 4 6.3.5.2. USER’S PARAMETER TABLE VIEW OPERATIONS ........75 6.3.5.3. PARAMETER SETTING VIEW OPERATIONS ..........76 6.3.5.4. SETTING ITEMS ...................77 6.3.5.5. SETTING EXAMPLES ..................78 SC110 / 210 6.3.6. BACKUP VIEW ................79 6.3.6.1. SCREEN COMPONENTS................79 6.3.6.2. BACKUP VIEW OPERATIONS ..............80 SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 5 10.1. GENERAL DESCRIPTION ....................93 10.2. CONNECTING THE CONTROLLER TO PC ..............93 10.2.1. INFRARED COMMUNICATION TYPE ..............93 10.2.2. STEREO JACK TYPE ...................94 SC200/ 210 10.3. SAVING SHORT TREND DATA ..............94 10.4. TRANSFERRING SETTING PARAMETERS ..............94 SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 6 ..........114 Appx 4.1. SUPPORTED FUNCTIONS ................. 114 Appx 4.2. ADDRESS REGISTERS ASSIGNMENTS ............. 114 Appx 4.3. EXCEPTION CODES ................... 118 Appx 5. DIGITAL DISPLAY ERROR MESSAGES ........ 119 Appx 6. REVISION HISTORY ..............120 SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 7: Before Use

The SC100/200 Series products are referred to as ‘the Controller’ in this manual if not explained otherwise. The ‘SC’ means any model of the SC100/200 Series products. Descriptions applicable to specific models are either mentioned with the par-... - Page 8 - Plan to change the screen image periodically so that the same image does not remain for the long time period. • The LCD surface is covered with a protective film at the factory shipment. Remove it once the unit is installed. SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 9 This Users Manual conforms to SC_LCD firmware version 1.50 or later. In this manual descriptions given with the following symbols are applied only to the firmware versions. SYMBOL APPLICABLE FIRMWARE VERSION SC_LCD firmware version 1.50 or later 1.50 SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 10: Function Descriptions

FUNCTION DESCRIPTIONS The SC100/200 Series is a multi-function controller equipped with a color LCD display with touch panel. It is designed to suit with a wide variety of applications using two PID function blocks together with numerous computational functions. FUNCTIONS & FEATURES •... -

Page 11: Specifications

If external noise interference is a concern, stereo jack type is recommended. Terminal Block blank : One block terminal /T : Separable terminal Other Options blank : none /Q : Option other than the above (specify the specification) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 12: Related Products

The following products are required for the setting up of the device via PC (not included in the package.) • PC Configurator Software (model: SCCFG Ver. 1.50 or later) Downloadable at M-System’s web site. • Loop Configuration Builder Software (model: SFEW3E Ver. 1.40 or later). Downloadable at M-System’s web site. • Infrared Communication Adaptor (model: COP-IRDA) •... -

Page 13: Display

480 × 272 pixels Pixel pitch 0.198 × 0.198 mm (128 × 128 DPI) Backlight Note: The backlight can be replaced in M-System factory. The LCD must be replaced at the same time. Screen saver standby time 1 to 99 minutes... -

Page 14: Supply Output

-80 to +250 Overrange input (out of the usable range) is handled as burnout. POTENTIOMETER Potentiometer input Total resistance 100 Ω to 10 kΩ Minimum span 50 % of total resistance Excitation ≤ 0.6 V DC SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 15 Approx. 12 V DC / 12 mA ON voltage/resistance ≤ 2 V, ≤ 1.5 kΩ OFF voltage/resistance ≥ 11 V, ≥ 15 kΩ Excitation 12 V DC ±10 %, 15 mA Current limiting circuit Approx. 30 mA SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 16: Output Specifications

Approx. 1.8 kg (3.97 lb) for 250 mm depth type Approx. 2.0 kg (4.41 lb) for 300 mm depth type Approx. 2.5 kg (5.51 lb) for 400 mm depth type Approx. 3.0 kg (6.61 lb) for 600 mm depth type SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 17: Performance

Input or output to contact output – Basic insulation (300 V) Input or output to Power – Reinforced insulation (300 V) RoHS Directive EN 50581 Protection against access to the terminal blocks Finger protection (VDE 0660-514) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 18: Front Panel Configuration

The MV increases in 4 seconds per full-scale when the acceleration button is pressed at once. Auto / Man selector Changes the control mode from auto to manual and vice versa. Manual-to-auto switching can be suppressed with the field terminal setting. (Refer to SC100/200 Series Function Block List) Monitor LED Indicates control operation mode. -

Page 19: Sc110/210 Front Panel Configuration (Mv Output Backup Type)

Changes the control mode from auto to manual and vice versa. Manual-to-auto switching can be suppressed with the field terminal setting. (Refer to SC100/200 Series Function Block List) Switches manual backup modes when the acceleration button is pressed at once. (Refer to: 11. BACKUP (MANUAL LOAD-... -

Page 20: System Configuration Example

CONTROL / SUPERVISION VIA MODBUS/TCP SCADA System Modbus/TCP Ethernet Communication Adaptor Multi-Function PID Controller Model: 72EM2-M4 Model: SC200/210 ETHER NET RS-485 SEND FIELD CNFG Modbus-RTU Multi-Function PID Controller Multi-Function PID Controller Model: SC200/210 Model: SC200/210 SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 21 SC200/ 210 CONTROL / SUPERVISION VIA MODUBS-RTU SCADA System RS-485/RS-232-C Converter Model: R2K-1 Modbus-RTU Multi-Function PID Controller Multi-Function PID Controller Model: SC200/210 Model: SC200/210 SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 22: Installation

• To clean the unit, use a soft cloth wet with water or mild detergent and rub its surface lightly. Do not use volatile liquid such as alcohol or thinner, as these may damage it. • Keep out the unit from high temperature and humidity. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 23: Environment

• Install output signal cables separately from power cables or other AC circuits. If they must be close to each other, use shielded cables. • When driving an inductive load it is recommended to install surge absorbers at the closest point possible from the load. SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 24 Wiring Inside the Panel • Keep physical distance of farther than 20 cm between the Controller and power cables. • Refer to Section 4.5. I/O SIGNAL SYSTEM for a detailed explanation of the wiring process. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 25: Power System

Generally a noise filter is attached to the power inlet to eliminate noise interferences to the power supply circuit. It is recom- mended to add an isolation transformer in case of AC power supply. Power Inlet Terminal Noise Filter Controller Isolation Transformer Twisted-pair Twisted-pair Twisted-pair Cable Cable Cable Shortest possible inside the panel SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 26: Grounding System

Install dedicated grounding lines for heavy duty current, low voltage power supply, operating circuit and light electrical circuit such as for the Controller. Controller Other Devices FG Terminal Ground Ground Panel (resistance for Other Ground 100 ohms or less) Devices SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 27: I/O Signal System

If the signal cables are not shielded, it is recommended to cover the power supply cables in the intersectional point with metal plate of 1.6 mm minimum thickness, as represented with dotted line in the drawing. Signal Cables Thickness 16 mm min. Power Cables SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 28: Nestbus Sc200/210 Nestbus Connection

• Connect a terminating resistor at both ends of the seg- ment. Termination Resistor • Terminating resistor is incorporated in each device. Close across T2 and T3 terminals to activate it. Con- sult each device’s specifications for exact terminal as- signment of the resistor. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 29: Cable Installation

If the NestBus cables are not shielded, it is recommended to cover the power supply/other signal cables in the intersectional point with metal plate of 1.6 mm minimum thickness, as represented with dotted line in the drawing. NestBus Cables Thickness 16 mm min. Power Cables Other Siganl Cables SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 30: Modbus-Rtu Sc200/210

• Connect a terminating resistor at both ends of the seg- ment. Termination Resistor • Terminating resistor is incorporated in each device. Close across T2 and T3 terminals to activate it. Con- sult each device’s specifications for exact terminal as- signment of the resistor. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 31: Cable Installation

If the Modbus-RTU cables are not shielded, it is recommended to cover the power supply/other signal cables in the intersec- tional point with metal plate of 1.6 mm minimum thickness, as represented with dotted line in the drawing. Modbus-RTU Cables Thickness 16 mm min. Power Cables Other Siganl Cables SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 32: Mounting On A Panel

Terminal fixing screws 4.8.2. PANEL CUTOUT unit: mm PANEL CUTOUT unit: mm • Single mounting • Clustered mounting +0.7 [68+72×(n - 1)] n = number of units Panel thickness 2.3 – 20 SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 33: External Dimensions & Terminal Assignments

• SEPARABLE TERMINAL *1. Standard model: 250 mm (9.84”) (with option /T) Option /3: 300 mm (11.81”) 52–M3.5 SCREW Option /4: 400 mm (15.75”) Option /6: 600 mm (23.62”) 4–M4 SCREW FOR FIXING TERMINAL 67.5 (2.66) SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 34 • SEPARABLE TERMINAL *1. Standard model: 250 mm (9.84”) (with option /T) Option /3: 300 mm (11.81”) Option /4: 400 mm (15.75”) 52–M3.5 SCREW Option /6: 600 mm (23.62”) 4–M4 SCREW FOR FIXING TERMINAL 67.5 (2.66) SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 35 • SEPARABLE TERMINAL *1. Option /M2, /R only *2. Option /3: 300 mm (11.81”) (with option /T) Option /4: 400 mm (15.75”) Option /6: 600 mm (23.62”) 52–M3.5 SCREW 4–M4 SCREW FOR FIXING TERMINAL 67.5 (2.66) SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 36 • SEPARABLE TERMINAL *1. Option /M2, /R only *2. Option /3: 300 mm (11.81”) (with option /T) Option /4: 400 mm (15.75”) Option /6: 600 mm (23.62”) 52–M3.5 SCREW 4–M4 SCREW FOR FIXING TERMINAL 67.5 (2.66) SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 37: Connection Diagram

VOLT / CURRENT INPUT – – – min. CJC SENSOR *3. Connect input resistor module (model: REM4) for current input. *4. Connect CJC sensor for thermocouple input. *5. Connect input resistor module (model: REM4). SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 38 VOLT / CURRENT INPUT – – – min. CJC SENSOR *4. Connect input resistor module (model: REM4) for current input. *5. Connect CJC sensor for thermocouple input. *6. Connect input resistor module (model: REM4). SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 39 VOLT / CURRENT INPUT – – – min. CJC SENSOR *4. Connect input resistor module (model: REM4) for current input. *5. Connect CJC sensor for thermocouple input. *6. Connect input resistor module (model: REM4). SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 40: Default Loop Configuration

4 – 20 mA DC *1. Factory default setting *1. Factory default Use Loop Configuration Builder Software (model: SFEW2) Note: Use the Loop Configuration Builder Software (model: SFEW3E) for the loops configuration. to modify setting. SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 41 07 : 0103 01 : 0301 G03 (Basic PID) PV high alarm is assigned to G01 (SC) AL4 lamp input terminal. 07 : 0104 00 : 0000 Note: Refer to SC100/SC200 Function Block List. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 42: Display Operations

Programming view appears only when Page 1/2: Field terminal block 'Config mode' is set to 'Front panel.' Page 2/2: Error status Skipped when set to 'SFEW' or 'SCCFG.' Backup (SC110/210 only) User’s Parameter Table SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 43 (Hardware buttons are not locked.) In order to release them, press/hold it again for approx. 5 seconds. Press Press & & Hold Hold Press & Hold SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 44: Operation Views

Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop specified in ‘Loop display (MV/OP)’ setting. (Refer to: 6.3.1.12. LOOP DISPLAY (MV/OP)) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 45: Digital Display Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button Used to increase SP value in the speed of 40 seconds per full-scale. -

Page 46: Bargraph Display View

Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop specified in ‘Loop display (MV/OP)’ setting. (Refer to: 6.3.1.12. LOOP DISPLAY (MV/OP)) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 47: Bargraph Display View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button * Used to increase SP value in the speed of 40 seconds per full-scale. -

Page 48: Dual Loop Bargraph View

Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop specified in ‘Loop display (MV/OP)’ setting. (Refer to: 6.3.1.12. LOOP DISPLAY (MV/OP)) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 49: Dual-Bargraph View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button * Used to increase SP value in the speed of 40 seconds per full-scale. -

Page 50: Short Trend View

Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop specified in ‘Loop display (MV/OP)’ setting. (Refer to: 6.3.1.12. LOOP DISPLAY (MV/OP)) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 51: Short Trend View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button* Used to increase SP value in the speed of 40 seconds per full-scale. -

Page 52: User's Parameter Table

• Only the parameter type identification is displayed when it is disabled in the Parameter Setting view. • ‘ ******* ’ is indicated in Range cell when illegal GROUP and/or ITEM No. are set for the parameter. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 53: Operations

The MV value UP/DOWN buttons and the AUTO / MAN selector are locked. Parameter settings are not available in the User’s parameter table of Operation views. Set the parameters in the Parameter list of Engineering views. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 54: Engineering Views

Operation Buttons Parameter List Submenu appears by moving over a specific item and touching on Enter button. Alarm Indicator Red bar blinks during error. PRG mode indicator 1.50 Yellow bar blinks during program mode SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 55: Onfiguration View Operations

UP button Used to go up to next item among listed selections. DOWN button Used to go down to next item among listed selections. Enter button Used to apply the data indicated on the display. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 56: Configuration Parameters

0: None, 1: PV1, 2: PV2, 3: SP1, 4: SP2, 5: MV1, 6: MV2, LP2 CH1: 2 7: FN1, 8: FN2, 9: FN3, 10: FN4 LP2 CH2: 4 LP2 CH3: 6 LP2 CH4: 0 SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 57 10 min. 0, 10, ... 50 min. 0 sec. 20 sec. 0, 20, 40 sec. 30 min. 0, 30 min. 0 sec. 30 sec. 0, 30 sec. 60 min. Every hour, 0 min. 0 sec. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 58: Config Mode

Temperature unit: °C. 6.3.1.11. MV 0/100% SYMBOL MV bargraph can be accompanied with symbols indicating 0% and 100% status respectively. Choose among: O, C, OP, CL, HI, LO, 100, 0, Max, Min or no indication. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 59: Loop Display (Mv/Op)

Loop variable identification/position can be either PV - SP - MV or SV - PV - OP. SP replaces SV and MV replaces OP in the function blocks programming. 6.3.1.14. GRAPH SCALE DIVISIONS Choose among 2 through 10 divisions for bargraph scales. 6.3.1.15. DECIMALS (% display) Choose 1 or 2 decimal places for % displays. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 60: Alarm Blinking

Choose blinking or not blinking of yellow bar during program mode (Item 01 of Group for Function block list is not 0.) 6.3.1.30. NUMERICAL KEY CONTROL 1.50 Choose disable/enable of numerical key control for SP and MV in the Digital Display. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 61: Start Mode

Choose the display language. The language setting is not changed when the initialization (Refer to: 6.3.1.35. INITIALIZE) is performed. 6.3.1.39. VERSION The Controller functions are divided by blocks and shared by multiple CPU. Firmware version No. of each CPU are indicated. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 62: Setting Examples

3) Touch color indicator (green section to the right of “Norm” in this example) you want to change, and touch [Enter]. 4) Color chart appears on the screen. Touch new color (blue) and touch [Enter]. Note: Touch [Back] at the bottom to go back to previous view. SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 63 [1/+] switches between numeric and special characters. Touching one key each time switches between the characters indicated on the key (e.g. A > B > C > A). Note: Touch [Back] at the bottom to go back to previous view. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 64: Programming View

STOP: Grey when the Controller operation is stopped; Red when the memory is failed. Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop being on the screen. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 65: Programming View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button * Used to increase SP value in the speed of 40 seconds per full-scale. - Page 66 NG : No good [Example] ER : Communication error OE : Operation procedure error DE : Data syntax error VE : Non-registered input unit table (not initialized) WE : Input unit table writing error SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 67: Tuning (Auto-Tuning) View

STOP: Grey when the Controller operation is stopped; Red when the memory is failed. Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop being on the screen. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 68: Tuning View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button * Used to increase SP value in the speed on 40 seconds per full-scale. -

Page 69: Tuning Parameters

Note 1. SM: Ai signal can be used as SP when Cascade/Local mode is selected. Note 2. All parameters except AT are locked during the SFEW communication mode. Note 3. For more details, refer to SC100/200 Series Function Block List. 6.3.3.4. AUTO-TUNING PARAMETERS... -

Page 70: Realtime I/O Monitoring View

• DiX and PiX display items depend upon the user’s terminal assignments. • Di / Do status is given as 1 or 0. • Pi displays indicate accumulated counts between 0 and 9999 (unit: count). SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 71 When a control overload error is occurring, the control cycle gets slow automatically. Error status is still displayed even if the power supply is reset until ‘0’ is set in both Group 00 and Item 40. SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 72 MV feedback Function block Control overload Modbus communication SC200/210 only Backup module SC110/210 only • Error status is detected when the power supply is reset. • Refer also to Appx 5. DIGITAL DISPLAY ERROR MESSAGES. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 73: Realtime I/O Monitoring View Operations

Only the acceleration button among the hardware buttons at the front is usable when the Realtime I/O Monitoring view is on screen. The MV value UP/DOWN buttons and the AUTO / MAN selector are locked. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 74: User's Parameter Table View

• Only the parameter type identification is displayed when it is disabled in the Parameter Setting view. • ‘ ******* ’ is indicated in Range cell when illegal GROUP and/or ITEM No. are set for the parameter. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 75: User's Parameter Table View Operations

Only the acceleration button among the hardware buttons at the front is usable when the Realtime I/O Monitoring view is on screen. The MV value UP/DOWN buttons and the AUTO / MAN selector are locked. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 76: Parameter Setting View Operations

Used to select an item to change its value. Back button Used to go back to User’s Parameter Table view. Parameter Setting Field Shows Parameter setting items. Refer to 6.3.5.4. SETTING ITEMS for detail. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 77: Setting Items

6.3.5.4. SETTING ITEMS ITEMS marked with ◆ in the SC100/200 Series Function Block List are available for changes. All parameters are reset to the default values by the initialization in the Configuration view. SETTING ITEM DATA INPUT DEFAULT CONTENTS Setting... -

Page 78: Setting Examples

ITEM Range Hi limit Range Lo limit Decimal place Engineering unit 1=ON DATA Hi limit DATA Lo limit DATA decimal place In the above example, DATA engineering unit field is used for a note. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 79: Backup View

STOP: Grey when the Controller operation is stopped; Red when the memory is failed. Auto / Man Auto: Green Auto indicator turns on. Man: Orange Man indicator turns on. The lamp indicates the status of the loop being on the screen. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 80: Backup View Operations

Pressing/holding the button for approx. 1 second switches the control mode between cascade (Cas) and local (Loc). Valid only when ‘Set mode Cas/Loc’ setting under the tuning parameters is set to ‘Cascade/Local.’ The button operation can be locked by SC field terminal setting. Refer to SC100/200 Series Function Block List. SP value UP button * Used to increase SP value in the speed on 40 seconds per full-scale. -

Page 81: Function Block Setting

PID controllers, computation modules or PLCs which are familiar to users. • User-Friendly Parameter Setting Software Loop Configuration Builder software for the SC100/200 Series (model: SFEW3E) is available. With the builder software, you can build configuration files, copy them, save them, and print them. -

Page 82: Field Input Setting

Di 5 / Pi 5 PD6: 1 Di/Pi selection (0 = Di, 1 = Pi) ▲ Caution ! When a channel is set to pulse input, ladder sequences employing the channel as discrete input do not function. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 83: Function Blocks In Relation With Screen Configuration

SP Bar Display ---- ---- ---- MV Display ---- PV Normal Range ---- MV Output Limit Range ---- ---- ---- FN Display Auto/Man ---- ---- Cas/Loc ---- ---- AL1 – AL4 Indicator RUN Indicator SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 84: Relations Between Function Blocks

LOOP COMMUNICATION FIELD TERMINAL BLOCK (1) COMMUNICATION TERMINAL BLOCK (16) NestBus, Modbus (SC200/210) Pv 1, 2 Mv 1, 2 Di 1...5 Do 1...5 (Pi 1...5) Ai 1...4 Ao 1, 2 Pi 6 (Di 6) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 85: Function Block Allocations

COMMUNICATION TERMINAL BLOCKS (16) 19 20 21 22 23 24 25 26 SC200/210 only FIELD TERMINAL BLOCK (1) EXTENSION FIELD TERMINAL 1 BLOCK (1) EXTENSION FIELD TERMINAL 2 BLOCK (1) SYSTEM COMMON TABLE (1) SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 86: Connecting Between Function Blocks

WARNING ! Parameters in the Parameter Setter block are rewritable up to 100 000 times. For example, if parameters are updated every hour, the memory will reach its usable limit in approx. 11 years. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 87: Item Reader

(Sending a set value) ITEM 14 FUNCTION SET VALUE BLOCK ITEM 17 ITEM 15 Changing Internal Switch status SET VALUE Changing a parameter by an external analog signal ITEM 11 SW STATUS INTERNAL SWITCH SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 88: Software Communication By Communication Terminals Sc200 / 210

Sender S # Always ‘FF’ Sender C # ‘01’ Sender G # ‘11’ (11 to 26) Sender G # ‘11’ Transmission range Always ‘0’ Destination address Always ‘0’ Card No. set on Programming menu Communication Terminal’s Group No. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 89: Communicating With The Sfew3E Program

4) Go to Engineering View and choose Configuration > 01 : Config mode > 02 : SFEW. The front monitoring LED starts blinking slowly to indicate the ready state. Refer to Section 6.3.1.4. CONFIG MODE to operate the Controller. Controller SFEW3E Connector adapter COP-US Stereo jack USB port SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 90: Auto-Tuning

Be aware that the process may react in an unexpected way during auto-tuning procedure. Naturally the parameters obtained in this method may not be the most appropriate. Manual adjustments are recommended to tune them finely. Refer to Section 6.3.3. TUNING (AUTO-TUNING) VIEW to operate the Controller for the following auto-tuning procedure. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 91: Auto-Tuning Operations

PID parameters are calculated so to suit SP signal change. Choose this option for secondary loop control in a cascade control loop. OPERATION MODE DESCRIPTION P, I and D parameters P and I parameters SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 92: Manual Adjustment Of Pid Parameters For Fine Tuning

Hunting of short cycles suggests too fast a response time of the control system and the derivative action may be too inten- sive. Set a smaller TD in such cases. Small TI (Small PB) Large TD SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 93: Communicating With The Sccfg Program

Detecting more than one module at once in the communication mode will result in error. (2) The Controller may not be able to establish normal communication in an environment present with noise from invert- ers. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 94: Stereo Jack Type

‘6.3.5.4. SETTING ITEMS’ table) can be uploaded and saved in a PC file. Setting files can be downloaded to the Controller device. They can be copied to multiple devices in turn. Transferred parameters become valid only after the power supply to the Controller is reset. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 95: Backup (Manual Loading)

• The control mode is set to Manual and manual loading for Mv 2 using the front control buttons is available in this mode. • RUN contact is turned OFF (open) in backup state, which may differ from RUN value in 6.3.4. REALTIME I/O MONITOR- ING VIEW. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 96: Backup Setting

Mv 2 output reaches the preset value. Preset Value Error occurrs in Control Module Error Output Tracking in preset ramp rate until the MV2 reaches the preset value Switched to Backup Module SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 97: Backup Recovery Mode (Auto/Manual Tracking)

PID Control Function Block Function Block MV (Direct direction display) Computational Function Blocks Field Terminal Field Terminal Mv 2 Output Mv 2 Output Auto tracking recovery mode is applicable. Use the manual tracking recovery mode. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 98: Auto Backup After Turning On The Power

11.2.4. AUTO BACKUP AFTER TURNING ON THE POWER 1.50 The Controller goes to the backup mode, when the backup unit is turned on and there is no communication between the main unit for 5 seconds. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 99: Function Block Setting

ITEM 86: Backup GROUP (2 or 3) Used to select the PID control loop to be backed up. 1.50 ITEM 87: Backup status Used to indicate backup status. “0: Normal” means that the status is “Normal” or “Backup Standby” . SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 100: Backup Operation & Display

11.3.1. STATUS TRANSITION DIAGRAM BACKUP VIEW Status: Normal Status: Backup Standby Status: Backup Running LED: All OFF LED: Mv 2 output LED: Mv 2 output Press & Press Hold & Hold Press & Hold Press & Hold SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 101: Switching Operation

• If the standby status is not switched to ‘Running’ status within 1 minute, the Controller goes back to the normal status. • Pressing and holding Auto/Man button switches back to the normal status. • MV and Auto/Man switching controls are not functional during the standby status. Other functions such as switching views are available. SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 102 53% ≤ Mv 2 < 72% 72% ≤ Mv 2 < 78% 78% ≤ Mv 2 < 97% 97% or more : OFF : ON : Blinking • MV2 output can be manually controlled with the hardware buttons. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 103: Returning To Normal Status

Loop Configuration Builder Software (model: SFEW3E). • Power is not supplied to the backup module. When the backup module has its own power supply, check whether the wiring is carried out between the backup module and the power supply. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 104: How To Replace The Control Module

Before replacing a failed control module, transfer its complete setting to the replacement module. CAUTION ! Replacing is conducted by a personnel qualified by M-System. Refer to Section 11.3.1. STATUS TRANSITION DIAGRAM regarding control operations to shift to/from the backup mode. - Page 105 Manual tracking mode: The MV 2 Output can be controlled with the MV control buttons at the right side on the screen. (5) Return to the normal status. The LEDs turn off. (Refer to: 11.3.3. RETURNING TO NORMAL STATUS) (6) Switch to automatic control mode or normal operating mode. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 106: Appx 1. Cold Start Parameters

QA 4 momentary value indication QA 5 momentary value indication QA 6 momentary value indication Do 1 output indication Do 2 output indication Do 3 output indication Do 4 output indication Do 5 output indication SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 107 Current SP % Deviation alarm 02, 03 Deviation output % Preset value SW Output hold SW External feedback % External feedback SW Auto/Man SW MV % MV high limit reached MV low limit reached SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 108: Appx 2. Function Block Parameters Default Setting

Unit FN3 engineering unit (max. 8 characters) Unit FN4 engineering unit (max. 8 characters) AL1 comment (max. 4 characters) AL2 comment (max. 4 characters) AL3 comment (max. 4 characters) AL4 comment (max. 4 characters) SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 109 Output rate-of-change limit (0: no limit applied) Preset value (applicable with ITEM 82 DATA 1) Backup recovery mode (0: auto tracking, 1: manual tracking) Backup GROUP ITEM 81 through 86 are available for the SC110/210 only. SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 110 (number of pulses per second at 100% momentary value output) Error detected by diagnostic (0: Normal conditions, 1: All discrete outputs OFF with RUN contact OFF PD6: Select Discrete / Pulse input 0 = Di, 1 = Pi SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 111 Comment Comment Comment Comment 10000 10000 ---- 10000 10000 Upper range ---- Lower range Decimal point position ---- (from rightmost digit) Unit Unit ---- Unit Unit Engineering unit ---- MV reverse indication (0: direct) SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 112: Appx 3. Appx 3. Error Codes

Abnormal block contents (NN) BLOCK RELEASE ■ DELETE MODEL NO. COMMAND ▲ (initial display *) Group 00, 01, 04, 05 or 80 are not deleted. ● = Always modifiable ▲ = Modifiable in PROGRAM mode SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 113 (1) In PROGRAM mode, write ‘1’ in GROUP 00 / ITEM 95 to execute BLOCK RE- LEASE. (2) Connect the Loop Builder Software (model: SFEW3E). Execute EEPROM Clear and download a new loop configuration. SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 114: Appx 4. Modbus Functions

Auto / Manual (0: Manual, 1: Auto) PV high alarm (0: Normal, 1: Alarm) PV low alarm (0: Normal, 1: Alarm) ---- ---- Reserved (DO NOT WRITE) MV reverse indication (0: Direct, 1: Reverse) SC100/200 Series Users Manual EM-6337-B Rev.15... - Page 115 Group 26, Discrete terminal 32 Read only for DO Send Terminal. Read/Write for DI Receive Terminal (Set ITEM 11 to FE) Either of AO Send, AI Receive, DO Send, DI Receive Terminal can be assigned to each Group. SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 116 “1.” Priority is given as: EEPERR > PVERR > MVAERR > MODERR > OVERLOAD. For example, MODERR is set with “1” when both MODERR and OVERLOAD are in error. Then OVERLOAD turns to “1” after MODERR error is cancelled. SC100/200 Series Users Manual EM-6337-B Rev.15...

- Page 117 DATA 36 (±32000, Data range ±32000) 41137 PR37 DATA 37 (±32000, Data range ±32000) 41138 PR38 DATA 38 (±32000, Data range ±32000) 41139 PR39 DATA 39 (±32000, Data range ±32000) 41140 PR40 DATA 40 (±32000, Data range ±32000) SC100/200 Series Users Manual EM-6337-B Rev.15...

-

Page 118: Appx 4.3. Exception Codes

EXCEPTION CODES CODE EXCEPTION DESCRIPTION Illegal Function Function code is not allowable for the slave. Illegal Data Address Address is not allowable within the slave. Illegal Data Value Data is not valid for the function. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 119: Appx 5. Digital Display Error Messages

*7: Function Block List reception time-out to a “field terminal” (error number 22). *8: “Communication error” dialogue appears. *9: Function Block List Group [00], Item 02 *10: Function Block List Group [05], Item 28 set to 1. SC100/200 Series Users Manual EM-6337-B Rev.15... -

Page 120: Appx 6. Revision History

5. Error Status shows history log. 6. Function Block List (EM-6460-B): Error of RUN contact can be reset manually. 7. Backup starts, if 5 seconds after supplying power, the connection with main unit is not established. SC100/200 Series Users Manual EM-6337-B Rev.15...

Need help?

Do you have a question about the SC100 and is the answer not in the manual?

Questions and answers