Advertisement

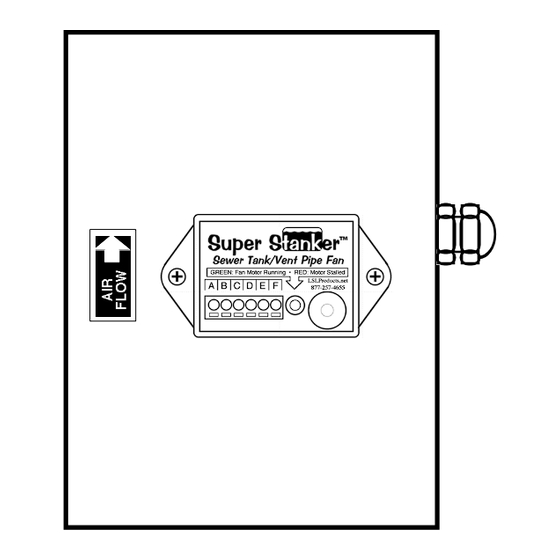

GENERAL INFORMATION — Super Stanker™ is designed to create a slight vacuum inside sewage holding tanks and drain pipes that helps prevent odor infiltration into living

areas. The fan's enclosure has the same outside dimensions as 4" Schedule 40 drain pipe, allowing it to be used with a pair of standard 4" rubber drain couplers (Fernco

#1056-44 or similar) for easy attachment to 4" vent pipes. Other rubber coupler sizes can be used to adapt the fan for use with smaller vent pipe sizes. The fan can be

mounted at any point along the vent pipe's run, at any angle — even upside-down. The brushless fan motor operates on safe, low-voltage DC power (a 120/240VAC to

13.5VDC power supply is included). A Fan Monitor constantly measures the fan motor's speed, sounding a warning beeper if the motor stalls. The motor is removable;

replacements are available.

Two 13.5 VDC power supplies can be connected to the same fan. (Power supplies are separately available for this purpose.) In applications with dual sewage lift pumps, this

allows the fan to operate whenever either pump is running, simply by plugging each power supply into separate wall outlets connected to each pump's AC control switch.

STEP-BY-STEP INSTALLATION INSTRUCTIONS

STEP 1: Determine the best mounting location for

the fan (i.e., easy access to the vent pipe and a

nearby 120/240 VAC wall outlet).

Note that the fan must be installed "downwind" of

all feeder pipes, and must be located high enough

to avoid direct exposure to sewage liquids.

Outdoor installation is not recommended, unless

the fan is installed inside a weather-tight

enclosure.

STEP 3: Cut a 6-1/4" inch (160 MM) section out

of the vent pipe at your intended installation point

(use the Vent Pipe Cutting Gauge shown at right

to measure the proper distance). CAUTION:

Make sure the vent pipe is adequately

supported from above before cutting it! Save

this pipe section for temporary use when servicing

the fan.

STEP 4: Trim away any rough edges on both ends

of the open vent pipe, and slip a rubber drain

coupler over each of them. Next, slide the fan in

place over the pipe ends (oriented so that the AIR

FLOW arrow points toward the end of the vent pipe

on the roof), slide the drain couplers into position

(each coupler covering approx 2 inches of the fan

enclosure), and tighten the hose clamps on the

couplers.

Vent Pipe

Fan

Rubber

Drain

Couplers

NOTES:

1. 4" Drain Couplers are shown; installation is

identical for other sizes.

Vent Pipe

2. Installing the fan with PVC pipe cement is not

recommended, since it would hinder any future

attempts to remove the fan for repairs or cleaning.

OPERATION — The LED indicator on the Fan Monitor glows green whenever the fan motor is operating at an adequate speed. If the fan motor stalls, the indicator LED will

flash red instead, and the piezo beeper will sound approx. every 1 second (unless disabled as described in Step 5 above).

WARRANTY— LSL Products warranties this product for a period of ONE YEAR from the date of purchase against defects in materials and workmanship. In the event a

problem, LSL Products will, at its option, repair or replace any defective components, at no charge to the owner. (The owner is responsible for the shipping charges

associated with initial return of the product). IN THE EVENT OF A PROBLEM, PLEASE CONTACT US PRIOR TO RETURNING THE PRODUCT. This warranty does not

cover damage due to unreasonable use of the product. IN NO EVENT SHALL LSL PRODUCTS NOR ANY OF ITS REPRESENTATIVES BE RESPONSIBLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty gives you specific legal rights, and you may have other rights which vary from state to state.

REVISION

B

1.

3.

4.

Vent Pipe

13.5VDC Power Supply(s)

Vent Pipe

Sewer Tank / Vent Pipe Fan

STEP 2: If not already present, install a roof-

mounted vent pipe cap, in order to keep debris and

rainwater from falling down into the fan. A simple

vent pipe cap can be made by cementing two 90

degree PVC elbows together, arranged so that the

open end of the 2nd elbow faces downward:

NOTE: A vent pipe cap MUST be

present, or the motor's lifespan will be

drastically reduced.

STEP 5: Strip 1/4" of insulation off the ends of the

13.5VDC Power Supply wires, and connect them

terminals A and B on the Fan Monitor's wire

connection block. (Either wire can go to either

terminal,

because

the

Monitor

provides the fan motor with the correct DC polarity).

Connect the Fan Motor's BLACK (–) wire to

terminal C, the RED (+) wire to terminal D, and the

White or BLUE (Tach) wire to terminal E.

NOTE: If using dual power supplies, connect the STRIPED wire on each

power supply to the same terminal on the Fan Monitor, and the PLAIN

(unstriped) wire on each power supply to the other terminal. This effectively

connects both supplies in parallel, allowing the fan motor to run whenever

either supply is receiving AC power.

Fan Monitor

If operation of the warning beeper is not desired, connect a wire between

terminals F and C. Otherwise, leave terminal F unconnected to anything.

Plug the 13.5VDC Power Supply into a 120/240VAC wall outlet. The Fan

Monitor will briefly beep upon power-up, and the indicator LED will glow

green to confirm that the fan motor is running.

This completes the installation procedure.

2.

5.

automatically

Fan Motor

White or Blue (Tach)

Red (+)

Black (–)

Advertisement

Table of Contents

Summary of Contents for LSL Products Super Stanker

- Page 1 Sewer Tank / Vent Pipe Fan GENERAL INFORMATION — Super Stanker™ is designed to create a slight vacuum inside sewage holding tanks and drain pipes that helps prevent odor infiltration into living areas. The fan's enclosure has the same outside dimensions as 4" Schedule 40 drain pipe, allowing it to be used with a pair of standard 4" rubber drain couplers (Fernco #1056-44 or similar) for easy attachment to 4"...

-

Page 2: Specifications

Nylock Nut, 18-8 SS, #8-32 Fan Motor Assy. w/Grills Enclosure Screw, 18-8 SS, #8-38 x 1" Flush Strain Relief, Airtight Fan Monitor Module DC Power Supply, 13.5 VDC LSL Products • 5804 Babcock Rd. #512 • San Antonio, TX 78240 • www.LSLProducts.net •...

Need help?

Do you have a question about the Super Stanker and is the answer not in the manual?

Questions and answers

How do we order a Super Stanker 4”?