Veeder-Root VaporTEK Installation, Setup And Troubleshooting Manual

Controller board

Hide thumbs

Also See for VaporTEK:

- Installation, setup and troubleshooting manual (59 pages) ,

- Maintenance and repair instructions (4 pages)

Summary of Contents for Veeder-Root VaporTEK

- Page 1 Manual No: 577014-335 ● Revision: B VaporTEK - VTEK3 Controller Board Installation, Setup and Troubleshooting Manual...

- Page 2 Customer Service will work with production facility to have the replacement product shipped as soon as possible. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

-

Page 3: Table Of Contents

VaporTEK Pump, ATEX/IECEX/ITRI Kit - P/N 900612-001 ........7 VaporTEK Pump, ATEX/IECEX Kit - P/N 900882-001 (Salzkotten)......8 VaporTEK Pump, PCEC Kit - P/N 900869-001 (China PCEC Version) ....8 VaporTEK-3 Controller Board Kit - P/N 900895-001 ..........9 VTEK-3 Pulse Interface Adapter Kit - P/N 900905-001..........11 VaporTEK High Voltage Relay Kit - P/N 900664-001..........11... - Page 4 Figure 18. VaporTEK System – Serial Connection And Monitoring Using RS422 – Interface With Re-regulation Function........31 Figure 19. VaporTEK System - Low Voltage Hook Signal With Relay Switch ..32 Figure 20. VaporTEK Low Voltage Relay Diagram ..........32 Figure 21.

-

Page 5: Figure 1. Vaportek System Basic Components

This manual contains installation and operation instructions for Veeder-Root’s VaporTEK. VaporTEK is a dispenser based, Stage II vapor recovery system that collects vapor during vehicle fueling and returns vapor to the underground storage tank (UST). Each VaporTEK system is designed to accommodate two active fueling points simultaneously. -

Page 6: Introduction

II 1/2G c T3 Solenoid: II 2G Ex MB EPV B EPV A Figure 2. Auxiliary VaporTEK System Components Contractor Certification Requirements Veeder-Root requires the following minimum training certifications for contractors who will install and setup the equipment discussed in this manual:... -

Page 7: Related Manuals

• PMC – Pressure Management Control • CCVP - Veeder-Root Vapor Polisher • Wireless – ISD/PMC Wireless • A current Veeder-Root Technician Certification is a prerequisite for the VR Vapor Products course. Warranty Registrations may only be submitted by selected Distributors. Related Manuals... -

Page 8: Safety Precautions

Introduction Safety Precautions Safety Precautions The following safety symbols may be used throughout this manual to alert you to important safety hazards and precautions. EXPLOSIVE FLAMMABLE Fuels and their vapors are extremely explosive if Fuels and their vapors are extremely flammable. ignited. -

Page 9: Safety Warnings

Veeder-Root maintains a continuous process of product development and therefore product specifications may not be as described in this manual. Please contact the Veeder-Root office nearest you, or visit our website at www.veeder.com for information on new or updated products. Changes affecting products or procedures described in this manual will be reported in subsequent revisions. -

Page 10: Vaportek Pump Certifications & Markings

Certificates can be obtained upon request. The IECEx certificates can be obtained Online at: http://iecex.iec.ch/ Hazardous Area Installation Instructions 1. VaporTEK Pump may be used with flammable gases and vapors with apparatus group II and temperature class T3. 2. VaporTEK Pump is certified for maximum operating ambient temperature of +55°C. -

Page 11: Material Compatibility With Constituents Of The Potentially Explosive Atmosphere

Material Compatibility With Constituents Of The Potentially Explosive Atmosphere The VaporTEK Pump is suitable for temporary exposure to petrol and associated vapors, ethanol blended fuels, diesel, biodiesels, LPG and associated vapors, water with minimal salt content, mild cleaning agents, AdBlue anticipated vehicle exhaust emissions, and small traces of engine oil or other lubricants which could be transferred by hand contact. -

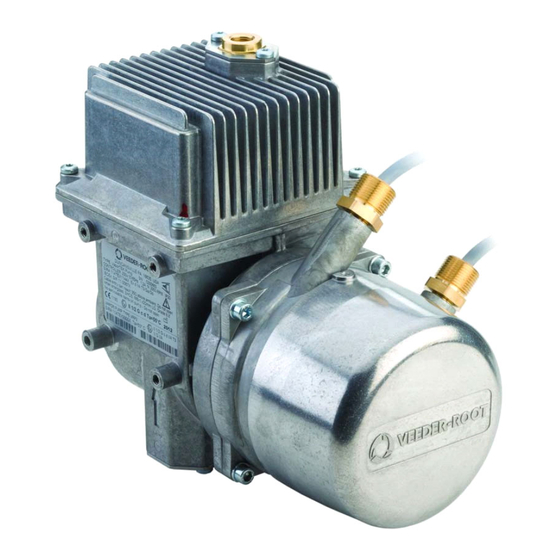

Page 12: Vaportek Pump, Atex/Iecex Kit - P/N 900882-001 (Salzkotten)

VaporTEK Pump, ATEX/IECEX Kit - P/N 900882-001 (Salzkotten) Quantity Description VaporTEK PUMP/MOTOR ASM, P/N 900882-001 577014-132 Pump Field Replacement Manual VaporTEK Pump, PCEC Kit - P/N 900869-001 (China PCEC Version) Quantity Description VaporTEK PUMP/MOTOR ASM, P/N 900868-001 VaporTEK Pump Install Manual Chinese 577014-090... -

Page 13: Vaportek-3 Controller Board Kit - P/N 900895-001

VaporTEK Kits VaporTEK-3 Controller Board Kit - P/N 900895-001 Item Quantity Description VEEDER-ROOT VAPORTEK-CONTROLLER 900890-001 VaporTEK-3 Controller Board, P/N – SK 141 031 916; P/N – VR 900890-001 MOTOR MOTOR POWER SIGNAL RS422 VaporTEK-3 Controller board Mounting BRKT ASM, P/N 900892-001... - Page 14 Introduction VaporTEK Kits Item Quantity Description Screw, PH, Phillips, M3-0.5 X 12LG, P/N 579291-001 Nut, Hex, M3-05, Class 8, Steel, Zinc Plated, Tooth Washer P/N 579201-001 Hex Nut, M6 X 1, Steel, P/N 579082-001 SHCS, M6X1 X 20MM LG, Grade 8.8; P/N 579281-001 Screw, PH, Phillips, M4-0.7 X 12LG/Lock washer M4;...

-

Page 15: Vtek-3 Pulse Interface Adapter Kit - P/N 900905-001

26 Pin Flat Ribbon cable; P/N 579292-001 18AWG, 2 Conductor Power Cable with Connector – 4 FT Long, P/N 900652-001 24AWG, 8 Conductor Signal Cables – 3 FT Long, P/N 900643-001 VaporTEK High Voltage Relay Kit - P/N 900664-001 Quantity Description High Voltage Relay... -

Page 16: Vaportek Valve Adapter Interface Kit - P/N 900Xxx-001

VaporTEK Pump Characteristics 1. The VaporTEK Pump is driven by the VaporTEK Controller. 2. The VaporTEK Pump has integrated flame arrestors at the inlet and outlet ports that prevent flame transmission. 3. The inlet/outlet ports have standard G ¼” female threads (ISO – 228-1). -

Page 17: Vaportek Pump Specifications

H = 235 mm 65 mm Flame Flow Direction to UST Arresters (2) Inlet Ports G 1/4” (2) L = 245 mm Figure 3. VaporTEK Pump Dimensions VaporTEK Pump Specifications Function Description Flow medium Gasoline vapor Flame Arrestors Type: Ex IIA; Inlet & Outlet Ports... -

Page 18: Vaportek Controller

VaporTEK Enhanced Electronic signal of fuel flow required VaporTEK Ultra Board Programming Mode Power OFF/ON cycle required VaporTEK Enhanced VaporTEK - master mode with monitoring system and re-regulation VaporTEK Ultra 15V Motion Chip 5V Board Logic Power LED - V1... -

Page 19: Vaportek Controller Pulse Interface (Optional)

Introduction VaporTEK Controller Pulse Interface (Optional) VaporTEK Controller Pulse Interface (Optional) The VaporTEK Pulse Interface Adapter board provides four low-load pulse train inputs to each side of the dispenser (see Figure 5). VAPORTEK-CONTROLLER VEEDER-ROOT 900890-001 To the encoder lines of target dispenser... -

Page 20: Vaportek Valve Adapter Board (Optional)

P4 – Input is higher than 2.5V DC. VaporTEK Valve Adapter Board (Optional) The VaporTEK-3 – Controller Board, Rev. C, provides a dedicated output to the VaporTEK Valve Adapter board pulse wide modulated (PWM) signal is used to control the valve power for each side separately. An on-board integrated current regulator is stabilizing the valve current against temperature drift on the valve solenoid head. -

Page 21: Figure 7. Vaportek Valve Adapter Board Connected To The Vaportek-3 Controller Board

VaporTEK Valve Adapter Board Duncansville,PA.16 EPV B EPV B Type: EPV10 SIRA 12ATEX6058X -40° Valve: II 1/2G c T3 Solenoid: II 2G Ex MB EPV B EPV A Figure 7. VaporTEK Valve Adapter Board Connected To The VaporTEK-3 Controller board... -

Page 22: Vaportek Pump Configuration

Introduction VaporTEK Pump Configuration VaporTEK Pump Configuration The VaporTEK Pump can be configured to operate in either a 2-Speed or a Variable-speed mode depending on the configuration type and available dispenser inputs/signals. VaporTEK Mode of Required Method of Operation Configuration... -

Page 23: Installation

Excessive vibration may require additional support and vibration mounts to secure the VaporTEK Pump. 5. Route the two cables (Motor and Signal) from the VaporTEK Pump into the dispenser’s electronic cabinet. Tie wrap the cables neatly and securely against fixed support members away from moving parts. -

Page 24: Figure 8. Vaportek Pump Installation Orientations

Installation VaporTEK Pump Preferred Pump Installation Orientation Fins Down Acceptable Pump Installations Orientation Fins Up Motor Facing Incorrect Pump Installation Motor On Top Motor Down Figure 8. VaporTEK Pump Installation Orientations... -

Page 25: Vaportek-3 Controller And Vaportek Pulse Interface Installation

Figure 9. Install The VaporTEK-3 Controller Board Mounting Bracket In The Dispenser’s Electronic Compartment 2. Plug in the ribbon cable connector that connects to the VaporTEK Pulse Interface Adapter board into the X8 male connector on the VaporTEK-3 Controller board (see item 2 in Figure 9). -

Page 26: Vaportek Pulse Interface Adapter Board Installation

Figure 10. VaporTEK Pulse Interface Adapter Board Mounted To Back Of VaporTEK-3 Controller Board Housing 2. Plug the 24V input cable wires into the terminal plug (item 2) on the VaporTEK Adapter Interface board The + to wire connects to a + terminal and the negative wire to a negative (-) terminal. Note: terminal polarities are stenciled on the board beneath the plug. -

Page 27: Figure 11. Vaportek-3 Controller Board Mounting Cover Secured With Safety Label Affixed

Installation VaporTEK-3 Controller and VaporTEK Pulse Interface Installation Figure 11. VaporTEK-3 Controller Board Mounting Cover Secured With Safety Label Affixed. -

Page 28: Alternate Vaportek-3 Controller Board Mounting

Figure 12. Apply Thermal Transfer Paste To These Component Surfaces 1. Fasten the VaporTEK-3 Controller board to the mounting surface with three M3-0.5 X12 long screws, and three M3-0.5 tooth washer hex nuts, (see Item 1, Figure 3). Torque each screw to a nominal 0.60 N-m (min. -

Page 29: Retrofit Installation Of Vaportek-3 Controller Board

Calibration regulations • Technical guidelines/regulations of the organization “technical monitoring association” - VdTÜV RETROFIT KITS TO REPLACE AN EARLIER VAPORTEK CONTROLLER BOARD (P/N 900628-001): • VaporTEK-3 Controller Board Kit P/N 900895-001 • Adapter Cable, Control (Signal) P/N 900898-001 (Screw terminal plug one end/4-pin snap plug other end) •... -

Page 30: Site Preparation

Connect the 4-pin snap plug end of the motor power adapter cable to the Motor Power connector on the VaporTEK-3 Controller board (Item 3 in Figure 9). 3. Attach the adapter cable’s Motor Power plug ground wire to the PE terminal on the VaporTEK-3 Controller board (Item 6, Figure 9). -

Page 31: Wiring Schematics

Using the 18AWG, 2 conductor cable included in the VaporTEK-3 Controller Kit, connect the hook signal from Side A to M1 on the VaporTEK-3 Controller board and connect the hook signal from Side B to 3. VaporTEK with Pulse Signal for Non E500S Dispensers - Requires VaporTEK Pulse Adapter Interface (see Figure 16). -

Page 32: Figure 15. Vaportek System - High Voltage Hook Signal Input

SHIFT SPACE ENTER M3 - VCC (+5V) MAIN Nozzle Switcher - Side A O/T - GND (OFF) TEMP. >120°C Nozzle Switcher - Side B O/T - GND (ON) TEMP. <120°C Figure 15. VaporTEK System - High Voltage Hook Signal Input... -

Page 33: Figure 16. Vaportek System - Liquid Pulse Signal Input

— M2 - V (PWM) • 230V SHIFT SPACE ENTER M1 - U (PWM) MAIN M3 - VCC (+5V) O/T - GND (OFF) TEMP. >120°C O/T - GND (ON) TEMP. <120°C Figure 16. VaporTEK System - Liquid Pulse Signal Input... -

Page 34: Figure 17. Vaportek System - Liquid Pulse Signal Input And Monitoring

For calibration purposes, remove the Vaporix cable and attach FB1 Service terminal here. SIDE B SIDE A L1 N 230V MAIN FB1 Service Terminal START Home PgUp PgDn — • SHIFT SPACE ENTER Figure 17. VaporTEK System - Liquid Pulse Signal Input And Monitoring... -

Page 35: Figure 18. Vaportek System - Serial Connection And Monitoring Using Rs422 - Interface With Re-Regulation Function

Using the 18AWG, 2 conductor cable from the kit, connect each nozzle hook signal on Side A of the dispenser to one high voltage relay circuit. A High Voltage source (110-230VAC) is connected to the M1 on the VaporTEK Controller through all the relay circuits on Side A (See Figure 18 for high voltage relay wiring diagrams). -

Page 36: Figure 19. Vaportek System - Low Voltage Hook Signal With Relay Switch

L - Main Phase 230 VAC M1 - Side 1 High Voltage Hook Signal M2 - Side 2 High Voltage Hook Signal Figure 19. VaporTEK System - Low Voltage Hook Signal With Relay Switch 110 - 230 VAC to VaporTEK... -

Page 37: Figure 21. Vaportek High Voltage Relay Diagram

Wiring Schematics VaporTEK Wiring 110 - 230 VAC VaporTEK High to VaporTEK Voltage Relay Controller 110 - 230 VAC Power Mains Neutral Line High Voltage Nozzle Hook 013-27.eps Signal Input Figure 21. VaporTEK High Voltage Relay Diagram... -

Page 38: Communication Setup - Vaportek Interface

Communication Setup - VaporTEK Interface Setup with Laptop Switch off, tag, and lockout the 230V AC Main power to the VaporTEK-3 Controller board and wait at least 30 seconds for it to power down. Connect your laptop to the VaporTEK-3 Controller board using the special USB Adapter flash adapter P/N: 141 057 636 as it’s shown in Figure 22. - Page 39 “M16 –Terminal” can be downloaded and used instead of HyperTer- minal. Once the HyperTerminal menu screen appears, click on ‘File‘ in the menu bar and select ‘New Connection’. 2. In the Connection Description dialog box Name field, enter ‘VaporTEKClick ‘OK‘ (see example below). Connection Description New Connection...

- Page 40 Communication Setup - VaporTEK Interface Setup with Laptop 4. In the COM Properties dialog box (COM X in the example below, set the all of the port setting fields as shown and click ‘OK’. COM X Properties Port Settings Bits per second...

- Page 41 Communication Setup - VaporTEK Interface Setup with Laptop 6. Click the ‘ASCII Setup‘ button to and set the properties shown below: ASCII Setup ASCII Sending Send line ends with line feeds Echo type characters locally Line delay: milliseconds. Character delay: milliseconds.

- Page 42 Communication Setup - VaporTEK Interface Setup with Laptop 9. Type ‘m‘ on your keyboard to display the following menu: New Connection Hyperterminal File Edit View Call Transfer Help *************************** * VTEK_3 Motor Controller * * ----------------------- * * SW 1.02...

- Page 43 Communication Setup - VaporTEK Interface Setup with Laptop New Connection Hyperterminal File Edit View Call Transfer Help 2. Set Config ------------- Pump Motor Type: VaporTEK VTEK-RS422 Type: Slave Device HV Nozzle Speed: M1 = 2500 rpm HV Nozzle Speed: M2 = 2500 rpm Set M1 - Input performance (0...250RPM x10):120...

- Page 44 Capture Print echo Once the VaporTEK Pump Unit starts running the fuel flow and the related motor speed information will be shown on the screen. Press the ‘f’ button again to disable this function. Press ‘s’ to show the power consumption data of motor.

- Page 45 Communication Setup - VaporTEK Interface Setup with Laptop 14. Show Calibration Table: Press ‘5’ Displays factory set calibration table when connected for the first time; thereafter shows the latest calibrated table. New Connection Hyperterminal File Edit View Call Transfer Help 5.

- Page 46 Communication Setup - VaporTEK Interface Setup with Laptop 16. Pulse – Ratio: Press ‘7’ This sub items allows a modification of Pulse Ratio. The pulse ratio defines the fuel flow rate which has to match the dispenser flow rate. Refer to the dispenser manufacturer’s manual to input the correct pulse ratio.

- Page 47 Communication Setup - VaporTEK Interface Setup with Laptop 18. Function Test - menu option ‘9’ DO NOT SELECT - this function test requires special testing equipment and is for factory use only. 19. Show Hot Keys: Press ‘h’ This item shows all other available hot keys.

-

Page 48: Vaportek Calibration

• Gas meter • A/L nozzle adapter (varies by nozzle manufacturer) • Hoses Initial Setup 1. Verify power is available at the VaporTEK-3 Controller board, both the V1 and V6 red LED’s are on and the V3 green LED is flashing slowly. - Page 49 VaporTEK Calibration Manual Calibration Using The Speed Setup If High Voltage Signals M1 And M2 Are Used 2. Connect the FB1 Terminal to the RS422 to the service connector if available or connect it directly to X4 connector. Direct connection requires batteries on FB1- Service Terminal.

-

Page 50: Gas Meter Calibration

VaporTEK Calibration Gas Meter Calibration VAPORTEK-CONTROLLER VEEDER-ROOT 900890-001 UNSAFE AREA START V3 V8 Home PgUp UNSAFE AREA SAFE AREA PgDn — • SHIFT SPACE ENTER MOTOR MOTOR POWER SIGNAL RS422 RS-422 Connector AVRN Nozzle Connect vapor flow meter to barbed fitting... -

Page 51: Figure 24. Locate The Burkert Gas Meter Calibration Factor

VaporTEK Calibration Gas Meter Calibration 2. When the display below appears, press the keys shown: *** SERVICE *** Gas measuring (1) SYS–Identify EC2000 3. When display below appears, press the key shown: VAPOR CONTROLLER * Gas measuring * Tot : 000,0 liter Cur : 000,0 l/min 4. -

Page 52: Pulse Rate Setup With Fb1 Terminal

Pulse rate setup on VaporTEK Interface The VaporTEK Interface receives pulses from an active encoder and calculates the current flow rate by using of the adjusted pulse rate - Range: 50 to 200 Pulses/liter (1 US Gallon = 3.785 liters). For example, the pulse rate for a VaporTEK Interface should be set to 136 pulses/litre for Gilbarco Encore 500S. -

Page 53: Auto-Calibration Using Fb1 Terminal

VaporTEK Calibration Auto-Calibration using FB1 Terminal 10 Errors Production Fuel Flow Impulse 5. When the display below appears, if necessary to change the pulse rate, press the keys shown: VAPOR CONTROLLER Press number Pulse assignment keys to enter Cur: ENTER... -

Page 54: Simulation With Fb1 Terminal

VaporTEK Calibration Simulation with FB1 Terminal Select Side Side 1 Side 2 5. Set the A/L Ratio rate: **Adjustment** Rate 100 % Offset Change with F2 6. Wait while the auto-calibration is calibrating through 15 points: Auto Calibration Side: Test point: Vap: 048.00 l/min... -

Page 55: Vaportek Pump Troubleshooting And Quick Help

Max 35 l/min Free Input When the flow rate input is provided through the FB1 Terminal the VaporTEK pump will start if greater than 6 liters/minute. The flow rate achieved by the VaporTEK Pump will be displayed in the FB1 Terminal. -

Page 56: Appendix A: Vaportek System Reference Wiring Diagrams

SHIFT SPACE ENTER VaporTEK Pump FB1 Service Terminal 230V Plug the orange connector into any connector on the M04406A001 cable CASH (A) VAPOR VAC TRIND SMRT CASH (B) Figure A-1. VaporTEK Plus For Collection - Encore 500S With VaporTEK-3 Controller... -

Page 57: Figure A-2. Vaportek System Plus For Collection Only W/3 Color Led - Encore 500S Dispenser

POWER SIGNAL RS422 M1 M2 L1 N PE FB1 Service VTEK3 Flash Terminal Adapter MAIN START 230V Home PgUp PgDn — • SHIFT SPACE ENTER Figure A-2. Vaportek System Plus for collection only W/3 Color LED - Encore 500S Dispenser... - Page 58 For technical support, sales or other assistance, please visit: www.veeder.com...

Need help?

Do you have a question about the VaporTEK and is the answer not in the manual?

Questions and answers