Summary of Contents for German RepRap X400v4

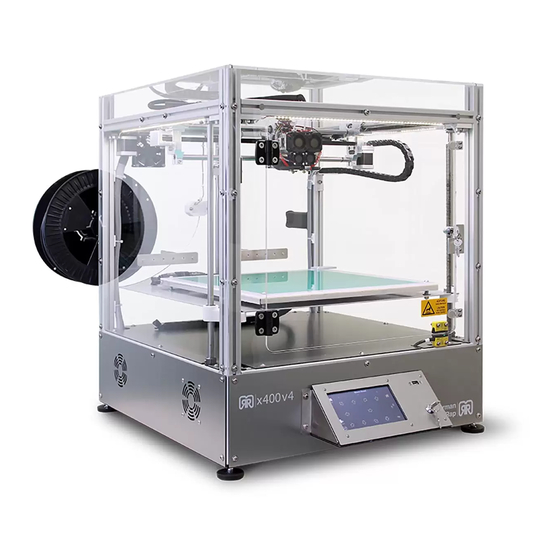

- Page 1 4 0 0 X400v4 3D Printer Manual Congratulations on purchase of your personal X400v4 3D printer German Rev.Nr. 1.11 RepRap...

- Page 2 German RepRap X400v4 02/89 3D Printer Manual...

-

Page 3: Table Of Contents

7.2 Dashboard ............................. 36 7.3 Device Panel ..........................39 7.4 Device Panel - Control ....................... 39 7.5 EEPROM ............................42 7.6 LOG-Files ............................43 7.7 Firmware-Update ........................44 7.9 External Manual ........................... 45 7.9 API Key ............................45 X400v4 03/89 3D Printer Manual... - Page 4 Return Shipment/ Original Package ................... 83 Operation .............................. 83 Miscellaneous ............................83 Toxic Threat ............................83 Safety Switch ............................83 Maintenance ............................83 15. Safety notes Power Supply............................84 Cleaning ..............................84 Playing Children ..........................84 Mains Voltage ............................84 X400v4 04/89 3D Printer Manual...

- Page 5 Humidity, Solar Radiation, Heat, Open Flames ............... 84 Ventilation ............................84 Long Absence, Tempest, Power Plug Reachability ............... 84 Installation Site ........................... 85 Disposal ..............................85 16. Legal Disclaimers Software Modifications/ Use of Applications ................85 Rev.Nr. 1.11 X400v4 05/89 3D Printer Manual...

-

Page 6: General Information

1,75mm / 0,4 mm Nozzles available* 0,25 | 0,3 | 0,35 | 0,5 | 0,6 | 0,8 mm German RepRap material variety depending on the application, as well as on size and geometry, Material a wide range of materials is available. For more information, contact your reseller. -

Page 7: System Requirements

Microsoft´s Internet Explorer is not supported 1.3 Additional Options In addition to the standard version the following options are available: • Base Cabinet For an inquiry please contact our sales partner of your region: https://www.germanreprap.com/en/subsidiaries-sales-partners/ X400v4 07/89 3D Printer Manual... -

Page 8: Unpacking And Installation

X and Y, directions. Please move the tool carriage very carefully, as in general it should not be moved by hand. Each X400v4 has a test print on its ceramic printing plate when getting shipped. This test usually consists of five individual squares. -

Page 9: Installation Site

2.3 Level the 3D Printer Once the correct location has been selected, your printer needs to be levelled. Depending on whether the X400v4 was delivered with or without base cabinet, either the machine or the cabinet feet must be adjusted. -

Page 10: Touch Display Assembly

German RepRap 2.4 Touch Display Assembly The touch display of the X400v4 must be connected with a few simple steps before initializing your 3D printer. In total, four cables must be connected. Touch Display Assembly First, connect the HDMI cable (A) to the Touch Display, then plug the Micro USB cable (B) into the matching port on the display. -

Page 11: Mounting The Spool Holder

RepRap Then mount the touch display using the four marked screws. The screws only need to be screwed in as there are already threads in the housing of the X400v4. 2.5 Mounting the Spool Holder The holder for the filament is dismantled for compact shipping and must be mounted in a few simple steps. -

Page 12: Base Cabinet And Carrying Handles

In addition, the key switch on the front of the 3D printer must be switched on. If this is the case, the startup screen will be displayed on the touch screen, once the X400v4 is powered up. - Page 13 To display the lower two icons of the display, simply swipe down on the display. If nothing is shown on the display, please check the power supply and whether the door of the X400v4 is properly closed. Home screen, Touch-Display...

-

Page 14: Touch Display/ Preparation

From the home screen, navigate to the Parameters (Fig. P.13) and adjust the Speed to 50%. Printer Status, Touch-Display X400v4 14/89 3D Printer Manual... -

Page 15: Extruder And Heated Bed

! You do not have to wait until the set temperatures have been reached. To switch off a heating element tap on it and enter a value of zero. To confirm use the enter button at the bottom right side. X400v4 15/89 3D Printer Manual... -

Page 16: Travel Movements And Machine Zero

You can find the command Home-All in the right upper corner of the touch-display. 3.6 Z-Axis Calibration If your X400v4 came with a built-in print bed (national shipping), please follow this chapter. If you have received your device by international shipping, the print bed was packed separately for safety reasons and has to be mounted in this step. - Page 17 The distance should be 0.05mm. If necessary, adjust the distance by loosening or tightening the print bed fastening screws. Levelling print bed X400v4 17/89 3D Printer Manual...

-

Page 18: Print Bed Coating

To do this, close the door of the X400v4 and navigate from the start screen of the touch display to Parameter. Here you can control the heating elements individually. Increase the temperature of the print bed to 60 °C and wait until the desired temperature is reached. -

Page 19: Z-Offset - Distance Extruder And Printing Bed

Familiarize yourself with the Repetier-Server and connect to your X400v4.( Chapter 7. Repetier-Server). Navigate to the EEPROM of your 3D printer and search for the following values in the lower third of the settings window: •... -

Page 20: Extruder And Filament Guidance

3.9 Extruder and Filament Guidance The X400v4 is equipped with two extruders, where as the left/first extruder sits lower compared to the right/ second extruder. This is intentional. We recommend new users to start their first 3D printing experience with only one extruder. - Page 21 To remove the leftover filament please retract at least 60mm of filament using the touch-display. After the filament was released by the extruder, you can either remove it at the tool head slide or at the filament tracking system ( rear side of the printer). X400v4 21/89 3D Printer Manual...

- Page 22 RepRap The filament spools can easily be hooked onto the back of the X400v4. The right filament holder ( A ), as viewed from the backside, serves as the filament supply for the left / first nozzle. The left holder ( C ) is for supplying the right / second nozzle.

-

Page 23: Keys

X400v4 against unwanted opening during a print job. Device key, X400v4 3.11 Door Switch The X400v4 has a safety switch installed at the front door (see picture), it checks if the door is properly closed. While the door is opened, all dangerous elements are switched off. -

Page 24: Starting A 3D Print

If you already have a G-Code file you can start your first print using one of the following procedures. Important: A G-code is device-specific! You may only start G-codes on the X400v4 that have been created for this device! 4.1 Standalone 3D Print It is possible to start a 3D print without connecting to your printer via network, just right away on your machine. -

Page 25: Printing Via Repetier-Server

G-Code has been uploaded, select the pink-marked printing symbol in order to start the print. Please note: At first, the printer does not move! The device first heats up the print bed and nozzles before the actual print job starts. X400v4 25/89 3D Printer Manual... -

Page 26: Workflow And Operation

One integrated software suite contains everything you need to print high quality parts • Customizable settings and advanced processes hand the control to your hands • Support for dual-extruders, multi-part printing and even multiple processes within one part X400v4 26/89 3D Printer Manual... -

Page 27: Quick Start Guide

file and launch the .run installation package. It is recommended to launch this program as super-user by opening Terminal cd‘ing to the directory where you unzipped the file, and then typing: sudo ./Simplify3D*installer.run and entering the administrator password. X400v4 27/89 3D Printer Manual... - Page 28 To import the downloaded profile, follow these steps: • Click on menu “File” “Import FFF-Profile” and choose the downloaded file. • Open the FFF settings window and check if the profile is visible. Select profile, Simplify3D Import profile, Simplify3D X400v4 28/89 3D Printer Manual...

-

Page 29: The Interface Layout

Processes define how your 3D model is going to be printed. All your created/edited processes will be listed here. 5. Toolbar • This toolbar contains quick access buttons for frequently used tools. You can move the toolbar anywhere you wish by clicking and dragging the top dotted line. Interface Layout, Simplify3D X400v4 29/89 3D Printer Manual... - Page 30 Move Model – Ctrl-left-click and drag (or Command-left-click on Mac) • Scale Model – Ctrl-right-click and drag up or down (or Command-right-click on Mac) • Rotate Model – Alt-left-click and drag right or left (or Option-Left Click on Mac) X400v4 30/89 3D Printer Manual...

- Page 31 To make adjustments to your Process, double-click on the Process or click Edit Process Settings. This will open the FFF (Fused Filament Fabrication) Settings window. Processes, Simplify3D X400v4 31/89 3D Printer Manual...

- Page 32 The animated Preview Mode in the Simplify3D™ Software allows you to inspect all aspects of your print operation prior to execution. The software according to the generated G-Code, virtually displays line by line how your model will be constructed. X400v4 32/89 3D Printer Manual...

- Page 33 The most reliable way to 3D print is to upload your G-Code on to your 3D printer. Please read chapter 4.2 3D Printing via Repetier-Server carefully on how to upload and start a 3D print. X400v4 33/89 3D Printer Manual...

- Page 34 Tutorials: tionality. https://www.simplify3d.com/support/articles/ Simplify3D offers a lot of learning support: Video Tutorials: https://www.simplify3d.com/support/videos/ Quality and Troubleshooting: https://www.simplify3d.com/support/print-quali- ty-troubleshooting/ Forum: https://forum.simplify3d.com X400v4 34/89 3D Printer Manual...

-

Page 35: Network And Printer Set Up

If your network settings are DHCP based you simply have to plug in a network-cable into the slot at the backside of the X400v4, in order to connect your 3D printer to the network. Furthermore there is the possibility to use a DHCP-based router to connect your computer and 3D printer directly without integrating it to the network. -

Page 36: Repetier-Server

Depending on the configuration of the Repetier-Server, you may end up directly in the device panel of your 3D printer. In order to get to the dashboard, click on the house icon in the top bar. X400v4 36/89 3D Printer Manual... - Page 37 3D printer like a Smart-phone or a tablet. Verifying Printer Settings To ensure that everything has been installed correctly click on your 3D printer and then on the right bar on printer-settings. Printer Settings, Repetier-Server X400v4 37/89 3D Printer Manual...

- Page 38 15200 and “Communica- tion-timeout” is enabled. Attention: We recommend a value of 60, but this may differ for certain geometries. One of our specialist dealers will be happy to advise you. General printer settings, X400v4 X400v4 38/89 3D Printer Manual...

-

Page 39: Device Panel

You can use this menu item to manually operate your 3D printer. You can manually traverse the axis or regulate the heating bed. The controls are separated into 3 categories: • General working area • Filament exchange • Extruder and temperature curves • Macros, to define your own commands Categories, Repetier-Server X400v4 39/89 3D Printer Manual... - Page 40 In the tab Move you can manually traverse the printer`s axes. This is either done by clicking on the corresponding arrow or via the slide controls, arranged around the virtual print bed, by pulling them to the required position. X400v4 40/89 3D Printer Manual...

- Page 41 As well as all the functions previously motioned, you also get to see here tem- perature cures for all heating elements. This view is especially useful in order to rule out malfunctions of the heating elements. Extruder and temperature curves, Repetier-Server X400v4 41/89 3D Printer Manual...

-

Page 42: Eeprom

You should generally only modify these settings after consulting the support. Incorrectly registered values can lead to a malfunctioning of the device or could even damage the 3D printer. X400v4 42/89 3D Printer Manual... -

Page 43: Log-Files

A maximum of 5 log files can be stored. From that point on every further task will delete the oldest entry. To record a 3D print you should just check the two boxes. It is not possible to log already started print jobs. LOG-Files, Repetier-Server X400v4 43/89 3D Printer Manual... -

Page 44: Firmware-Update

Make sure that in Printer Board Type the Arduino DUE Programming Port is selected • Select the path of the BIN file as you click Upload Firmware Image • The upload and installation will then be executed Firmware Upload -X400, Repetier-Server X400v4 44/89 3D Printer Manual... -

Page 45: External Manual

The preceding overview of Repetier-Server should introduce the necessary functionalities to operate your 3D printer, for further instructions please visit : https://www.repetier-server.com/documentation/ External manual, Repetier-Server 7.9 API Key Please create a backup of you API-key before updating Repetier-Server. Please consult chapter 10.2 update Repetier-Server. API- Key, Repetier-Server X400v4 45/89 3D Printer Manual... -

Page 46: G-Code Management

G-Code management, Repetier-Server After creating a new group you can choose into which one you want to upload a G-Code, either via Repe- tier-Server or directly using a flash-drive and the touch screen at the X400v4. Please note: If you do not create any new groups, all uploaded G-Codes will be stored in Default. -

Page 47: G-Code Download

The last step is to click download in the G-Code preview window. G-Code Download, Repetier-Server Please note: While updating the Repetier-Server all stored print data will be deleted. Please secure your G-Codes as described above. X400v4 47/89 3D Printer Manual... -

Page 48: Tool Heads And Consumables

8.2 Setting Up the Second Extruder The X400v4 is equipped with two extruders, the left/first extruder sits lower compared to the right/second extruder. This is intentional. We recommend to new users to start their first 3D prints with only one extruder. - Page 49 266,66. The distance of the second extruder to the first one is approx. - 32mm, which will result in a step-value of approx. 8500steps. ( Distance in mm * 266,66 steps/mm = distance in steps) X400v4 49/89 3D Printer Manual...

- Page 50 Make sure that the extruder is not heated up for too long when it is not extruding filament, otherwise the hot end might clog. Tip: It is easier to insert the filament, when you straighten the end and cut it off diagonally. X400v4 50/89 3D Printer Manual...

-

Page 51: Filament Tracking System (Fts)

Filament Tracking System, x400v4 You can find the filament tracking units on the back side of your X400v4, both units are assigned to a specific extruder. Please always guide the filament through the FTS before inserting it into the feeding hose. - Page 52 If you have to extrude a lot of material, simply move the toolhead to another position and continue ext- ruding. Continue printing, Touch-Display Attention: The maintenance key should only be used by trained personnel and for the maintenance of the device. X400v4 52/89 3D Printer Manual...

- Page 53 In case it is not possible to extrude filament using the touch-display, try to use a new spool of filament. If this does not solve the problem stop the 3D-print and check if the extruder gear is dirty or if the brass nozzle is clogged. X400v4 53/89 3D Printer Manual...

-

Page 54: Touch-Display

G-Codes shows all the print-files you have stored on your 3D printer. By clicking on them you get informa- tion about filament consumption as well as printing time. From there you can easily start your 3D print. X400v4 54/89 3D Printer Manual... - Page 55 Move Head - Select Step Distance : Use Distance on the right hand side to open the window below. Here you can define the step-size for the movement you want to make. Move Head- Select Step Distance, Touch-Display X400v4 55/89 3D Printer Manual...

- Page 56 Filament Remove Filament to finally pull filament out of the extruder or Insert Filament to push filament into the extruder. Printers, Touch-Display Printers shows the active 3D printer. There is no need to change/edit something here. X400v4 56/89 3D Printer Manual...

- Page 57 Fan sets the speed of the object-fan. Speed will speed up or slow down the whole printer, Flow is just influ- encing the material flow without changing the speed of the axes. Turn lights on/off is not supported. * Depending on your 3D printer and its configuration this view-port might be slightly different. X400v4 57/89 3D Printer Manual...

- Page 58 After you choose a file to upload, you will be asked into which group you want the file to be imported. Please consult the chapter Repetier-Server to see how to create/edit or delete a new group. The uploaded print-job can be later found in G-Code. X400v4 58/89 3D Printer Manual...

- Page 59 The command G1 X100 would move the tool head to the coordinate X = 100mm (image above). There is no possibility to enter empty space characters, spaces will be generated automatically, e.g. if you want to type G1 X100, simply enter G1X100. X400v4 59/89 3D Printer Manual...

- Page 60 German RepRap Via Send Script you can choose from predefined scripts that are provided from German RepRap for a specific printer. The commands shown here are predefined for the X400v4, for other printers this may vary. Console - Send Script, Touch-Display ATTENTION: Lift Z 0.2mm will ignore the MAX-Z length and therefore it is possible to collide with the hotend!

- Page 61 The arrows on the left side will execute a slow movement, the ones on the right side will execute a fast movement. ATTENTION: A fast executed long movement (e.g. 50mm) might cause the nozzle to clog. Rather use smaller step-sizes to extruder filament. X400v4 61/89 3D Printer Manual...

- Page 62 Extrude and Retract- Set Temp. , Touch-Display Temperatures displays the temperature history of the selected device. Simply click the upper bar to select your desired component. ATTENTION: Extruder 3 displays the temperature of the heated chamber. Temperatures - Select Graph, Touch-Display X400v4 62/89 3D Printer Manual...

- Page 63 Messages will show you messages for events like print finished or paused. You need to delete them in the menu by clicking the red button. In case of a paused message, the print will continue when you click on the red button. Messages, Touch-Display X400v4 63/89 3D Printer Manual...

- Page 64 Webcam, Touch-Display Screensaver: You can set a time to let the screen go into screensaver mode. This prevents the machine from taking any commands via the display after it goes into saving mode. Screensaver, Touch-Display X400v4 64/89 3D Printer Manual...

-

Page 65: How To Determine The 3D Printer's Mac Address

Please read Chapter 6. Network and Printer Set Up. There you can find information about how to integrate your 3D-printer in your network. After connecting to your printer please select the house-symbol at the upper right corner. This will lead you to the dashboard. Network settings, X400v4 X400v4 65/89 3D Printer Manual... -

Page 66: Update The Repetier-Server

Attention! Never perform a Repetier-Server upgrade without consulting the support. Only use updates which were approved by German RepRap! For updating the Repetier-Server you must have an internet connection Before you update your Repetier-Server please make sure, to first make a copy of your license-code and then deactivate it. - Page 67 Add New Printer, Repetier-Server Upload Configuration-File, Repetier-Server After updating the Repetier-Server the touch-display will stay black for the moment. Please run the setup routine to activate the graphical user interface. See chapter: 13 Setup-Routine X400v4 67/89 3D Printer Manual...

-

Page 68: Removal Of The Cooling Fan

German RepRap 10.4 Removal of the Cooling Fan The X400v4 is equipped with a controllable cooling fan, which can easily be removed in case of e.g. maintenance work. Please make sure that the 3D printer is not connected to the power grid. -

Page 69: Pva Solution For Enhanced Adhesion

A simplified assembly is possible if the upper threads in the long profiles are drilled to a diameter of 7mm. As a result, the threaded bolts are pluggable. In this case, the base cabinet can be mounted separately and the printer will be placed on top afterwards. X400v4 69/89 3D Printer Manual... -

Page 70: Carrying Handles

For mounting the carrying handles, remove the marked screws at the left and right side of the 3D printer. Removal of existing screws, carrying handles Afterwards use the screws, delivered with the handles, to mount them. Mounting the carrying handles X400v4 70/89 3D Printer Manual... -

Page 71: Housing Fan

10.8 Housing Fan The X400v4 has two housing fans on its rear wall which make it possible to ventilate the encloser when the door is closed. Depending on the filament used, this can increase print quality as well as process reliability. - Page 72 Enter the Process Settings of Simplfy3D and navigate to the tab Scripts. You can set commands that are going to be executed at the beginning of a 3D print (Starting Script) or at the end (Ending Script). The figures may differ slightly depending on the version of the Repetier-Server or Simplify3D. X400v4 72/89 3D Printer Manual...

-

Page 73: Installing The Heated Bed

11. Installing the Heated Bed This chapter will show you how to replace or install the heated bed of the X400v4 3D printer. If your X400v4 is send to you by air cargo, the heated bed is packed separately for safety reasons. To put the printer into commission, follow these simple steps to mount and adjust the heated bed. -

Page 74: Inserting The Heated Bed

11.3 Inserting the Heated Bed Insert the heated bed into the printer so that the plug connection faces the back side. Inserting the heated bed, X400v4 Then the heated bed must be installed with the provided screws on each of the four corners:... -

Page 75: Heated Bed Wiring

Mounting clips, X400v4 The next step is to plug the grounding cable on to the supporting plate. You can use a cable tie to secure the grounding cable. Grounding cable heated bed, X400v4 X400v4 75/89 3D Printer Manual... -

Page 76: Fixing Corner Screws

200 ° C. Wait about 30 minutes for the entire printer to heat up and repeat the procedure described above. Please be especially careful when working with a hot heated bed and hot end, there is a risk of burns. X400v4 76/89 3D Printer Manual... -

Page 77: Direct Connection

12.1 Wiring The industrial PC inside the X400v4 has two network slots. One of those is to establish a DHCP-based network connection, the other one has a static IP-address and therefore is able to establish a direct connec- tion between the printer and your personal computer. - Page 78 Enter the following IP address to establish a connection to the 3d printer: 192.168.1.2 Info: By using this method you assign a static IP-address to your computer, which is in the same name space as your 3D printer. Entering static IP address X400v4 78/89 3D Printer Manual...

-

Page 79: Setup Routine

13.1 Starting the Setup Routine To reconfigure your X400v4, the setup routine must be run. This requires a connection via the network cable to your 3D printer. Enter the assigned IP-address of your 3D printer and add a /setup.php into your browser to establish a con- nection. - Page 80 German RepRap Step 2: Here you find information about the software used for the 3DprintBox. Setup Routine, step 2 X400v4 80/89 3D Printer Manual...

- Page 81 Please check if your touch display is working properly, otherwise use calibrate touch-screen to re-calibrate it. Setup Routine, step 3 Step 4: Please click the button restart to finish the configuration of the 3DPrintBox. Setup Routine, step 4 After restarting, your 3D printer is reconfigured and ready for use. X400v4 81/89 3D Printer Manual...

- Page 82 German RepRap X400v4 82/89 3D Printer Manual...

-

Page 83: Important Notices

As part of your responsibility for your fellow human beings, please save this manual for eventual questions and give it in case of a resell to the new owner. X400v4 83/89 3D Printer Manual... -

Page 84: Safety Notes

In case of long term absence or tempest you should unplug the device as a precaution. We recom- mend this for all devices that are plugged to the printer, even via USB. X400v4 84/89 3D Printer Manual... - Page 85 Only use the software packages provided by German RepRap GmbH via download at their website at http:// www.germanreprap.com. German RepRap GmbH cannot be held liable for the loss of data on any external or internal storages. The device has been pre-installed with software and works as can be reasonably expected. It cannot be guar- anteed that the software is error free.

- Page 86 You must take measures for fire protection that are not included into the device. (Provi- sion of fire extinguishers and fire blankets, ban on smoking) Risk assessment in accordance with EN ISO 19353. X400v4 86/89 3D Printer Manual...

- Page 87 Do not reach into the work area of the machine while the service key is activated! Transport 7.1 The transport is carried out by German RepRap GmbH. The device can by moved by the assembled wheels. Packed delivery: Machine weight: 50 Kg Local requirements for the delivery: forklift, lift truck when a transport via the assembled wheels is not possible.

- Page 88 Machines and devices must be equipped with an Installation which allows a separation from any power supply. These installations must be clearly marked and be secured against unintentional activation. After energy is cut off, it must be possible to dissipate any residual energy without risk. X400v4 88/89 3D Printer Manual...

- Page 89 The incurred process waste must be separated into recyclable material and hazardous substances in accord- ance with local laws and practices. The device itself must also be separated into recyclable material and hazardous substances in accordance with local laws and practices. X400v4 89/89 3D Printer Manual...

Need help?

Do you have a question about the X400v4 and is the answer not in the manual?

Questions and answers