Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Rioned HD30

- Page 1 HD30 user manual...

- Page 2 Rioned. Rioned reserves the right to make changes to parts at any time, without providing prior or direct notification to the buyer. The content of this user manual may also be changed...

-

Page 3: Preface

Finally, at the end of this user manual you will find an index to help you quickly find information and a number of annexes containing, among other things, Rioned's contact details. -

Page 5: Table Of Contents

Table of contents Preface ............3 Cleaning a wall, terrace or floor........28 4.5.1 Warnings for spray gun ..........28 4.5.2 Preparations for spraying ..........28 Table of contents......... 5 4.5.3 Pressurizing the system..........28 4.5.4 Starting spraying ............28 Introduction ........7 4.5.5 Depressurizing the system ......... 29 Ending the work ............ - Page 6 10.9 900000649 Pressure regulator 160 bar.....60 10.13 900000653 High pressure reel NW10 - 30 m.... 64 10.10 900000650 High pressure reel NW8 - 40 m..... 61 10.14 900000654 Pressure regulator 250 bar incl. temp. 10.11 900000651 Motor/pump group P21 protective protection..............65 cap blue excl.

-

Page 7: Introduction

INTRODUCTION Introduction Congratulations on the purchase of the HD30! The HD30 is suitable for cleaning house connections, rainwater drains and grease-blocked and industrial pipes. The HD30 is also suitable for cleaning street furniture, terraces etc. The HD30 is directly connected to a water supply, so a tank is not necessary. - Page 8 INTRODUCTION...

-

Page 9: Description And Principle Of Operation

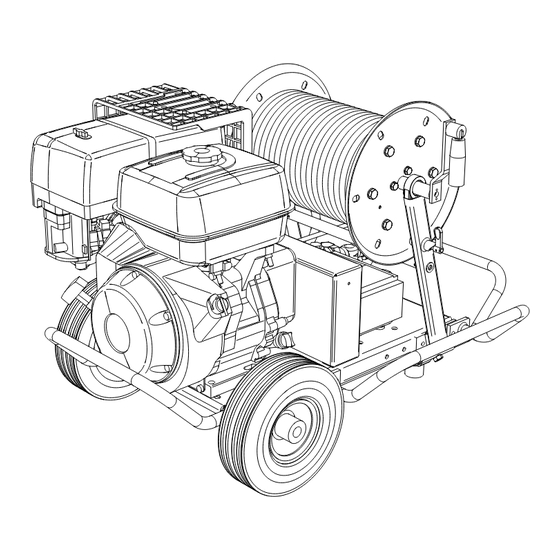

DESCRIPTION AND PRINCIPLE OF OPERATION Description and principle of operation Introduction In this chapter we briefly describe the operation, the main components and the symbols used for the machine and the accompanying accessories. Machine 2.2.1 Design and principle of operation The engine drives the high-pressure pump via a V-belt The high pressure pump draws water from the water supply network via the non-return valve and pressurizes it. - Page 10 DESCRIPTION AND PRINCIPLE OF OPERATION...

- Page 11 The following is a brief explanation of parts from the illustrations above that are not discussed further in the manual. Non-return valve (4) The valve ensures that the contaminated water used by the HD30 cannot get back into the water supply network. High pressure valve (5) This valve regulates the supply of water to the high pressure hose.

- Page 12 DESCRIPTION AND PRINCIPLE OF OPERATION Wheels (17) The HD30 rolls on these when you move it.

-

Page 13: Symbols On Pressure Gauge, Pressure Regulator And Valve Controls

DESCRIPTION AND PRINCIPLE OF OPERATION 2.2.2 Symbols on pressure gauge, pressure regulator and valve controls Maximum allowable Pressure gauge (7) pressure The maximum operating pressure is indicated on a sticker near the Danger zone Operating pressure gauge. range Reduce the operating pressure with the handwheel of the pressure regulator until the indicator of the pressure gauge is halfway between and the maximum operating pressure. - Page 14 DESCRIPTION AND PRINCIPLE OF OPERATION...

-

Page 15: Safety

SAFETY Safety Introduction This user manual contains very important safety instructions. In this chapter we provide general instructions. ALWAYS follow these instructions for use and maintenance. In other chapters we provide specific safety instructions for each action or situation. ALWAYS follow these instructions too. Also observe the following safety instructions: >... -

Page 16: Use Only By Authorized Personnel

> substances subject to special rules Do NOT use the machine in an explosive environment. Rioned ONLY guarantees the safety when working with the machine if the machine is used as described in this user manual. NEVER exceed the following limit values (EN IEC 60204-1): >... -

Page 17: Spray Break

SAFETY This safety sticker shows you what you should not spray on: Recommendation: do not use spray lances shorter than 75 cm. 3.10 Spray break If you leave the spraying area for a short time, do the following: 1. Stop the machine (see section ‘Stopping spraying’ in ‘Unblocking a sewer’ and section ‘Stopping spraying’... -

Page 18: Water Discharge

SAFETY 3.15 Water discharge Ensure that the water is drained off properly. Clean the discharge water before discharging it into the sewer system in the following two cases: > when cleaning with harmful chemicals, or > when the object to be cleaned is contaminated with environmentally harmful substances. -

Page 19: Safety Sticker

SAFETY 3.18 Safety sticker The safety sticker is located on the back of the vehicle. The symbols used have the following meaning: 1. Hearing, head and eye protection must be worn 2. Safety shoes with extra protection required 3. Reading the manual is mandatory 4. - Page 20 SAFETY...

-

Page 21: Operation: Standard Functions

Checks before departure ALWAYS check the following before you drive off with your HD30: > Is the high pressure hose completely rolled up? > Is the reel fixed by means of the reel latch? Check fluids: >... -

Page 22: Preparations At The Workplace

OPERATION: STANDARD FUNCTIONS Preparations at the workplace 4.3.1 Preparing the machine 1. Place the machine at the desired location. 2. When used on a slope, block the wheels with wheel chocks. 3. Slide the bracket into the frame and secure it with the wing screw. -

Page 23: Workstations

OPERATION: STANDARD FUNCTIONS For unblocking a sewer: the spray nozzle. For cleaning façades, terraces and floors: the spray gun. 4.3.3 Workstations The machine has different workstations. These workstations are: At the manhole or sewer pipe The following operation is possible here: >... -

Page 24: Starting The Engine

OPERATION: STANDARD FUNCTIONS Starting the engine ALWAYS wear personal protective equipment! See section ‘Personal protective equipment’ for all the protective equipment. 4.4.1 Starting Honda GX340 A brief explanation of the start procedure is provided below. FUEL VALVE Read the engine operating manual for the full explanation! The engine operating manual is supplied with this machine. -

Page 25: Stopping The Engine

OPERATION: STANDARD FUNCTIONS TAKE CARE! Do not let the starter handle fly back against the engine. Let the starter rope retract gently to prevent damage to the starter. 6. If you moved the choke lever to the CLOSED position to start the engine, gradually move it to the OPEN position while the engine is warming up. -

Page 26: Unblocking A Sewer

OPERATION: STANDARD FUNCTIONS 4.4.4 Unblocking a sewer 4.4.5 Spray nozzle warning WARNING! Ensure that the spray nozzle never exits the sewer while spraying. A high pressure water jet can cause serious injuries! How do you prevent this? A mark has been applied approximately five meters from the end of the hose. When you see this mark, do the following: 1. -

Page 27: Stopping Spraying

OPERATION: STANDARD FUNCTIONS 3. Check whether the water is drained off. 4. Continue flushing for a while after the blockage is removed. 5. Reel the hose in slowly at the same time. 4.4.8 Stopping spraying After unblocking, it is important to flush as follows: replace the ‘Open nozzle’ with the ‘Blind nozzle’. -

Page 28: Cleaning A Wall, Terrace Or Floor

OPERATION: STANDARD FUNCTIONS Cleaning a wall, terrace or floor 4.5.1 Warnings for spray gun WARNING! ALWAYS observe the following warnings when working with the spray gun: Before use: • Set the pressure regulator to half of the maximum operating pressure (see section ‘Symbols on pressure gauge, pressure regulator and valve controls’). -

Page 29: Depressurizing The System

OPERATION: STANDARD FUNCTIONS 2. Squeeze the trigger of the spray gun to start spraying. Release the trigger to stop spraying. 4.5.5 Depressurizing the system The system can be depressurized in one way: with the high pressure valve. Depressurizing the system with the high pressure valve Move the throttle lever on the engine to decrease the engine speed Set the lever of the high pressure valve to the closed... - Page 30 OPERATION: STANDARD FUNCTIONS 12.Stop the engine. NOTE When pumping out the water, there is no need to place a spray nozzle or spray gun on the high pressure hose. Removing antifreeze Complete the following procedure to remove the antifreeze from the lines: 1.

-

Page 31: Operation: Extra Functions

If your machine cannot be connected to a water tap, it is possible to obtain water from ditches or canals. Proceed as follows: ALWAYS check the following before you drive off with your HD30: > Is the high pressure hose completely rolled up? > Is the reel fixed by means of the reel latch? >... - Page 32 OPERATION: EXTRA FUNCTIONS...

-

Page 33: Maintenance

You may ONLY make changes to the machine if you have received written authorization from Rioned. The use of original replacement parts and Rioned-approved accessories is important for safety. If you use other parts, Rioned is NOT liable for any consequential damage. -

Page 34: Maintenance Schedule

MAINTENANCE Maintenance schedule Maintain the various parts of the machine according to the following schedule: Check oil levels Before the work Clean water filter Before the work and when very dirty Check high pressure hose and Before the work other hoses Clean bodywork Weekly or when very dirty Poke the nozzle holes clean... -

Page 35: Maintenance Before The Work

MAINTENANCE NOTE The maintenance of the engine is beyond the scope of this user manual. That information can be found in the documentation you received with the machine. Maintenance before the work The following parts must be checked or cleaned before the work: 6.4.1 Check oil levels >... -

Page 36: Weekly Maintenance

MAINTENANCE Weekly maintenance Clean the bodywork weekly. Use lots of water and automotive shampoo. The bodywork should be cleaned earlier if it is heavily soiled. Maintenance every 50 hours of operation The nozzle holes must be poked clean every 50 hours of operation: Maintenance every 250 hours of operation or at least once every six months The following parts must be maintained every 250 hours of operation or at least once... -

Page 37: Maintenance Every 1000 Hours Of Operation Or At Least Once A Year

Clean the pressure valves of the high pressure pump once a year. See accompanying annex for more information. 6.8.3 Major scheduled maintenance Have Rioned technical service inspect and maintain the machine once a year. This will ensure the continued good performance and long service life of the machine. - Page 38 MAINTENANCE...

-

Page 39: Malfunctions

Main or accessory fuse 1. Replace defective fuse. blown. 2. Restart engine. 3. If the fuse blows again, contact Rioned. Battery voltage too low. Charge the battery or replace the battery Air in fuel line. Bleed air at engine. - Page 40 3. Descale pressure valves 4. Replace pressure valves. High pressure pump sealing 1. Stop machine. ring worn. 2. Replace sealing ring. Ceramic pistons in high Contact Rioned. pressure pump damaged. Pressure regulator internally Contact Rioned. restricted or damaged.

-

Page 41: Index

HD30 ................9 working in ..............7 personnel engine stop operation by authorized personnel ......16 HD30, use ..............17 poking the nozzle holes clean ......... 36 pressure gauge ..............36 symbols ................13 fault prohibited to work during – ........16 pressure regulator ............ - Page 42 starting engine with eControl+ ............24 reeling out manually ..............31 restrictions on use ............16 technical specifications ........... 47 thunderstorm working during ............16 safety bystanders ..............16 troubleshooting ............... 39 general ................. 15 type plate location ................ 45 safety instructions dangers of non-compliance with safety instructions . 15 safety sticker ..............19 water discharge ...............

-

Page 43: Attachments

ATTACHMENTS Attachments... -

Page 44: Annex 1 Ec Declaration Of Conformity

ATTACHMENTS Annex 1 EC declaration of conformity Rior, Industrie- en handelsonderneming B.V. declares that: Brand: Rioned Type: HD30 Machine number: > is in conformity with the Machinery Directive (2006/42/EC); > complies with the provisions of the following other EC Directives: 2014/30/EC >... -

Page 45: Annex 2 Type Plate

ATTACHMENTS Annex 2 Type plate The type plate is located on the protective cover between the motor and the pump and contains the following information: CE Marking Manufacturer of the machine Not applicable Chassis number of the machine Identification of the machine Manufacturer's address details Year of manufacture of the machine Name of the machine... -

Page 46: Annex 3 Dimensions

ATTACHMENTS Annex 3 Dimensions... -

Page 47: Annex 4 Technical Specifications

ATTACHMENTS Annex 4 Technical specifications General Length, high pressure hose: 40 m Diameter, high pressure hose: 3/8" (NW10) 5/16" (NW8) Weight: 90-100 kg Capacity, fuel tank: 6.1 litres Application range: 40 - 200 mm Tyre size: 260 x 80 x 20 mm Recommended tyre pressure: 2 bar Engine... - Page 48 ATTACHMENTS High pressure pump Type Speck P21 Number of cylinders: Number of valves: Maximum capacity: see type plate Mass: 8.5 kg Maximum water temperature: 60 °C Oil type: GX 80W90 (P/N 71002000090) Volume: 0.37 l Type Speck P30 Number of cylinders: Number of valves: Maximum capacity: See type plate...

-

Page 49: Annex 5 Contact Details

ATTACHMENTS Annex 5 Contact details Rioned Customer Service Centaurusweg 45 5015 TC Tilburg P.O. Box 5070 NL-5004 EB Tilburg Tel. no.: +31 13-5479100 E-mail: info@rioned.com Internet: www.rioned.com AGENTS South Netherlands Clément Thobie Mobile +31 6-46062830 West Netherlands Ronald Groenewege Mobile +31 6-51145821... - Page 50 ATTACHMENTS...

-

Page 51: Exploded Views

EXPLODED VIEWS 10 Exploded views... -

Page 52: Table Of Machines

EXPLODED VIEWS... -

Page 53: 900000088 Frame

EXPLODED VIEWS... -

Page 54: 900000405 Accessories 100 Bar 40 Lpm

5015 TC Tilburg 24900000147 Prod. no.: Tel.: 013-5479100 e: info@rioned.com Drawing no.: Sizes in mm This drawing is the property of Rior B.V. / Rioned and may not be reproduced without her consent, nor given 900000147 to third parties. WWW.RIONED.COM File: C:\VaultWorkspace\Inventor\24\24900000147.iam... -

Page 55: 900000155 Frame With Protective Brackets

EXPLODED VIEWS... - Page 56 EXPLODED VIEWS...

-

Page 57: 900000456 Accessories 120 Bar 22 Lpm

EXPLODED VIEWS... -

Page 58: 900000647 High Pressure Reel Nw10 - 40 M

EXPLODED VIEWS... -

Page 59: 900000648 Motor/Pump Group P30

EXPLODED VIEWS... - Page 60 EXPLODED VIEWS...

- Page 61 EXPLODED VIEWS...

- Page 62 EXPLODED VIEWS...

- Page 63 EXPLODED VIEWS...

- Page 64 EXPLODED VIEWS...

- Page 65 EXPLODED VIEWS...

- Page 66 EXPLODED VIEWS...

Need help?

Do you have a question about the HD30 and is the answer not in the manual?

Questions and answers