Summary of Contents for Rioned UrbanJet

- Page 1 USER’S MANUAL RIONED URBANJET RIONED P.O. Box 5070 5004 EB Tilburg The Netherlands Telephone: +31 13 5479100 E-mail: info@rioned.com Internet: www.rioned.com...

- Page 2 RIONED. This restriction also holds for the corresponding drawings and diagrams. RIONED has the right to change parts at any time without any prior or direct warning to the client. Also, the contents of this manual can be changed without any prior warn- ing.

- Page 3 Foreword This user’s manual is a manual for the professional user. This user’s manual has the purpose to control the machine in a safety manner and must be saved with the machine. The photos and drawings help you understand the text easier. First the user’s manual gives you an overview of the most important safety aspects.

- Page 4 10/18...

-

Page 5: Table Of Contents

Table of Contents Introduction ................8 1.1 Use ..................8 Security ..................9 2.1 Instruction indications in this manual........9 2.2 Descriptions security measures ..........9 2.3 Personnel protection outfit ............9 2.4 Work area................10 2.5 Use in closed room............... 10 2.6 Water outlet ................ - Page 6 7.13 Using the device during periods of frost ........38 7.14 Additional preparations when preparing for use:....... 39 Symbols ................... 40 8.1 Pressure gauge..............40 8.2 Security sticker..............41 8.3 High-pressure valve ............. 41 Options..................42 9.1 Second HP- hose reel ............42 9.2 Pulsator system ..............

- Page 7 Appendix .................. 77 15.1 EC declaration Of Conformity For Machinery ......77 15.2 Sales Managers ..............78 15.3 Dimensions ................. 79 Index ..................80 10/18...

-

Page 8: Introduction

INTRODUCTION RIONED wishes to thank you for your purchase of the RIONED drain and sewer- clearing machine. We recommend that you read this manual thoroughly and see that the machine is handled and maintained in the proper manner. If your machine should give trouble and need servicing, when you want to order parts, or if you have any questions, contact your RIONED dealer. -

Page 9: Security

SECURITY Be responsible for other people when you are working with this machine. This manual contains instructions for fundamental conditions that must be fol- lowed by use and maintenance of this machine. That is why it is necessary that authorised and qualified personnel must read the user's manual and the user’s manual must always be available with the ma- chine. -

Page 10: Work Area

Work area • Mark the work area clearly. • Minimum distance “work area - demarcation”: 6 meters. • Remove all lose parts inside the demarcation. • Never spray from an unstable place (ladder, boat, scaffold,...) • Working with artificial light: Adjust lighting armatures (waterproof) Use in closed room Look to it that the combustion gas is adequate carried away. -

Page 11: Personnel Qualification And Education

mum (±the half of the maximum pressure). You must do this before you start the machine. Never exceed the maximum pressure that is marked on the manometer when using the spray gun. After use of the high-pressure circuit depressurise it. Never let the high-pressure hose spray outside a sewer, drain, or pipe. -

Page 12: Making Changes And Fabricate Spare Parts

2.14 Making changes and fabricate spare parts Changes to the machine are only permitted if Rioned has given written author- isation. The use of original spare parts and accessories are for the safety nec- essary. Rioned is not responsible for injuries or damages if other spare parts are used. -

Page 13: Technical Specifications

TECHNICAL SPECIFICATIONS General Description (symbol) Unit Dimensions see chapter 15.3 Dimensions page: 79 Weight : >440 kg Quantity water tank : 300 l (2x standard) Fill medium : Water Maximum temperature medium : 55 °C (333,15 K) Total length high-pressure hose : 60 m Total length supply hose : 35 m... - Page 14 Motor Description (symbol) Technical unit Type : Kubota V1505 Turbo Number of cylinder Bore x stroke (d x l) : 78 x 78,4 mm (3.07 x 3.09 in.) Power (P) : 32,7 kW at 3000 min-1 DIN 70020 Fuel : Diesel Cooling : Water cooled Weight (m)

-

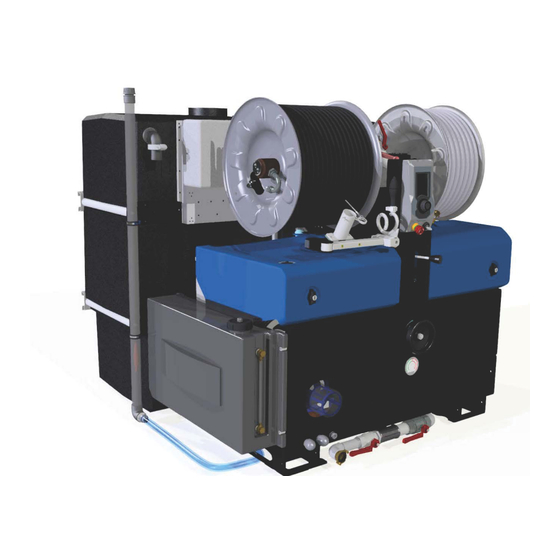

Page 15: Construction

CONSTRUCTION The high-pressure machine contains the following main parts: High-pressure hose on reel Supply hose on reel Reel locking device Control box Switch box Emergency stop High-pressure (HP) valve Supply pipe Water filter Drain valve/draw-off tap Pressure regulator Pressure gauge Swivel locking device Cap fix nipple Supply valve water filter... - Page 16 10/18...

- Page 17 10/18...

- Page 18 10/18...

- Page 19 10/18...

-

Page 20: Econtrolplus

eControlPlus 5.1 Control box: Corona Navigation bullets Function Tachometer Pointer ECO Mode Icons Left Icons Right Engine LED Engine symbol High Pressure LED High Pressure symbol Vacuum LED Vacuum symbol Navigator Emergency Stop Key (Off-Manual-Riomote) 10/18... - Page 21 10/18...

-

Page 22: Explanation Graphics (Only Econtrolplus)

Explanation Graphics (only eControlPlus) 10/18... -

Page 23: Corona

6.1 Corona The Corona is OFF (grey) unless: • The Control Unit is: Set to Riomote Control Error applicable Switched OFF by the Eco Start/ Stop-system Diesel engine: Pre Heat, Petrol engine: no function Run dry error Oil level 10/18... -

Page 24: Push Buttons

6.2 Push buttons When system is switched ON with the key (47), are lighted. is lighted on machines featuring a vacuum functionality. are lighted when the corresponding functionality is active, regardless Manual Control or Riomote Control. In case of “Run Dry”, is blinking with 1 ON/OFF cycle per second. - Page 25 10/18...

-

Page 26: Navigation Bullets

6.3 Navigation bullets The navigation bullet (32) has two general states: • Passive (Grey) • Active (Blue) Depending on the user’s location in the menu, one of them is on display or, in case of a pop-up, all navigation bullets disappear. Features in navigation bullets are in specified order, if applicable: •... -

Page 27: Function

6.4 Function A function (33) has two general states: • Passive (Grey) • Active (Blue) Depending on the user’s location in the menu, one of them is on display or, in case of a pop-up, all navigation bullets disappear. Regardless if a function is active, possible settings on display should always in- dicate its current status. -

Page 28: Tachometer

6.5 Tachometer The tachometer (34) has two general states: • Passive (default) • Passive (eco) • Active (default) • Active (eco) Depending on the user’s location in the menu, one of them is on display. The pointer which indicates the engine’s RPM should always display the current RPM. -

Page 29: Icons

6.6 Icons The icons always display the current status of the corresponding feature, regardless “Manual Control” or “Riomote Control”. Since the “Hose Reel” and “Spray Bar” are never used simultaneously, they share the same designated area on screen. • Pulsator on •... -

Page 30: Control

CONTROL If you control, maintain or inspect the machine, you must have the right qualifications for this job. If you do not have the necessarily knowledge, you may not use the machine. Further, you must convince yourself that you understand this manual thoroughly. -

Page 31: Before Starting

Stick in the cover lips into the openings. Lower the front side. Fasten the cover with the knob. Before starting Check the oil level in the engine, the oil reservoir and high-pressure pump using the dipsticks. Add oil, if necessary. Check the level of the fuel in the fuel tank. -

Page 32: Hydraulic Reel Control

Cleaning a wall, a terrace or floor: spray lance gun Hydraulic reel control By means of pushing the control lever upwards or downwards high-pressure hose can be unrolled or rolled up. Due to the proportional func- tioning of this valve you can also control the speed of the reel. By putting the lever into the position you can unroll the hose manually. -

Page 33: Hose Guide

Hose guide Purpose: To guide the HP hose into the sewer. To wind the HP hose on the reel drum. To keep the hose clean. Use: • Put the end of the hose through the opening of the hose guide. •... -

Page 34: Starting The Engine At The Back Of The Unit

Put on protection looking glasses and ear protectors before starting the machine. Start the machine. Proceed as follows: 7.9 Starting the engine at the back of the unit: Position key control box: • Insert key: • Position 1 (manual control): •... - Page 35 • Icon “Manual control ON” is displayed for 2 seconds. • Then the main menu is displayed • ECO mode is standard always active if option “ECO Start/ Stop” or “ECO Stop” is available. Check the error icon. If the error icon is visible, then go to See “Errors eControl”...

-

Page 36: Unclogging A Drain

7.10 Unclogging a drain Screw a suitable nozzle onto the high-pressure hose. Put the hose through the hose guide for safety manners (option). Unwind the hose a little. Put the nozzle into the drain that is to be cleaned. Screw the pressure regulator fully open (right). Open the high-pressure valve. -

Page 37: Cleaning A Wall, Terrace Or Floor

Important! Rewind hose onto reel under pressure to avoid crushing. If machine has run out of water, ensure hose is unwound before pressurizing. 7.10.2 Stop spraying: By eControl: Press button “High Pressure OFF”. • “High Pressure LED” extinguishes. • “High Pressure OFF” on display for 2 seconds. •... -

Page 38: Stop Working

working pressure. Never exceed the maximum pressure that is marked on the manometer when using the spray gun. Screw the spray gun including in the delivery onto the high-pressure hose. Fasten it by using the two spanners provided. COMPLETELY unroll the high-pressure hose. Attach the spay lance gun. -

Page 39: Additional Preparations When Preparing For Use

Drain the water tank and the water filter. Close the drain valve and mount the filter again. Put 25 l. antifreeze into the water tank. Open the supply valve to the water filter. Start the machine and let it idle. Note: it is not necessary to attach a gun to the high-pressure control. -

Page 40: Symbols

SYMBOLS Pressure gauge Maximum allowed pressure Danger zone Working area 10/18... -

Page 41: Security Sticker

Security sticker High-pressure valve Open and close the HP valve as follows: 10/18... -

Page 42: Options

OPTIONS Second HP- hose reel Purpose: Most used in smaller sewers/pipes or with spray-gun. Position: The second hose reel can be mounted at the machine instead of the supply reel hose. Total length 2 high-pressure hose can differ from, 50 m and higher. Pulsator system Purpose: With less water use, quicker to the stoppage. -

Page 43: Working Lamp

el to low, the solenoid opens. You are always sure of water during working with the machine. Installation: • Couple a supply hose on to the coupling of the supply pipe or use the supply hose. • Open the water tap. •... -

Page 44: Suction Ventury

The locking pin is released and the HP reel can turn freely without resistance. To get the HP reel in hydraulics you put the device in position “B”. The pin gets back in locking position and you can use the hydraulics again. Suction Ventury Purpose: The suction ventury takes care that you can pump dirt and/or liquid out of res-... -

Page 45: Anti-Freeze With Anti Freeze Tank

ervoirs. HP-hose Preparations: You must always check if there is enough water in the water tank. Use: • Connect the HP hose onto the coupling of the suction ventury (see il- lustration A). • Place the suction ventury in a reservoir. •... - Page 46 Push button on the control box. Let the high-pressure pump remove all the water, which is still in the high-pressure hose and pump. Close the high-pressure valve or push button , when anti freeze flows out of the HP hose (watch the colour of the water). Connect the HP-hose (with special connection) to the supply hose.

-

Page 47: Options Econtrol

Options eControl 10.1 Winding the HP Hose Reel 10.1.1 Via eControlPlus The engine must run to use this function! Push the Navigator (45) to activate the navigation menu. Turn the Navigator clockwise and set the naviga- tion bullet to position “HP Hose Reel”. Push the Navigator to activate the function. - Page 48 • Clockwise for unwind the HP hose Push the Navigator to rotate the reel. (38) • Symbol lightens when pushing the Navi- gator. Release the Navigator to stop the rotation. (38) • Symbol disappears when releasing the Navigator. Ending function HP hose Reel Turn the Navigator and set the switch to position “neutral”.

- Page 49 10.1.3 Wind via Riomote See to it that the engine runs. Push the button or set handle to position “Wind” on the Riomote. 10/18...

-

Page 50: Pulsator System

10.2 Pulsator system Not possible on ProfiJet T4 10.2.1 Pulsator On via eControl The engine must run to use this function! Turn the Navigator (45) clockwise and set the navigation bullet to position 2 “Pulsator”. Push the Navigator to activate the option. •... - Page 51 10.2.2 Pulsator OFF via eControl Press button “High Pressure OFF” (42) (see chapter 4.3.2 "Stop spraying:" page.: 23) Turn the Navigator clockwise and set the naviga- tion bullet to position 2 “Pulsator”. Push the Navigator to activate the option. • Navigation bullet extinguishes •...

- Page 52 • Navigation bullet lightens blue 10.2.3 Pulsator ON and RPM Control Push the Navigator (45) to deactivate the func- tion. • Pulsator icon extinguishes • Navigation bullet lightens blue Go to “Home” or press the “Engine symbol” • Tachometer lightens (see chapter 6.5 "Tachometer" page.: 28) Control throttle by turning the Navigator clock- wise (RPM+) or counter-clockwise (RPM-).

-

Page 53: Eco Mode Off

10.3 ECO mode OFF To change the ECO mode, the engine must run! ECO mode is standard always ON if function is available on machine. Turn the Navigator (45) clockwise and set the navigation bullet to position 5 “Eco Mode”. Push the Navigator to activate the function. - Page 54 • “Eco Mode” icon extinguishes • Navigation bullet lightens blue • “Eco Mode” icon disappears Wait 2 seconds! • “Hours Total” is displayed. 10/18...

-

Page 55: Eco Versions

10.4 ECO versions The ECO mode has two versions: ECO Start/Stop ECO Stop 10.4.1 ECO Start/Stop behaviour: Stop: • Press “High pressure OFF”: Water stops spraying RPM engine decreases. Engine stops after 30 seconds if no activity takes place. Start: •... -

Page 56: Riomote Control

10.5 Riomote Control Purpose: To operate the high-pressure machine from a distance. 10.5.1 Emergency stop test Check before working with the Riomote Control if the emergency stop works well. Proceed as follows: Put the key into the keyhole. Turn the key to position 2 “Radio Control ON”. •... - Page 57 • Start the engine by means of button “START” • Push the “STOP” button The machine has to cut off now. If this is not the case it is not allowed to work with the Riomote Control. Contact your supplier. 10.5.2 Battery If the indication on the Riomote Control starts burning it's indi-...

-

Page 58: Management

10.6 Management Turn the Navigator (45) clockwise and set the navigation bullet to position 6 “Management”. Push the Navigator to activate the function. • Navigation bullet extinguishes. • Management underline lightens. Software version. • Press Navigator shows actual software settings •... -

Page 59: Unwinding Manually Of The Econtrol Driven Hose Reel

10.7 Unwinding manually of the eControl driven hose reel Your machine could be fitted with a mechanical free-wheel locking device. With this device you can put the HP hose reel in “complete free-wheel position” or in “eControl”. If you want to unwind manually you put the device in position “A”. The locking pin is released and the HP reel can turn freely without resistance. - Page 60 10/18...

-

Page 61: Maintenance

MAINTENANCE Attention! Always stop the engine first and depressurize the system before serving or repairing the machine. To depressurize the system, you open the HP valve. If the spray lance gun is attached you must also pull the trigger. 11.1 Daily maintenance Oil level Check all oil levels once a week. -

Page 62: Hydraulic System

Check the torque of the attachment bolts for the engine; tighten them, if necessary. For more information concerning the engine, you can find it in the book deliv- ered with this machine. Carriage: Lubricate all mechanical moving parts in the system. Check that all nuts and bolts have been correctly tightened. -

Page 63: Extensive Periodical Maintenance

To let the oil out of the reservoir you unscrew plug D. Catch the oil in a bucket. 11.5 Extensive periodical maintenance Have the high-pressure machine checked and maintained from time to time by the technical service of Rioned. In this way, long life and quality will be guar- anteed. 11.6 Maintenance scheme... - Page 64 Puncture nozzle holes : Every 50 working hours Replace all parts immediately if there is wastage or defect. 10/18...

-

Page 65: Troubleshooting

TROUBLESHOOTING Failure Reason Solution Engine does not start or stops Machine has run out of fuel Add fuel abruptly. Main or secondary fuse blown Replace the defect fuse and restart engine. If problem repeats, contact your dealer Battery voltage too low. Load or replace. - Page 66 Failure Reason Solution Pressure varies. Water level in tank too low Stop the engine, refill the tank and restart engine Water supply valve not sufficiently Open the supply valve completely opened Water filter clogged. Stop the machine and clean the filter Pump sucks air Stop the machine and check all hoses and couplings for leakage...

- Page 67 Failure Reason Solution Certain functions are not exe- Receiver is faulty Contact your supplier cuted Interruption in electric circuit Check all plugs. Plug in and push. Check control lights if functions are indicated 10/18...

-

Page 68: Errors Econtrol

Errors eControl 13.1 Emergency stop A pop-up notifies the user that Emergency Stop is pushed. Engine, High Pressure, Vacuum, Pulsator, Hose Reel and/or Spray Bar are switched OFF. Eco Mode is switched ON. The user can only restart operation by releasing (rotate) the Emergency Stop. 13.2 Temperature engine A pop-up notifies the user of the error. -

Page 69: Temperature Transmission

13.3 Temperature Transmission A pop-up notifies the user of the error. Whilst applicable, the error is also listed under “Management” (see chapter 10.6 "Management" page.: 58). Engine, High Pressure, Vacuum, Pulsator, Hose Reel and/or Spray Bar are switched OFF. Eco Mode remains unchanged. The user can dismiss the pop-up by pushing the Navigator in Manual Control. -

Page 70: Temperature Heat Exchange

13.5 Temperature Heat Exchange A pop-up notifies the user of the error. Whilst applicable, the error is also listed under “Management” (see chapter 10.6 "Management" page.: 58). Engine, High Pressure, Vacuum, Pulsator, Hose Reel are switched OFF. Eco Mode remains unchanged. The user can dismiss the pop-up by pushing the Navigator in Manual Control. -

Page 71: Oil Level

13.7 Oil level A pop-up notifies the user of the error. Whilst applicable, the error is also listed under “Management” (see chapter 10.6 "Management" page.: 58). If running, Engine to stationary. High Pressure, Vacuum, Pulsator, Hose Reel are switched OFF. Eco Mode remains unchanged. -

Page 72: Battery Charge

13.9 Battery Charge A pop-up notifies the user of the error. Whilst applicable, the error is also listed under “Management” (see chapter 10.6 "Management" page.: 58). Engine, High Pressure, Vacuum, Pulsator, Hose Reel and/or Eco Mode remain unchanged. The user can dismiss the pop-up by pushing the Navigator in Manual Control. 13.10 Run Dry A pop-up notifies the user of the warning. -

Page 73: Water Level Maximum

13.11 Water Level Maximum Only available if option “Electronic Water Level control” is mounted. A pop-up notifies the user of the warning. Whilst applicable, the error is also listed under “Management” (see chapter 10.6 "Management" page.: 58). Engine, High Pressure, Vacuum, Pulsator, Hose Reel and/or Eco Mode remain unchanged. -

Page 74: Exploded Views And Part Lists

EXPLODED VIEWS AND PART LISTS 10/18... -

Page 75: Exploded View Pump P45(60L-250B)

14.1 Exploded view Pump P45(60L-250B). 10/18... -

Page 76: Pressure Regulator Ulh 261

14.2 Pressure regulator ULH 261 Item No. Qty Order number Factory No. Description 1 67-262-101-001 01-0630 Casing 1 67-262-101-002 07-2788 Guide Plug 1 67-262-101-102 06-1131 Guide ring 1 67-262-101-003 06-0255 O-Ring 1 67-262-101-005 11-0477 Piston Rod 1 67-262-101-006 06-1129 O-Ring for 5 1 67-262-101-007 00-6113 Support Ring for 6... -

Page 77: Appendix

15.1 EC declaration Of Conformity For Machinery RIOR B.V. / RIONED Centaurusweg 45, Tilburg, The Netherlands, Herewith declares that: High pressure device RIONED UrbanJet, Machine number: • is in compliance with the Machinery Directive (2006/42/EC); • is in conformity with the provisions of the following other EEC direc-... -

Page 78: Sales Managers

Sales Managers EXPORT D.Maas Area Sales Manager Centaurusweg 45 5015 TC Tilburg Tel.: +31 13-547 91 00 Fax: +31 13-547 91 04 THE NETHERLANDS Rioned Centaurusweg 45 50115 TC Tilburg Tel.: +31 13-547 91 00 Fax: +31 13-547 91 04 10/18... -

Page 79: Dimensions

15.3 Dimensions 10/18... -

Page 80: Index

....9 accessories ....12 antifreeze ..39 attention ....37 responsible ..... 9 hours till service ..58 rioned ..2 caution ....37 copyright ....2 injuries ....12 sales managers ..78 security covers ..9 sharp objects ..37 special repair couplings days till service ..58...

Need help?

Do you have a question about the UrbanJet and is the answer not in the manual?

Questions and answers