Summary of Contents for Peri Trio

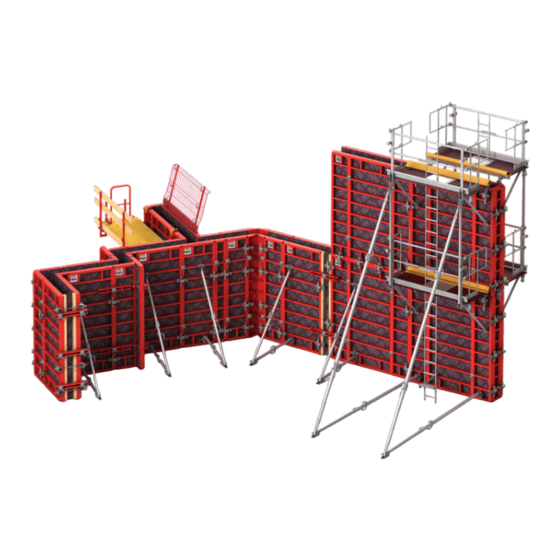

- Page 1 TRIO Panel Formwork Instructions for Assembly and Use – Standard Confi guration Edition 01 | 2017...

-

Page 3: Table Of Contents

Content Overview Working and concreting platforms Main components – Concreting Platform TRIO 120 x 270 – Bracket System – MAXIMO MXK Presentational reference – Scaffold Brackets TRG 80 and TRG 120 Introduction – Guardrail Post Holder TRIO Target groups Extensions Additional technical documentation –... -

Page 4: Overview

A15 Parapets, Foundations, Beams A5 Tie Technology A16 Circular structures A6 Push-Pull Props, Kickers A17 Shaft formwork A7 90° Corners A8 Oblique angles B1 TRIO 330 A9 T-Junctions B2 TRIO Alu A10 Offsets B3 TRIO Structure A11 Length compensations A12 Stopend formwork... -

Page 5: Key

For a better understanding, detailed illustrations are partly incomplete. The safety installations which have possibly not been featured in these detailed drawings must nevertheless still be available. TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 7: Introduction

– Lifting Gear Combi MX – Lifting Gear MX – Pallets and Stacking Devices – Concrete Cones – PERI Bio Clean Data Sheet: Anchor Bolt PERI 14/20 x 130 ƒ PERI Design Tables – Formwork and Shoring ƒ Brochure: TRIO ƒ... -

Page 8: Intended Use

2.70 m (steel and aluminium) 40 cm including Push-Pull Props and 1.20 m (steel) safety equipment. PERI TRIO is a panel formwork used 0.90 m (aluminium) for forming walls and columns with 0.60 m (steel) As anchor systems, DW 15 or DW 20 different dimensions. -

Page 9: Care And Maintenance Instructions

Never clean powder-coated components, e.g. panels and accessories, with a steel brush or hard metal scraper; this ensures that the powder-coating remains intact. TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 10: Safety Instructions

Instructions for Assembly and Use sup- risk assessment has been carried out the contractor must create installation plied by PERI are available at all times by the contractor. instructions in order to ensure safe and understood by the site personnel. -

Page 11: System-Specific 7 A16

PERI design no persons are allowed to remain ƒ tables. under the suspended load. -

Page 12: A1 Storage And Transportation

117321 Perm. load-bearing capacity 650 kg/device = 2.6 t/stack Number of panels per stack 2 – 5 TRIO Panels of one size Crane sling angle ß ≤ 45° 4-sling lifting gear L = 3.0 m (Fig. A1.02) Max. stacking height 3 stacking devices on top of each other Fig. - Page 13 – During moving operations, no persons are allowed to remain under the suspended load. – Ensure transport units are correctly stacked and secured. – Use PERI lifting accessories and slings. – Use the designated load-bearing points on the components. – Store, transport and move...

-

Page 14: Setting Down Panels Individually 10 B1

(12), the locking pins of the Lifting Gear Combi (11) can also be inserted into the drilled holes of the panels. Fig. A1.04a Fig. A1.04b View “X” Ground Fig. A1.05 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 15: Turning Panels Individually

Ensure that the chain is always tensioned! The bottom panel is already placed in position with the formlining facing downward and does not have to be turned. Fig. A1.07 Frame side Fig. A1.08 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 16: Transportation On The Construction Site

6. Lift up stack with the crane. If necessary, clean tie holes and The tie rods prevent the panels from holes on the side for the locking pins. moving. (Fig. A1.09) Fig. A1.09a TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 17: Putting Loads Into The Stacking Device

Stacking devices (1) – are suitable for lifting by crane or forklift, Fig. A1.10 – can also be moved with the PERI Pallet Lifting Trolley, – can be lifted both from the longitudinal and front sides. 1. Place the first panel with the... -

Page 18: Stacking Aid Trio Corner

Stacking aids are to be used only in conjunction with transportation straps. Pos. Component Item no. Stacking Aid TRIO Corner 124554 Stacking Aid TRIO Corner LI 128313 Stacking Aid TRIO Corner RE 128494 Fig. A1.12b Fig. A1.12c (Fig. A1.12a + A1.12b + A1.12c) Installation Take into account there are right and left versions. -

Page 19: A2 Standard Operating Sequence

– Follow Instructions for Use for Lifting Hook MAXIMO 1.5 t! Fig. A2.01 1. Mount Brace Connector TRIO on the horizontal panel, see Section A6. 2. Mount Push-Pull Prop, see Section A6. – on the first panel: 2 Push-Pull Props. - Page 20 7. Release the 2-sling lifting gear. Forming from the external or internal corner in the direction of the compensation. Concreting From a working scaffold. Fig. A2.04 (Fig. A2.05) Fig. A2.05 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 21 3. Dismantle the Tie System DW 15/20. 4. Release panel connection. 5. Release panel from the concrete, e.g. with the stripping bar.g. (Fig. A2.06) Fig. A2.06 6. Carefully lay the panel down and clean. TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 22 3. Install Tie System DW 15/20. 4. Release crane lifting gear. 5. Mount the working and concreting platform. (Fig. A2.08) Cleaning – With PERI Bio Clean and PERI spraying equipment. – Follow Instructions for Use. Fig. A2.08 TRIO Panel Formwork...

-

Page 23: A3 Panels

S) N) A) M) S) Panels with steel frames (red powder-coated) N) Standard panels or multi-purpose panels A) Panels with aluminium frames (yellow powder-coated) M) Panels only as multi-purpose panels TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... - Page 24 10.4 Connecting holes for Scaffold Brackets, Push-Pull-Props and other accessories (Fig. A3.03b + A3.03c) 10.5 Levering corner (Fig. A3.03a) 10.6 Connecting holes for transportation 10.7 Frame 10.8 Plywood formlining TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

-

Page 25: A4 Panel Connections

4. Close sliding part. Continuous adjustment using the keyway (20.4) is possible. 5. Secure wedge. (Fig. A4.04) The Alignment Coupler BFD (20) is 20.5 now mounted. Fig. A4.03 10.3 Fig. A4.04 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 26: Compensation Waler Tar 85

Waler 85 For stopend formwork. (Fig. A4.07) Assembly 1. Push Stopend Tie TS (25) through the TRIO Waler 85 (24) and attach to the frame profiles of the panels. 2. Tighten by means of the Wingnut Pivot Plate (33). (Fig. A4.08) Fig. -

Page 27: Tie System Dw 15 (Standard)

Due to their conical shape, tie holes in the panels which are filled with concrete can be freed with a hammer blow. (Fig. A5.04) Fig. A5.04 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 28: Inclined Anchorage With Dw

Fig. A5.06 Fig. A5.07 Fig. A5.08 Inclined on one side Inclined on both sides Height offset max. 3° max. 2 x 3° max. 1 cm per 10 cm wall thickness TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 29: A6 Push-Pull Props

A6 Push-Pull Props Brace Connector TRIO 41.1 Push-Pull Props and Kickers are attached to the panel with the Brace Connector TRIO. Connecting to both horizontal and vertical panel struts is possible. 41.2 Pos. Component Fig. A6.01 41 Brace Connector (Fig. A6.01) Assembly 1. - Page 30 1. Attach Push-Pull Prop or Kicker with bolt and cotter pin to the Brace Connector TRIO. (Fig. A6.04a) 2. Mount Base Plate, e.g. with PERI Anchor Bolt 14/20 x 130 or similar (42). (Fig. A6.04b) Take into consideration the Data Sheet for PERI Anchor Bolt 14/20 x 130.

-

Page 31: A7 Corners

External corner consisting of: Internal corner consisting of: As seen from the outside, the Panel – Panel TR 60 (14) – TRIO Inside Corner TE (5) or Internal TR 72 (15) must always be positioned – Panel TR 72 (15) Corner TAE (Alu) on the right and Panel TR 60 (14) –... - Page 32 L of 3.0 m per panel joint – Universal Waler 245 (26) with Waler Stop (27) and Tie Yoke (28) (Fig. A7.06 + A7.06a) Fig. A7.06 Fig. A7.06a TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

-

Page 33: A8 Oblique Angles

(Fig. A8.01) Alignment Couplers BFD are to be mounted from bottom to top on both external and internal formwork. For the number of Alignment Couplers BFD for other panel heights, see TRIO min. 75° max. 165° Poster. Fig. A8.01 Internal formwork... -

Page 34: A9 T-Junctions

Walers 85 (24) with Stopend Tie TS (25) and Top Tie Bracket AH (55) with tie sets, see Section A12 Stopend formwork with timbers. (Fig. A9.02) Fig. A9.02 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 35: Obtuse-Angle Wall Connections

(Fig. A9.04) TRM 72 TRM 72 Fig. A9.04 With Wall Thickness Compensator WDA (18) or timbers. (Fig. A9.05) Fig. A9.05 With Cam Nut DW 15 (19). (Fig. A9.06) Fig. A9.06 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 36: A10 Offsets

(Fig. A10.01) 25 14 Wall offset 21 – 80 cm Consisting of inside and outside corners. Pos. Components TRIO Inside Corner TE 14 Panel TR 60 22 Multi Panel TRM 72 23 Compensation Waler TAR 85 25 Stopend Tie TS 50 Compensation provided by contractor (Fig. -

Page 37: Height Offsets

Height offsets For height offsets: depending on the offset, Alignment Couplers BFD (20) are mounted alternately on the frame struts of the right and left panels. (Fig. A10.05) Fig. A10.05 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 38: A11 Length Compensations

Fig. A11.02a The bottom Compensation Waler TAR 85 (23) must be mounted in the strut with the hooks from below if a TRIO Panel is installed on the opposite side, e.g. Multi Panel TRM 72. (Fig. A11.02b) Fig. A11.02 Fig. A11.02b TRIO Panel Formwork Instructions for Assembly and Use –... -

Page 39: Trio Filler Profile Tpp

A11 Length compensations TRIO Filler Profile TPP Compensations from 20 to 36 cm Consisting of: – Filler Profile TPP (53) (2x) – Plywood filler 21 mm (51) (Fig. A11.03a) Anchoring is to take place so that the anchor forces are transferred in the middle through the Compensation Waler TAR 85 (23) to the adjacent panel. -

Page 40: A12 Stopend Formwork

Fig. A12.01 Timbers and filler plywood For all wall thicknesses The concrete pressure from the stopend formwork is transferred with the TRIO Stopend Tie TS and Walers 85 to the TRIO Panels. For use with panel widths < 2.40 m at the wall end. -

Page 41: Stopend Panel Without Water Bar

- b - Ø Reinforcement H = 2.70 m and 1.20 m Required components: – 2 x Stopend Panel TRIO AT 3/AT 5 (56) for approx. 2.5 cm/5 cm concrete cover – 1 x Stopend Panel TRIO MT (57) (Fig. A12.03) Assembly 1. -

Page 42: Stopend Panel With Water Bar

A12 Stopend formwork Stopend panel with water H = 2.70 m and 1.20 m Required components: – 2 x Stopend Panel TRIO AT 3 (56) Fig. A12.06a for approx. 2.5 cm or AT 5 for approx. 5 cm concrete cover respectively –... -

Page 43: Stopend Waler Height 270

Perm. fresh concrete pressure 60 kN/m² height 270 The fresh concrete pressure of the stopend formwork is transferred to the TRIO Panels by means of the Stopend Walers. Wall end with Panels 270 x width Valid for TRIO Panels: 270 x 30/45/60/90/120/240 Shown: 270 x 120 „X"... -

Page 44: Stopend Waler Height 330

Perm. fresh concrete pressure 80 kN/m² Perm. fresh concrete pressure 60 kN/m² The fresh concrete pressure of the stopend formwork is transferred to the TRIO Panels by means of the Stopend „X" Walers. Wall end with Panels 330 x width... -

Page 45: A13 Working And Concreting Platforms

Perm. load: 150 kg/m² Load Class 2 according to DIN EN 12811-1. Fig. A13.01 The load-bearing points of the Fig. A13.01b Concreting Platform TRIO 120 x 270 58.2 are coloured yellow. Fig. A13.01a Pos. Components Item no. TRIO Panel according to size 10.7 Frame profile... - Page 46 A13 Working and concreting platforms Assembly on panel 58.5 Do not stand under suspended 10.7 loads. 1. Attach the TRIO Concreting Platform Fig. A13.04a with the suspension beam to the top frame profile. Guide from below using guide rope. (Fig. A13.04) 2.

- Page 47 2. Incline the guardrail (58.1) backwards, max. 15°. 3. Install securing pin (58.2) and secure 58.2 58.2 with cotter pin. Guardrail is now in an inclined position. (Fig. A13.06) Fig. A13.05 Fig. A13.06 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 48 62.3 Sliding sleeve 62.4 Eyebolt 62.5 Guardrail Extension Fig. A13.07a Fig. A13.07b Fig. A13.07c Fig. A13.07d 62.6 Retaining claw 62.7 Lug End Guardrail MXP right 115946 left 115945 69.1 Bolt TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 49 5. Push the sliding sleeve (62.3) downwards. The suspension beam is now Fig. A13.08 engaged. (Fig. A13.08c + A13.08d) 62.4 Fig. A13.08a Fig. A13.08b Fig. A13.08c Fig. A13.08d TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 50 (62.7) are outside of the guardrail. (Fig. A13.10 + A13.10a + A13.10b) Fig. A13.10a Fig. A13.10 62.5 62.7 Fig. A13.10b Fig. A13.10c (without crane chain) TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 51 (Fig. A13.12a) 2. Remove 4-sling lifting gear. 10.2 The retaining claw (62.6) grips the frame profile and concreting Fig. A13.12a platform is secured. (Fig. A13.12 + A13.12a) Fig. A13.12 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 52 Fig. A13.14b Fig. A13.14c Fig. A13.14d (Fig. A13.14 + A13.14a + A13.14b) 4. Push the sliding sleeve downwards. (Fig. A13.14c) The suspension beam is now engaged. (Fig. A13.14d) TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 53 (Along the same lines as the Concreting Platform MX 100 x 240.) 2. Remove 4-sling lifting gear. The retaining claw (63.3) grips the frame profile and concreting platform is secured. (Fig. A13.12a) TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 54 MX 100 x 100 (63) for 90° corners on the internal formwork. Subsequently mount the Concreting Platform MX 100 x 240 (62) in both directions. (Fig. A13.18) Fig. A13.18 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

-

Page 55: Bracket System - Maximo Mxk

Regarding the assembly and widths of influence, see design information for the Scaffold Bracket MXK-RS! Pos. Components Item no. Scaffold Bracket MXK-RS 126540 Guardrail Post MXK 126360 Fig. A13.19a (Fig. A13.19a) TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 56: Scaffold Brackets Trg 80 And Trg

A13 Working and concreting platforms Scaffold Brackets TRG 80 and TRG 120 A concreting platform is mounted on the TRIO Panels using the Scaffold Brackets TRG 80 and TRG 120 (61). Technical data – Perm. load: 150 kg/m² Load Class 2 according to DIN EN 12811-1 –... -

Page 57: Guardrail Post Holder Trio

– Guardrail Post HSGP-2 (66) (Fig. A13.22 + A13.22a) Technical data Max. width of influence 1.35 m Assembly 1. Hook in Guardrail Post Holder TRIO (65) into the connecting holes of the vertical struts of the panels. 2. Secure with cotter pin. Fig. A13.22 3. -

Page 58: A14 Extensions

(Fig. A14.01a – d) For extension possibilities, number and arrangement of Alignment Couplers BFD, Compensation Walers TAR 85 and formwork ties, see TRIO poster. Fig. A14.01a Fig. A14.01b Fig. A14.01c Pre-assemble extension units in a horizontal position, with the formlining facing downwards, on a flat assembly surface. -

Page 59: Extensions Up To H = 8.10 M

(Fig. A14.03a + A14.03b) For extension possibilities, number and arrangement of Alignment Couplers BFD, Compensation Walers TAR 85 and formwork ties, see TRIO poster. Pre-assemble extension units in a horizontal position, with the formlining facing downwards, on a flat assembly surface. -

Page 60: A15 Parapets, Foundations, Beams

2. Press the Safety Hook (70.1) down- wards over the edge profile and the panel strut of the formwork. Tension and Compression Brace is locked in position. Fig. A15.02 TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration... -

Page 61: Foundation Tie Clamp Trio Tls

Required length of the Perforated Foundation Tie: Foundation width + 50 cm. Assembly 1. Place TRIO Panels on the Perforated Foundation Tie (86). 2. Attach Foundation Tie Clamp TRIO TLS (85) to the bottom connection hole by means of bolts (85.1). -

Page 62: Foundation Strap Trio

The Foundation Strap (75) is used for forming individual foundations using the “windmill configuration“. (Fig. A15.04 + A15.04a) Pos. Components Quantity 10 Panel TRIO height x width 75 Foundation Strap TRIO 76 Locating board H [cm] Fig. A15.04a perm. B [cm] Fig. -

Page 63: Circular Structures

A16 Circular structures Polygonally formed 2,6° 2,6° TRIO Panels Circular structures can be formed with TRIO by using the corresponding panel widths and filler timber. See table below. 2,6° 2,6° Anchoring takes place by means of filler timber. min. 4 cm Fig. -

Page 64: Shaft Formwork

(Fig. A17.02) – Panel TR 30 is secured using the inner drilled holes. – With TRIO Panel TR 60, 72, 90 and 120, secure in the outer bore hole. 3. Transport panel unit to place of use and attach to the internal formwork with the Alignment Couplers BFD. - Page 65 Extensions Place shaft elements on top of each 90.2 other and secure with bolts (90.2). (Fig. A17.07a + A17.07b) Fig. A17.07a Fig. A17.07b TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 66 A17 Shaft formwork Not permissible for other formwork systems. Shaft Corner TRIO 330 (Fig. A11.01) Pos. Components Item no. Shaft Corner TRIO 330 129945 89.6 Hole of the lug Horizontally pre-assemble the shaft formwork. (Fig. A17.09a) Fig. A17.08 89.6 Do not attach the crane hook into the lug hole (89.6)!

- Page 67 1.5 t. – Follow Instructions for Use for the Lifting Hook MAXIMO 1.5 t. Lifting Hook MAXIMO 1.5 t For use with: two Shaft Corners TRIO (89) and two TRIO Corners TE (5) height 270/330. (Not shown) Pos. Components Fig. A17.09a...

- Page 68 A17 Shaft formwork Height 270 Shaft Corner TRIO Two TRIO Shaft Corners 330 and two Corners TE 270-2 Height 270 Wall thickness 150/200/250 Internal shaft wall Pos. Components Item no. 6 Corner TE 270-2 022580 20 Alignment Coupler BFD 023500...

- Page 69 Height 270 Wall thickness 150/200/250 Internal shaft wall Pos. Components Item no. 20 Alignment Coupler BFD 023500 45 Panel TRIO 270 x 120 022510 89 Shaft Corner TRIO 330 129945 Arrangement of the Alignment Couplers BFD Shown: – Shaft dimensions 2.50 m x 2.50 m –...

- Page 70 A17 Shaft formwork Height 3300 Shaft Corner TRIO Two TRIO Shaft Corners 330 and two Corners TE/4 330 Height 330 Wall thickness 150/200/250 Internal shaft wall Pos. Components Item no. 7 Corner TE/4 330 054374 20 Alignment Coupler BFD 023500...

- Page 71 Height 330 Wall thickness 150/200/250 Internal shaft wall Pos. Components Item no. 20 Alignment Coupler BFD 023500 46 Panel TRIO 330 x 120 054314 89 Shaft Corner TRIO 330 129945 Arrangement of the Alignment Couplers BFD Shown: – Shaft dimensions 2.50 m x 2.50 m –...

- Page 72 (Fig. A17.05 + A17.05a + A17.05b) 5. Pull the complete internal formwork upwards and move. Fig. A17.05b 1) Closing formwork is the external formwork Fig. A17.05 of the shaft. TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

- Page 73 A17 Shaft formwork There are two possibilities for constructing a shaft: With two Shaft Corners TRIO ƒ With four Shaft Corners TRIO ƒ The option to be used is project-specifi- cally determined. It depends on: the striking clearance ƒ 10 cm the weight per shaft and ƒ...

- Page 74 A17 Shaft formwork Wall thicknesses Dimensions in the illustrations of the wall thicknesses (WD) are given in mm. Shaft with Shaft with two Shaft Corners TRIO four Shaft Corners TRIO Wall thickness 150 (Fig. A17.08a + A17.08b) Fig. A17.08b Fig. A17.08a Wall thickness 200 (Fig.

- Page 75 The holes are congruent. 3. Insert bolts (89.3) through the congruent holes and secure with cotter pins. (Fig. A17.11 + A17.11c) Fig. A17.11a Fig. A17.11b 89.3 Fig. A17.11 Fig. A17.11c TRIO Panel Formwork Instructions for Assembly and Use – Standard Configuration...

-

Page 76: Standard Joint

B1 TRIO 330 Standard joint Panel connection with 3 x Alignment Coupler BFD (20). (Fig. B1.01) For concreting height 3.30 m, only anchor rows are to be used. Fig. B1.01 Combination 330 + 270 h = 330 with h = 270 (Fig. -

Page 77: Obtuse And Acute-Angled Corners

B1 TRIO 330 Obtuse and acute-angled corners Inside Panel connection per side with Outside 5 x Alignment Coupler BFD (20). Panel connection per side with (Fig. B1.05) 8 x Alignment Coupler BFD (20) and 2 x Compensation Waler TAR 85 (23). -

Page 78: Extensions Up To H = 5.40 M

Alignment Couplers Fig. B1.07a Fig. B1.07b BFD, Compensation Walers TAR 85 and formwork ties, see TRIO poster 330. Pre-assemble extension units in a horizontal position, with the formlining facing downwards, on a flat assembly surface. Place timbers or the like underneath. -

Page 79: Extensions Up To H = 8.10 M

(Fig. B1.08a + B1.08b + B1.08c) For extension possibilities, number and arrangement of Alignment Couplers BFD, Compensation Walers TAR 85 and formwork ties, see TRIO poster 330. Pre-assemble extension units in a Fig. B1.08a Fig. B1.08b horizontal position, with the formlining facing downwards, on a flat assembly surface. -

Page 80: Trio Aluminium Panels

– For extensions in connection with steel panels, the aluminium panels must always be used on top! – When using TRIO Alu Panels, the same formwork guidelines apply as for the TRIO 270 Steel. – TRIO Alu Panels can be combined with steel panels. -

Page 81: Trio Structure

(Fig. B3.01) When using TRIO Struture Panels, the same formwork guidelines apply as for the TRIO 270 Steel. It can be fully combined with TRIO 270 and TRIO 330 Steel. Fig. B3.01 Assembly of profiled boards Fixing can be done from either the front or the back. -

Page 82: Trio Panel Formwork

TRIO Panel Formwork Item no. Weight kg 054304 399.000 Panel TR/4 330 x 240 Steel panel with 18 mm plywood. 1320 2400 054314 196.000 Panel TR/4 330 x 120 Steel panel with 18 mm plywood. 1200 Panel TR/4 330 x 90 054324 138.000... - Page 83 TRIO Panel Formwork Item no. Weight kg 054334 118.000 Panel TR/4 330 x 72 Steel panel with 18 mm plywood. 054354 106.000 Panel TR/4 330 x 60 Steel panel with 18 mm plywood. Panel TR/4 330 x 30 054364 73.400...

- Page 84 TRIO Panel Formwork Item no. Weight kg 054344 134.000 Multi Panel TRM/4 330 x 72 Complete with Steel panel with 18 mm plywood. For oblique 88 pc. 030300 Plug Ø 20/24 mm angles, wall connections etc. 19 x 30 = 054374 85.800...

- Page 85 TRIO Panel Formwork Item no. Weight kg Wall Thickness Comp. WDA/4 330 054391 20.100 Wall Thickness Comp. WDA/4 330 x 5 054401 21.400 Wall Thickness Comp. WDA/4 330 x 6 054435 12.400 Wall Thickness Comp. WDA/4 330 x 10, Alu For adjusting to wall thicknesses.

- Page 86 TRIO Panel Formwork Item no. Weight kg 023050 62.300 Stopend Panel TR/4 330 x 24 Steel panel with 18 mm plywood. 054384 62.200 Filler Plate LA/4 330 x 36 For continuous compensations from 6 to 36 cm. Ø24 Filler Support TPA 330 054430 6.400...

- Page 87 TRIO Panel Formwork Item no. Weight kg 101829 9.820 Filler Profile TPP 330, Alu For compensation with 21 mm filler plates. 022570 330.000 Panel TR 270 x 240 Steel panel with 18 mm plywood. 1320 2400 Panel TR 270 x 120 022510 162.000...

- Page 88 TRIO Panel Formwork Item no. Weight kg 022520 114.000 Panel TR 270 x 90 Steel panel with 18 mm plywood. 022530 97.200 Panel TR 270 x 72 Steel panel with 18 mm plywood. Panel TR 270 x 60 022550 87.400...

- Page 89 TRIO Panel Formwork Item no. Weight kg 022560 59.500 Panel TR 270 x 30 Steel panel with 18 mm plywood. 022540 103.000 Multi Panel TRM 270 x 72 Complete with Steel panel with 18 mm plywood. For oblique 44 pc. 030300 Plug Ø 20/24 mm angles, wall connections etc.

- Page 90 TRIO Panel Formwork Item no. Weight kg 103317 56.900 Internal Corner TEI 270/135° Steel panel with 18 mm plywood. For 135° internal corners. 103337 76.500 Outside Corner TEA 270/135° Steel panel with 18 mm plywood. For 135° external corners. Articulated Corner TGE 270 023200 94.900...

- Page 91 TRIO Panel Formwork Item no. Weight kg 023040 50.500 Stopend Panel TR 270 x 24 Steel panel with 18 mm plywood. 105523 127.000 Shaft Element TSE 270 Complete with Panel for moving complete shaft internal 7 pc. 105400 Pin Ø 20 x 140, galv.

- Page 92 TRIO Panel Formwork Item no. Weight kg Wall Thickness Comp. WDA 270 023182 16.200 Wall Thickness Comp. WDA-2 270 x 5 023192 17.200 Wall Thickness Comp. WDA-2 270 x 6 023995 10.100 Wall Thickness Comp. WDA 270 x 10, Alu For adjusting to wall thicknesses.

- Page 93 TRIO Panel Formwork Item no. Weight kg 101813 8.040 Filler Profile TPP 270, Alu For compensation with 21 mm filler plates. Stopend Panels TRIO MT w/o waterstop bar 023061 26.500 Stopend Panel TRIO MT 270 x 20 023062 30.400 Stopend Panel TRIO MT 270 x 24/25...

- Page 94 TRIO Panel Formwork Item no. Weight kg Stopend Panels TRIO AT Note 023060 17.200 Stopend Panel TRIO AT 270 x 3 Concrete cover approx. 30 or 50 mm. 105953 19.000 Stopend Panel TRIO AT 270 x 5 External piece for stopend formwork.

- Page 95 TRIO Panel Formwork Item no. Weight kg 022610 58.300 Panel TR 120 x 90 Steel panel with 18 mm plywood. 022620 48.600 Panel TR 120 x 72 Steel panel with 18 mm plywood. 022640 43.500 Panel TR 120 x 60 Steel panel with 18 mm plywood.

- Page 96 TRIO Panel Formwork Item no. Weight kg 022630 56.300 Multi Panel TRM 120 x 72 Complete with Steel panel with 18 mm plywood. For oblique 44 pc. 030300 Plug Ø 20/24 mm angles, wall connections etc. 19 x 30 022660 32.900...

- Page 97 TRIO Panel Formwork Item no. Weight kg 103330 35.900 Outside Corner TEA 120/135° Steel panel with 18 mm plywood. For 135° external corners. Wall Thickness Comp. WDA 120 023282 7.610 Wall Thickness Comp. WDA-2 120 x 5 023292 8.090 Wall Thickness Comp. WDA-2 120 x 6 023990 4.680...

- Page 98 For compensation with 21 mm filler plates. Stopend Panels TRIO AT Note 023067 7.790 Stopend Panel TRIO AT 120 x 3 Concrete cover approx. 30 mm. 105978 8.590 Stopend Panel TRIO AT 120 x 5 External piece for stopend formwork.

- Page 99 TRIO Panel Formwork Item no. Weight kg Stopend Panels TRIO MT w/o waterstop bar 023068 11.800 Stopend Panel TRIO MT 120 x 20 023069 13.500 Stopend Panel TRIO MT 120 x 24/25 023071 16.300 Stopend Panel TRIO MT 120 x 30 023072 18.500...

- Page 100 TRIO Panel Formwork Item no. Weight kg 022820 15.600 Panel TR 60 x 30 Steel panel with 18 mm plywood. Inside Corner TE 60-2 022840 18.000 Steel panel with 18 mm plywood. For 90° internal corners. Panel Alu TRA 270 x 90 023850 70.200...

- Page 101 TRIO Panel Formwork Item no. Weight kg 023870 49.300 Panel Alu TRA 270 x 60 Aluminium panel with 18 mm plywood. 023880 31.400 Panel Alu TRA 270 x 30 Aluminium panel with 18 mm plywood. Multi Panel Alu TAM 270 x 72...

- Page 102 TRIO Panel Formwork Item no. Weight kg 023891 42.200 Corner Alu TAE 270/2 Alu element with 18 mm plywood. For 90° internal corners. 023900 33.600 Panel Alu TRA 90 x 120 Aluminium panel with 18 mm plywood. 1200 023950 18.000 Panel Alu TRA 90 x 60 Aluminium panel with 18 mm plywood.

- Page 103 15.200 Alu element with 18 mm plywood. For 90° internal corners. Panels TRIO Structure TS/4 330 054305 374.000 Panel TRIO Structure TS/4 330 x 240 054315 183.000 Panel TRIO Structure TS/4 330 x 120 054325 131.000 Panel TRIO Structure TS/4 330 x 90...

- Page 104 Wall Thickness Comp. WDAS 120 x 6, Alu Panel with 21 mm base plate. 023500 4.580 Alignment Coupler BFD, galv. Technical Data For all panel connections for MAXIMO, TRIO and Permissible tension force 20.0 kN. RUNDFLEX. Fillers up to 10 cm. max 220 124941 14.100...

- Page 105 123842 9.070 Tension and Compression Brace MX 15 – 100 1 pc. 018060 Cotter Pin 4/1, galv. For use with MAXIMO and TRIO. Note Adjustable in 0.5-cm-increments from 15 to 40 cm and in 0.5-cm-increments from 15 to 100 cm.

- Page 106 023640 1.140 Bulkhead Tie TS, galv. Technical Data For force application from the stopend formwork Permissible tension force 20.0 kN. in MAXIMO and TRIO panels. DW 15 thread. DW 15 023660 3.300 Brace Connector TRIO, galv. Complete with For connecting push-pull props and kicker braces 1 pc.

- Page 107 For sealing unused tie holes Ø 20, Ø 22, Delivery unit 250 pieces. Ø 24 mm. 112588 5.520 Stripping Bar TRIO 1180 Ø26 Chamfer Strip, l = 2.70 m 054240 1.900 Chamfer strip made of plastic. For TRIO Column Formwork. Edge length 15 x 15 mm. 2700...

- Page 108 Hole 2 = 15 kN Ø20,5 117321 31.000 Lifting Gear Combi MX Note For transporting stacks of MAXIMO and TRIO Follow Instructions for Use! Panels. For attaching Lifting Hook MAXIMO 1.5 t and Stacking Device MAXIMO. 117322 25.000 Lifting Gear MX...

- Page 109 Stacking Device MAXIMO Note For stacking and transportation of 2 – 5 MAXIMO Follow Instructions for Use! or TRIO Panels of all sizes. Suitable for crane and Technical Data fork-lift transport. Permissible load-bearing capacity 650 kg per post, 2.6 t per stack.

- Page 110 Permissible load 150 kg/m 023680 16.700 Scaffold Bracket TRG 120 with maximum width of influence 1.35 m. For assembly of a working and concreting scaffold with MAXIMO and TRIO. Mounted on horizontal and vertical struts. 930 / 1297 798 / 1165...

- Page 111 1.35 m. formlining. 1135 101592 2.810 Guardrail Post Holder TRIO Complete with For assembling of a guardrail to TRIO Panels. 1 pc. 018060 Cotter Pin 4/1, galv. Accessories Guardrail Post HSGP-2 116292 4.720 116292 4.720 Guardrail Post HSGP-2 As guardrail for different systems.

- Page 112 Item no. Weight kg 022950 129.000 Concreting Platform TRIO 120 x 270 Technical Data Working and concreting platform for MAXIMO Permissible load 150 kg/m and TRIO. Attached from above to the panel, self-securing. 1800 2680 1165 1330 Connector SB-1, 2 - MX/TR/D...

- Page 113 Technical Data 023020 0.676 For use with Foundation Tie Clamp TRIO, Permissible tension force 12.9 kN. DOMINO, LIWA and HANDSET. 023800 4.840 Foundation Strap TRIO For connecting TRIO panels with 6 cm wide edge profiles, assembled in a "windmill" configuration.

- Page 114 TRIO Panel Formwork Item no. Weight kg Tie Rods DW 15 Note 030030 1.440 Tie Rod DW 15, spec. length Non-weldable! Take official Approval into Cutting Cost Tie Rod DW 15, B 15 030050 0.000 consideration! 030005 0.720 Tie Rod DW 15, l = 0.50 m...

- Page 115 TRIO Panel Formwork Item no. Weight kg 030370 1.660 Wingnut Pivot Plate DW 15, galv. Note For anchoring with Tie Rod DW 15 and B 15. With Wrench size SW 27 . pivoting captive nut. Maximum angle of tilting 8°.

- Page 116 TRIO Panel Formwork Item no. Weight kg 031636 0.063 DK Cone DW 15/55 Note For waterproof, fire-resistant and soundproof Delivery unit 50 pieces. anchor points with Tie Rod DW 15. Used with Spacer Tube rough 22. 031637 0.055 DK Cone DW 20/55...

- Page 117 Permissible load 90 kN. SW 27 DW 15 Concreting Platform MX 100 x 240 127273 192.000 Working and concreting platform for MAXIMO and TRIO. Attached from above to the panel, selfsecuring. 2378 1351 End Guardrails MXP Complete with 115945 10.700 End Guardrail MXP left 2 pc.

- Page 118 TRIO Panel Formwork Item no. Weight kg 127885 71.600 Concreting Platform Hatch MX 100 x 100 Working and concreting platform for MAXIMO and TRIO. Attached from above to the panel, selfsecuring. 1000 126360 4.920 Guardrail Post MXK As guardrail for MAXIMO and TRIO.

- Page 119 TRIO Panel Formwork Item no. Weight kg 126356 10.200 Scaffold Bracket MXK For assembly of a working and concreting scaffold with MAXIMO and TRIO. Accessories Guardrail Post MXK 126360 4.920 126540 14.600 Scaffold Bracket MXK-RS For assembly of a working and concreting scaffold with MAXIMO and TRIO.

- Page 120 Item no. Weight kg 117466 10.600 Push-Pull Prop RS 210, galv. Note Extension length l = 1.30 – 2.10 m. Permissible load see PERI Design Tables. For aligning PERI Formwork Systems and precast concrete elements. 1300 max 2100 Ø48,3 Ø17 Ø21...

- Page 121 Item no. Weight kg 117469 39.900 Push-Pull Prop RS 650, galv. Note Extension length l = 4.30 – 6.50 m. Permissible load see PERI Design Tables. For aligning PERI formwork systems and precast concrete elements. 4300 max 6500 Ø48,3 Ø17 Ø21...

- Page 122 2 pc. 018060 Cotter Pin 4/1, galv. 1 pc. 113063 Bolt ISO 4014 M12 x 80-8.8, galv. 1 pc. 113064 Hex Nut ISO7042-M12-8-G, galv. Ø21 Accessories Anchor Bolt PERI 14/20 x 130 124777 0.210 102018 4.880 Base Plate-2 for RS 1000/1400, galv.

- Page 123 2 pc. 711071 Nut ISO 7042 M8-8, galv. 028020 22.000 Push-Pull Prop RSS II Note Extension length l = 2.91 – 3.80 m. Permissible load see PERI Design Tables. For aligning PERI Formwork Systems. min 2910 max 3800 Ø32 Ø16,5 Ø16,5...

- Page 124 1110 For aligning PERI Formwork Systems. Complete with 1 pc. 027170 Pin Ø 16 x 42, galv. 1 pc. 018060 Cotter Pin 4/1, galv. Note Permissible load see PERI Design Tables. min 500 max 820 min 790 max 1110 Ø30 Ø16x42...

- Page 125 Extension length l = 2.03 – 2.92 m. 1 pc. 027170 Pin Ø 16 x 42, galv. For aligning PERI formwork systems. 1 pc. 018060 Cotter Pin 4/1, galv. Note Permissible load see PERI Design Tables. min 2030 max 2920 Ø32 Ø16,5 Ø16x42...

- Page 126 PERI (L.L.C.) TOO PERI Kazakhstan www.peri.ca www.peri.pt www.peri.ae www.peri.kz Mexico Algeria Azerbaijan Lebanon PERI Lebanon Sarl PERI Cimbras y Andamios, S.A. de C.V. S.A.R.L. PERI PERI Repesentative Office www.peri.com.mx www.peri.dz www.peri.com.tr lebanon@peri.de Panama Egypt Hong Kong Malaysia PERI Panama Inc.

- Page 127 PERI Australia Pty. Ltd. PERI Danmark A/S PERI S.r.l. PERI Sverige AB www.periaus.com.au www.peri.dk www.peri.it www.peri.se Estonia Lithuania Slovania PERI UAB PERI oplate i skele d.o.o PERI AS Europe www.peri.ee www.peri.lt www.peri.com.hr Albania Spain Luxembourg Slovakia PERI Kalıp ve İskeleleri PERI S.A.U.

- Page 128 Tunnel Formwork Shoring Systems Construction Scaffold Facade Scaffold Industrial Scaffold Access Protection Scaffold Safety Systems System-Independent Accessories Services PERI GmbH Formwork Scaffolding Engineering Rudolf-Diesel-Strasse 19 89264 Weissenhorn Germany Tel. +49 (0)7309.950 - 0 Fax +49 (0)7309.951- 0 info @ peri.com www.peri.com...

Need help?

Do you have a question about the Trio and is the answer not in the manual?

Questions and answers