Table of Contents

Advertisement

Operating manual

HF R ...-15 / 17 D / R

Size 125 up to 500

HF R ...-13 D / R

Size 450 up to 1250

HF R ...-16 R

Size 160 up to 400

HF R ...-48 R

Size 50 up to 200

These operating instructions are valid for the standard and ATEX versions.

www.hlu.eu

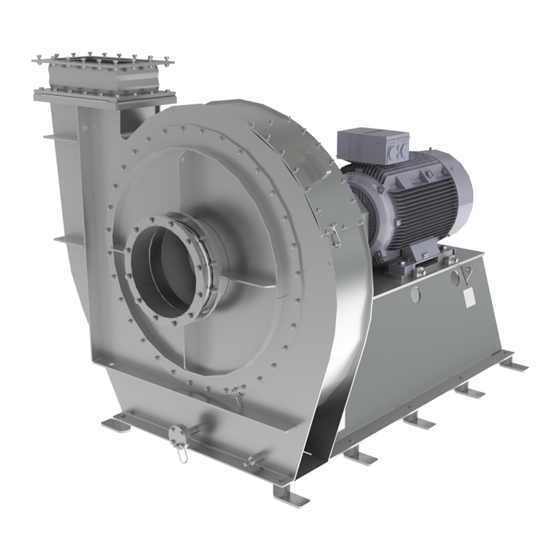

Centrifugal fans

Size 80 up to 140

Size 200 up to 800

RV 45/63

Size 160 up to 1250

MRV 45/63

Size 160 up to 355

RV 20

RV 28

Advertisement

Table of Contents

Summary of Contents for HLU HF R 48 R Series

- Page 1 RV 45/63 Size 160 up to 400 Size 160 up to 1250 HF R ...-48 R MRV 45/63 Size 50 up to 200 Size 160 up to 355 These operating instructions are valid for the standard and ATEX versions. www.hlu.eu...

- Page 2 EEA, the operating instructions must be translated into the language of the user country accordingly. If the translated text contains divergences, always refer to the wording of the original (German) operating instructions, or contact the manufacturer. www.hlu.eu 06.2019...

-

Page 3: Table Of Contents

Installation, mounting, Initial commissioning Operating modes Operation Maintenance / Cleaning Cleaning Lubrication Tensioning of V-belts Inspection interval / Function checking Vibrations Tightening torques for bolt connections General hints for maintenance Checks Troubles, causes and measures Emergency Dismantling / Disposal www.hlu.eu 06.2019... -

Page 4: Ec-/Eu-Declarations Of Conformity

Name and address of the persons, who are authorized, to assort the technical documents: Anne-Christin Vögl-Schmitt, Hürner Luft- und Umwelttechnik GmbH, Ernst-Hürner-Straße, 35325 Mücke-Atzenhain, Germany Marcel Pfeifer, HLU Systemtechnik GmbH, Sälzerstraße 20a, 56235 Ransbach-Baumbach, Germany Page 1 of 2 Konformitätserklärung www.hlu.eu... - Page 5 Name and address of the persons, who are authorized, to assort the technical documents: Anne-Christin Vögl-Schmitt, Hürner Luft- und Umwelttechnik GmbH, Ernst-Hürner-Straße, 35325 Mücke-Atzenhain, Germany Marcel Pfeifer, HLU Systemtechnik GmbH, Sälzerstraße 20a, 56235 Ransbach-Baumbach, Germany Page 2 of 2 Konformitätserklärung www.hlu.eu...

-

Page 6: Construction And Correct Use For The Intended Application

Fig. 1a| Overview of the fan HF R ...-15 / 17 D | Direct drive Sleeve Housing Impeller Motor Outlet adapter Sleeve Housing cover with inlet adapter Condensate drain Frame Vibration absorber Fig. 1b| Overview of the fan HF R ...- 16 / 13 D | Direct drive www.hlu.eu 06.2019... - Page 7 HF R | RV | MRV Sleeve Housing Impeller Outlet adapter Belt drive Flange bearing drive cover Sleeve Motor Frame Housing cover with inlet adapter Vibration absorber Condensate drain Fig. 1c| Overview of the fan HF R ...-48 R | Belt drive www.hlu.eu 06.2019...

- Page 8 Centrifugal fans HF R | RV | MRV Designation Designation Frame Housing Vibration dampers Support Motor Housing cover with inlet adapter Motor cover (opt.) Impeller Fig. 1d| Overview of the fan HF RV / MRV | Direct drive www.hlu.eu 06.2019...

- Page 9 10 V-Belt Support Shaft cover Vibration dampers 12 Driver cover Motor 13 Housing Bearing 14 Housing cover with inlet adapter Shaft 15 Impeller Belt pulley, Fan Fig. 1e| Overview of the fan HF RV / MRV | Belt drive www.hlu.eu 06.2019...

-

Page 10: Correct Use For The Intended Application And Field Of Application

The max. ambient temperature is 40 °C. Sufficient cooling can be ensured regardless of the volume flow, in accordance with the above-mentioned conditions. The fan was developed, designed and built exclusively for industrial and commercial use. Using the fan for domestic purposes is excluded. www.hlu.eu 06.2019... - Page 11 The plastic fans are not covered by the „Regulation No 327/2011 of the European Commission about the implementation of Directive 2009/125/EC (ErP Directive)“ because they are intended for the extraction of highly corrosive media. www.hlu.eu 06.2019...

-

Page 12: Product Specific Data

Technical data sheet Fig. 2a| Overview of the fan HF R | Direct drive Fig. 2b| Overview of the fan HF R | Belt drive: Belt flange bearing (RF) and Belt block bearing (RB) www.hlu.eu 06.2019... - Page 13 ØD HF R 50-48 HF R 63-48 HF R 80-48 HF R 100-48 HF R 125-48 HF R 160-48 1100 1180 1021 HF R 200-48 1353 1390 1215 Dimensions and design can be changed | Dimensions in mm www.hlu.eu 06.2019...

- Page 14 1250 1350 1950 RV 28-500 1400 1550 1300 1400 1950 RV 28-560 1550 1600 1400 1700 2150 RV 28-630 1700 1800 1550 1750 2250 RV 28-710 1900 2100 2050 2100 2700 RV 28-800 2150 2250 2150 2250 2800 www.hlu.eu 06.2019...

-

Page 15: General Data

For the value applicable to each fan, see the manufacturer internet site, or contact us via phone. Others More relevant data are given on the type label. The service life of bearing is depending on the load at > 25 000 h. www.hlu.eu 06.2019... -

Page 16: Power Supply (See Motor Type Label)

4.1 Signs and explanations The information given in the operating manual is binding is marked with a „book“. Warnings are marked with a „STOP“ sign. Danger warnings are marked with a warning triangle. Notes are marked with a hand symbol. www.hlu.eu 06.2019... -

Page 17: Fan Marking

Fig. 3a| Type label (normal application) Order no. (AB) Construction year Fan-specific data Fig. 3b| Type label (explosive atmosphere) Caution Fans without explosion protection marking are not permissible for operation inside the explosion-hazarded atmosphere. This applies to the environment and the exhausted fluid. www.hlu.eu 06.2019... -

Page 18: Built-In Safety Systems (To Be Implemented By The User)

The electrical connections are made using a 4-wire supply cable sys- Interval Method tem, 3 phases and 1 earth conductor with three-phase motors and V, F, M using a 3-wire supply cable system, 1 phase, 1 neutral wire and 1 earth conductor with alternating current motors. www.hlu.eu 06.2019... -

Page 19: Interfaces Of The Fan

(regulations relating to accident prevention) the safety of work equipment (protective equipment and maintenance) product recycling (Waste Management Law) material disposal (Waste Management Law) cleaning (cleaning agents and disposal) and comply with the requirements for environment protection. www.hlu.eu 06.2019... -

Page 20: General Warning Symbols

5.2 Operating and hazardous areas on the fan Hazardous area During setup, maintenance and repair work, the overall area around the fan is a hazardous area. www.hlu.eu 06.2019... -

Page 21: Installation Of Spare And Wear Parts

In connection with the order confirmation, you will receive a data card and a spare parts list for the fan. If you need spare parts, please, inform our sales partner: Hürner Luft- und Umwelttechnik HLU Systemtechnik Ernst-Hürner-Straße Sälzerstraße 20a 35325 Mücke-Atzenhain... -

Page 22: Installation

0 °C and + 40 °C. To avoid permanent deformation by preventing static load at the contact points between the rolling elements and bearing raceways, the impeller has to be turned for a ¼ turn at regular intervals (at least every 4 weeks). www.hlu.eu 06.2019... -

Page 23: Transport To The Place Of Installation (At The Customer's Site)

Attention: The focus must be on the bot- tom! The lifting and transporting of the fans can be done manually depending on the size and the weight. Fig. 4| Transport of the fan to the site www.hlu.eu 06.2019... -

Page 24: Installation, Mounting, Initial Commissioning

After a run-in period of 1 or 2 hours check the drive at regular intervals and re-tighten the belts, if necessary. The condensate drain at the bottommost point of the housing has to be connected. See point 3.2. Ensure that connected lines do not carry loads which lead to a distortion of the fan housing. www.hlu.eu 06.2019... -

Page 25: Operating Modes

The fan pipe connections may be performed only using flexible cou- plings (compensators). 6.7 Operating modes The fan is switched on and off via an on-site operating unit provided by the user, or operated via an on-site supervisory system. It is designed for continuous operation. www.hlu.eu 06.2019... -

Page 26: Operation

During maintenance and repair work, mind all rotating and mobile parts. Risk of entanglement! Tight clothing must be worn in the dan- ger area. During maintenance and repair work, mind the squeezing hazards. www.hlu.eu 06.2019... -

Page 27: Cleaning

Make sure that the cooling fins of the electric motor are not clogged by pollution in order to avoid overheating, if necessary clean them. Caution When doing cleaning work, wear protective equipment in complian- ce with the operational regulations for occupational health and safety (e.g. protective gloves). www.hlu.eu 06.2019... -

Page 28: Lubrication

Only the fan type HF R 250-17 R with a speed over 2000 min-1 has got a regreasable bearing installed. Speed fan Quantity Nominal fan 2000 2500 3000 3500 of grea- size sing min-1 min-1 min-1 min-1 HF R 250-17 8000 h 7000 h 5500 h 4500 h www.hlu.eu 06.2019... - Page 29 8000 h 7000 h 5500 h 4500 h 3200 h 2700 h 2000 h HF R 315-16 R 7000 h 5000 h 4000 h 3000 h HF R 355-16 R 7000 h 5000 h 4000 h 3000 h HF R 400-16 R 7000 h 5000 h 4000 h 3000 h www.hlu.eu 06.2019...

- Page 30 RV / MRV 8000 h 8000 h 8000 h 8000 h 8000 h 7000 h 6000 h 45/63-315 R RV / MRV 8000 h 8000 h 8000 h 8000 h 8000 h 7000 h 6000 h 45/63-355 R www.hlu.eu 06.2019...

-

Page 31: Tensioning Of V-Belts

Measure the deflexion using a centimetre ruler. A required deflexion (Ea) of 17 mm per 1000 mm of free belt side length was determined. The required deflexion is calculated by means of the following simplified equation: (e = Centre distance) www.hlu.eu 06.2019... - Page 32 SPZ75 SPA118 SPB190 SPC280 SPZ80 SPA125 SPB200 SPC300 SPZ85 SPA132 SPB212 SPC315 SPZ90 SPA140 SPB224 SPC335 SPZ95 SPA150 SPB236 SPC355 SPZ100 SPA160 SPB250 SPC375 SPZ112 SPA180 SPB280 SPC400 SPZ125 SPA180 SPB315 SPC425 SPZ140 SPC450 SPC475 SPC500 SPC530 SPC560 www.hlu.eu 06.2019...

-

Page 33: Inspection Interval / Function Checking

Interval with single-shift operation ½ y Superordinate facility for connecting the supply voltage Settings of the on-site protective devices Fan motor function checking Bearing function checking Check belt tension and correct if necessary Check the impeller for damage www.hlu.eu 06.2019... -

Page 34: Vibrations

8.6 Tightening torques for bolt connections On the basis of VDI 2230 the following tightening torques are recommended for bolts of strength class 8.8: Nominal Tightening Nominal Tightening diameter [mm] torques [Nm] diameter [mm] torques [Nm] 11,3 27,3 www.hlu.eu 06.2019... -

Page 35: General Hints For Maintenance

After completing work, please, check: The completeness of performed work, Unless there is reason to complain, the fan can be taken into operation After checking and replacing the wear parts, please check, if all safety devices are fully operable. www.hlu.eu 06.2019... -

Page 36: Troubles, Causes And Measures

Adjust motor protective switch correctly correctly Motor is Motor protective switch is not adjusted Adjust motor protective switch correctly switched off correctly Change motor, by the motor Motor winding defective consult manufacturer or motor supplier protection Impeller blocked Check impeller switch www.hlu.eu 06.2019... -

Page 37: Emergency

Depending on the fan application, the housing and the impeller must be considered as special waste and discarded accordingly. Injection moulded or sintered housings are provided with recycling signs indicating which type of plastic material was used. www.hlu.eu 06.2019... - Page 38 Operating manual Centrifugal fans HF R | RV | MRV Notes www.hlu.eu 06.2019...

- Page 39 Operating manual Centrifugal fans HF R | RV | MRV www.hlu.eu 06.2019...

- Page 40 Hürner Luft- und Umwelttechnik GmbH HLU Systemtechnik GmbH Ernst-Hürner-Straße Sälzerstraße 20a 35325 Mücke-Atzenhain 56235 Ransbach-Baumbach Germany Germany + 49 6401 9180 - 0 + 49 2623 92 95 9 - 0 + 49 6401 9180 - 142 + 49 2623 92 95 9 - 99 info@hlu.eu...

Need help?

Do you have a question about the HF R 48 R Series and is the answer not in the manual?

Questions and answers